Electrical Analogy of Fluid Flow

advertisement

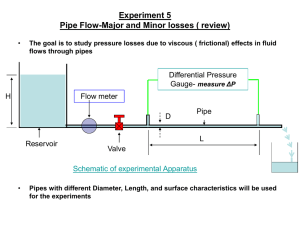

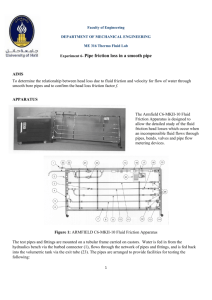

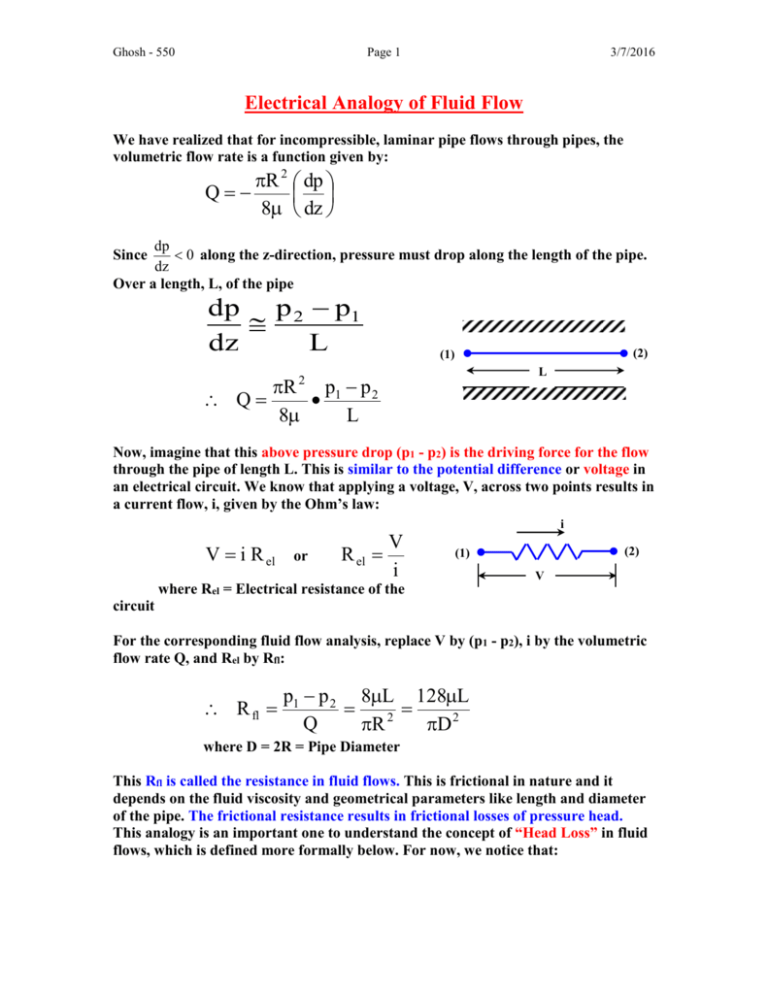

Ghosh - 550 Page 1 3/7/2016 Electrical Analogy of Fluid Flow We have realized that for incompressible, laminar pipe flows through pipes, the volumetric flow rate is a function given by: R 2 dp Q 8 dz dp 0 along the z-direction, pressure must drop along the length of the pipe. dz Over a length, L, of the pipe Since dp p 2 p1 dz L (2) (1) L R 2 p1 p 2 Q 8 L Now, imagine that this above pressure drop (p1 - p2) is the driving force for the flow through the pipe of length L. This is similar to the potential difference or voltage in an electrical circuit. We know that applying a voltage, V, across two points results in a current flow, i, given by the Ohm’s law: i V i R el or R el V i (2) (1) V where Rel = Electrical resistance of the circuit For the corresponding fluid flow analysis, replace V by (p1 - p2), i by the volumetric flow rate Q, and Rel by Rfl: R fl p1 p 2 8L 128L Q R 2 D 2 where D = 2R = Pipe Diameter This Rfl is called the resistance in fluid flows. This is frictional in nature and it depends on the fluid viscosity and geometrical parameters like length and diameter of the pipe. The frictional resistance results in frictional losses of pressure head. This analogy is an important one to understand the concept of “Head Loss” in fluid flows, which is defined more formally below. For now, we notice that: Ghosh - 550 Page 2 p1 p 2 Q 3/7/2016 128L D 2 D 2 Since Q VA V 4 (A = Pipe cross sectional area) p1 p 2 V32L or, p1 p 2 64 V 2 L 64 L V 2 VD 2 D Re D D 2 [ Re D VD ] The above expression shows that the loss of flow energy per unit mass between points (1) and (2) in a pipe flow may be expressed as: p1 p 2 L V2 f D 2 where f = friction factor = 64 for laminar flows. Re D The above expression is called the Darcy-Weisbach formula. It relates the loss of L pressure head to the friction factor, , and the average velocity of the flow. A more D general form of this formula is derived from the Engineering Bernoulli equation below. The plot of f vs. ReD shown below is called the Moody Diagram and is plotted for a large range of Reynolds numbers. Ghosh - 550 Page 3 3/7/2016 Moody Diagram As we can see from the plot the far left region corresponds to laminar flow, where the friction factor is given by f = 64/ReD derived before. It turns out that for turbulent flows f is not only dependent on ReD, but a roughness factor also. The roughness is measured as a protruding length from the smooth wall of the pipe. Thus “relative roughness,” , which is a parameter in the Moody Diagram for D different pipe materials in turbulent flows, is a non-dimensional quantity. For “smooth pipes” the relative roughness is considered to be zero. Continue