Nolan-Norton Presentation

July 19, 1990©

by

Arthur M. Schneiderman

Presentation date:

July 19, 1990

Venue:

Nolan-Norton

Study Group Meeting

Notes

None

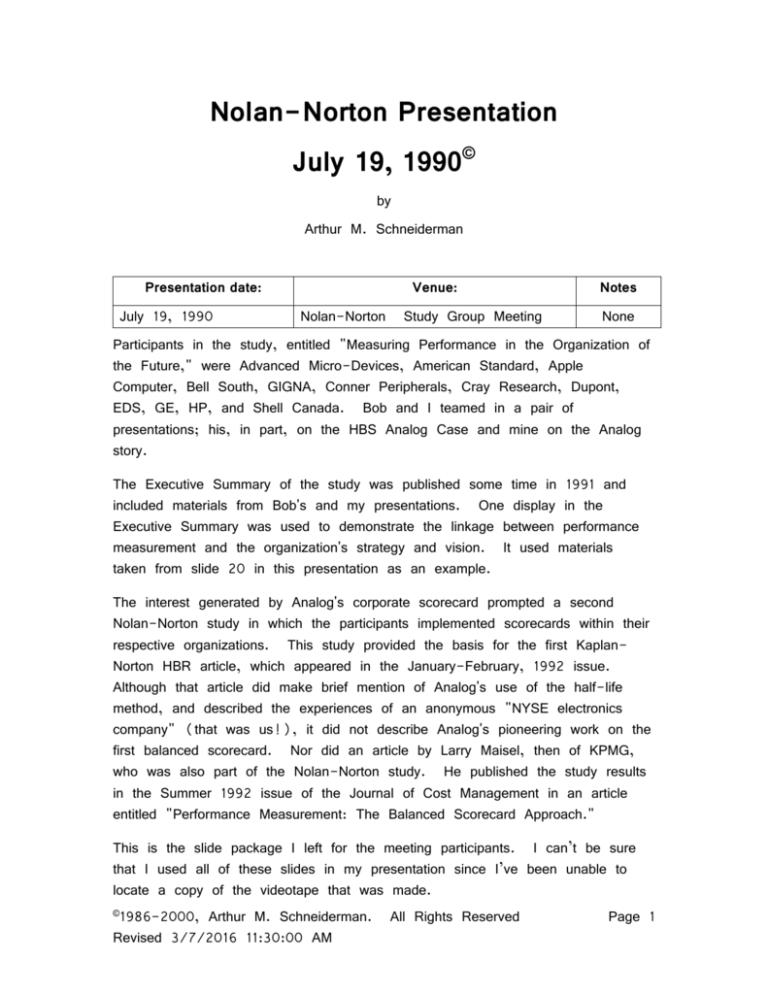

Participants in the study, entitled "Measuring Performance in the Organization of

the Future," were Advanced Micro-Devices, American Standard, Apple

Computer, Bell South, GIGNA, Conner Peripherals, Cray Research, Dupont,

EDS, GE, HP, and Shell Canada. Bob and I teamed in a pair of

presentations; his, in part, on the HBS Analog Case and mine on the Analog

story.

The Executive Summary of the study was published some time in 1991 and

included materials from Bob's and my presentations. One display in the

Executive Summary was used to demonstrate the linkage between performance

measurement and the organization's strategy and vision. It used materials

taken from slide 20 in this presentation as an example.

The interest generated by Analog's corporate scorecard prompted a second

Nolan-Norton study in which the participants implemented scorecards within their

respective organizations. This study provided the basis for the first KaplanNorton HBR article, which appeared in the January-February, 1992 issue.

Although that article did make brief mention of Analog's use of the half-life

method, and described the experiences of an anonymous "NYSE electronics

company" (that was us!), it did not describe Analog's pioneering work on the

first balanced scorecard. Nor did an article by Larry Maisel, then of KPMG,

who was also part of the Nolan-Norton study. He published the study results

in the Summer 1992 issue of the Journal of Cost Management in an article

entitled "Performance Measurement: The Balanced Scorecard Approach."

This is the slide package I left for the meeting participants. I can’t be sure

that I used all of these slides in my presentation since I’ve been unable to

locate a copy of the videotape that was made.

©1986-2000,

Arthur M. Schneiderman.

Revised 3/7/2016 11:30:00 AM

All Rights Reserved

Page 1

Since nearly all of the slides that I used are described in other presentations

on this website, I’ve omitted explanatory notes.

©1986-2000,

Arthur M. Schneiderman.

Revised 3/7/2016 11:30:00 AM

All Rights Reserved

Page 2

Nolan-Norton Presentation, July 19, 1990

Slide 1

TO TAL Q UALITY M ANAGEM ENT

Art Schneiderman

Analog Devices

ANALO G DEVICES "at a glance"

Q UALITY IM PRO VEM ENT PRO CESS

GO ALS

culture

scorecard

IS

PRO BLEM

SO LVING

projects

M ETRICS

Nolan-Norton, July 19, 1990

©1987-2000 Arthur M . Schneiderman All Rights Reserved.

©1986-2000,

Arthur M. Schneiderman.

Revised 3/7/2016 11:30:00 AM

All Rights Reserved

6/11/90-06110-5

Page 3

Nolan-Norton Presentation, July 19, 1990

Slide 2

Analog Devices at a Glance

•

Headquartered in Norwood M assachusetts

•

Publicly Held (NYSE Symbol ADI)

•

$453 M illion in Sales (FY1989)

•

48% of Sales O utside United States

•

5200 Employees Worldwide

©1987-2000 Arthur M . Schneiderman All Rights Reserved.

©1986-2000,

Arthur M. Schneiderman.

Revised 3/7/2016 11:30:00 AM

All Rights Reserved

c. 2/13/90-PREZ_1

Page 4

Nolan-Norton Presentation, July 19, 1990

Slide 3

ANALO G DEVICES AT A GLANCE

(cont)

Products: ICs, assembled products, subsystems

Applications: precision measurement & control

M arkets: data acquisition

40% industrial/instrumentation

30% military/avionics

13% computer

17% other

Integrated supplier

design

manufacturing (8 locations)

direct sales (100 locations)

©1987-2000 Arthur M . Schneiderman All Rights Reserved.

©1986-2000,

Arthur M. Schneiderman.

Revised 3/7/2016 11:30:00 AM

All Rights Reserved

c. 1990-PREZ-1a

Page 5

Nolan-Norton Presentation, July 19, 1990

Slide 4

ADI CO RPO RATE Q IP CO UNCIL

M EM BERS:

CHARTER:

Jerry Fishman

Executive VP

Kozo Imai

VP, Japanese O perations

Larry LaFranchi

O perations Controller

Bill M anning

Division GM

Doug Newman

VP, Sales and M arketing

Art Schneiderman, Chairman

VP, Q uality/Productivity Improvement

Ray Stata

Chairman of the Board and President

Goodloe Suttler

Division GM

Suzanne Thomson

Director, Training & Development

Tom Urwin

VP, European O perations

Q IP O rganization

Q IP Goals Deployment

Training

M onitoring

priorities

Juran

metrics

Incenting/Rewarding

©1987-2000 Arthur M . Schneiderman All Rights Reserved.

©1986-2000,

Arthur M. Schneiderman.

Revised 3/7/2016 11:30:00 AM

All Rights Reserved

4/8/90-Q IP-15a

Page 6

Nolan-Norton Presentation, July 19, 1990

Slide 5

1989 Top Customers Worldwide

Customer

IBM (US, Japan & France)

GE/RCA

Fuji (Japan)

HP (US, UK & Germany)

Honeywell (US, Germany)

General Dynamics (US)

Raytheon (US)

Siemens (US, Germany)

TI (US)

M itsubishi (Japan)

Fujitsu (Japan)

Toshiba (Japan)

M arconi (US, UK)

Hughes (US)

Rockwell (US)

Hitachi (Japan)

Westinghouse (US)

Philips (US, Europe)

M otorola (US)

DCASR (US)

Bookings

$M

Cumulative

%

26.8

10.5

10.3

9.1

7.4

5.4

5.1

5.1

4.1

4.0

4.0

3.7

3.6

3.4

3.3

3.3

3.1

3.1

3.0

2.7

6.0

8.3

10.6

12.6

14.2

15.5

16.6

17.7

18.6

19.5

20.4

21.1

22.0

22.8

23.5

24.3

25.0

25.6

26.3

26.9

©1987-2000 Arthur M . Schneiderman All Rights Reserved.

©1986-2000,

Arthur M. Schneiderman.

Revised 3/7/2016 11:30:00 AM

All Rights Reserved

c. 1990-PREZ-11

Page 7

Nolan-Norton Presentation, July 19, 1990

Slide 6

CUSTO M ER PREFERENCE RATINGS

D/A and A/D CO NVERTERS

Analog Devices

Burr-Brown

National

Motorola

PMI

Linear Technology

Maxim

Intersil

TI

Signetics

Harris

TRW

Analogic

Crystal

Teledune Philbrick

1

2

3

4

least

5

most

Preference

Source: EDN, 1/90

©1987-2000 Arthur M . Schneiderman All Rights Reserved.

©1986-2000,

Arthur M. Schneiderman.

Revised 3/7/2016 11:30:00 AM

All Rights Reserved

6/11/90-06110-4

Page 8

Nolan-Norton Presentation, July 19, 1990

Slide 7

TO P 10 M IXED SIGNAL IC SUPPLIERS

Sales $M

300

RM S=1.4

250

200

150

100

50

0

ADI

National

NEC

Philips

TI

Toshiba

Hitachi

Sanyo

M atsushita

M otorola

Source: VLSI Research

©1987-2000 Arthur M . Schneiderman All Rights Reserved.

©1986-2000,

Arthur M. Schneiderman.

Revised 3/7/2016 11:30:00 AM

All Rights Reserved

2/16/90-02140-1

Page 9

Nolan-Norton Presentation, July 19, 1990

Slide 8

PRO JECTED WO RLDWIDE GRO WTH RATES

1987-1992

average annual growth rate, %/year

25

20%

20

15

13%

11%

10

5

0

Electronic Equipment

Semiconductor Sales

ADI's Growth Goal

©1987-2000 Arthur M . Schneiderman All Rights Reserved.

©1986-2000,

Arthur M. Schneiderman.

Revised 3/7/2016 11:30:00 AM

All Rights Reserved

c. 2/13/90-PREZ-10

Page 10

Nolan-Norton Presentation, July 19, 1990

Slide 9

Q UALITY IM PRO VEM ENT PRO CESS

GO ALS

culture

scorecard

IS

PRO BLEM

SO LVING

projects

M ETRICS

©1987-2000 Arthur M . Schneiderman All Rights Reserved.

©1986-2000,

Arthur M. Schneiderman.

Revised 3/7/2016 11:30:00 AM

All Rights Reserved

3/11/90-03110-1

rev 4/8/90

Page 11

Nolan-Norton Presentation, July 19, 1990

Slide 10

GO ALS

cult ure

scorecard

IS

PRO BLEM

SO LVING

projects

ADI's CO NSTITUENCIES

M ETRICS

CUSTO M ERS

partnership

ADI's

growth

BUSINESS

O BJECTIVES

EM PLO YEES

capital

return

STO CKHO LDERS

©1987-2000 Arthur M . Schneiderman All Rights Reserved.

©1986-2000,

Arthur M. Schneiderman.

Revised 3/7/2016 11:30:00 AM

All Rights Reserved

c. 1/17/89-?/3/12/90-03120-2

rev 4/8/90

Page 12

Nolan-Norton Presentation, July 19, 1990

Slide 11

GOALS

cult ure

scorecard

IS

PROBLEM

SOLVING

projects

M ETRICS

BUSINESS

O BJECTIVES:

ADI Q IP GO ALS

M ARKET LEADERSHIP (RM S)

REVENUE GRO WTH

PRO FITABILITY

DRIVERS:

BE RATED #1 BY O UR CUSTO M ERS

IN TO TAL VALUE DELIVERED

EXTERNAL LEVERS:

PRO DUCTS

DEFECT LEVELS

O N-TIM E DELIVERY

LEADTIM E

PRICE

RESPO NSIVENESS

INTERNAL LEVERS:

TIM E TO M ARKET

PRO CESS PPM

M ANUFACTURING CYCLE TIM E

YIELD

©1987-2000 Arthur M . Schneiderman All Rights Reserved.

©1986-2000,

Arthur M. Schneiderman.

Revised 3/7/2016 11:30:00 AM

All Rights Reserved

c. 1/17/89-AM S-5

rev. 4/8/90-04080-2

Page 13

Nolan-Norton Presentation, July 19, 1990

Slide 12

Process Quality Improvement

Counter Action I

%

(Dip Soldering Process)

0.4%

0.4

0.3

Failure Rate

Counter Action II

0.2

ppm

40ppm

Omit Hand Rework

Process

Basic Working

Guide Manual

30

PC Board Design

Instructions

20

3ppm

10

Masking Method

Improvement

0

Revision of Manufacturing

Engineering Standards

Dip Solder was

made to one

worker job

40

0.1

Counter Action III

0

11

1

4

78

7

10

1

4

7

10

10

1

4

80

79

7

10

1

4

7

10

81

1

4

82

7

10 month

FY

Source: Kenzo Sasaoka, President

Yokagowa-Hewlett-Packard 7/84

©1987-2000 Arthur M . Schneiderman All Rights Reserved.

©1986-2000,

Arthur M. Schneiderman.

Revised 3/7/2016 11:30:00 AM

All Rights Reserved

Page 14

Nolan-Norton Presentation, July 19, 1990

Slide 13

YOKOGOWA HEWLETT PACKARD

Dip Soldering Defects

10,000

1

.01

100

.001

10

.0001

0

PPM

Failure Rate %

1,000

50 % improvement each:

3.6 months

.1

1

12

24

36

48

60

months

©1987-2000 Arthur M . Schneiderman All Rights Reserved.

©1986-2000,

Arthur M. Schneiderman.

Revised 3/7/2016 11:30:00 AM

All Rights Reserved

12/12/85-ZD4

Page 15

Nolan-Norton Presentation, July 19, 1990

Slide 14

PRO PO SED HALF-LIFE M O DEL VALUES

M O NTHS

PRO JECT TYPE

uni-functional

EXAMPLES

MO DEL HALF-LIFE

operator errors

EXPECTED RANGE

3

0 to 6

9

6 to 12

18

12 to 24

WIP

cross-functional

new product cycle time

outgoing PPM

multi-entity

vendor quality

warranty costs

©1987-2000 Arthur M . Schneiderman All Rights Reserved.

©1986-2000,

Arthur M. Schneiderman.

Revised 3/7/2016 11:30:00 AM

All Rights Reserved

3/19/87-imp-9

rev. c. 1989-hflf-2

Page 16

Nolan-Norton Presentation, July 19, 1990

Slide 15

TARGET HALF-LIVES

O rganizational Complexity

months

hi

14

18

22

med

7

9

11

low

1

3

5

low

med

hi

Technical Complexity

©1987-2000 Arthur M . Schneiderman All Rights Reserved.

©1986-2000,

Arthur M. Schneiderman.

Revised 3/7/2016 11:30:00 AM

All Rights Reserved

6/11/90-06110-1

rev. 5/28/91

Page 17

Nolan-Norton Presentation, July 19, 1990

Slide 16

GOALS

cult ure

scorecard

THE DEM ING CYCLE

IS

PROBLEM

SOLVING

projects

M ETRICS

R

S

S

E

PLAN

S

36

E

HALFLIFE

U

27

9

C

ACT

DO

O

L

M PI

18

T

R

S

CHECK

P

©1987-2000 Arthur M . Schneiderman All Rights Reserved.

©1986-2000,

Arthur M. Schneiderman.

Revised 3/7/2016 11:30:00 AM

All Rights Reserved

3/12/90-03120-3

rev 5/27/91

Page 18

Nolan-Norton Presentation, July 19, 1990

Slide 17

ADI RESPO NSE TO HALF-LIFE CO NCEPT

Critics

Supporters

Embodies the concept of KAIZEN

Doesn't reflect where we need to be

Easy to understand

Hard to understand

M akes sense

Hard to use

Data not negotiation based

manual vs. computerized

realistic

Accepted by line organization

assumes instant startup

Works

assumes constant rate of learning

focuses on results not process

focuses on results not process

"...the rate at which individuals and organizations learn

may become the only sustainable competitive advantage..."

Ray Stata

©1987-2000 Arthur M . Schneiderman All Rights Reserved.

©1986-2000,

Arthur M. Schneiderman.

Revised 3/7/2016 11:30:00 AM

All Rights Reserved

2/18/90-02180-2

Page 19

Nolan-Norton Presentation, July 19, 1990

Slide 18

SAM PLE IM PRO VEM ENT CURVE

linear scale

defect level

3

2.5

2

1.5

1

0.5

0

1

3

5

7

9

11 13 15 17 19 21 23 25 27 29

months

©1987-2000 Arthur M . Schneiderman All Rights Reserved.

©1986-2000,

Arthur M. Schneiderman.

Revised 3/7/2016 11:30:00 AM

All Rights Reserved

2/19/90-02190-1a

rev 5/28/91

Page 20

Nolan-Norton Presentation, July 19, 1990

Slide 19

SAM PLE IM PRO VEM ENT CURVE

logarithmic scale

defect level

3

2

1

0.5

0.3

0.2

0.1

1

3

5

7

9

11 13 15 17 19 21 23 25 27 29

months

©1987-2000 Arthur M . Schneiderman All Rights Reserved.

©1986-2000,

Arthur M. Schneiderman.

Revised 3/7/2016 11:30:00 AM

All Rights Reserved

2/19/90-02190-1

rev 5/28/91

Page 21

Nolan-Norton Presentation, July 19, 1990

Slide 20

ADI QIP GOALS

IC OPERATIONS, ESTABLISHED PRODUCTS

METRIC

1987

HALF-LIFE

1992

EXTERNAL

On time delivery

85%

9

>99.8%

Outgoing defect levels

500 PPM

9

<10 PPM

Lead time

10 wks

9

<3 wks

Manufacturing Cycle Time

15 wks

9

4-5wks

Process Defect Levels

5000 PPM

6

<10 PPM

Yield

20%

9

>50%

Time to Market

36 mths

24

6 mths

INTERNAL

WHILE AGGRESSIVELY PURSUING

CORPORATE-WIDE COST MANAGEMENT

©1987-2000 Arthur M . Schneiderman All Rights Reserved.

©1986-2000,

Arthur M. Schneiderman.

Revised 3/7/2016 11:30:00 AM

All Rights Reserved

c. 7/12/87-Q IP-16/Q S-16B

rev. 7/25/87

Page 22

Nolan-Norton Presentation, July 19, 1990

Slide 21

FY1990 CORPORATE SCORECARD

FINANCIAL

End FY89

ACTUAL

BHMK

Q1 90

ACTUAL

BHMK

Q2 90

ACTUAL

BHMK

Q3 90

ACTUAL

BHMK

Q4 90

ACTUAL

BHMK

FY 90

ACTUAL

SALES

SALES GROWTH YTY

CONTRIBUTION MARGIN

ROA (CM)

QIP

ON TIME DELIVERY (To FCD)

% CRDs NOT MATCHED

EXCESS LEADTIME

LABOR TURNOVER

MANUFACTURING METRICS: IC PRODUCTS

OUTGOING PPM

PROCESS PPM

CYCLE TIME

YIELD

MANUFACTURING METRICS: ASSEMBLED PRODUCTS

OUTGOING PPM

PLUG-IN YIELD

CYCLE TIME

% COST OF SCRAP/REWORK

NEW PRODUCTS

ACTUAL

FY87 PLAN

ACTUAL

FY87 PLAN

ACTUAL

FY87 PLAN

ACTUAL

FY87 PLAN

ACTUAL

FY87 PLAN

ACTUAL

BOOKINGS POST-85 PROD

FY89

1Q90

2Q90

3Q90

4Q90

FY90

FORECAST 3rd YR BOOKINGS

of new product releases

©1987-2000 Arthur M . Schneiderman All Rights Reserved.

©1986-2000,

Arthur M. Schneiderman.

Revised 3/7/2016 11:30:00 AM

All Rights Reserved

c. 1989-Scorecard

Page 23

Nolan-Norton Presentation, July 19, 1990

Slide 22

1

2

1990 Scorecard

ADI

Qtr 2 1990

?

Line Item

Actual

Budget

Variance

%

%

WKS

%

96.10

52.10

2.80

8.40

97

41

3

19

-1.00

10.70

-.10

-10.70

-1 #

26 #

-3

-56

IC Outgoing PPM

IC Process PPM

IC Cycle Time

IC Yield

DYS

%

1210.00

1624.00

50.10

40.40

908

1516

62

38

302.00

108.00

-12.30

2.80

33 #

7#

-20

7

AP Outgoing PPM

Plug In Yield

AP Cycle Time

Scrap/Rework Cost

%

DYS

%

1483

91.40

21.90

7.70

1977

91

29

14

-494.00

.50

-6.70

-6.40

QIP:

On Time Delivery % (To FCD)

CRDs Not Matched

Excess Leadtime

Employee Turnover

Retrace

Utilities

1989 Scorecard

Commentary

©1987-2000 Arthur M . Schneiderman All Rights Reserved.

©1986-2000,

Arthur M. Schneiderman.

Revised 3/7/2016 11:30:00 AM

All Rights Reserved

% Var.

-25

1

-23

-45

Return

1Q 90-Scorecard-1

Page 24

Nolan-Norton Presentation, July 19, 1990

Slide 23

1

2

1990 Scorecard

ADI

Qtr 2 1990

?

Line Item

Actual

Budget

Variance

NEW PRODUCTS:

Post 1985 Products

Forecasted 3rd Year Bookings

$M

$M

40.30

9.90

42

-1.60

FINANCIALS:

Sales

Sales Growth (YTY)

Contribution Margin

ROA (Contribution Margin)

$M

%

%

%

116.40

1.20

6.30

7.50

117

2

8

10

-.30

-.30

-2.00

-2.00

Retrace

Utilities

1989 Scorecard

Commentary

©1987-2000 Arthur M . Schneiderman All Rights Reserved.

©1986-2000,

Arthur M. Schneiderman.

Revised 3/7/2016 11:30:00 AM

All Rights Reserved

% Var.

-4 #

-0

-20

-24

-21

#

#

#

#

Return

1Q 90-Scorecard-2

Page 25

Nolan-Norton Presentation, July 19, 1990

Slide 24

GOALS

cult ure

scorecard

PERFO RM ANCE M EASUREM ENT

IS

PROBLEM

SOLVING

projects

M ETRICS

If you don't measure it,

it will not improve.

does not mean

measurement

improvement

©1987-2000 Arthur M . Schneiderman All Rights Reserved.

©1986-2000,

Arthur M. Schneiderman.

Revised 3/7/2016 11:30:00 AM

All Rights Reserved

5/22/90-05220-4

Page 26

Nolan-Norton Presentation, July 19, 1990

Slide 25

GOALS

cult ure

scorecard

IS

PROBLEM

SOLVING

projects

M ETRICS

GO AL:

IM PRO VE CUSTO M ER SERVICE

CUSTO M ER SERVICE M ETRICS

O N TIME

% late

% early

RESPO NSIBILITY

factory

warehouse

% on time

credit

customer

LATENESS/EARLINESS

shipped late, how late?

shipped early, how early?

still late, how late?

months to ship late backlog

LEAD TIME

customer requested lead time

% CRD's matched

excess lead time

RESPO NSIVENESS

time to schedule an order

©1987-2000 Arthur M . Schneiderman All Rights Reserved.

©1986-2000,

Arthur M. Schneiderman.

Revised 3/7/2016 11:30:00 AM

All Rights Reserved

4/8/90-04080-3

rev 5/13/90

Page 27

Nolan-Norton Presentation, July 19, 1990

Slide 26

On Time Customer Service Improvement

Quarterly Data (1Q87 – 4Q89)

100

ADS

ADBV

MED

CLD

IPD

DSP

MDL

ADI

10.8

16.5

8.4

18.0

13.8

6.9

54.9

13.2

10

1

0.1

Half Life

In Months

©1987-2000 Arthur M . Schneiderman All Rights Reserved.

©1986-2000,

Arthur M. Schneiderman.

Revised 3/7/2016 11:30:00 AM

All Rights Reserved

4Q 89-% Late

Page 28

Nolan-Norton Presentation, July 19, 1990

Slide 27

Percent Of Lines Shipped Late (Jun 89 through May 90)

100

ADBV

ADS

CLD

DSP

IPD

10

MDL

MED

ADI

NS

NS

+++

+

+

+

1

0.1

Half NS

NS

Life (In months)

NS

NS

N/A

7

©1987-2000 Arthur M . Schneiderman All Rights Reserved.

©1986-2000,

Arthur M. Schneiderman.

Revised 3/7/2016 11:30:00 AM

All Rights Reserved

% Late M ay 90

Page 29

Nolan-Norton Presentation, July 19, 1990

Slide 28

RELATIO NSHIP BETWEEN LEADTIM E

AND O N-TIM E DELIVERY

AD XXX

0.1

1

0.95

0.08

0.8

0.06

0.6

0.04

0.4

0.02

0.2

0

0

50

100

113

0

150

lead time

M arket requirements:

O TD > 95%

leadtime < 100

O ur requirements:

O TD < 50%

or

leadtime > 113

LO SS O F M ARKET SHARE

©1987-2000 Arthur M . Schneiderman All Rights Reserved.

©1986-2000,

Arthur M. Schneiderman.

Revised 3/7/2016 11:30:00 AM

All Rights Reserved

5/16/90-05160-1a

Page 30

Nolan-Norton Presentation, July 19, 1990

Slide 29

IM PRO VING O N THE

O TD/LEADTIM E TRADEO FF

1. increase inventory

2. build to good forecasts

3. reduce manufacturing cycle time

©1987-2000 Arthur M . Schneiderman All Rights Reserved.

©1986-2000,

Arthur M. Schneiderman.

Revised 3/7/2016 11:30:00 AM

All Rights Reserved

5/16/90-05160-2

Page 31

Nolan-Norton Presentation, July 19, 1990

Slide 30

RELATIO NSHIP BETWEEN LEADTIM E

AND O N-TIM E DELIVERY

AD XXX

0.1

1

0.95

0.08

0.8

0.06

0.6

0.04

0.4

0.02

0.2

0

0

50

100

113

0

150

lead time

M arket requirements:

O TD > 95%

leadtime < 100

O ur requirements:

O TD < 50%

or

leadtime > 113

LO SS O F M ARKET SHARE

©1987-2000 Arthur M . Schneiderman All Rights Reserved.

©1986-2000,

Arthur M. Schneiderman.

Revised 3/7/2016 11:30:00 AM

All Rights Reserved

5/16/90-05160-1a+b

Page 32

Nolan-Norton Presentation, July 19, 1990

Slide 31

ADI Half-Lives by month 5/89 to 4/90

60

50

40

30

20

10

0

May Jun

Jul

Aug Sep Oct Nov Dec Jan Feb Mar Apr

89

90

Hlf Life

5/89

9

6/89

7

7/89

7

8/89

7

9/89

8

10/89

10

11/89

11

12/89

15

1/90

47

2/90

60

3/90

60

4/90 N/A

©1987-2000 Arthur M . Schneiderman All Rights Reserved.

©1986-2000,

Arthur M. Schneiderman.

Revised 3/7/2016 11:30:00 AM

All Rights Reserved

c. 1990

Page 33

Nolan-Norton Presentation, July 19, 1990

Slide 32

Percent Of CRDs Not Matched (Jun 89 through May 90)

100

ADBV

ADS

10

Half

NS

48

Life (In months)

W/I

CRD %

CLD

DSP

NS

NS

IPD

N/A

MDL

MED

ADI

NS

NS

60+

©1987-2000 Arthur M . Schneiderman All Rights Reserved.

©1986-2000,

Arthur M. Schneiderman.

Revised 3/7/2016 11:30:00 AM

All Rights Reserved

Apr 90-CRDs not matched

Page 34

Nolan-Norton Presentation, July 19, 1990

Slide 33

Weeks Of Excess LT - NonExcess Orders Excluded (Jun 89 - May 90)

100

ADBV

ADS

CLD

DSP

IPD

MDL

10

MED

ADI

+

++

+

+

+

+

1

NS

15

Half

Life (In months)

61

57

W/I

CRD %

NS

NS

N/A

35

NS

NS

15

25

38

20

29

49

©1987-2000 Arthur M . Schneiderman All Rights Reserved.

©1986-2000,

Arthur M. Schneiderman.

Revised 3/7/2016 11:30:00 AM

All Rights Reserved

Dec 89-Excess LT

Page 35

Nolan-Norton Presentation, July 19, 1990

Slide 34

48 CUSTOMERS IN

VENDOR RATING DATABASE

ABB

AGFA

Allen Bradley

Allied Signal

Ametek

Apollo

AT&T

Brown Engineering

Compugraphic

Currie-Peak-Frazi

Eaton

Finnegan

Ford

General Electric

GEC

Gould

Hewlett-Packard

Honeywell

Hughes

Instron

JET Electronics

Kodak

Loral

Lucas

M/A-COM

Martin Marietta

Marquette Electric

Masscomp

Microcircuits Semiconductor

McDonald Douglas

Parker Air & Space

Penastar

Perkin Elmer

Raytheon

Reliance Electric

Rockwell

Sanders

Siemens

Sikorsky

Tektronix

Teleco

Teledyne

Teradyne

Texas Instruments

Trillium

United Technologies

Waters Associates

Westinghouse

©1987-2000 Arthur M . Schneiderman All Rights Reserved.

©1986-2000,

Arthur M. Schneiderman.

Revised 3/7/2016 11:30:00 AM

All Rights Reserved

c. 7/90-VRS Database

Page 36

Nolan-Norton Presentation, July 19, 1990

Slide 35

ON TIME DELIVERY, CUSTOMER MEASURED

100.00

QIP STARTED

%

L

A

T

E

10.00

HALF-LIFE = 10 MONTHS

1.00

Fe Ap

1987

Ju

Au Oc Dec Fe Ap

1988

Ju

Au Oc Dec Fe Ap

1989

Actual Data

Ju

Au Oc Dec Fe

1990

Trend

(Ave: 21 C9ompanies per point)

©1987-2000 Arthur M . Schneiderman All Rights Reserved.

©1986-2000,

Arthur M. Schneiderman.

Revised 3/7/2016 11:30:00 AM

All Rights Reserved

Feb 90-CM D

Page 37

Nolan-Norton Presentation, July 19, 1990

Slide 36

HEWLETT-PACKARD VENDO R RATINGS

year

ADI rank

total suppliers

1986

8

16

linear IC suppliers

1987

5

8

linear IC suppliers

1988

5

15

all IC suppliers

1989

1

12

all IC suppliers

*

*

category

tied with one other supplier

©1987-2000 Arthur M . Schneiderman All Rights Reserved.

©1986-2000,

Arthur M. Schneiderman.

Revised 3/7/2016 11:30:00 AM

All Rights Reserved

5/22/90-05220-1

Page 38

Nolan-Norton Presentation, July 19, 1990

Slide 37

ADS Q IP TEAM STRUCTURE

ADS SAFETY COMMITTEE

ON TIME DELIVERY

DIRTY HARRYS

PLANNING QIP

TRANSIT

WIP QIP

PPM STEERING

ALCATRAZ

BENT LEADS DIPS

ELIM INATORS

COG PPM

FINAL TEST ESD

HERM EDICS

SLASHERS

TEST EQUIPM ENT

YIELD STEERING

TEST

TRIM

VISUAL

FAB STEERING

BM W'S

DIRT DEVILS

ELIM INATORS

ERRORBUSTERS

ETCH JIT

ON TIM E DELIVERY

PROM IS ECN

WAFER SAVERS

TTM STEERING

DESIGN & LAYOUT

DESIGNER TASK FORCE

LAYOUT TASK FORCE

FABCATS

PROCESS DEVELOPM ENT

HANDO VER

SPC GROUP 1 707

SPC GROUP 11 OP07/27

SPC GROUP 12 574

SPC GROUP 14 521/534

SPC GROUP 3 711/712

SPC GROUP 4 569

SPC GROUP 8 570/1/3

SPC SOLDER DIP

WIRE BOND SPC

SETUP TIM E REDUCTION

©1987-2000 Arthur M . Schneiderman All Rights Reserved.

©1986-2000,

Arthur M. Schneiderman.

Revised 3/7/2016 11:30:00 AM

All Rights Reserved

6/11/90-06110-2

Page 39

Nolan-Norton Presentation, July 19, 1990

Slide 38

TYPICAL Q IP PRO JECTS

NAM E

M EM BERS

PRO JECT

M ETRIC

BMW'S

8 FAB LINE O PERATO RS

2 FAB TECHNICIANS

2 FAB ENGINEERS

3 FAB SUPERVISO RS

REDUCE THE Q UANTITY

O F BRO KEN/M ISSING

WAFERS PER M ILLIO N

M O VES

YIELD

ERRO RBUSTERS

6 FAB LINE O PERATO RS

3 FAB TECHNICIANS

1 FAB ENGINEER

1 FAB M ANAGER

REDUCE M ISPRO CESSING

IN PHO TO

YIELD

DIRT DEVILS

2 FAB LINE O PERATO RS

2 YIELD ENHANCEM ENT

1 FAB SUPERVISO R

1 Q .C. INSPECTO R

1 FAB TECHNICIAN

1 EQ UIPM ENT REPAIR

REDUCE PARTICLE

CO UNT IN FAB

YIELD

PLANNING Q IP

2 BUSINESS PLANNING

2 M ANUF. SUPERVISO RS

5 P.C. PLANNING

1 FINANCE

1 PURCHASING

1 CUSTO M ER SERVICE

INCREASE CUSTO M ER

SERVICE WHILE

REDUCING CYCLE TIM E

AND M INIM IZING

INVENTO RIES

O N TIM E DELIVERY

ALCATRAZ

5 TEST O PERATO RS

2 BRAND O PERATO RS

1 Q .A. ENGINEER

1 BRAND SUPERVISIO R

ELIM INATE FACTO RY

ESCAPES

PPM

FABCATS

1 C.A.S. O PERATO R

1 M ASK FAB M ANAGER

1 Q .C. M ANAGER

1 FAB M ANAGER

1 P.C. PLANNING

2 P/L CO O RDINATO RS

1 FAB CO O RDINATO R

M INIM IZE TAT O N NEW

PRO DUCT DEVELO PM ENT

LO TS

TIM E TO M ARKET

©1987-2000 Arthur M . Schneiderman All Rights Reserved.

©1986-2000,

Arthur M. Schneiderman.

Revised 3/7/2016 11:30:00 AM

All Rights Reserved

6/11/90-06110-3

Page 40

Nolan-Norton Presentation, July 19, 1990

Slide 39

©1986-2000,

Arthur M. Schneiderman.

Revised 3/7/2016 11:30:00 AM

All Rights Reserved

Page 41

Nolan-Norton Presentation, July 19, 1990

Slide 40

GOALS

cult ure

scorecard

IS

PROBLEM

SOLVING

projects

PRO BLEM SO LVING

M ETRICS

The Deming Cycle (PDCA)

1

PERCEPTION OF PROBLEM

2

EVALUATION OF

CURRENT SITUATION

3

ANALYSIS OF CAUSES

4

PLANNING OF

COUNTER-M EASURES

DO

5

IM PLEM ENTATION OF

COUNTER-M EASURES

CHECK

6

EVALUATION OF RESULTS

7

STANDARDIZATION

8

SUM M ARY & FUTURE PLANS

PLAN

WHAT

WHY

WHO

WHEN

WHERE

HO W

ACTIO N

©1987-2000 Arthur M . Schneiderman All Rights Reserved.

©1986-2000,

Arthur M. Schneiderman.

Revised 3/7/2016 11:30:00 AM

All Rights Reserved

5/22/90-05220-3

Page 42

Nolan-Norton Presentation, July 19, 1990

Slide 41

CENTRAL PRINCIPLES O BSERVED

IN TQ M IM PLEM ENTATIO N

Primacy of the Customer

customer first

customer satisfaction

market-in

Use of the PDCA cycle for continuous

improvement

Strong CEO and top management leadership

policy deployment

Education and training for all

Respect for all people

teamwork

participative management

©1987-2000 Arthur M . Schneiderman All Rights Reserved.

©1986-2000,

Arthur M. Schneiderman.

Revised 3/7/2016 11:30:00 AM

All Rights Reserved

4/24/90-04240-2

Page 43

Nolan-Norton Presentation, July 19, 1990

Slide 42

GOALS

culture

scorecard

THE Q IP CULTURE

IS

PROBLEM

SOLVING

projects

M ETRICS

We each have a dual function

daily job

SDCA cycle

process improvement

PDCA cycle

We are committed to improving customer satisfaction

We are dedicated to (kaizen)

continuous improvement

We are part of a parallel organization:

functional and cross-functional

We are a continuously learning organization

©1987-2000 Arthur M . Schneiderman All Rights Reserved.

©1986-2000,

Arthur M. Schneiderman.

Revised 3/7/2016 11:30:00 AM

All Rights Reserved

4/8/90-04080-4

rev 7/9/90

Page 44

Nolan-Norton Presentation, July 19, 1990

Slide 43

REQUIREMENTS FOR QUALITY IMPROVEMENT

Top Management

Commitment

leadership

profit opportunity

changed objectives

competition

hands-on management

Systematic

Sense of Urgency

Method

proven results

kaizen

data driven

fuel for change

cross-functional

visibility

support

Pilot Projects

Company Wide

Involvement

overcome skepticism

weakest link

build credibility

internal customers

get ball rolling

develop champions

policy deployment

vendors/customers

Organization/

©1987-2000 Arthur M . Schneiderman All Rights Reserved.

©1986-2000,

Arthur M. Schneiderman.

Revised 3/7/2016 11:30:00 AM

All Rights Reserved

Systems

training

guiding

:

monitoring

rewarding

:

12/16/85-ADI-2

Page 45