Copy of course_overview

advertisement

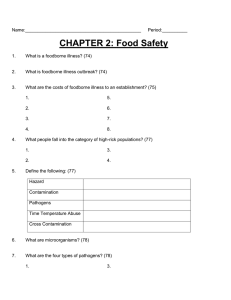

Cooperative Extension Service Luke F. LaBorde Ph.D. Extension Specialist and Associate Professor Department of Food Science College of Agricultural Sciences The Pennsylvania State University University Park, PA 16802-2504 (814) 863-2298 Fax: (814) 863-6132 email lfl5@psu.edu Food Safety and Sanitation for Food Manufacturers Overview of the Course The goals of the Penn State Food Safety and Sanitation for Food Manufacturers course are to 1) present an introduction to the scientific basis behind food safety and 2) provide practical information on sanitation and security procedures necessary to produce safe food products. The course content is directed at food processors, packers, handlers, and distributors of food products. It is also appropriate for educators, regulators, technical sales personnel, and others interested in the science and technology of manufacturing safe foods. The course contains information that any food processor will find useful. However, it will be of particular use for establishments that produce potentially hazardous foods. For this reason, we wish to offer students the option of receiving food safety certification under the Pennsylvania Food Employee Certification Act in the “General Certification Category” as described in Section 76.5(b)(2)(i)(A) of the Act. Such establishments include, but are not limited to, salad manufacturers, shellfish or seafood processing, ice manufacturer, fresh juice processor, cut fruits, tofu manufacturer, garlic-in-oil, sushi operations, cider press and butcher stand in a farmers market that processes meat and/or poultry, makes sausages, slices meats and cheeses. It is also appropriate for the FECA compliant categories of frozen desert manufacturers, bakeries, and retail food establishments that process food for direct sale to consumers. This course was developed by the Dr. Luke LaBorde of the Penn State Department of Food Science and the Distributed Learning Group in the Penn State College of Agricultural Sciences (CoAS) and consists of 12 chapters delivered in an online format through the Angel Penn State Course Management System (http://cms.psu.edu). Course registration and handling of fees will be handled by the CoAS Conferences and Shortcourse office. This is an independent study course. The student is responsible for reading the text and completing various activities. However, the instructor can be contacted if any questions or problems with the course arise. Students progress through the material at their own rate yet movement through each succeeding chapter is restricted unless certain requirements are met. The course sequence is as follows. The entry point to the course is the Welcome Page. The returning student may click on a “last page visited” link to return to where left off from the previous session. For the first time student, directions are given for accessing the course Syllabus. Here information is given an outline of the chapters and provided information on computer technical requirements, course features, and navigation directions. Each chapter begins with an introductory web page describing the learning objectives along with a brief overview of the chapter. To continue to the rest of the chapter, the student must first complete an un-graded pre-quiz. After completing the pre-quiz, the student is directed back to the chapter and instructed to read the text. The course material is supplemented with relevant photographs, diagrams, and graphics that reinforce key learning points. Each chapter also has a learning activity which consists of an interactive “drag and drop” Flash® animation. The student must drag a text box containing the correct answer back to each question box. Feedback is automatically given as to whether or not the correct choice was made and the student may make as many attempts as necessary to complete the exercise. Also within each chapter are links to additional information for students who desire a more in-depth discussion of a An Equal Opportunity University particular point mentioned in the course text. This is called the Learning Library and the student is not tested on this material unless it has also been presented in the main course text. Hardcopies of Learning Library materials and print-outs of Flash animations are included in this application. At the end of the chapter, the student is directed to a post-quiz. They may take the quiz as many times as necessary to achieve a minimum score of 75% after which they may move to the next chapter. Pre- and post-quiz data will be automatically compiled by the courseware so that the instructor can assess the effectiveness of individual chapters and the overall course. After all chapters have been completed, a Penn State Certificate of Achievement will be issued. Those that wish to obtain Pennsylvania Food Employee Certification will be instructed as to where they may take a proctored exam that consists of 80 multiple choice questions. A passing score of at least 75% will be required to obtain FECA certification. The instructor for the course will be Dr. Luke LaBorde, associate professor and extension specialist in the Penn State Department of Food Science. His areas of expertise encompass all aspects of the quality and safety of fresh and processed fruits and vegetables. As part of his extension responsibilities, he teaches or co-teaches several workshops each year including the annual Penn State Sanitation Short Course, Safer Cider Workshop, Juice Hazards Analysis Critical Control Point (HACCP) and others on Acidified Food Processing, Good Manufacturing Practices, and Good Agricultural Practices. He has also taken the FECA approved ServSafeTM food safety course and received an exam score that qualifies him for instructor status. . Course Outline Twelve chapters will be presented. The amount of time to complete each depends on the student’s motivation, background in the content area, and his or her ease with computer learning. Based on test runs with selected reviewers, it is estimated that individual chapters take between 45 and 75 minutes to complete or between 9 to 15 hours to complete the entire course. Because the speed at which the student moves through the course is self controlled and he/she may log-off at any time and later re-enter the course where they left off, the entire time to complete the course may be up to several weeks. However, a time limit of 6 months will be given by the instructor to complete the course. A summary of the content of each of the chapters follows. Chapter 1. Foodborne Illness and Injury Microbial, chemical, and physical hazards and the types of illness or injury they cause will be described. Differences between a foodborne illness case and an outbreak and intoxication and infection mechanisms for development of foodborne disease. Why thermal processes that kill microorganisms may not be adequate to eliminate microbial toxins. Common symptoms of microbial foodborne disease. Populations particularly susceptible to microbial foodborne disease. Differences between food allergies and food intolerances. The eight types of foods that account for 90% of known food allergies. Chapter 2. Food Microbiology The difference between pathogenic, spoilage, and beneficial microorganisms. The 4 phases of microbial growth and decline in the order they occur. The major types of food microorganisms and how they differ from each other. A description of how bacteria grow. The 5 factors that affect microbial growth. Why Listeria monocytogenes is not adequately controlled by refrigeration alone. The difference between acid and low-acid foods regarding the potential for microbial growth. What water activity means and how it affects microbial growth. The difference between mesophiles, psychrotrophs, and thermophiles. The lower and upper temperature limits for the Temperature Danger Zone. Terms used to describe oxygen requirements for microorganisms. Places in the body or environment where bacterial pathogens can be found Chapter 3. Food Protection Definition and examples of potentially hazardous foods. Why ready-to-eat food can be classified as higher risk foods. Situations in the flow of food where raw materials, ingredients, or processed food products may be exposed to TDZ temperatures. Ways assurances of safe products from suppliers can be obtained Visual clues that frozen food might be unsafe. Why a “First In First Out” system helps to maintain safe food. General storage conditions that prevent food contamination. The proper way to thaw frozen foods and ingredients. When it is necessary to consult a process authority. Ways to prevent post-processing contamination and microbial growth. Why labeling packages correctly protects the consumer from foodborne disease and limits manufacturer liability. Hazards associated with reduced oxygen packaging Chapter 4. Worker Hygiene and Personal Practices That Cause Food Contamination Symptoms and conditions that would exclude a person from working with food. Personal hygienic practices that all employees who handle food should follow at home to maintain overall cleanliness on the job. How protective clothing prevents food contamination. The proper way to wear a hair restraint. How eating, drinking, and using tobacco might contribute to food contamination. How wearing jewelry or eating, drinking, and chewing gum increases risks for microbiological and physical contamination. How to prevent cross-contamination when moving between unsanitary and sanitary food-handling areas. Situations before or after which hands should be washed. The 5 steps for effective handwashing. Practices that can cause hands to become recontaminated immediately after handwashing. The correct use of hand sanitizers. Advantages of using disposable hand gloves. Characteristics of toilet facilities that prevent them from becoming a source of contamination. Chapter 5. Safe Water Use Characteristics and uses of potable water in processing plants. Risks associated with municipal, ground, and surface water. Significance of detecting coliforms in the potable water supply. When water should be tested. Back flow how backflow prevention devices work. Situations in which aerosols and floor splash can cause food contamination. Examples of a direct cross connections. Example of indirect cross connections. Chapter 6. Design and Maintenance of Buildings and Grounds Describe how trees, bushes, and grass outside buildings increase food safety risks. How improper grading of roads, parking lots, and receiving yards causes standing water problems. How the type and placement of interior and exterior light fixtures affects food safety risks. How the type and condition of the roof on a processing building affects food safety risks. The best path for the movement of raw materials and ingredients through the plant. Recommended construction and use of doors, windows, walls, floors, and drains. How proper air flow minimizes food safety risks. Proper placement of waste containers. The proper way to store materials both inside and outside buildings. Chapter 7. Design, Use, and Maintenance of Equipment and Utensils Definition and examples of a food contact and non-food contact surfaces. Desirable characteristics of materials used as food contact surfaces. Why stainless steel is the preferred material for food contact surfaces. Why some plastic materials and rubber materials may be unsuitable as food contact surfaces. Examples of equipment sanitary design principles that minimize food safety risks. How proper placement of equipment minimizes food safety risks. How a preventative maintenance and calibration program impacts food safety. Repair procedures that can contribute to contamination risks. How maintenance, repair, and calibration of equipment minimizes food safety risks. Chapter 8. Food Safety Regulations Differences between laws and regulations. Federal government agencies responsible for food safety regulations Federal agency that regulates pesticides, sanitizers, and water quality. General rules for determining whether a food is regulated by federal or state and local regulations. Two general conditions that qualify a food as adulterated. The purpose and scope of Good Manufacturing Practices. What to do and what not to do when an inspector arrives at your processing establishment. Chapter 9. Cleaning as Part of the Sanitization Process The 5 steps for cleaning and sanitizing and the goal of each. Why it is necessary to thoroughly clean a surface before sanitizing it. Properties of select cleaners and the soils they remove. Ideal characteristics to look for when purchasing a cleaner. Why it is necessary to prevent build up of scale on equipment surfaces. Differences between temporary and permanent hardness Situations in which manual cleaning would be most effective. Precautions to take when using high pressure cleaning methods. Differences between manual or mechanical cleaning methods. Chapter 10. Sanitizers and the Sanitization Process Why complete sterilization of food contact equipment is usually not a desirable goal. Characteristics of an ideal sanitizer. Advantages and disadvantages of various physical and chemical sanitizing treatments. How pH affects the activity of hypochlorite sanitizers. Why continuous monitoring for pathogens in food or on food contact surfaces is not a practical way to ensure safe foods. Advantages for using indirect methods over direct methods to verify sanitizing effectiveness. The concept and usefulness of ATP bioluminescence testing. Why the zone concept is useful for developing a microbiological sampling program. Chapter 11. Food Processing Security USDA recommendations for evaluating food security risks. The three types of individuals capable of intentionally contaminating food and possible motivations for each. The four types of security hazards and examples from each group. Critical security areas and why it is important to concentrate control efforts in these areas. The three main strategies for minimizing security risks. Signs that indicate an employee might be a security risk. Ways that employers can prevent workers from becoming security risks. Examples of ways to limit access to critical interior and exterior security areas. Examples of ways to increase visibility on the grounds and inside food processing and storage buildings. Ways to prevent visitors from becoming security risks. Chapter 12. Controlling Food Hazards – The HACCP Approach Reasons why HACCP is more effective in preventing foodborne illness and injury than the traditional inspection system. Why prerequisite programs are needed for HACCP to be effective. The purpose of a process flow chart. The 2 factors in the hazard analysis that determines whether or not a food safety hazard is significant. Critical control points and monitoring procedures. Why records are an important part of HACCP. Food Safety and Sanitation for Food Manufacturers Conformance of the course to requirements in the Food Employee Certification Act Pursuant to Section 76.7 of the Act, this course contains instruction in the following topics with reference to relevant course modules. Category (1) Foodborne illness. (2) Time and temperature. (3) Relationship between personal hygiene and food safety. (4) Food safety tracking system. (5) Cleaning and sanitizing. (6) Facilities and equipment layout. (7) Statutory and regulatory requirements. Course module that addresses material in category Chapter 1. Foodborne Illness and Injury Chapter 2. Food Microbiology Chapter 2. Food Microbiology Chapter 3. Food Protection Chapter 4. Worker Hygiene and Personal Practices That Cause Food Contamination Chapter 3. Food Protection Chapter 11. Food Security Chapter 12. Controlling Food Hazards – The HACCP Approach Chapter 9. Cleaning as Part of the Sanitization Process Chapter 10. Sanitizers and the Sanitization Process Chapter 3. Food Protection Chapter 5. Safe Water Use Chapter 6. Design and Maintenance of Buildings and Grounds Chapter 7. Design, Use, and Maintenance of Equipment and Utensils Chapter 8. Food Safety Regulations Chapter 12. Controlling Food Hazards – The HACCP Approach Required information submitted with this application Pursuant to Section 76.13 of the regulation, the applications materials include the following information is included with this application. Form, information, or materials The Food Employee Certification Training Program Approval Application (1) The name and mailing address of the instructor (2) A course syllabus demonstrating that the course addresses regulatory or food industry changes, updates or advancements, or offers a general review of food safety considerations and procedures. (3) A copy of all teaching materials for the course. Where located in this application See attached Form AFSLS-278 Provided on Form AFSLS-278 See attached “Course Outline” Web page printouts attached. The course is locked to registered students. However, a username and password will be issued to PDA FECA reviewers upon request. (4) A copy of all materials to be distributed See above to persons taking the course. (5) The proposed sites and dates of the n.a. (online course) course. (6) The certification category with respect Provided on application form and attached to which approval is sought. “Course Overview” (7) Other information the Department See attached “Conformance of the Course might reasonably require in evaluating to Requirements in the Food Employee whether to approve the continuing Certification Act” education course.