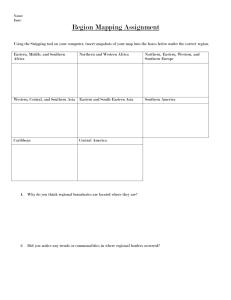

iskra power tools' market position

advertisement

CPE 702 – P.F. JEANDET INTERNATIONAL MARKETING Christelle Monteillet – Cemiyle Parlak – Antoni Yalap ISKRA POWER TOOLS INTRODUCTION Iskra is a Power Tools Company created around 1950 and started by serving the Yugoslavian market. The firm acquired notoriety by the quality of its products and its low workforce costs. Some cooperation agreements were made between Iskra and other niche players present in the Eastern Europe markets. Iskra which serves the Eastern Europe Professional and Do-It-Yourself (DIY) segments is seeking new opportunities. The company would enter the Western Europe markets where the competition is rude between manufacturers such as Black & Decker, Bosch and Makita which strategies are different. The aim is to penetrate the French and Italian markets, two less mature than the others. Some others think that Iskra’s comparative advantages are adapted to Eastern Markets and would stay in the Eastern Europe markets (moreover, the fall of communism involves the opening of the Russian and new countries markets). We will try the management to define a market strategy. But before, we want to present the international and European Power Tools Sector, define the position of Iskra in this industry and close by suggesting an action plan with concrete recommendations. PART ONE PRESENTATION OF THE EUROPEAN POWER TOOLS INDUSTRY INTERNATIONAL POWER TOOLS INDUSTRY Definition: We will begin by explaining what is a power tool? Power tools included any tool containing a motor that was capable of being guided and supported manually by an operator. Power tools played an intermediary role between traditional hand tools and sophisticated machine tools. The large availability of electrical energy and the relatively low cost of electric tools facilitated their use in small workshops, the building and construction industries and households. Segmentation: The power tools industry is divided in two segments: professional and hobby, according to the usage. Users of the first category worked in industries such as assembly-line manufacture, foundries and shipbuilding or woodworking. On the other hand, the building and construction trade covered both professional and Do-It-Yourself (DIY) segments. Purchase Behavior: The power tools purchase behavior depend on labor costs and disposable income. The professional power tool sector was most developed in high-labor-cost countries and the DIY market was more pronounced in countries with higher personal disposable incomes. 1 The global turnover: In 1989, the worldwide electric power tool industry was valued at just of over DM 10 billion (that is to say, €5 billion). The sales were concentrated in three major markets: North America, 28% Europe, 47% Far East, 18% As we can see, Europe is the leader in term of market shares. Since 1980, the industry had grown an average of 3% per year on a worldwide basis. Manufacturing: a large number of manufacturers produce a wide range of tools but a majority of them depend heavily on subcontractors. The big manufacturers make the central components such as motors. Power tools are mass produced even if the productivity depends on manufacturers’ efficiency or the level of mechanization. Here is the pie representing manufacturing costs: MANUFACTURING COSTS (%) 14% 12% 50% 9% 15% Materials Machining Molding Assembly Final Assembly Trends: after 1980s, a certain number of facts are influencing the competition in the world: The more and more large preference for battery-powered (cordless) tools. Japanese are manufacturing 20% of these products. The globalization and the opening of Eastern Europe Markets: that is profitable for larger players like Iskra in terms of flexibility (markets open their doors: benefiting from uncertainties in exchange rates, competitiveness). EUROPEAN POWER TOOLS INDUSTRY Figures: Europeans, as we saw, are dominating the power tools sector. Germany, France, Great Britain and Italy represent 75% of region’s sales. The industrial segment is the more important. We will see the importance of the four countries in the next table. Table 1: 1989 Unit Sales and Percentage of the Market in Europe’s Largest Markets Country Thousands of Pieces % European Sales Germany 7 000 28 France 5 000 20 Great Britain 4 300 17 Italy 2 500 10 Other Countries 6 200 25 TOTAL 25 000 100 2 Source: Bosch The growth rates are very irregular from a country to another one. Indeed, as we said before, these rates change continuously. The next table is demonstrating this fact for the European countries: Table 2: European Power Tools Markets’ Percent of Growth in 1989 and 1990 Country % Growth 1989 Country % Growth 1990 Portugal 20 Greece 35 Spain 18 Germany 18 Italy 15 Portugal 18 Greece 15 Italy 12 Finland 12 Netherlands 10 Austria 12 Sweden 10 Sweden 10 Ireland 8 Great Britain 8 Belgium 6 Germany 8 Spain 6 France 8 Austria 4 Belgium 8 Denmark 3 Switzerland 8 Switzerland 3 Netherlands 5 France 0 Ireland 5 Great Britain 0 Denmark -5 Norway 0 Norway -5 Finland -3 1989 Source: Databank – 1990 Source: Bosch Segments and channels: We are said that professional tools are sold in hardware stores, by tools specialists or by manufacturers or direct sales force distributors. Purchase criteria are: quality, durability, after-sales service. In the hobby segment, customers buy from wholesalers, hardware and department stores, home centers, mail-order houses and supermarkets, that is to say, not specifically from specialists. Purchasing factors are different from the professional segment’s factors: manufacturer’s image, quality and price. The price, brand name and packaging are important factors. The competition seems to be rude. We know that the change in purchasing patterns had led to a change in the distribution of power tools. In the professional segment, direct sales play a more significant role in the distribution process especially in the more mature and structured markets. On the other hand, the consumer segment is under control of mass merchandisers. In other words, manufacturers develop the establishment of more direct links with professionals while with consumers the trend is to establish more visible links. We also know that the Northern Europe markets are mature meanwhile the Southern Europe markets are not. The role of mass merchandisers and of direct sales is more important. The Third table, below, shows us the difference between North and South Europe through two countries: Germany and Italy (in professional and DIY segments): Table 3: Percentage of each distribution network, in 1990, in Italy and Germany Channel Germany Italy DIY Segment Wholesalers 5 25 Hardware Stores 55 45 Mass Merchandisers 15 11 3 Home Centers Others (Mail order, …) 21 4 19 Professional Segment Direct 10 Hardware Stores 50 Wholesalers 40 Mass Merchandisers Source: Black & Decker, Iskra Company Records 55 25 20 Eastern Europe and USSR: we are in a difficult period. The communist USSR felt and new independent states emerged and started to try to develop market economies. Three consequences are to be taken in power tools sector: 1. For companies present in West, these new countries markets constituted a new target. 2. Power Tools manufacturers in Eastern Europe wanted to be more efficient after privatizations on local markets and abroad. 3. The opening of the Russian markets. Competition in Europe: in 1989, there were 75 power tool manufacturers in the world in two categories: multinationals and domestic manufacturers. The large players were present in professional and Do-It-Yourself (DIY) segments by a full range of products and accessories. The small players were present in a few segments. The smaller manufacturers benefited from an expertise image in their field. In Europe, the major competitors were: Black & Decker: It was the largest power tool manufacturer in the world. Black & Decker owned plants in 10 countries and sales points in more than 100 another countries. It represented, with a turnover of $1.077M, 25% of total market. Two third of incomes were from consumer segment and one third from professional one. The firm pioneered the introduction of products to the DIY segment. Black & Decker had has a good brand and quality image. A joint-venture was made in Kranj for the Eastern Market. Makita: This is a Japanese company. Makita entered the market in 1950. The management of this company believe in Price strategy. Their products cost 20 to 30% less than the average price). The added value of Makita is the good quality and the After-Sales Service. The firm is present only in professional segment with a wide range of products. Europe is a target for them. Their goal: own 25% of the market. Bosch: Is the third bigger manufacturer. The firm owns plants in Germany and Switzerland. Bosch is present in professional and DIY segments and is distributed through all channels. Skil: Present in United States and in professional segment. Its aim: to develop a DIY strategy. In Europe, the firm is present in Nordic markets in professional sector. The company is also present in France and Germany. The strength of Skil is the Price strategy. Other niche players: Elu (Germany), Kango (Great Britain). The table below shows the major competitors of Iskra, perceived successful by Iskra: Table 4: Major competitors of Iskra Competitor Black & Decker Bosch Festo Location USA Germany Germany 4 Specialist / Generalist Generalist Generalist Specialist Hilti Ryobi Stayer Source: company records. Germany Japan Italy Specialist Generalist Generalist PART TWO A MEMBER OF THIS INDUSTRY: ISKRA POWER TOOLS A SWOT ANALYSIS We present, below, a SWOT analysis of Iskra Power Tools which will enable us to know, in internal, its strengths and weaknesses and in external environment, its opportunities and the threats to overcome: SWOT ANALYSIS INTERNAL Strengths Weaknesses Low-priced products. Unable to supply the requested quantities. Low-priced workforce. Important delays in starting the production process. Payment terms Quality of the products. Problems with management of stocks. The experience of the Eastern market and of collaboration with different foreign firms in Lack of communication between design, Eastern Europe. production and marketing departments. Try to increase its attractiveness for foreign firms: with Skil, a generalist in the power tool industry, Iskra’s competitive advantage was to be a low-cost supplier; with ELU, Kango, and Bosch on the other hand, Iskra’s success was based on the high perceived value of a niche product; with Ryobi, price competitiveness and market presence in Eastern Europe were important. Lack of creativity and new products and lack of technological innovation by the R&D department. The products range is not very large (200 tools) The brand is not very well-known High indirect costs for Iskra’s production Knowledge of the Western European markets (6OOOOO units/year). For example, Kress by Perles, company controlled by Iskra. with 400 to 500 employees as Iskra, produces around 1000000 units. EXTERNAL Opportunities Threats Market Studies for the penetration of the Firm’s major suppliers are based in Serbia, Russian market with joint-ventures. where there is a political crisis. Agreements with Makita, Bosch or Black & The Yugoslavian suppliers do not possess a Decker for cooperation on Eastern Europe high quality standard. Markets. High Customs and entrance fees (we are in 5 Investments in the cordless products, on 1991) production and design. The Import delays for the items sold on the Penetration and development of French and domestic market are too long. Italian markets under Perles brand. The large players like Bosch, Black & Decker Establishing of a wide distribution network and Makita want to enter the Eastern Europe (wholesalers, retailers, specialized markets for advantageous workforce prices. supermarkets). If Iskra invest in Russia, the firm must take all Iskra Commerce is trading all products to necessary measures for the payments. Some foreign markets: this firm can work exclusively solvability problems can occur. for these markets. ISKRA POWER TOOLS’ MARKET POSITION In Western Europe: Iskra is present in both DIY and professional segments. Its strategy is characterized by joint-ventures agreements after the 1960s. The company wanted to expand its product offering on other markets and it consisted in electric drills which were based on the company’s expertise. The cornerstone of these agreements was exchange programs with other toll manufacturers. Namely, Iskra signed for cooperation with small power tool manufacturers like Perles, Skil Europe and Ryobi, respectively Swiss, UK and Netherlands, and Japan based. Selling Iskra’s products under their name, Perles and Skil made Iskra take benefit from their own distribution network and he their own products sold under the Iskra name in Yugoslavia. In order to strengthen ties with Western power tool producers, Iskra operated as an OEM supplier thanks to its company’s expertise. For example, agreements were concluded with Elu, a German woodworking tools manufacturer, and Kango, a UK company specialized in drills. In Eastern Europe: Iskra concluded agreements with power tools manufacturers in order to strengthen its business ties in this area. In Czechoslovakia, Iskra operated on a three-way trading agreement with Naradi and Merkuria in 1978: Perles shipped drills from Switzerland to Naradi, these products were marketed under the Naradi name to Merkuria (a trading company) which sold products under the Iskra name. This cooperation enabled Iskra to get a 10% market share in Czechoslovakia. In Poland, Iskra signed for the same agreement with Celma and it marketed Celma’s products under Iskra’s name in Yugoslavia. In the USSR, Iskra entered in contact with the Institute for Power Tools in Moscow in 1984 during 5 years but only 100 power tools were brought to Yugoslavia. In Yugoslavia: With a market share of 50% in 1989, Iskra was selling its products with Iskra Commerce thanks to its own network or by its factory in Kranj. The point is that the market was larger in Serbia than in Slovenia or Croatia because these two countries had access to Italy and Austria geographically speaking. COMPETITORS’ STRATEGY: Black and Decker: As we saw it before, Black and Decker was the largest power tool maker with 25% market share. Its segments were divided in two parts: the DIY segment represented 1/3 and the professional one 2/3 and the company was selling in 100 countries around the world. 6 We can note that its competitive advantage is namely the introduction of new products (25% and the level of 50% was expected for 1991), low costs (thanks to the standardization of motors, flexibility...), and a strengthened presence in Eastern Europe thanks to joint-ventures in Kranj and Czechoslovakia. Bosch: This company was the third largest power tool producer in the world. Bosch produced both DIY and professional segments and we can notice that it had a strong position in Europe were its products were sold by all channels. Following the reunification of East and West Germany, Bosch operated a joint-venture with VEB Elektrowerkzeuge Seibnitz in Dresden to assemble power tools at this place and to sell its products with its network. Besides, Bosch’s management planned to concentrate the Export Department in Seibnitz. Makita: With a presence on foreign markets except Europe, this company was specialized in the professional segment only and was selling under a broad range of tools. Characterized by its price competitiveness, the quality of its products and its After-Sales service, Makita wasn’t nonetheless in competition with Iskra on its market. Skil: This company is a major manufacturer on the market and it is particularly strong in Germany and France. Its segments are divided into two areas; the Nordic market which is covered by the professional segment, and the rest of Europe by the DIY one. Niche players: With companies such as Festo and Elu in Germany or Kango in Great Britain, niche players made the majority of sales on their own markets with premium prices. KEY SUCCESS FACTORS OF THE COMPETITORS Small power tool manufacturers: Makita, Skil, niche players Niche products Price competitiveness Quality Large power tool manufacturers: Black and Decker, Bosch Product innovation Low costs Strengthening of presence in foreign markets PART THREE STRATEGY AND MANUFACTURING RECOMMENDATIONS MANUFACTURING STRATEGY The first priority of the company is the simplification of the manufacturing chain. That means a more fluent production process. The current organization leads to a waste of time. That’s why it is very important to implement the just in time (JIT), which allows a best management of the stocks. Parts’ inventories were too high because of difficulties in linking purchasing more closely to assembly. An example: the manufacturing manager ordered parts 3 months in advance, but parts arrived in 6 months. Relationship with suppliers and subcontractors are to be reviewed. 7 On the one hand, the new organization must be more flexible to adapt itself to the placed orders; on the other hand, new investment is indispensable to work with computer-aided manufacturing and design system to reach the level of our competitors. For the productivity, Iskra has high indirect costs for its production volume, but the company could not fire more workers because they had recently reduced the staff; Besides, the motivation of the employees is necessary by, for instance, internal promotion and training. The second priority is improving the internal relationship between different departments, in particular between design and manufacturing, and design and marketing. The philosophy of this department was “we draw, you make” and “we design, you sell”. It’s necessary to hire young designers to modernize the team and to increase the creativity of the department. A better coordination improves the fluidity of information. Consequently, a recovery of information is essential from sales department to manufacturing department. Iskra must find new suppliers, who respond to Iskra’s quality checklists. Despite efforts to upgrade the quality of the finished components, results were unsuccessful. It’s important to establish a system to harmonize the payment of the customers and of the suppliers. THE IMPLEMENTATION OF MANUFACTURING STRATEGY First, evaluate and study the problems, then to invest in new technology (JIT, CAD, CAM, …) The fluidity of the communication between different departments will increase the productivity of the company. Try to improve the circulation of information in the firm. With more creativity, the engineers can create new products to raise the line of products which is too limited. Better order the premises for a best result in terms of competitiveness and production process. MANUFACTURING OPTIONS Iskra has three options: positioning itself as a niche, an OEM manufacturer, or realize investments. Niche manufacturer: Focus on Europe market (France and Italy) Specialization on company’s expertise (angle grinders and drills) Sell both segments Strengthening ties with volume players Development of Perles distribution network OEM manufacturers: Focus on Europe and Eastern Europe markets Sell both segments 8 Low costs strategy Agreements with volume manufacturers to take benefit form their distribution network Investment opportunities: Agreements negotiations with volume manufacturers (about distribution channels) Productivity reorganization (new machines, with standardization of tasks, ...) R and D and design investments MARKET STRATEGY Iskra Power Tools’ aim is to enter the Western Europe professional and DIY markets. We will suggest a certain number of recommendations and propose an action plan to follow, explaining why and how to do, when necessary. Before establishing a market strategy: Make a market study. o Why? To know our capabilities, strengths and weaknesses. o How to do? Take part in professional specialized exhibitions, studying the opportunities in Western and Eastern Europe and making “brand and products notoriety” studies close by professional and householders. Restructure and improve firm’s internal capacities. o Why? To prepare an exportation strategy more easily and to increase our competitiveness and performance on local and foreign markets. o How to do? Investing in Research and Development, machines, computers, computer-aided production and design programs to perform the production capacity and facilitate the creativity of our experienced designers (so, they can create more and more new and innovative and battery-powered durable products). We can improve the communication between engineers, designers, sales force and blue collars. The production process must be performed (stocks and subcontractors). New representatives and “young” designers can be hired meanwhile a part of blue collars can be fired. The marketing of the products and the distribution network. o Why? To increase sales and profits. o How to do? Create a Sales Department in Iskra Power Tools separate from Iskra Commerce. This company can work exclusively for foreign markets. Develop relationship with wholesalers, retailers (which can introduce our products), supermarkets, etc… Improve the Brand Image. o Why? To reach the level of Bosch or Black & Decker and to have a good image near professional and DIY users. o How to do? Implementing an After-Sales Service, propose a free-call number for information, suggest a larger range of products and accessories, etc… 9 Establishing an external marketing strategy: Choice of the market (Eastern or Western Europe). o Why? In order to see where our profit is: the fall of USSR involves the opening of a new large market. Our comparative advantages are a good argument for companies which want to enter these new countries. On the other hand, we do not know very well Western Europe and have not a serious distribution network except Perles. o How to do? A market study can permit us to find an orientation. Study the opportunities toward Russia even if we should forecast solvability problems and toward new independent states. Bargain cooperation agreements with the biggest manufacturers like Black & Decker, Bosch or Makita: we sell them our cultural proximity with Eastern countries, our products and our low-priced workforce. Plan a Joint-Ventures and Cooperation plan (Eastern or Western Europe). o Why? To reinforce our presence and do know our brand. o How to do? To strengthen Perles (that we own) capacities in Western Europe, find new companies manufacturing tools (be careful with the quality) and specialized manufacturers, make acquisitions on small but efficient firms. In Western Europe, especially in France, find partners (specialized wholesalers, supermarkets like Bricorama for DIY segment) to promote our products and tools. Establish a marketing strategy for Western Europe. o Why? To attract new customers and new industrial sectors. o How to do? Create a central office in each Western country we want to enter to collect orders, give information by a free-call number, provide an AfterSales assistance, hire representatives to prospect new customers and new markets, edit brochures to present our products, place adds in specialized bulletins and newspapers, make cooperation with retailers (they will promote our brand and touch a percentage on sales). Develop direct sales system with professional and make agreements with niche players meanwhile the method is different with DIY segment. o Why? Because the first preoccupation of the professionals is not the visibility but the quality and the service and because, making agreements with niche players, we can provide them our tools and enlarge our presence. To attract the householders, the method is more visible. o How to do? Send our representatives (with some major products) meet niche players and professionals, take orders, etc… Prospect, by phone for example, new customers. With DIY users, the method is more visible: place advertisements in papers, on radio, etc… Why not, in 5-6 years, implement a website to inform about our products? The unique way to make efficient this strategy is to reinforce Perles presence in the Western Europe and give to the management the necessary funds and means. To summarize, the company (which want to enter the Western Europe) should concentrate on less mature and less structured markets such as France or Italy: France: The second biggest market in Europe. France represents 20% of the total European market with 5 million power tools sold and 8% growth rate. There is no national 10 strong producer of power tools. The distribution network is not as developed as in Germany for example and an important factor of purchase is the price. Italy: Has a small power tools producer but 60% of its production is exported. In value, 70% of the Italian market is exported. The leaders are Bosch and Black & Decker (with Star). Japanese and other countries are not very influent and the market is closed to Yugoslavia. A clearing agreement exists between Yugoslavia and Italy (we are in 1991). Within 2 years, Iskra hopes to reach 3% market shares instead of 1.5%. Our priorities are: concentrate our efforts on Western Europe, particularly in France and Italy by the development of Perles distribution network (in Professional and DIY segments), serving first as a Niche Player and second as OEM if problems with production process are solved. Our other priority can be the implementation of a market strategy to enter the Russian market. CONCLUSION As we have seen, the best strategy depends on the best choice: Iskra had chosen to follow a market strategy oriented to the Western Europe Markets. With a wide distribution network and a particular attention on the range of products will permit to succeed in Western Europe. Iskra is present in the world. Since this period (1989-1991), the company had followed a good marketing strategy (even if it is not very well known). The products are sold everywhere in the world and the firm is present in France and Italy, two markets which constituted its aim in 1991. Iskra Group is conquering the world … THE END 11