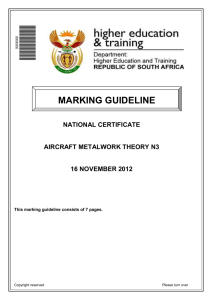

aircraft metalwork theory n3 qp nov 2012

advertisement

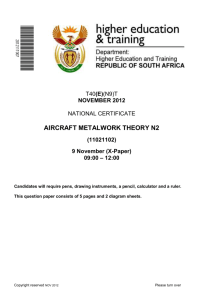

T50(E)(N16)T NOVEMBER 2012 NATIONAL CERTIFICATE AIRCRAFT METALWORK THEORY N3 (11021113) 16 November (X-Paper) 09:00 – 12:00 Candidates will require pens, a pencil, ruler and drawing instruments. Calculators may be used. This question paper consists of 4 pages and a 2-page diagram sheet. Copyright reserved NOV 2012 Please turn over (11021113) -2- T50(E)(N16)T DEPARTMENT OF HIGHER EDUCATION AND TRAINING REPUBLIC OF SOUTH AFRICA NATIONAL CERTIFICATE AIRCRAFT METALWORK THEORY N3 TIME: 3 HOURS MARKS: 100 ________________________________________________________________________ INSTRUCTIONS AND INFORMATION 1. Answer ALL the questions. 2. Read ALL the questions carefully. 3. Number the answers correctly according to the numbering system used in this question paper. 4. Start each question on a NEW page. 5. ALL drawings and sketches must be neat and in good proportion. 6. Write neatly and legibly. Copyright reserved NOV 2012 Please turn over (11021113) -3- T50(E)(N16)T QUESTION 1: TOOLS 1.1 1.2 1.3 FIGURE 1, DIAGRAM SHEET 1 (attached) shows a 'slip roll former'. Give a description of this metal-forming machine and name the parts A to D. (6) FIGURE 2, DIAGRAM SHEET 1 (attached) shows a tool type. Name the parts A to F and also indicate the name of the tool. (7) Name the portable hardness tester and describe how it is used. (2) [15] QUESTION 2: MATERIALS 2.1 Give FOUR reasons why metals are electroplated. 2.2 To facilitate easy handling of aluminium a specific designated number is allocated to alloys. Describe the main alloying elements of the following: 2.2.1 2.2.2 2.2.3 (4) 1xxx 5xxx 7xxx (6) [10] QUESTION 3: CORROSION 3.1 3.2 How can dissimilar metals be protected against corrosion when magnesium is involved? Explain the anodising process with the aid of a sketch. (3) (7) [10] QUESTION 4: FASTENERS 4.1 Explain the difference between a channel gang nut and an anchor nut. (4) 4.2 Explain the difference between radius dimpling and coin dimpling with the aid of neat sketches. (6) 4.3 Sketch and describe the removal of solid shank rivets. Copyright reserved NOV 2012 (10) [20] Please turn over (11021113) -4- T50(E)(N16)T QUESTION 5: REPAIRS 5.1 5.2 Explain, with the aid of neat sketches, how a damaged transition honey comb structure can be repaired. Make a neat, labelled sketch of a semi-monocoque fuselage construction. (15) (5) [20] QUESTION 6: DEVELOPMENT FIGURE 3, DIAGRAM SHEET 2 (attached) shows a transitional sheet metal article rectangular to square. Copy this article in the ANSWER BOOK and then develop the article. Show the full development and construction lines to scale 1:1. [15] QUESTION 7: GENERAL Indicate whether the following statements are TRUE or FALSE. Choose the answer and write only true or false next to the question number (7.1 – 7.10) in the ANSWER BOOK. 7.1 Joggles are used to form odd-shaped parts or finishing touches for which large machines are not suitable. 7.2 Ketts saws are used to cut irregular lines on the inside of a sheet without cutting through the edges. 7.3 The purpose of a hardness tester is to determine the results of the heattreatment process. 7.4 The hole to be drilled for a taper-lock fastener must be drilled at 10 degrees perpendicular to the material. 7.5 The method to repair a dented steel-tube longeron is called a welded patch repair. 7.6 The minimum spacing for a single row of aircraft rivets is two times the length of the rivet shank. 7.7 The most commonly used aluminium alloy sheets on aircraft are 7075-T6. 7.8 Most rivets used during aircraft construction are known by their raised dottype rivets. 7.9 Black-coloured Cleco fasteners are 4,0 mm (5/32') fasteners. 7.10 Rivet pitch is the distance between one row of rivets and the next row. TOTAL: Copyright reserved NOV 2012 Please turn over [10] 100 (11021113) -5- T50(E)(N16)T DIAGRAM SHEET 1 FIGURE 1 FIGURE 2 Copyright reserved NOV 2012 Please turn over (11021113) -6- T50(E)(N16)T DIAGRAM SHEET 2 FIGURE 3 Copyright reserved NOV 2012 Please turn over