Specifications for Refrigeration Measures

advertisement

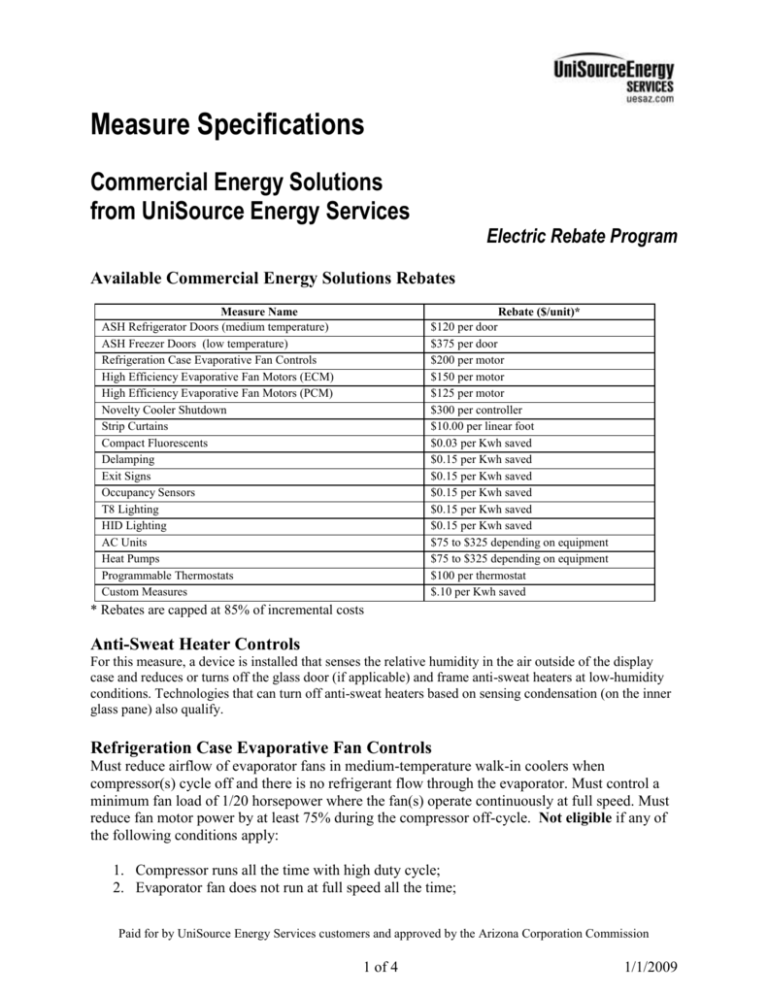

Measure Specifications Commercial Energy Solutions from UniSource Energy Services Electric Rebate Program Available Commercial Energy Solutions Rebates Measure Name ASH Refrigerator Doors (medium temperature) ASH Freezer Doors (low temperature) Refrigeration Case Evaporative Fan Controls High Efficiency Evaporative Fan Motors (ECM) High Efficiency Evaporative Fan Motors (PCM) Novelty Cooler Shutdown Strip Curtains Compact Fluorescents Delamping Exit Signs Occupancy Sensors T8 Lighting HID Lighting AC Units Heat Pumps Programmable Thermostats Custom Measures Rebate ($/unit)* $120 per door $375 per door $200 per motor $150 per motor $125 per motor $300 per controller $10.00 per linear foot $0.03 per Kwh saved $0.15 per Kwh saved $0.15 per Kwh saved $0.15 per Kwh saved $0.15 per Kwh saved $0.15 per Kwh saved $75 to $325 depending on equipment $75 to $325 depending on equipment $100 per thermostat $.10 per Kwh saved * Rebates are capped at 85% of incremental costs Anti-Sweat Heater Controls For this measure, a device is installed that senses the relative humidity in the air outside of the display case and reduces or turns off the glass door (if applicable) and frame anti-sweat heaters at low-humidity conditions. Technologies that can turn off anti-sweat heaters based on sensing condensation (on the inner glass pane) also qualify. Refrigeration Case Evaporative Fan Controls Must reduce airflow of evaporator fans in medium-temperature walk-in coolers when compressor(s) cycle off and there is no refrigerant flow through the evaporator. Must control a minimum fan load of 1/20 horsepower where the fan(s) operate continuously at full speed. Must reduce fan motor power by at least 75% during the compressor off-cycle. Not eligible if any of the following conditions apply: 1. Compressor runs all the time with high duty cycle; 2. Evaporator fan does not run at full speed all the time; Paid for by UniSource Energy Services customers and approved by the Arizona Corporation Commission 1 of 4 1/1/2009 3. Evaporator fan motor runs on poly-phase power; 4. Evaporator fan motor is not shaded-pole; or 5. Evaporator does not use off-cycle or time-off defrost. Evaporative Fan Motor This measure is applicable to the replacement of an existing standard-efficiency shaded-pole evaporator fan motor in refrigerated display cases or fan coil in walk-ins. The replacement unit is either an ECM or permanent split-capacitor (PSC) motor. Compact Fluorescent Lamps This incentive applies to screw-in or hardwired compact fluorescent lamps (CFLs) and applies only if an incandescent lamp is being replaced. All screw-in CFLs must be ENERGY STAR®-rated. Any lamp receiving a retail buy-down by TEP is not eligible. The lamp/ballast combination must have an efficacy ≥ 40 lumens per Watt (LPW). For screw-in CFLs, electronic ballasts are required for lamps ≥ 18 Watt. For hardwired CFLs, only complete new fixtures or modular retrofits with hardwired electronic ballasts qualify. The CFL ballast must be programmed start or programmed rapid start with a PF ≥ 90 and THD ≤ 20%. Delamping Delamping is the permanent removal of existing fluorescent lamps. Customers are responsible for determining whether or not to use reflectors in combination with delamping in order to maintain adequate lighting levels. Unused lamps, lamp holders, and ballasts must be permanently removed from the fixture to claim the delamping credit. This measure is applicable when retrofitting T12 to T8 or simply delamping a T8 fixture. It is not available for delamping a T12 fixture. A pre-notification application and pre-inspection are required for delamping projects. Exit Signs High-efficiency exit signs must replace or retrofit an existing incandescent or CFL exit sign. Electroluminescent and light-emitting diode (LED) exit signs are eligible under this category. Nonelectrified and remote exit signs are not eligible. All new exit signs or retrofit exit signs must be UL or ETL listed, have a minimum lifetime of 10 years, and have an input wattage ≤ 5 Watts. Occupancy Sensors (Wall Box and Ceiling Mount) Only passive infrared and/or ultrasonic detectors are eligible. Wall box and wall-, ceiling-, or fixturemounted sensors must be hardwired to control interior lighting fixtures. New T5HO / T8HO Fixtures This measure consists of replacing existing Metal Halide (MH) / High Pressure Sodium (HPS) fixtures with new fixtures with at least two high output lamps along with high output electronic ballasts. Existing MH/HPS fixtures with lamp wattages between 150 watts and 250 watts shall be replaced with either 2 lamp four foot linear fixtures or 4 lamp two foot linear fixtures. Existing MH/HPS fixtures with lamp wattages equal to 250 watts and less than 400 watts shall be replace with 3 lamp linear fixtures. Existing MH/HPS fixtures with lamp wattages equal to 400 watts and less than 750 watts shall be replace with 4 lamp T5HO or 6 lamp T8HO linear fixtures. Existing MH/HPS fixtures with lamp wattages equal to 750 watts and less than 1,000 watts shall be replaced with 6 lamp T5HO or two (2) 6 lamp T8HO linear fixtures. Existing MH/HPS fixtures with lamp wattages equal to or greater than 1,000 watts shall be Paid for by UniSource Energy Services customers and approved by the Arizona Corporation Commission 2 of 4 1/1/2009 replaced with two (2) 4 lamp T5HO linear fixtures. All fixtures must have a reflector with a minimum of 90% reflectivity. Low Pressure Sodium (LPS) lamps are not eligible to be replaced under this prescriptive incentive. Note: Replaced PCB ballasts and HID lamps must be disposed of properly. Documentation of disposal may be requested by the program staff. Linear Fluorescent T8 or T5 Lamps with High Output Electronic Ballasts T5HO or T8HO lamps and electronic ballasts. The new full wattage F32/T8 and F54/T5 lamps must have a color rendering index CRI ≥81 watts. The electronic ballast must be high frequency (≥20 kHz), UL listed, and warranted against defects for 5 years. Ballasts must have a power factor (PF) ≥ 0.90. Ballasts for 4-foot lamps must have total harmonic discharge (THD) ≤20% at full light output. Note: Replaced PCB ballasts and HID lamps must be disposed of properly. Documentation of disposal may be requested by the program staff. Linear Fluorescent T8 or T5 Lamps with Electronic Ballasts This measure consists of replacing existing T12 lamps and magnetic ballasts with T5 or T8 lamps and electronic ballasts. The new T8/T5 lamps must have a color rendering index (CRI) ≥ 80. The electronic ballast must be high frequency (≥ 20 kHz), UL listed, and warranted against defects for 5 years. Ballasts must have a power factor (PF) ≥ 0.90. Ballasts for 4-foot lamps must have total harmonic discharge (THD) ≤ 20% at full light output. For 2- and 3-foot lamps, ballasts must have THD ≤ 32% at full light output. Air Conditioners and Heat Pumps Equipment must have a minimum SEER rating of 14. Programmable Thermostats Equipment must be ENERGY STAR®-labeled. To meet ENERGY STAR standards, programmable thermostats must be capable of maintaining two separate programs (to address changing occupancy and comfort needs) and up to four temperature settings for each program. A manufacturer's specification sheet must accompany the application. Thermostats for evaporative coolers are not eligible. Strip Curtains on Walk-ins New strip curtains or clear plastic swinging doors must be installed on doorways of walk-in boxes and refrigerated warehouses. This incentive is not available for display cases or replacing existing strip curtains. Incentive is based on linear footage of door. Custom Measures The Commercial Energy Solutions Program offers rebates for energy efficiency improvements that are not listed in the table above, but meet the custom project criteria. Custom projects must have isolated and measurable or verifiable energy savings. Projects replacing inefficient equipment with more efficient equipment must demonstrate that the old equipment has been eliminated from the resale market. All custom measures must pass a Total Resource Cost (TRC) Test, as defined and calculated by KEMA, using energy savings and incremental measure costs provided by the customer. Equipment specifications, hours of operation, project cost information, and copies of the calculations that were used to determine savings (in excel format) are required for the applicant Paid for by UniSource Energy Services customers and approved by the Arizona Corporation Commission 3 of 4 1/1/2009 to be eligible for a rebate. It is up to the applicant to present a convincing case for how energy savings should be estimated. The Commercial Energy Solutions Team is available to assist in developing energy savings estimates. Examples of custom measures include but are not limited to: Economizers – Air-side or water-side High Intensity Discharge (HID) or fluorescent light fixture improvements not covered under the prescriptive measures Improved Automatic Controls (time switches, sensors, etc.) Building envelope improvements (solar screens, etc.) Ineligible projects include, but are not limited to, cool roofs, electrical generation projects including renewables, fuel switching, and customer-owned on-site generation. Measures that are listed in the table above are NOT eligible for a custom rebate. Custom rebates are calculated using $0.10 per estimated first year kilowatt hour saved. Actual rebate payments are based on either (1) documented electrical energy (kWh) reduction or (2) an electrical energy reduction estimate approved by KEMA. Under no circumstances will the rebate payment exceed 85% of the energy-efficiency-related project costs, which are defined as the incremental costs associated with implementing the energy-saving measures. Rebate: Description $0.10 Annual kWh Savings /kWh Rebate Subtotal kW Savings Annual Operating Hours Measure Cost Enter Operating Schedule and Days Closed Below Day of Week Start Time End Time Total Hours Days Closed per Year Weeks Closed per Year Monday Tuesday Wednesday Thursday Friday Weeks/Year Hours/Week Calculated Hours/Year Saturday Sunday Paid for by UniSource Energy Services customers and approved by the Arizona Corporation Commission 4 of 4 1/1/2009