Larry's Safety Manual - Sanitary District of Decatur

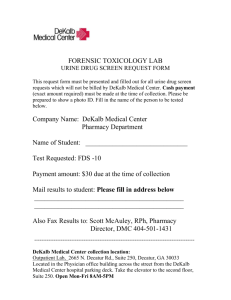

advertisement