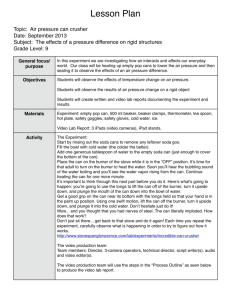

15592 - nycsca

advertisement