Thomas Mathes – Assistant General Manager, Hotel Monaco, Chicago

advertisement

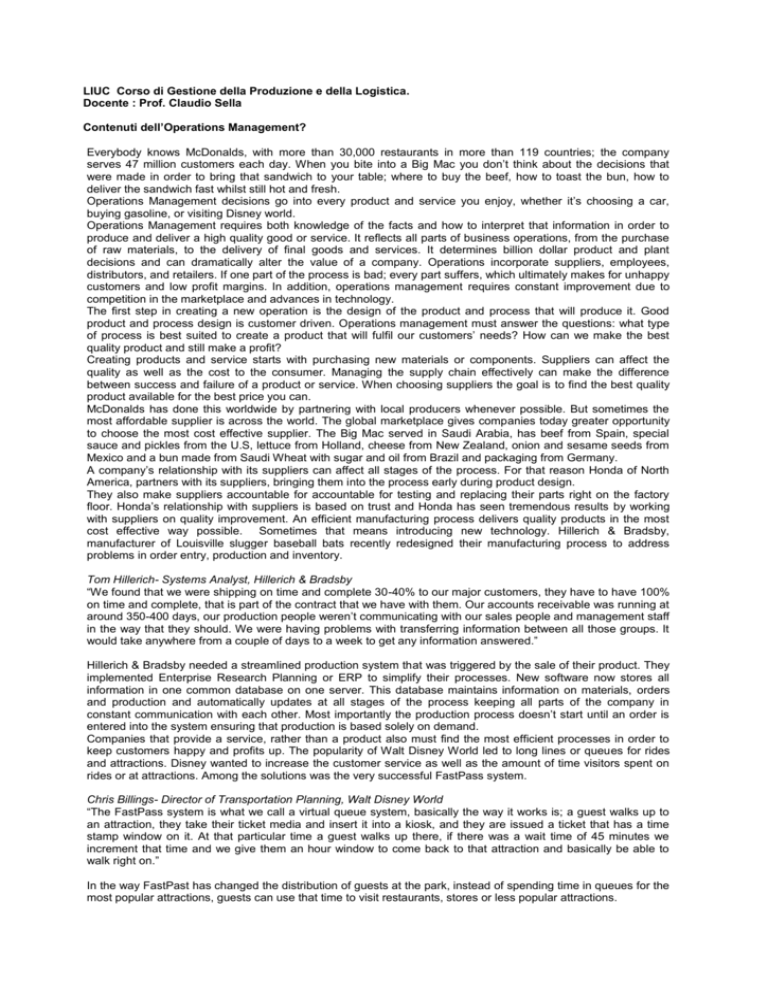

LIUC Corso di Gestione della Produzione e della Logistica. Docente : Prof. Claudio Sella Contenuti dell’Operations Management? Everybody knows McDonalds, with more than 30,000 restaurants in more than 119 countries; the company serves 47 million customers each day. When you bite into a Big Mac you don’t think about the decisions that were made in order to bring that sandwich to your table; where to buy the beef, how to toast the bun, how to deliver the sandwich fast whilst still hot and fresh. Operations Management decisions go into every product and service you enjoy, whether it’s choosing a car, buying gasoline, or visiting Disney world. Operations Management requires both knowledge of the facts and how to interpret that information in order to produce and deliver a high quality good or service. It reflects all parts of business operations, from the purchase of raw materials, to the delivery of final goods and services. It determines billion dollar product and plant decisions and can dramatically alter the value of a company. Operations incorporate suppliers, employees, distributors, and retailers. If one part of the process is bad; every part suffers, which ultimately makes for unhappy customers and low profit margins. In addition, operations management requires constant improvement due to competition in the marketplace and advances in technology. The first step in creating a new operation is the design of the product and process that will produce it. Good product and process design is customer driven. Operations management must answer the questions: what type of process is best suited to create a product that will fulfil our customers’ needs? How can we make the best quality product and still make a profit? Creating products and service starts with purchasing new materials or components. Suppliers can affect the quality as well as the cost to the consumer. Managing the supply chain effectively can make the difference between success and failure of a product or service. When choosing suppliers the goal is to find the best quality product available for the best price you can. McDonalds has done this worldwide by partnering with local producers whenever possible. But sometimes the most affordable supplier is across the world. The global marketplace gives companies today greater opportunity to choose the most cost effective supplier. The Big Mac served in Saudi Arabia, has beef from Spain, special sauce and pickles from the U.S, lettuce from Holland, cheese from New Zealand, onion and sesame seeds from Mexico and a bun made from Saudi Wheat with sugar and oil from Brazil and packaging from Germany. A company’s relationship with its suppliers can affect all stages of the process. For that reason Honda of North America, partners with its suppliers, bringing them into the process early during product design. They also make suppliers accountable for accountable for testing and replacing their parts right on the factory floor. Honda’s relationship with suppliers is based on trust and Honda has seen tremendous results by working with suppliers on quality improvement. An efficient manufacturing process delivers quality products in the most cost effective way possible. Sometimes that means introducing new technology. Hillerich & Bradsby, manufacturer of Louisville slugger baseball bats recently redesigned their manufacturing process to address problems in order entry, production and inventory. Tom Hillerich- Systems Analyst, Hillerich & Bradsby “We found that we were shipping on time and complete 30-40% to our major customers, they have to have 100% on time and complete, that is part of the contract that we have with them. Our accounts receivable was running at around 350-400 days, our production people weren’t communicating with our sales people and management staff in the way that they should. We were having problems with transferring information between all those groups. It would take anywhere from a couple of days to a week to get any information answered.” Hillerich & Bradsby needed a streamlined production system that was triggered by the sale of their product. They implemented Enterprise Research Planning or ERP to simplify their processes. New software now stores all information in one common database on one server. This database maintains information on materials, orders and production and automatically updates at all stages of the process keeping all parts of the company in constant communication with each other. Most importantly the production process doesn’t start until an order is entered into the system ensuring that production is based solely on demand. Companies that provide a service, rather than a product also must find the most efficient processes in order to keep customers happy and profits up. The popularity of Walt Disney World led to long lines or queues for rides and attractions. Disney wanted to increase the customer service as well as the amount of time visitors spent on rides or at attractions. Among the solutions was the very successful FastPass system. Chris Billings- Director of Transportation Planning, Walt Disney World “The FastPass system is what we call a virtual queue system, basically the way it works is; a guest walks up to an attraction, they take their ticket media and insert it into a kiosk, and they are issued a ticket that has a time stamp window on it. At that particular time a guest walks up there, if there was a wait time of 45 minutes we increment that time and we give them an hour window to come back to that attraction and basically be able to walk right on.” In the way FastPast has changed the distribution of guests at the park, instead of spending time in queues for the most popular attractions, guests can use that time to visit restaurants, stores or less popular attractions. “Basically it has given guests now more time to experience more attractions, so they are able in the same amount of time that they have in day to experience a significantly higher percentage of attractions. So given that, that’s one of the key reasons that guests come to visit its been very, very successful.” How do you know if your process is the most efficient for your product or service? Measuring is an important element of operations management; it is the only way to track improvement or failure in a process. Businesses use statistical analysis to identify and correct potential problems early in the process. Sam Kennedy – Associate Engineer, Honda of North America “Statistical control is simply monitoring the consistency and repeatability of a specific process. If we apply statistics and understand the actual capability of the process, we can predict the failure rate within that process and make running adjustments so that we don’t have actual problems occur.” One example of this is the door-closing test at Honda. This test measures the speed required to close a car door without slamming. Results are entered into the computer where it is examined by statistical analysis software. This software measures results for individual cars as well as tracking the distribution of results for individual cars as well as tracking the distribution of results across several weeks. Using this information, plant workers can measure the efficiency of the entire process and make adjustments if needed. “In manufacturing, you are always trying to find ways to do things better and more efficiently and the bottom line in trying to improve quality. We call this ‘continuous improvement’. Matt Robbins- General Manager, Gortrac “In some part of continuous improvement we do a daily production meeting where we discuss the previous days activities. The whole purpose behind the production meeting is really to discuss what’s hot that day. We actually record the days productivity numbers and compare that to the previous day, the previous week, the previous month. The reason we measure ourselves is to see how well we are doing and are we progressing towards our goals.” Sometimes changes in the market force a company to rethink its product or service design. For example when the Kimpton Group got into the hotel business the market was saturated with brand name chain hotels that were stripped down for the business traveller. Kimpton decided to stand out by opening boutique hotels, such as the Hotel Monaco in Chicago. Boutique hotels typically have 75 to 200 rooms, are priced in the 4 star range and focus on customer service in an intimate luxury setting. The hotels are designed to serve both the business traveller and the pleasure traveller by providing a number of special services. In addition the hotel uses specialised software, to track their guests preferences and desires. Thomas Mathes – Assistant General Manager, Hotel Monaco, Chicago “Capturing those business clients means that we have to exceed their expectations and deliver every time they return to our hotel. That’s a very powerful function within the hotel to meet those customers’ needs. That determines guest loyalty.” Operations management is the key to making any business more successful. ABTco create speciality building products such as wood and vinyl siding, shutters and trim, interior wood and tile board. Several years back it was a struggling division of a larger company that primarily specialised in paper products. The parent company put it up for sale because it didn’t fit well in their core business. Investors bought the business for $100 million. George Brophy- Chairman & CEO, ABTco “The former owners were people that had a lot of paper making background, whereas my people have a very specific background on engineered wood and they were the best in the industry. We knew long before we bought the company that we could improve the operations.” Using fundamentals of operations management, the new owners reorganised the manufacturing process to improve quality and efficiency. They closed down lines that produced unprofitable products and started up idle lines to fill product shortages. As a result their siding unit increased production capacity 23% in one year without adding any space or capital expense. The plastics group increased output 30% at one plant alone. Increasing efficiency allowed for new product development in a shorter period of time. Instead of a year, the company could now produce a new product within 3 months. As a result sales improved (9%), more importantly operating income grew by $22million, (292%) in the first year of new ownership. When the investors took the new company public its value on the NASDAQ was $300million, not bad for a company they had purchased just a year earlier for onethird that price. Good operations management was the key to ABTco’s success and the continued well being of many other companies. All companies need high quality products and services, delivered in a timely manner at a competitive and profitable price to customers who appreciate their value. In fact the need for strong operations management never ends without it a business cannot know how well it is doing or how to improve. In a competitive market a business that doesn’t improve doesn’t last long.