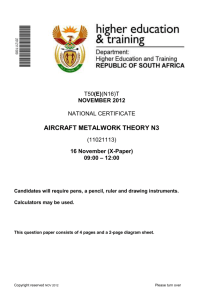

aircraft metalwork theory n3 memo nov 2012

advertisement

MARKING GUIDELINE NATIONAL CERTIFICATE AIRCRAFT METALWORK THEORY N3 16 NOVEMBER 2012 This marking guideline consists of 7 pages. Copyright reserved Please turn over MARKING GUIDELINE -2AIRCRAFT METALWORK THEORY N3 T50(E)(N16)T QUESTION 1 1.1 A B C D Wire roller Handle Slip roll release Roller adjustment A slip roll former is used to make a cylinder or a duct The slip roller consists of three rollers interconnected by gears and turned by a crank handle The rollers can be individually adjusted to produce a tight or loose roll 1.2 A B C D E F (6) Balance weight Clamping handle Slot-adjusting casting screw Link adjustment screw Adjustable stop Bending leaf handle Name of tool: Cornice brake 1.3 (7) Barcol tester - It's a handheld tester for testing soft material It's only necessary to exert a light pressure of the instrument to the material to drive a spring-loaded indenter into the material to be tested. The hardness reading is instantly indicated on the dial. (2) [15] QUESTION 2 2.1 2.2 To protect the base metal against corrosion To protect the base metal against wear To produce a desired appearance To protect the base metal against chemical reactions To increase the dimensions of the part To serve as a base for further plating operations 1xxx Pure aluminium 5xxx Magnesium 7xxx Zinc Copyright reserved (4) (6) [10] Please turn over MARKING GUIDELINE -3AIRCRAFT METALWORK THEORY N3 T50(E)(N16)T QUESTION 3 3.1 3.2 Each surface is insulated as follows: At least two coats of zinc chromate are applied to each surface Next a layer of pressure-sensitive vinyl tape Smooth the tape to prevent air bubbles from forming (3) Anodizing process ANODIZING: IS AN ELECTROCHEMICAL ACTION BETWEEN ALUMINUM OXIDES ON THE SURFACE OF THE METAL AND (CRO2) CHROMIC ACID. ELECTRON FLOW IS NEGATIVE TO POSITIVE CAUSING THE OXIDES TO SOFTEN AND CLING TO THE ALUMINUM ALLOY SURFACE. THE PART IS THEN DIPPED INTO WARM H2O. (7) [10] QUESTION 4 4.1 Channel gang nut Simply u-shape channel constructed so that the anchor nuts are inserted and held in position by the top ledge of the channel (2) Anchor nut It's a self-locking nut with lugs for fastening it to the structure usually by riveting (2) Copyright reserved Please turn over MARKING GUIDELINE -4AIRCRAFT METALWORK THEORY N3 T50(E)(N16)T 4.2 Radius dimpling 4.3 (6) Coin dimpling Removal of solid shank rivets RIVET REMOVAL (SOLID SHANK) Copyright reserved (10) [20] Please turn over MARKING GUIDELINE -5AIRCRAFT METALWORK THEORY N3 T50(E)(N16)T QUESTION 5 5.1 Transition repair Outline the repair Using a router remove the damaged core area Fabricate a fibreglass honeycomb core to replace the damaged core Prepare potting compound Butter the edges of core Install the buttered core Prepare glass-fibre adhesive Prepare four glass-fibre laminates Apply four glass cloth laminates to repair area Allow to cure Apply necessary erosion and corrosion treatment Copyright reserved (15) Please turn over MARKING GUIDELINE 5.2 -6AIRCRAFT METALWORK THEORY N3 T50(E)(N16)T Semi-monocoque fuselage construction (5) [20] QUESTION 6 Rectangular to square development Copyright reserved Please turn over MARKING GUIDELINE -7AIRCRAFT METALWORK THEORY N3 T50(E)(N16)T [15] QUESTION 7 7.1 7.2 7.3 7.4 7.5 7.6 7.7 7.8 7.9 7.10 False True True True True False True False True True [10] TOTAL: Copyright reserved 100 Please turn over