1 - Senior Design - University of Idaho

advertisement

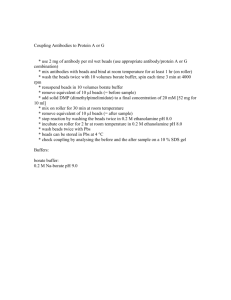

Interim Design Report for the Conditioning of Waste Oil from French Fry Manufacturing for Use in Biodiesel Production To: Don Sturtevant Prepared by: French Fry Fuel Team Members: Marie E. Stark Kate Burlingame Shane Bird John Neal Charles Weatherspoon December 11, 2007 ii 201 W. Lathen St. #8 Moscow, Idaho (208) 407-4607 fffuel@uidaho.edu Dec. 04, 2007 Don Sturtevant Corporate Energy Manager J.R. Simplot Company One Capitol Center 999 Main street P.O. Box 27 Boise, ID 83707-0027 Dear Mr. Don Sturtevant: Enclosed is a copy of “Interim Design Report for the Conditioning of Waste Oil from French Fry Manufacturing for Use in Biodiesel Production.” This report summarizes the teams’ research and design ideas completed in the first semester of our fall 2007 senior design class. It will encompass the research, testing, and treatment processes of the Simplot oil. Funding for our project was provided by Simplot with a budget of 10,000 dollars. Our report will be submitted to the University of Idaho Mechanical and Biological Agricultural Engineering departments as a fulfillment of our mechanical systems design class under Dr. Tom Hess and Dr. Steve Beyerlein. This report includes information regarding the concepts of reducing waste oil free fatty acids and processes used to remove water and other carbon impurities. After testing, our team determined that the mainstream oil was suitable for conversion to biodiesel. We then focused our attention on the dissolved air flotation (DAF) oil. This oil is a combination of used fry oil and waste oil cleaned off the plant floor. We will recommend evaporative water removal processes and esterification concepts to treat this waste oil. We would like to thank you and Dr. Tom Hess for the assistance provided throughout the design process. Additionally we would like thank Joe Thompson, Paul Mann, and Dr. Van Gerpen for their help and consulting throughout the project. If you have any questions or comments please feel free to contact us through the phone number and email address stated above. We also recommend visiting our website: http://seniordesign.engr.uidaho.edu/2007_2008/frenchfryfuel/. It contains the team information, research, and process outlines. Sincerely, Team French Fry Fuel iii EXECUTIVE SUMMARY This report provides the analysis and research of processes taken to condition waste potato frying oil from Simplot. Particular emphasis was placed on the dissolved air flotation (DAF) oil. In the beginning of the semester the team’s goal was to condition the mainstream waste oil from Simplot. The mainstream oil turned out to have 1.5% free fatty acid content and <.1% by volume water content. Not much conditioning would be needed. Our attention turned to the other waste oil stream called the DAF oil. There are three major factors that must be addressed with our approach to condition the DAF oil. First, the oil has particles much larger than the mainstream oil. A filtering process must filter this oil to roughly 30 microns. Second, the DAF oil has a high free fatty acid content making the oil harder to condition. Finally, the DAF oil is pumped with water from the plant to a holding tank. Therefore the oil has a high water content that needs to be removed. Methods researched for water removal included two different types of evaporators called flash and falling film. These are heat exchangers that evaporate the water in the oil using a heat source. The evaporators used to remove the water are very costly and involve multiple mechanical components. To reduce the free fatty acid content of the oil the team proposes to use a process called acid esterification. For this process BD20 beads were explored. The beads serve as catalyst and take the place of an acid in the esterification process. Sulfuric acid is produced at Simplot and is being considered to be used as well. Continuous paper filters were considered for removing the particles. Our team is looking into the BD20 beads for the catalyst instead of the sulfuric acid. Although, Simplot produces sulfuric acid, this can be a dangerous chemical around the plant. The sulfuric acid may be cost efficient, but we recommend the use of beads since they can treat high free fatty acid, while being safe around the food processing plant. The team also recommends the use of the falling film evaporator for removing the high water content, however this evaporator is very costly and other mechanical means of removing water will be investigated. iv Table of Contents 1.0 2.0 3.0 4.0 4.1 4.2 4.3 5.0 6.0 6.1 6.2 6.3 7.0 Background .............................................................................................................. 5 Problem Definition................................................................................................... 5 Project Plan .............................................................................................................. 6 Concepts Considered ............................................................................................... 6 Particulate Removal System .................................................................................... 7 Water Reduction System.......................................................................................... 8 FFA Reduction System ............................................................................................ 9 Concept Selection .................................................................................................. 10 System Architecture ............................................................................................... 11 Particulate Removal System .................................................................................. 11 Water Reduction System........................................................................................ 11 FFA Reduction System .......................................................................................... 12 Future Work ........................................................................................................... 13 List of Figures Figure 1: Integrated Solution .............................................................................................. 7 Figure 2: Bag Filter ............................................................................................................. 8 Figure 3: Self Cleaning Paper Filter ................................................................................... 8 Figure 4: Flash Evaporator.................................................................................................. 9 Figure 5: Falling Film Evaporator ...................................................................................... 9 Figure 6: System Design ................................................................................................... 10 List of Tables Table 1: Project Parameters ................................................................................................ 5 Table 2: Semester 1 Team Progress .................................................................................... 6 5 1.0 Background The J.R. Simplot Company is one of the largest privately held firms in the country, employing approximately 10,000 people worldwide. As a large agribusiness firm, Simplot has significant fuel costs associated with their transportation fleet. As a means to reduce this cost, Simplot would like to use the waste oil generated in the Simplot French Fry Plant located in Caldwell, Idaho to manufacture biodiesel. Currently Simplot sells this waste oil as cattle feedstock or disposes of it as waste; however, the rising price of gas makes converting the oil to biodiesel a financially favorable option for Simplot. 2.0 Problem Definition The waste oil from Simplot’s production lines forms three waste streams. The largest of these streams has been tested and determined to be suitable for conversion to biodiesel. The other two streams, which constitute oil recovered in plant cleanup (MOP) and oil that passes through the wet electrostatic precipitator (WESP) currently conjoin and are transported to a dissolved air flotation (DAF) tank. The goal of this project is to examine the MOP and WESP oils and determine a treatment plan to condition the oil. The team will design a system to remove free fatty acids (FFA), water, particulates, and other carbon impurities from the used oil to a specification defined by the biodiesel manufacturer. A cost estimate of full scale production will be provided for the design selected. In addition to these client needs, a smaller “bench top” model will be designed and constructed for presentation in late April. A detailed list of these needs can be found in the following table. Table 1: Project Parameters User Need Remove Impurities Small bench Top Design Bench Top within Budget Cost Estimate for Full Scale Specification Reduce Free Fatty Acid Concentration Reduce Water Content Remove Impurities System must fit in booth at Engineering Expo Cost analysis of system Cost analysis of system Target Value <4% by weight <.1% by volume <50-100μm <Standard Banquet Table Size Within budget Dollars per gallon 6 3.0 Project Plan The system required to pretreat Simplot’s oil is a complex one. In order to understand this process, Team FFF has consulted many experts in the field, including Dr. Jon Van Gerpen, head of the biological and agricultural engineering department, Scott Burn, a consultant in the field, Joe Thompson, a biodiesel expert on the University of Idaho campus, and Paul Mann, a consultant. Working in Joe Thompson’s biodiesel lab, the team has tested FFA concentration and water concentration on the mainstream oil. After testing the oil, the team converted it to biodiesel in the lab. Additionally, a thorough literature review was conducted to review current technologies available. A summary of the team’s progress to date can be found in the figure below. Table 2: Semester 1 Team Progress % Complete 100% 100% 75% 100% 100% 100% 100% 100% 100% 100% 100% 100% 100% 90% 4.0 Task Gather Information on biodiesel and establish specifications Visit Simplot French Fry Plant Owner All Deadline 9-10/2007 All 10/1/2007 Create project specs and list of needs Get in contact with Joe Thompson and perform research on oil samples Contact Van Gerpen and discuss options with him Brainstorm 2 design concepts for each design parameter Research 2 filter systems Research Sulfuric Acid Research BD20 Beads Research Flash Evaporators Research Falling Film Evaporators Snapshot Day Design Review Final Interim Report Due All All 10/10/2007 10/15/2007 All 11/14/2007 All 11/5/2007 Chuck Marie Kate Shane John All All All 11/9/2007 11/9/2007 11/9/2007 11/9/2007 11/9/2007 11/30/2007 11/30/2007 12/11/2007 Concepts Considered For the concept generation phase, Team FFF initially tested, analyzed, and constructed a design that would condition the mainstream frying oil. After lab analysis, the mainstream oil was determined to be acceptable for the conversion into biodiesel. From this point Team FFF, under the client’s direction, diverted their efforts towards the conditioning of the DAF oil. 7 Team FFF developed two concept solutions for each of the three design parameters to treat the DAF oil. These concept solutions are summarized in the following pages. The ideas developed for the three design parameters can be integrated into the final design. Our scope did not allow for complete prototype assembly and testing. Figure 1 below shows the current integrated solution create by Team FFF. Figure 1: Integrated Solution 4.1 Particulate Removal System The oil collected from the cleanup of the plant is full of charred bits of potato and carbon impurities. These particles inhibit the production of biodiesel from the oil. The particles clog machinery at the biodiesel plant and will damage an engine running the bio diesel. A filtration system is needed in the pretreatment design to lower the level of particles. The first system that was considered to handle this need is an inline bag filter. This system pressurizes the oil and pushes it through a sock filter. Particles above a certain size will be filtered out. However, because the sock filter is made from felt with a weave knit pattern some particles may still be able to push through. An inline bag filter system is simple and cheap when compared to the other option considered. The sock filter would require continuous replacement to prevent clogging that would stop the flow of oil through the system. This would add an additional maintenance and labor cost. 8 Figure 2: Bag Filter The second solution concept is a self-cleaning continuous paper filter system. This system pushes the oil through the filter paper by gravity. The oil passes through the paper into a collection basin while the particles are retained on the surface of the paper. The paper continuously rotates across the basin, removing all particles. This is a low maintenance system. However, the paper roll still needs to be replaced eventually. A major concern about this system is that it has a high initial cost. Figure 3: Self Cleaning Paper Filter 4.2 Water Reduction System Water removal is a large concern in the production of biodiesel. Water can oxidize the oil thus creating free fatty acid. Also, if there is water in the system when oil goes through the biodiesel processing it creates soap as a byproduct. This lowers the total yield of the oil. The water also hinders the esterification process if used in the pretreatment process. There are two systems that are currently being considered for drying the oil. The first is a vacuum flash evaporator. This system heats the oil and pumps it through a nozzle into a vacuum tank. This flashes off high levels of water from the oil. This system can only 9 handle oil up to 5% water by volume. Any higher level of water will require more flash evaporators. When compared to the other system considered, the flash evaporator is cheaper and simpler to design. Figure 4: Flash Evaporator The second system considered to dry the oil is a falling film evaporator. This system is a tube in shell heat exchanger that has the oil fall down on the tubes as a thin film. The tubes are heated with steam, which then heats the oil to evaporate the water. The water vapor is then pumped out and condensed. This system requires a high level of design and thus makes the system more costly. However, this system can handle higher levels of water than the flash evaporator. Figure 5: Falling Film Evaporator 4.3 FFA Reduction System FFA formation typically occurs when the oil has been stored for an extended period of time and water has been allowed to stay in the oil. FFAs are formed in oils from the process of water molecules hydrolyzing fats. It is extremely important for the production of biodiesel to reduce the amount of FFA in the oil. The purpose of reducing FFA is that the formation of soaps may occur at high levels of FFA during the transesterification process. Soaps inhibit the complete formation of biodiesel and result in a lower yield of fuel. Chemical processes, such as esterification, may reduce the content of FFA, where upon shipment to the biodiesel facility, transesterification may then be implemented to convert the FFA to biodiesel. Team FFF designed two concept solutions to help reduce the amount of FFA in the oil. The first concept solution utilizes an existing method of esterification most commonly used in biodiesel production. This acid catalyzed reaction uses sulfuric acid as a catalyst. The sulfuric acid is dissolved in methanol before reaction with the oil. An important and inhibiting problem associated with using sulfuric acid is the oil needs to be completely dried as the reaction takes place, due to the properties of water reducing the formation of biodiesel. Using sulfuric acid reports a high rate of biodiesel conversion. The acid is a byproduct from another system process Simplot has invested in, so cost of using the acid is a low consideration. The second concept considered uses a newly introduced product called Amberlyst BD20 beads. These beads are another solution to acid esterification with out the hazardous protocols needed when using sulfuric acid. The beads are used in a filter-like system where the oil may wash through and react with the chemical beads, thus lowering the FFA content. The beads have increased attributes to the conversion of higher quality oil. 10 They allow the oil to have a FFA content ranging from 0.5- 100% and have high conversion reaction times, as well as fewer toxic chemicals. Based on these characteristics, the problem associated with the use of the beads involves cost (the product is new to the market) and what cost savings the beads may have compared to sulfuric acid. 5.0 Concept Selection The selection process involved evaluating the strengths and weaknesses of each of the two concept solution considerations for the three design parameters. After initial concept generation Team FFF presented our progress to a board of peers, the team professor, and clients in a conceptual design review on Friday, November 30th 2007. The goal of the review was to obtain explicit direction for the project for the semester ahead. We wanted to identify which processes or mechanisms the client would like to pursue and which concept designs to further investigate. The best component of each of the three design parameters was selected and integrated into one design concept (see Figure 6 below). Figure 5: System Design The two filter systems were discussed including the request of exact price estimates for the currently in-use paper filter system as well as the low cost and easy to use bag filter system. The criteria for determining the filter system had not been previously identified. After discussion with our client, we are open to further design considerations and will provide cost estimates for both filtering systems. The FFA reduction system was developed by either selecting sulfuric acid for the acid-catalyzed FFA esterification process or using a newly developed product, BD20 beads that use the same principles as acid esterification. It was determined to request samples of the BD20 beads from the manufacturer and test the new product and determine if the beads were an economically viable option compared to using the readily available, yet hazardous, sulfuric acid. Next, the two processes for water removal were discussed. A falling film evaporator and a flash evaporator system were analyzed and compared. In order to further identify which system, for each process, to implement into the design, an accurate price of both sulfuric acid and natural gas that is currently being used on site is needed. In addition, further characterization of the MOP and WESP oils must be achieved. An initial concern involving the use of WESP, MOP and DAF oil was if these oils would be at compliance level regarding water and FFA content if the particulate matter was removed. We were given samples of these oils to further test and determine if the MOP oil, in particular, may be recovered before being combined with the WESP oil. Our client 11 and advisors expressed their general interest in evaluating all design considerations on a cost effective basis. If we want to exceed our client’s expectations, then we need to look at the whole process and develop every step, from particulate removal to water and FFA reduction to meet their standards for biodiesel production and keep a cost effective analysis in mind. The following discussion will develop a conceptual design case for each integrated design and its individual parameters, showing how the overall design will exceed customer expectations. 6.0 System Architecture 6.1 Particulate Removal System A 50 micron felt filter bag may be used to filter particulates from waste streams. McMaster-Carr provides 50 micron polypropylene felt bags that withstand a maximum temperature of 300°F. They also provide 50 micron nomex felt bags that withstand a maximum temperature of 400°F. McMaster-Carr also provides stainless steel filterbag/cartridge housings that are rated for 300 and 400°F operational temperatures [1]. http://www.mcmaster.com/ The fluids that are filtered through the bag and bag housing will not be above 400°F because this is close to the flash point of the oil. The type of filter bag and housing used in our system will depend on the temperatures of the fluids that are filtered through them. The lower rated temperature bags and housings cost less than the higher temperature bags and housings. Filter bags are sized with a maximum flow in gallons per minute. The filter bags that are sold by McMaster-Carr are rated from a range of max flows between 20 and 275 gallons per minute. An alternative to the bag filtration system is a continuous paper filter. Disposable paper continuously passes through the system and removes particulates from the oil. Simplot in Caldwell, Idaho currently uses two continuous paper filters on their production lines. The oil is gravity fed into this system so there will not be continuous pressure in the oil filtration system. The only maintenance needed for this system is changing the paper roll. Heat and Control sells these filters[2]. www.heatandcontrol.com This type of filter might be more than is truly needed for our system because it is used to remove ultra-fine particulates and we need to only remove 50 to 100 micron sized particulates because the biodiesel manufacturer has filters that remove particulates up to biodiesel specification requirements. 6.2 Water Reduction System Our current water content specification requirement is less than .1% by volume. The biodiesel manufacturing company does not have a permit for handling water from a waste stream so this specification must be met at Simplot before the oil is transported to Blue 12 Sky. Simplot currently has a DAF system that skims the oil off the top of the water in a large tank. We received a sample of this oil and are in the process of testing the water content. We have researched two types of water removal methods that may be used after the oil comes out from the DAF system. One system is a flash evaporation system. This system requires a vacuum pump, nozzle, and a system for heating the oil and water above the water vaporization temperature. The oil and water are heated with steam in a shell and tube heat exchangers. Currently flash evaporators are designed to remove water content up to 5%. If the water content is higher than 5%, a series of flash evaporators may be used to remove the water. Another system that may be used to remove water content above 5% is a falling film evaporator. A falling film evaporator consists of a large heat exchanger. This heat exchanger is heated by steam. We have recently received a sample of oil that was collected upstream from the DAF tank at the WESP. This oil separated from the water after it settled. We have found out that it is beneficial to remove the oil from the WESP upstream before it mixes with the oil from the MOP. An option for initially removing large quantities of water from this oil is by using a settling tank with a skimmer on the top that is similar to the DAF system. Further research needs to be done on this type of a system. 6.3 FFA Reduction System As previously stated, two methods for reduction of the FFA content were developed. After preliminary research, acid esterification using Amberlyst BD20 beads is the recommended process. Although these processes produce similar results, the BD20 beads allow for an easier system design. The beads can be used to treat varying levels of FFA concentrations; the oil is simply processed more slowly through the standing column of beads for higher FFA concentrations. This allows for a longer reaction time. Additionally, because the beads are hydrophobic they repel up to 5% water at the reaction sites. This eliminates the need for continuous drying, which is required in esterification using sulfuric acid as the catalyst because the water that is generated in the reaction will act as a limiting agent. BD20 beads are not hazardous. The Rohm and Haas website, the manufacturer of the Amberlyst beads, states that similar ion exchange beads are disposed of by land filling or incineration. Reducing the cost of waste disposal associated with toxic compounds such as sulfuric acid may offset the potentially higher price of the beads. Furthermore, using the beads as a catalyst eliminates the risk of accidental workplace injuries, accidents, and food contamination. More research is needed to determine if the BD20 beads are a financially viable option for this design. Because the beads are an emerging technology there is not currently any information on the price of the beads. 13 7.0 Future Work . Testing of the DAF oil is the first step for our project continuation. The tests for FFA and water content will determine what type of processes we will implement. If the water content is high, then the falling film evaporator will have to be used instead of the flash. For the heating element in the evaporators, natural gas costs will need to be researched. The price of the BD20 beads will decide whether or not we want to use them in place of the sulfuric acid in the esterification process. Prices of filters used at Simplot need to be compared to other filters to see if one is more cost effective than the other. Our client requested that we look into other mechanical means of removing the water from the DAF oil. For example, a heated agitated tank may be a simpler and much more cost effective way of removing the water. This would also allow easier modeling for the bench scale required at the end of the next semester. The bench scale model will be an important deliverable and must be the focus of next semester. Flow rates, temperatures, costs, and other characteristics of the system will need to be accurately modeled in the bench scale, and then scaled up appropriately for the client and plant operation.