Machine Shop Safety - University of Toronto

advertisement

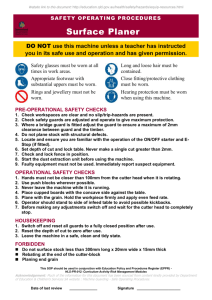

University of Toronto Machine Shop Safety Workers and students using machines and power tools are faced with a potential risk of injury due to the fast moving parts of the machines. These risks can be reduced by insuring that both the employees and the students know the safe operating procedures for the machines and power tools. This standard is based on Regulation 851, as amended (Regulation for Industrial Establishments) made under the Occupational Health and Safety Act of Ontario and on the following standards: ANSI O1.1-1975, Safety Requirements for Woodworking Machinery; ANSI/ASME B.15.1-1984, Safety Standard for Mechanical Power Transmission Apparatus; ANSI/UL 987, Safety Standard for Stationary and Fixed Electric Tools; ANSI B11.8-1983, Safety Requirements for the Construction, Care, and Use of Drilling, Milling and Boring Machines; ANSI B11.11-1984, Safety Requirements for the Construction, Care and Use of Gear Cutting Machines; ANSI B11.9-1975, Safety Requirements for the Construction, Care and Use of Grinding Machines; ANSI B11.6-1984, Safety Requirements for the Construction, Care and Use of Lathes; ANSI B11.10, Safety Requirements for the Construction, Care, and Use of Metal Sawing Machines; ANSI B7.1-1978, Safety Requirements for the Construction, Care and Protection of Abrasive Wheels; ANSI B11.1, Safety Requirements for the Construction, Care, and Use of Mechanical Power Presses; ANSI B11.4, Safety Requirements for the Construction, Care, and Use of Shears; ANSI B11.3, Safety Requirements for the Construction, Care and Use of Mechanical Power Press Brakes; ANSI B186.1, Portable Air Tools; ANSI Z49.1, Safety in Welding and Cutting; CSA Standard CAN C22.2 No. 745-1-95, Safety of Portable Electric Tools Part 1; CSA Standard CAN C22.2 No. 745-2 Series, Safety of Portable Electric Tools Part 2; CSA Standard W117.2-94 Safety in Welding, Cutting, and Allied Processes. SCOPE: All machine shops, as well as, all other rooms at the University where machines and/or power tools are used. RESPONSIBILITIES: Principal investigators/supervisors and all others in authority shall: Provide students and all other designated people with adequate training on the operation of the machines and power tools; Ensure that all persons working with the machines and power tools have received the required training; Schedule the use of machines and power tools; Ensure that only qualified persons who are authorized to access the workshop operate the machines and the power tools; Ensure that the machines and power tools are maintained and are in good condition; Ensure that all persons operating the equipment wear appropriate protective equipment; Ensure that all persons working with machines and power tools follow the safety procedures outlined in this manual; The users of machines and power tools shall: Operate the machines and power tools according to the safety procedure outlined in this manual; Follow the instruction of the supervisor/principal investigator; Inspect any equipment for defects prior to its use; Report any defects in any part of the equipment; Wear appropriate protective equipment; Report all injuries to the supervisor/principal investigator; Keep the work area clean. GENERAL SAFETY GUIDELINES: All mechanical motion is potentially hazardous. Motion hazards, such as rotating devices, cutting or shearing blades, in-running nip points, reciprocating parts, linear moving belts and pulleys, meshing gears, and uncontrolled movement of failing parts, are examples of motion and peculiar to any one machine operation. Personnel working within machine shops or areas where they are exposed to machinery or equipment hazards must be aware of the potential for accidents. The following guidelines must be followed when working with machines and power tools: Eye protection must be worn at all times while using a machine or while in the vicinity of the machine. Hearing protection must be worn when excessive noise levels are present. Foot protection must be worn while in the machine shop or when using any machines. Open toed footwear must never be worn around the machines. Loose clothing, long hair, dangling accessories, jewellery or other similar items that could catch in the moving machine, must not be worn while working with the machines unless they are so tied, covered or otherwise secured as to prevent the hazard. Gloves should not be worn around machine unless sharp or rough materials are being handled. If gloves are being worn, care should be exercised not to get them caught in any machinery. A minimum of two persons shall be in the shop at any time the facility is in use. Tools shall only be used for their designated purpose. A tool or an attachment shall not be used for something it was not designed to do. The tools should be always operated at the correct speed for the job at hand. All guards must be kept in place. Under no circumstance should the guards be removed from a machine. Machines and tools shall be cleaned after each use. The machines shall be cleaned using a brush. Hands or compressed air shall not be used to clean machine. Compressed air must not be used for cleaning ones clothes. Machines designed for a fixed location shall be securely anchored to prevent movement. Tools must be returned to proper storage area after use. Damaged tools and machines shall be reported to the person in charge of the machine shop or the person responsible for the equipment. Defective tools or machines must not be used. Person shall not engage in horseplay while operating a machine. The operator should watch the work while operating a machine. The operator must be free of distractions during the machine operation. If a distraction is present the work shall be stopped. No person must ever reach over the equipment while it is running. No person shall disable or tamper with safety releases or other automatic switches. Power tools shall be disconnected before performing maintenance, changing components or clearing jams. Machines shall be lockedout/taggedout before repair. Chuck keys or adjusting tools must be removed prior to operation. No person that is sick, fatigued or is taking medications should operate any machines. Bystanders shall be kept away from moving machinery. Only one person shall operate a machine at any one time. Users of machine shops shall be aware of the location of first aid kits, fire exits, fire extinguishers, fire alarms, eye washes, deluge showers, emergency telephones and other safety related facilities. Accidents must be reported to the person in charge of the machine shop and the supervisor. Machine Safety Drill Press Eye protection must be worn at all times. Gloves must never be worn. Loose clothing, long hair, dangling accessories, jewellery and other similar items that could get caught in the moving machine shall not be worn. Work must be securely clamped to the table to prevent it from spinning. The speed setting of the drill shall be appropriate to the work being done. The bit shall be mounted securely to the full depth of the chuck and in the center. The chuck key must be removed before starting the drill. The feed stroke shall be adjusted so that there is no possibility of the bit striking the table. Machine guards must not be tampered with or removed. The drill spindle shall be allowed to stop of its own accord. The machine shall be cleaned of chips and cutting fluid after use. The drillings shall be removed using a brush, never by hand. Boring Mill Eye protection must be worn at all times. Loose clothing, long hair, dangling accessories, jewellery and other similar items that could get caught in the moving machine shall not be worn. Work must be securely clamped to the table. Tools must not be left on the revolving table. The operators must never reach across the table, adjust the machine or make measurements while the machine is in motion. The guards must be closed during the operation. The spindle hole and boring bar must be clean and free from nicks. Turnings must not be allowed to build up on the table. The turnings shall be removed using a brush, never by hand. Grinder Eye protection must be worn at all times. Loose clothing, long hair, dangling accessories, jewellery and other similar items that could get caught in the moving machine shall not be worn. Grinding wheels shall be examined for cracks before turning the machine on. Wheels that are badly worn or cracked shall be replaced. No flammable or combustible materials that could be ignited by the sparks from the grinder wheel shall be present nearby. When starting and stopping the grinder the operator shall stand to one side of the grinding wheel. Before using a new wheel, the wheel shall be left running for few seconds to ensure it is balanced. If excessive imbalance or wobbling is noted the grinder must be shut off. A grinding wheel that has been dropped or received a heavy blow shall not be used, even if there is no apparent damage. A wheel proper to the work being done must be used. The side of the straight wheel must never be used for grinding. Work shall not be forced against the wheel. Under no circumstances must the maximum operating speed of the wheels be exceeded. The gap between the face of the wheel and tool support must be kept to a minimum. The guard must be as close as possible to work being ground. The guard must never be removed or tampered with. The cutting surfaces shall be kept sharp by properly dressing the wheel. Water container shall be kept handy for cooling off the work piece. The wheel shall be stopped before making adjustments. The machine shall be stopped when not in use. Users shall keep hands clear of the rotating grinding wheel. Lathe Eye protection must be worn at all times. Loose clothing, long hair, dangling accessories, jewellery and other similar items that could get caught in the moving machine shall not be worn. All stop controls shall be checked before starting work. All belt and gear guards must be in place before starting the machine. The lathe must be stopped to perform any adjusting, measuring, cleaning or lubricating. The spindle shall be stopped by shutting the lathe off and letting it coast to a stop. If the lathe is equipped with break treadle, the break treadle shall be depressed to stop the spindle. The users must never attempt to stop the spindle with hands or fingers. The lathe shall not be stopped by reversing its direction of rotation. The chuck key must be removed before starting the machine. The users shall keep hands clear of the chuck rim when the lathe is in motion. All tools, measuring instruments and other objects must be removed from the saddle or lathe bed before starting the machine. All work shall be solidly clamped with an appropriate size work-holding device. All work shall be solidly supported. Chucks must be mounted and removed by hand. Files used shall have sound handles. The chips shall be removed using a brush or pliers, never by hands. Air hoses shall not be used to clean the machine. No sand paper or polishing cloth shall be wrapped around any revolving part of the lathe. If vibration or odd noise develops, the machine shall be stopped immediately. Milling Machine Eye protection must be worn at all times. Loose clothing, long hair, dangling accessories, jewellery and other similar items that could get caught in the moving machine shall not be worn. Users of milling machine must fully understand all the machine controls before starting the work. The clutch and feed controls must be in neutral before the machine is started. The machine must not be started until the guards are in position. The work table must be kept free from tools and loose material. Proper feed rate and spindle speed must be used. The holding device shall be solidly mounted to the table and the work firmly held before commencing work. Heavy attachments such as the vise, dividing head, or rotary table shall not be moved without help. Adjustments must not be made near a moving cutter. The cutter must be stopped to check the work and clear away metal waste. Chips shall be removed with a brush, not the hand. Air hoses shall not be used to clean the machine. Before any cleaning work is carried out, the machine must be isolated from the power supply. Before changing a workpiece, the milling fixture, the vise or the clamp must be withdrawn well clear of the cutting area. Sharp edges shall be removed from completed work. Band Saw Eye protection must be worn at all times. Gloves should be worn when handling saw band. Adjustable guards shall be kept as close over the point of operation as the work permits. Band wheel covers must be closed before tensioning band or starting machine. The saw shall be at full speed before starting to feed in work. Stock shall be fed into the saw only as fast as the teeth will easily remove material. Stock shall be held flat on the table. The machine shall be stopped before making adjustments or measurements. The machine shall be stopped only on low speed. The electrical supply must be disconnected before removing panels or drive covers. Users must never reach over the sawline to position or guide materials. Proper speeds and blades shall be used for the material being cut. Dust collector shall be used when dust is generated. The operator shall not leave the table until the blade has come to a complete stop. Horizontal Cut-off Saw Eye protection must be worn at all times. Safety shoes or boots shall be worn. Correct speed must be used. The blade must be eased into the workpiece. Care must be taken not the drop the saw frame. The cut-off piece must be handled carefully, due to the sharp edges and corners present. Table Saw Eye protection must be worn at all times. Hearing protection should be worn if the noise level is excessive. (sound levels exceed 85dBA). The guards must be in place during the saw operation. The guards must not be removed or tampered with during the operation of the saw. The operator shall stand to one side of the blade when cutting. The operator or any other person must never stand directly behind the blade when cutting. The rip fence shall be aligned for slightly more clearance behind the blade than in front. A proper blade must be used for the material being cut. The blade must be sharp. The machine must be stopped before making adjustments. Stock should be free of knots, splits, and warps. When ripping narrow and short pieces push sticks and feather boards shall be used. Users must never reach around, over, or behind a running blade to control the stock. The operator must not leave until the saw has come to a complete stop. The saw shall be cleaned after use and scraps placed in the appropriate scrap bin. Radial Arm Saw Eye protection must be worn at all times. All safety guards must be in place before starting the machine. The guards must not be removed or tampered with during the machine operation. Proper blade for the job must be used. Sharp blade, free of gum deposit must be used. When using the machine, the operators shall keep their hands at least 6 inches away from the blade. The length of the cut must not be adjusted, until the motor is back at the column. The operator must not leave the machine with the motor running. The stock must be pushed all the way through past the blade to avoid kickback. Push stick shall be used when ripping narrow pieces. A spreader must be used during ripping to avoid kickback. The blade should go through the wood at its own pace. Jigs shall be used when making irregular cuts. When crosscutting, the operator’s hand shall never be removed from the operating handle. Scraps shall be removed from the table using a brush, never hands. Jointer and Planer Eye protection must be worn at all times. Hearing protection shall be worn when working with a planer. The guards on the jointer or planer shall not be removed or tampered with. The knife projection of the horizontal cutter head of the jointer shall not extend more than 1/8 inch beyond the body of the head. The clearance between the path of the knife projection and the rear table shall not be more than 1/8 inch. The clearance between the path of the knife projection and the front table shall not be more than 3/16 inch. The opening between the table and the head shall be just large enough to clear the knife. The cutting and planing shall be done with the grain of the wood. Holddown-push blocks should be used when joining narrow stock. Operators must keep their hands away from the head. Cut depth shall be adjusted before turning the machine on. Shaper Eye protection must be worn at all times. The guards must not be adjusted during machine operation. Deep cuts should be avoided. The spindle shall be brought up to operating speed slowly, by applying power in a series of short starts and stops. Knives and grooves in the collars must fit perfectly and be free of dust. Knife must not be used once it’s so short that its butt end does not extend beyond the middle point of the collar. The two knives must balance perfectly. Direction of the cut must be made in the opposite direction of the rotation of the cutting head. Holddown-push blocks or jigs shall be used when shaping narrow stock. Long handled brush shall be used to remove chips and scraps from the worktable. Sander Eye protection must be worn at all times. When working with wood, respirators shall be worn. The workpiece shall be held by a clamp, vise, vise grips or pliers. The belt of the belt sander shall be free of tears and defects. The belt shall be mounted correctly. The sanding belts shall not be too tight or too loose. Care must be taken when holding a metal workpiece. The metal can heat up due to friction from the sander. Gloves should be worn when handling metal workpieces. Belt sanders shall have both the pulleys and the unused run of the sanding belt enclosed. Disc sanders shall have the periphery and back of the revolving disc guarded, and the space between the revolving disc and the edge of table shall not exceed ¼ inch. Correct grade of abrasive material must be used. Materials must not be pushed against the sander with excessive force. Shears Eye protection must be worn at all times. Before the machine is used, all cuttings and scrap from the shear table and the surrounding area shall be removed. Users shall avoid touching knife edges when taking measurements. The shear table shall be kept free of loose tools and materials. Safety guards shall not be removed or tampered with. When clamping, the user shall keep the other hand away from hold down. Only the persons operating the machinery shall be in close proximity of the shears. Leather gloves should be worn when handling sheet metal. Scraps shall be removed promptly and deposited in the appropriate scrap bin. Shears must only be used to cut materials specified in the manufacturers instructions. Bending Brake Eye protection must be worn at all times. Machine capacity must not be exceeded. Leather gloves should be worn when handling sheet metal. Operator’s hands must be located at a safe distance from the point of operation. Only the persons operating the machinery shall be in close proximity. Filing Machine Eye protection must be worn at all times. Users shall keep their hands away from the machine table, to prevent their fingers from getting caught between the workpiece and the machine table. Punch Press Eye protection must be worn at all times. The maximum rating of the machine must not be exceeded. Care must be taken when handing the sheet metal, due to sharp edges. Gloves should be worn when handling sheet metal. Portable Power Tools Safety Circular Saw Eye protection must be worn at all times. The operator shall stand to one side of the saw when cutting. No person shall reach under the material being cut. The material being cut must be placed on a rigid support. The blade must clear the supporting surface and the power cord. The operator must never use a leg or an arm to support the material being cut. When changing or adjusting the blades the saw shall be disconnected from the power source. Keys and adjusting wrenches must be removed before operating the saw. Thin tubular materials must not be cut with a circular saw. Short pieces of material shall not be held by hand. Proper blade for the job must be used. Sabre Saw Eye protection must be worn at all times. Reciprocating saw must be held with both hands. Proper blade for the type of work being conducted must be used. Material being cut shall be clamped or otherwise secured and supported as close to the cutting line as possible. Before starting a cut the operator must make sure the saw will not make contact with clamps, vise, workbench or other support. No person shall reach under the material being cut. The base of the saw must be held in firm contact with the material being cut. The saw must not be laid down until the motor has stopped. Cutting curves that are too sharp shall be avoided due to the possibility of the blade breaking. The blade must not be inserted or withdrawn from the cut while the motor is running. Chain Saw Eye protection must be worn at all times. Hearing protection shall be worn when using a chain saw for prolonged periods. Leather gloves should be worn to absorb some vibration. Chain saws must be equipped with a hand guard and should be equipped with chain brake. Chain saws should also be equipped with anti-kickback chains. Saw must be run at high rpm when cutting. Chain must be sharpened to proper specifications. Correct chain tension must be maintained. Depth gauges must be set to manufacturers’ settings. Chain saw must be held securely with both hands. The cut shall not be allowed to close on the saw. When starting, the saw shall be firmly held on the ground with the chain pointing away from the operator’s body and nearby obstructions. The saw shall never be drop started. Chain saws shall only be used to cut wood. Chop Saw Eye protection must be worn at all times. Proper abrasive cutting wheel for the material being cut must be used. The rpm of the saw must not exceed the manufacturer’s specifications. The centre hole on the blade must fit the mandril and be snugly fastened in place with proper washer and lock nut. The blade guard must not be removed. The blade must be stopped before moving material. The far end of the material being cut shall be supported. Quick-Cut Saw Eye protection must be worn at all times. Respiratory protection should be worn when dry-cutting masonry or when working in confined space. Leather gloves and hearing protection should be worn when operating the saw. Saws must be equipped with proper blades or disks for the job. The blade guard must not be removed. Cracked, broken or worn blades and disks must be replaced. The saw shall be carried with the disk or blade removed and with the muffler away from the operator. The saw shall be started in an area clear of people and obstacles. Under no circumstances shall anyone stand in front of the saw as it starts or while it’s running. The material being cut shall be supported and securely held. The cut shall be as close as possible to the supporting surface. When operating the saw, the operator shall stand with legs apart for balance and support. The saw shall be securely held with both hands. Only the cutting edge of the disk or blade shall be used. The side of the disk must never be used for cutting. During a cut the saw shall be run at full throttle. Drills Eye protection must be worn at all times. The drill must be properly grounded and double insulated. Before making adjustments or changing attachments, the drill must be disconnected from the power source. The operators should not crowd or push the tool beyond capacity. Appropriate drill bits shall be used for the type of work. The bit shall be mounted securely to the full depth of the chuck. The drill bits shall be kept sharp. Stock shall be clamped or otherwise secured to prevent it from moving. The material must never be supported on the operator’s knee. The drill must be restrained just before the bit or cutting attachment emerges through the material. The drill shall be controlled with both hands. Small work pieces shall be properly secured and supported. The operator must never hold a small work piece with his/her hand while drilling. Before starting the drill shall be turned on for a moment to make sure that the shank of the bit or attachment is centred. While drilling deep holes, the drill shall be withdrawn several times with the motor running to clear the cuttings. Once the drill is no longer being used it shall be unplugged and the bit shall be removed. Planes Eye protection must be worn at all times. Loose clothing, long hair, dangling accessories, jewellery and other similar items that could get caught in the moving machine shall not be worn. The plane shall be held with both hands. Both hands shall be kept on the plane until the motor stops. Edge guide shall be used to direct the plane along the desired cut. The plane shall never be guided with operator’s fingers. When block plane is used the free hand shall not be used to support the work. The work must be free of obstructions, such as nails and staples. The blades must be kept in good conditions and sharp. When replacing the cutter blades, the blades must be the same weight and seated at the same height. The plane must be disconnected from the power source before adjusting or changing blades or cutter head. The work planed must be supported. When planning doors and large pieces of plywood, a jack should be used to secure the material. Routers Eye protection must be worn at all times. Hearing protection should be worn when using a router. The router shall be held with both hands. The work shall be supported and secured in fixed position by a vise, clamps or other such device. The operators must never use his/her hand or knee to hold the work. The bit shall be securely mounted in the chuck and the base shall be tight. Before switching the motor on, it shall be insured that the bit can rotate freely. The router shall be fed smoothly through the cut in the correct direction. The router shall be disconnected from the power source when mounting bits or making major adjustments. When the cut is complete, the router shall not be lifted from the work until motor has stopped. Pneumatic Fastening Tools (Nail/Air Guns) Eye protection must be worn at all times. Pneumatic tools which shoot nails, rivets, or staples must be equipped with a device that keeps fasteners from ejecting unless the muzzle is pressed against a firm surface. The tool shall never be pointed at items that are not going to be fastened. The tool must never be pointed at anyone. The air pressure must be turned off before adjusting the tool. Air hoses must be clear of traffic and must not pose a tripping hazard. Hands must be kept away from discharge area. The finger shall be kept off the trigger until ready to begin work. Fasteners shall not be driven into hard, brittle surfaces or areas where the fastener may pass through the material and protrude on the other side. The air must not be used to blow dust or dirt out of clothes. Pneumatic Impact Tools (Jackhammers) Eye protection must be worn at all times. Hearing protection shall be worn when the tool is in operation. The trigger shall not be squeezed until the tool is on the work. There shall be no people in the vicinity of the operation. If other people must be in the vicinity they shall also wear eye and hearing protection. The tool must not be pointed at anyone. No person shall stand in front of the operator handling a pneumatic impact tool. The operators handling heavy jackhammers shall wear safety shoes. The air pressure must be turned off before adjusting the tool. Air hoses must be clear of traffic and must not pose a tripping hazard. Powder-Actuated Tools In Ontario, it is required that the operators be trained before using the tools and carry proof of training on the job. Welding and Cutting Safety Proper eye protection must be worn while using the torch. Leather gloves, full length work pants, and a shirt with sleeves shall be worn while welding. Welding and cutting operations shall be conducted in a designated area free from flammable materials. Welding and cutting areas shall be periodically checked for combustible atmospheres. Gas cylinders shall never by stricken, rolled or exposed to extreme heat. The cylinders shall be stored and secured upright at all times. The unused gas cylinders from the welding and cutting area. The cylinders shall be isolated from other flammable materials. Hoses shall be kept out of doorways and away from other people. If a hose has a break or a puncture, it must not be used. The torch tips shall be kept clean of grease, oil and slag. Proper fitting wrenches shall be used when making connections. Vise grips or pipe wrenches shall not be used. Reverse flow check valve shall be installed. All portable welding equipment must be properly grounded. All equipment shall be checked prior to use. Proper regulator for the gas being used must be used. When opening the cylinder valve, the operator shall stand to the side of the regulator. The oxygen hose shall not be used to blow off clothing. The burning shall not be done directly on a concrete floor. The torch has to be pointed away from the operator and other people at all times. Workers doing oxyacetylene work shall not carry butane lighters. When welding in confined space, adequate ventilation must be present. When electric arc welding, the ground shall be dry and the cables shall be in good conditions and properly connected. When electric arc welding, screens and shielding shall be erected to protect nearby people. Electrodes shall be removed from electrode holder when not in use. Adequate ventilation shall be provided during electric arc welding.