7. Aluminum Age Hardening Experiment

advertisement

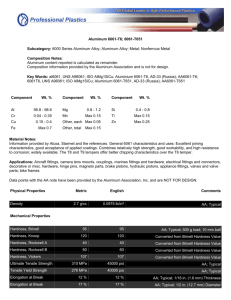

MFET 3451 Age Hardening of Aluminum Alloys Experiment # 7 Objective: a) To perform age hardening or precipitation hardening of Aluminum alloys. b) To learn the effects of age hardening on the hardness of Aluminum alloys. Equipment: Heat treatment furnace with proper controls for age hardening, suitable tongs, appropriate quenching media, and consumables as needed. Materials: The three alloys will be studied in this experiment are among the most widely used heat treatable aluminum alloys. They represent three different alloys: a) 2024 Al (Al-4.5Cu-1.5Mg-0.6Mn), b) 6061 Al (Al-1Mg-0.6Si-0.25Cu- 0.2Cr), and c) 7075 Al (Al-5.6Zn-2.5Mg-1.6Cu-0.3Cr). Procedure: Step 1: Identify the different samples using proper identification methods. Step 2: Measure the Rockwell hardness values of all the as-received samples. Step 3: This step is called solution treatment. This process involves treating alloys between solvus and solidus temperature (Figure 1) and held there until (at least 1hr) a uniform solid-solution structure is obtained. Step 4: This step consists of quenching the solution treated alloys rapidly in water at room temperature. Step 5: Measure the hardness of the quenched samples and tabulate as follows: Alloy 2024 6061 7075 Solution treatment temperature 495 ºC 525 ºC 490 ºC Rockwell Hardness As- Received Solution Treated Step 6: This step involves aging the alloys both artificially and naturally. Naturally aging of alloys involves allowing the quenched samples to age on their own and artificial aging involves reheating the quenched samples. 1 This Session: Prior to the session, the instructor should place four pieces of aluminum alloy (suggested dimensions)25 mm x 25mm x 2mm) in the °C solution-treating furnace. The pieces should be in the furnace for about one hour. Begin the session by acquainting the students with the nomenclature for aluminum alloy tempers 0, T3, T4 and T6. Then take the aluminum alloy pieces from the furnace and immediately quench each one in room temperature water. As promptly as possible, one piece should be put into the freezer until the next session, four piece should be put into the 220°C furnace. four pieces should be put into the 175°C furnace. one piece will be used to establish the hardness in the solution treated condition and the initial portion of the natural age hardening response. After quenching the last piece, carefully grind opposite surfaces flat with an abrasive belt grinder. Then measure the hardness of the sample in at least three places. Record the elapsed time between quenching and hardness testing, which should be no more than five minutes. Continue to measure the hardness of the piece in at least three places at time intervals of 15, 30,45, 60 minutes. after quenching. This piece should be stored by the instructor at room temperature until the next session. Remove one sample from each of the furnaces after soaking times of 15, 30, 45 and 60 minutes. The samples can be cooled in water. Again, carefully grind opposite surfaces flat with an abrasive belt. Measure the hardness of each sample in at least three places. cold roll one piece about 5%, measure its thickness after rolling, cut or saw it into four pieces and put all of them into the 220°C furnace, cold roll one piece about 5%, measure its thickness after rolling, cut or saw it into four pieces and put all of them into the175°C furnace, cold roll one piece about 5%, measure its thickness after rolling, grind opposite faces flat and then measure its hardness in at least three places; make subsequent hardness measurements at intervals of 15, 30, 45 and 60 minutes after cold rolling. 2 Step 7: Measure the hardness values of these samples and tabulate as follows: Rockwell Hardness AL Aging time (hrs) As Is 495 ºC 220 ºC 175 ºC Cold 220 /175 Natural Freezer 0 15 minutes 30 minutes 45 minutes 1 Hour Assignment: 1. Are the hardness values comparable to theoretical values? 2. Plot the hardness data and compare the hardness for the different aging periods. 3. Is their any relation between a) aging temperature and peak hardness values, b) alloy composition and peak hardness c) time required to achieve peak hardness at different aging temperatures. 4. What other properties other than hardness is effect by precipitation hardening of Al alloys Table 1-2.-Designations for Aluminum Alloy Groups Aluminum- 99.0 percent minimum and greater ………………………………………1xxx Aluminum alloy, grouped by major alloying element: Copper……………………………………………………………………………………2xxx Magnanese………………………………………………………………………..……...3xxx Silicon……………………………………………………………………………………4xxx Magnesium……………………………………………………………………………….5xxx Magnesium and silicon…………………………………………………………………...6xxx Zinc……………………………………………………………………………………….7xxx References: 1. Heat Treating, Metals Handbook, ninth edition, ASM International, Metals Park, Ohio, Volume 4, (1990). 2. Aluminum Standards and Data, Seventh Edition, The Aluminum Association, Inc., (1982). 3. “Aluminum and Aluminum Alloys,” ASM International, 1993. 3 Figure 1: Al-Cu phase diagram (Al rich, partial), showing three steps in precipitation hardening and the microstructures that are produced Figure 2: Al-Cu phase diagram showing GP Zones 4