mep center review criteria - Nebraska Department of Economic

advertisement

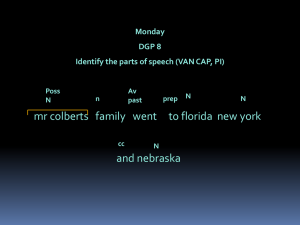

i CONTENTS MEP CRITERIA FOR CENTER PERFORMANCE EXCELLENCE Center Profile 1.0 Center Leadership 1.1 Leadership System 1.2 External Partnerships and Resources 2.0 Center Planning 2.1 Strategic Plan 2.2 Operating Plan 3.0 Center Customer Knowledge and Relationships 3.1 Market Knowledge and Analysis 3.2 Customer Relationship Management 4.0 Center Performance Information and Analysis 4.1 Performance Measurement Information 4.2 Performance Analysis 5.0 Center Workforce Practices and Work Environment 5.1 Work Practices and Organization 5.2 Employee Education, Training, and Development 5.3 Employee Well-Being and Satisfaction 6.0 Center Process Management 6.1 Service and Product Offerings 6.2 Marketing Operations 6.3 Customer Engagement and Sales 6.4 Service Delivery 6.5 Support Services 7.0 Center Performance 7.1 Customer and Regional Impact Results 7.2 Market Penetration Results 7.3 Financial Profile and Health 7.4 Customer Satisfaction 7.5 Capacity Utilization and Operational Efficiency 7.6 Employee Well-Being and Satisfaction 7.7 Other Significant Accomplishments ii Center Profile 1. Organizational Characteristics: The Nebraska Manufacturing Extension Partnership is a statewide center established in 1994. The Nebraska Manufacturing Extension Partnership (MEP) was formed specifically to help Nebraska manufacturers build on their strengths, identify and capitalize on opportunities, and increase competitiveness and profitability. The MEP organization is designed to capitalize on the geographic distribution of Nebraska’s community colleges, supplementing the colleges’ expertise in training with the expertise from programs under the University of Nebraska-Lincoln Food Processing Center, Nebraska Business Development Center and the Department of Economic Development. Since 1994, the Nebraska MEP’s funding level remained constant. Exhibit CP-1 presents major center events and milestones over the period. The Nebraska MEP’s Director reports directly to the Nebraska Industrial Competitiveness Alliance (NICA). Seven Customer Agents serve SME’s in six regional offices across the state. Exhibit CP-2 depicts this organizational structure. 2. Service Delivery Area: The Nebraska MEP is headquartered in the city of Lincoln, the state capitol in Lancaster County. The market served by the Nebraska MEP is the entire state of Nebraska. There are 2,168 manufacturers in Nebraska and they are all considered potential MEP clients. The largest numbers of manufacturers in the state are printing, followed by food processing, machinery, metal fabrication, stone/clay, wood, chemical, apparels and plastics. The geographic distribution of firms and customer agent office location is depicited in the map on Exhibit CP-3. 3. Leadership Team: The Nebraska MEP’s senior leadership consists of the Director, Dr. Darl Naumann; Mr. Dave Wright, Operations Manager, who has responsibility for key administrative areas, including contract administration; Ms. Lori Shaal who is responsible for accounting, report generation, and procurement; and, Mr. Rich Stites who has responsiblity for the Edgerton Quality Award development and maintenance. Mr. Jack Ruff Dr. Steve Taylor and Mr. Leon Milobar are responsible for lead generation activities. 100% stability of our customer agents for this contract year is responsible for developing long-term partnerships with clients. 4. FTE Staff by type and Location: As of February 1, 2000 the Nebraska MEP had 19 FTE employees. Exhibit CP-4 presents their distribution by job type. 5. Financial Summary: Exhibit CP-5 provides an overview of the Nebraska MEP’s recent and projected financial status. 6. Characteristics of Service Region: Exhibit CP-6 presents a summary overview of the SME population in the six Community College regions. 7. Products, Services, and Service Delivery Model: Exhibit CP-7 displays the general types of products and services the Nebraska MEP offers. Exhibit CP-8 presents a summary overview of the project activity to date. Exhibit CP-9 shows the growth over time of third party service provision. 8. Requirements and Constraints: The Nebraska MEP has five major stakeholder groups, each of which has its own specific set of needs and preferences. Exhibit CP-10 lists, by stakeholder, some of the general requirements each group expects the Nebraska MEP to meet. We have no overriding external requirements that significantly constrain how we operate. 9. Recent Changes: the most significant change in the Nebraska MEP’s operations over the last year has been a dramatic expansion of Lean Manufacturing activity. Principles of Lean Manufacturing 101, served as the first step to learning the basics of lean. Lean 200 courses in Set-Up Reduction, Value-Steam Mapping, and Visual Workplace are targeted to progressive firms by the Nebraska MEP. This expansion presented management with the challenge of providing service while continuing to meet growing educational needs. Alliances formed for delivery of Y2K services are the basis for expansion into e-Commerce. iii iv v vi vii viii ix x xi xii xiii Chapter 1 CENTER LEADERSHIP 1.1 Leadership System Leadership for Nebraska Manufacturing Extension Partnership (NMEP) is provided by an industrydominated board, the Nebraska Industrial Competitiveness Alliance (NICA) and its actively engaged and knowledgeable chair, A.F. “Tony” Raimondo from Behlen Manufacturing. The Chair works through a senior staff leadership team which includes: the NICA/MEP Chair Mike Baldino from Kelley Klosures, MEP Director, Dr. Darl Naumann; Community College (CC) President, Dr. LaVern Franzen; Nebraska Food Processing (FPC) Director Dr. Steve Taylor; Nebraska Business Development Center (NBDC) Director, Robert Bernier; Nebraska Chamber of Commerce and Industry (NCCI) President Barry Kennedy; and, Director of Existing Business Assistance for the Nebraska Department of Economic Development (NDED), Jack Ruff. This team is supported by the MEP Director of Operations, Dave Wright and Finance Manager, Lori Shaal. This team exercises day-to-day responsibility for developing and executing NMEP plans and building a high-performance organization. 1.1.1 Core Values, Expectations and Balancing Competing Objectives: Leadership and staff together have developed NMEP’s vision, mission, values and strategies. The Nebraska Manufacturing Extension Partnership is a program operated by the Nebraska Industrial Competitiveness Alliance (NICA). The mission statement reads as follows: The Nebraska Manufacturing Extension Partnership coordinates technical and business consulting services that will enhance the competitiveness and profitability of Nebraska’s manufacturing firms; particularly small- and medium-sized manufacturers. Our strategy is to have every Nebraska manufacturer paired with an MEP Customer Agent (CA). This professional relationship allows the CA to link a specific client manufacturer to a specific service provider that can definitely help the manufacturer modernize and grow. The Long-term Goals of the Nebraska MEP are as follows: The preferred choice of SME’s when they need manufacturing-related assistance; Ethics and the Protection of proprietary information as the foundation of NMEP assistance; NMEP as a Great partner and the best utilization of existing resources; and Our NMEP Benchmarked among regional MEP centers, centers of comparable size, and the top MEP centers in the country. The Nebraska MEP is based on the following guiding principles: Industry-based, industry defined services—MEP services address the needs of the Nebraska Market as well as the unique needs of each company. These may include the latest technological advances. They just as likely include assistance in business planning, plant layout, marketing and new product development; Building upon State and local resources—MEP works closely with local state organizations including university, governments and industry to build upon existing state resources and establish or expand programs. In partnerships efforts, MEP channels individual strengths into a single goal of more reach, focus, and service for manufacturers; Programs built on merit-based competition—Our MEP competes equally for national MEP funding. Our MEP is evaluated and judged on industry need, market awareness, and service commitment and delivery; 1-1 Leveraging private sector resources—The array of private sector consultants is large, but often the cost-of-sales for these consultants keeps them out of reach for smaller manufacturers. NMEP services link these customers and consultants, often acting as brokers in helping firms locate private sector experts who can help them with their unique challenges; A perfect resource for companies who seek modernization—Companies interested in modernization may not know how to pursue it. They must have commitment and willingness to invest wherever possible the resources necessary to initiate and implement improvements. NMEP does not seek to assist companies uninterested in helping themselves; Making the firm’s dollar go further—Manufacturers face a wide variety of needs that our MEP can assist them with, in such areas as environment, work force development, marketing and production technologies. Rather than creating new programs to address these topics, our MEP cooperates to develop and deliver specialized programs through our MEP network; Bottom-line impacts are the real measure of success—Our MEP’s success is defined not by the breadth of the services it delivers, but by the real bottom-line impacts these services bring to client companies. Our MEP rigorously and regularly evaluates these impacts, in such terms as increase in sales, jobs, and productivity; and, Investing in the future—Our MEP is committed to serving industry, both for today and for the future. That’s why innovative methods of extension and assistance to manufacturers are being explored and developed. Successful alignment of State goals for job creation, retention, and investment with NMEP goals for sales increase, process improvement, human resources improvement, information system improvement, and management improvement is complete. There is recognition that even the small SME will pay for highimpact projects with an appropriate return on investment (ROI). 1.1.2 Communicating core values, expectations, key directions, and objectives All new employees go through an intensive orientation process, including reporting and evaluation training and meetings with the Center Director, Operations Director and Financial manager. Extensive written material is made available, including the strategic plan, operating plan and marketing plan. Ongoing reinforcement of values, expectations, direction and performance is carried out by the leadership team, including: All professional staff involved in planning; Reinforcement of values, expectations, key direction and performance competed at monthly meetings; Seven monthly meetings of Customer Agents, moved geographically; Seven monthly meetings of Operating Committee; Monthly meetings with NICA/MEP Chair; Quarterly meetings with NICA/MEP Committee; Semi-Annual report and meeting with NICA board. All meetings are well structured, with the Customer Agent and leadership team alternating in development of the agenda. Meetings are complimented by: “Staff Stuff” communicated on the internet; “Chat room” on the internet; Shared calendars; Performance numbers posted on internet and wall; 1-2 1.1.3. Ensuring an SME driven and involved board; The Nebraska Industrial Competitiveness Alliance (NICA) is a twenty-eight member board appointed by the governor of Nebraska to recommend public policy regarding competitiveness and to plan and oversee programs to enhance the technological capabilities of business and to provide a competitive, quality workforce. 1-3 NICA appointed by the Governor for three-year terms. A minimum of 51% SMEs (industry) representation in statute. LB659 in statute to formally make NICA a division of NDED. NICA board members on working committees on the workforce, science and technology, mentoring and competitiveness issues. The Nebraska Manufacturing Extension Partnership was formed specifically to help Nebraska manufacturers build on their strengths, identify and capitalize on opportunities, and increase competitiveness and profitability. Governing the Nebraska Manufacturing Extension Partnership are the NICA/MEP Directors. The overall NICA Board is appointed by the Governor and is comprised of representatives from business, government and education. The NICA/MEP Directors set program policy for our MEP, review service provider scopes of work to insure that program objectives are being reached, and serve as the final decision- makers 1.1.4 Focusing sharply on SMEs The senior leadership team focuses on client satisfaction, new clients, penetration of the market and impact. Services are widely distributed between manufacturers who employ 1500 and less than 10. Key indicators on impact and client satisfaction are posted and monthly staff meetings are used to review progress. Yearly performance tracking indicates a majority of projects with SME’s of less than ten, followed by a focus on SME’s of less than 200. Our target market from a pool of 2100 Nebraska manufacturers is around 900 SME’s based on market research and our strategic plan. Seminars and workshops are used to provide client awareness of NMEP services. Four of six Customer Agents are members of American Society for Quality (ASQ); Jack Ruff (NDED) and the Center Director are certified Lead Auditors for ISO 9000; Center Director member of the National Association of Manufacturers, ASQ, NEDA, National Alliance of Business; Center Director has direction of all business development programs for the Nebraska Department of Economic Development. 1.1.5 Building a strong Leadership Team Our MEP is organized under a matrix organization with representatives from each partner organization with program direction from the MEP Director. The MEP administrative support is provided by the Department of Economic Development. The MEP Program Director is hired by the NICA Board and serves as the CEO of the program. The Director is responsible for overall program management. The Nebraska Manufacturing Extension Partnership is organized contractually through formal cooperative agreements. The Department of Economic Development is the fiscal agent. Service providers are organized into a MEP Operating Committee with the MEP Director as its Chair. The Nebraska Manufacturing Extension Partnership Director is responsible for overall program management and operation. The Director reports to the NICA/MEP committee and the entire NICA board. The daily operations of the MEP as well as the strategic planning work are the primary functions of the Director and the Central Staff. The Central Staff are responsible for developing and delivering services, monitoring the effectiveness of the service, reporting and accounting and developing program information. 1-4 Operations Committee meets monthly; Daily meetings with operations manager and financial manager; Weekly meetings with marketing manager Annual retreat. 1.1.6 Reviewing overall performance Leadership team meets to openly discuss and systematically review center performance against plan as measured on operational metrics aligned with NMEP’s strategic plan. We post and subsequently review progress with leadership team at Weekly headquarters meetings on internal developments and business metrics. On the fourth Tuesday of each month, the leadership team meets with Customer Agents to assess any SME complaints, and discusses resolving client issues and actions necessary to prevent any similar future occurrence. NMEP’s operating and strategic plans define critical short- and long-term operating metrics designed to provide a comprehensive gauge by which to track progress against goals. The leadership team uses these plans in the following methods: Operating plan discussed monthly; Strategic plan discussed semi-annuallly 1.2 External Partnerships and Resources Because of the importance of partnerships to NMEP’s success, the Center Director builds and maintains effective relations with external communities, including: the Nebraska Community College Association, Nebraska State Colleges, University of Nebraska, Coordinating Commission for PostSecondary Education (CCPE), Nebraska Public Power District (NPPD), Omaha Public Power District (OPPD), Economic Development Corporations, Nebraska Economic Developers Association (NEDA), Nebraska Chamber of Commerce and Industry (NCCI), AFL-CIO, Nebraska Food Industry Association (NFIA), Nebraska Departments of Agriculture, Environmental Quality (NDEQ), Education (NDE), Labor (NDOL), Revenue, Nebraska Rural Development Commission, Nebraska Information and Technology Commission, Nebraska County Officials Association (NACO), and the Nebraska League of Municipalities. 1.2.1 Creating Action-Oriented Partnerships These partnership development relationships provide NMEP with technology, research, technical expertise, training and engineering services, marketing and referral services, and services in specialized areas. The partnership with these organizations are used to develop: Resources and in-kind partnerships/affiliations; Utility Partnerships; Seminars/Workshops to address Manufacturers’ and NMEP staff needs; Supplier development programs; Programs in the six community colleges, state colleges, and university system; and, Customized training for Manufacturers. There are five partners involved contractually in the NMEP. They are the University of NebraskaLincoln Nebraska Food Processing Center (FPC), the University of Nebraska at Omaha’s Nebraska Business Development Center (NBDC), the Nebraska Chamber of Commerce and Industry, the Nebraska Community Colleges and the Nebraska Department of Economic Development (DED). All five partners 1-5 provide delivery of services as contractual obligations to the program: FPC, NBDC, NCCI, CC, and DED. In addition, each of the six community colleges in cooperative agreements with our MEP, are Work Keys Service Centers. The performance-based contracts allow NMEP access to expert’s time and other resources available in those organizations. NMEP estimates a formal match of over $1 million in cash funds. Each of the partnership organizations has core expertise and competencies. When combined with the expertise of the Customer Agents, it provides a well-rounded network of experienced technical experts that are capable of solving the typical technical and management problems of manufacturing firms. Third party consultants are brought in when necessary as well as support, when requested from other MEP centers and Federal laboratories. 1.2.2 Strengthen State and Regional Support: Communication with public officials includes NMEP pursues a wide range of strategies to improve public support. Communications with public officials include: Monthly newsletters; Reviews by district for Legislators; Annual Report; NEDA; Diplomats/Ambassadors; State Chamber; and, Manufacturers Association. The leadership team has developed broad contacts within the State Executive and Legislative Branches of government in order to create an understanding of the need for, and the importance of, manufacturing and the NMEP. The Speaker of the Nebraska Unicamerial sits on the NICA board and NICA/MEP Directors, and the December 1999 NICA board meeting was hosted at the Governor’s Residence by Gov. Mike Johanns. Beyond formal reporting, the leadership team personally communicate regularly and informally with major stakeholders, keeping them abreast of center activity and plans. 1.2.3 Participation in and contribution to the MEP system The Center Director is an active participant and contributor to center director’s meetings, and several staff members are, or have been, active contributors to MEP working groups, including evaluation, people and management systems, marketing, and the new working group for operations managers. Members of the leadership team attend and present at the ModForums, and several of the NICA board members have attended the ModForum each year. Staff have worked with NIST/MEP to adapt or develop services, management and performance measurement techniques. NMEP Customer Agents have been involved in the development of Lean Manufacturing, and the NMEP has adapted Red Flags for Manufacturing for direct application with Manufacturers. NMEP is a participant in the MEP Knowledge Base Information Specialists Pilot and has been a pilot site for the Westar Evaluation. 1.2.4 Improving Partnerships and linkages 1-6 The NMEP has a working relationship with the Nebraska Community Colleges that deliver customized training to our clients and ACT WorkKeys Job Profiling services. We have formal, performance-based contracts with those colleges. NMEP is evaluating performance in cooperation with ACT, Inc. in a pilot study of WorkKeys effectiveness. In addition, the NMEP has a contractual relationship with the NCCI for delivery of the Export Manager for Hire program. We are developing metrics so that the NCCI and NMEP can review progress against plans for these measures both among themselves and on a formal, quarterly basis. We are also working with other partners to follow referrals, including: Lead tracking helps evaluate informal partnerships with NEDA, Diplomats; Third party tracking helps evaluate private and public subcontractors. 1-7 Chapter 2 CENTER PLANNING 2.1 Strategic Plan Many of the operating procedures that occur on a frequent and repetitive basis are a product of the “Steps for Success: The Nebraska Manufacturing Extension Partnership Strategic Planning Process.” The strategic plan details a yearlong process for implementation of the operating plan and creation of the operating plan for the next year. Where appropriate, actions in this operating plan reference strategies and goals in the Strategic Plan: FY 2000-FY 2005. 2.1.1 Planning Process The “Steps for Success” is the structure of the ongoing process used by our MEP to evaluate its program and formulate strategic actions that will guide the delivery of program services. The MEP Strategic Planning Timeline (Figure 2.1.1), schedules the elements of the process within the context of a 12-month period designed to coincide with the DED program year. The process requires specific planning activities monthly. Figure 2.1.2 shows the fourteen steps in our planning process. The steps evaluate the prior year’s strategic planning process and our leadership system. It is based upon lessons learned and input from other sources such as our NICA board, funding partners, clients, employees and State leaders. The steps then evaluate our mission, vision, values, and quality policy for appropriateness, alignment and improvement. The planning process then steps into the review of last year’s plan and a strategic look at the next five years. This includes existing and future key business parameters in such areas as financial, market, client, organizational, funding partners, non-funding partners, and impact. The process conducts a full performance analysis and review to determine where we currently are with respect to our key business indicators. The final steps determine the strategies, objectives and tasks required to get from here to there based on stakeholder input through out the process. 2.1.2 Key Conclusions The following are key conclusions regarding our plan: 2.1.2.a Key Investors’ Goals, Requirements, and Projected Funding The State requires direct support of industry clusters, evidence of market needs, and a compelling case based on State benefits. NIST/MEP expects the NMEP to raise 66% of its funds from local sources and expand penetration, regional and client impact, and revenue generation. The State’s primary measure of NMEP success is jobs created/retained and investment. Many state legislators are regional supporters of NMEP. The State sees participation in the NMEP as a good business extension program with a great payoff in goodwill. Presently, the State views the program in alignment with State goals for economic development and projects no difficulty in supplying 66% matching cash funds for future expansion of this program. 2-1 2-2 2-3 2.1.2.b Non-investor Stakeholders Relationships with many new partners such as the utilities, economic development community, AFLCIO, Dept. of Labor, and private consulting firms are proving successful, significantly increasing resources devoted to improving competitiveness and expanding our client base. These relationships continue to evolve as we are better able to develop programs that benefit the small manufacturer. (e.g. Magnus-Farley, Inc./WorkKeys Job Profile/Worker Training Program) 2.1.2.c Market Segments NMEP leads the Governor’s Value-Added Agriculture initiative with a majority of our services to the food processing industry. We see continued needs in Metal Fabrication, Machinery, and Electrical Industries. There is an accelerating trend for Quality System standardization and certification. Quarterly Economic trends completed jointly by NICA and the University of Nebraska show high-tech incubation is spawning a large number of new local companies, and new job creation is about $3-$8/hr higher than replacement of existing workers. The trend for NMEP activities with these firms is Workforce development. 2.1.2.d Center Activities, Capabilities and Performance The NMEP staff is bright, energetic, committed and has a high esprit de corps. The staff and management have come a long way in two years in developing practices for the manufacturing environment. Repeat business trends continue to remain strong, indicating a good business base and numerous potential advocates. We also have experienced success across all SME SIC categories and size categories. As our market research revealed, the most active and numerous projects came in Food, followed by Metal Fabrication, Machinery, Electrical, Transportation and Plastics. The majority of our clients are in the less than 10 employee category, but there is an increasing trend toward companies of less than 200 employees. Referrals are providing a steady flow of appointments, followed by seminars, workshops, and events. Our strategy the last two years has been to increase external consultant resources. We are learning to better manage complex projects, including those provided by third parties in three-way contracts between suppliers and customers. 2.1.2.e Opportunities, Threats, and Market Weaknesses The service regions have a large number of potential clients, and NMEP needs to increase its presence in almost all regions of the State. The Northeast region has a 42% market penetration rate, Southeast 21%, Metro 20%, West 18%, Central 16%, and Mid-Plains 7%. The State is very large geographically and is difficult to serve in the Mid-Plains and Western region. We have concentrated on the West in the past two years and need to focus on the Mid-Plains Region. The strength of the NMEP is lack of turnover in Customer Agents. This has allowed us to build a strong working relationship with our clients. 2.1.3 Summary of Strategic Objectives Our mission is to coordinate technical and business consulting services that will enhance the competitiveness and profitability of Nebraska’s manufacturing firms; particularly small- and mediumsized manufacturers. 2-4 The Long-term Goals of the Nebraska MEP are as follows: The preferred choice of SME’s when they need manufacturing-related assistance; Ethics and the Protection of proprietary information as the foundation of NMEP assistance; NMEP as a Great partner and the best utilization of existing resources; and Our NMEP Benchmarked among regional MEP centers, centers of comparable size, and the top MEP centers in the country. Our objectives reflect the mission, vision and goals of the NMEP and the State of Nebraska: Retain a high caliber staff by providing challenging work, rewarding assignments, and a learning environment; Demonstrate high client benefits in job creation/retention, and impact, including investment, sales increase, process improvement, human resources improvement, information system improvement, and management improvement; Balance public purpose in a stable financial environment by a steady growth in fee-for-service and third party projects; Continue to focus on Value-Added Agriculture, metal fabrication, machinery, and electrical manufacturing, while addressing regional needs of all manufacturers; Strengthen our Information Technology, e-Commerce, and Organizational effectiveness areas; and, Develop long lasting relationships with our clients, increasing repeat business and moving more firms toward quality. In addition, in cooperation with the Department of Economic Development, the NMEP’s vision is to become a total quality organization. This partnership will result in ISO 9000 certification in July of 2001. 2.1.3.a Market Segments NMEP will focus center activity on Value-Added Agriculture, metal fabrication, machinery, and electrical manufacturing, while addressing regional needs of all manufacturers. The “transformation” of small- and medium-sized manufacturers towards quality organizations in the Value-Added supply chain is an additional objective. 2.1.3.b.c Service/Product Offering and Delivery In addition to engineering and technical services, marketing and business services, and workforce development assistance, we will continue to offer a number of new higher value services, including Lean workshops, Red Flags for Manufacturing, ISO and Quality assistance. 2.1.3.d Marketing/Sales We continue to work on generating leads from seminars and workshops and converting them to new projects. Our projects continue the trend of referral from our clients and partners. 2.1.3.e Workforce Practices A substantial commitment to human resource development is necessary to deploy these initiatives. HR activities will include training of service delivery personnel to meet certification standards, and to improve project management and customer relations. We are actively developing specific training and Standard Operating Procedures as we move towards ISO 9000 certification in July of 2001. 2-5 2.1.3.f Partnerships Our partnership activity will place increased emphasis on developing long term working relationships with the Utilities, Labor, AFL-CIO and private consultants. We continue to rely on our clients and partners for referrals. 2.1.3.g Performance Measurement and Evaluation Finally, we are committed to more fully involving personnel at all levels in measuring, analyzing and improving performance. A particular focus will be improving measurement of project impact, and training in estimating project ROI. 2.1.2 Key Objectives and Goals FY ’00 We establish goals and objectives each year for all major aspects of our business. They are made based on an assessment of our past performance, current and future capacity, and the progress in achieving our strategic plan. Our goals and objectives are quantifiable and given to management so that we can measure our performance and track our progress in their achievement. 2.1.3 Current Year Budget See Center Profile, Exhibit CP-5, for our budget with revenues and expenditures by category. 2.1.4 Action Agenda Strengthen business development operations Align high-impact and high-value added service with state goals for Value-Added Agriculture; Participate in Targeted Market Research at DED; Participate in Business Visitation Program; Align NMEP services with State Workforce Development Strategy; Align NMEP services with International Export Assistance Improve analytical capabilities Use outside resources to improve data base management; Implement an improved and more comprehensive FileMaker Pro reporting capability; Integrate FileMaker Pro data base with financial data base; Integrate FileMaker Pro data base with other state data bases. Become a Total Quality Organization Document and share the vision and content; Begin more formal benchmarking; Identify training requirements for deployment and buy-in; Continue the certification process for ISO 9000. Utilize the Center Performance Criteria as the basis for internal improvement process Conduct an annual organizational effectiveness survey; Staff “score” the progress of the organization using the criteria; Staff identify and prioritize issues and opportunities for improving the “low score” areas; 2-6 2.1.5 Evaluating and Improving Planning Process The leadership team works with the NICA/MEP Directors and the Operating Committee to evaluate the current status of plans and to set the agenda and process for the annual planning process. The team uses staff input from the center performance criteria review to assess planning efforts and processes. 2.2 The Operating Plan Key thrusts from the current operating plan support long-term strategic goals. 2.2.1 Major Operating Thrusts Delivery on objectives were developed based upon previous performance and the projected service plan for July 1, 2000 - June 30, 2001. The following table depicts contact objectives by method of delivery: NMEP CONTACT OBJECTIVES BY METHOD OF DELIVERY NO. OF FIRMS CENTRAL METRO MID-PLAINS NORTHEAST Firms Contacted 300 500 100 175 300 100 1475 Assessments 20 25 10 20 25 8 108 Free Projects 40 66 15 40 35 10 206 Fee Projects 22 24 6 22 20 8 102 Training 14 20 5 13 13 5 70 Group Programs 10 19 5 14 17 5 70 Job Profiles 4 4 4 4 4 4 24 Follow-up Eval 27 31 12 27 29 13 139 Sub-Total 437 689 157 315 443 153 2194 2-7 SOUTHEAST WESTERN TOTAL Chapter 3 CENTER CUSTOMER KNOWLEDGE AND RELATIONSHIPS 3.1 Market Knowledge and Analysis The market served by the Nebraska Manufacturing Extension Partnership is the entire state of Nebraska. There are 2,122 manufacturers in Nebraska and they are all considered potential MEP clients. The largest numbers of manufacturers in the state are printing, followed by food processing, machinery, metal fabrication, stone/clay, wood, chemical, apparels and plastics which make up the top 10 manufacturing industries in the state of Nebraska. These firms are predominantly small firms with limited design and product development capabilities. Ninety-eight percent of the manufacturers in Nebraska have less than 500 employees. This is identical to the national average. The remaining two percent, only 49 manufacturers, employ more than 500 employees. Eighty-eight percent of the companies within the state employ 100 or less employees. There are only 14 manufacturers in the state that employ more than 1,000 employees. Nebraska manufacturing averaged 113,700 in total employment, accounting for almost 14 percent of the state’s nonagricultural work force. Employment totaled 54,600 in durable goods production and 59,100 in the manufacture of non-durable goods. Among manufacturing industries in Nebraska, food processing is the largest, with 36,000 employees, or 61 percent of the employment in non-durable goods production and 32 percent of total manufacturing. Meat products manufacturing accounts for over two-thirds of Nebraska’s food processing employment. Agriculture is Nebraska’s primary source of wealth and its dominant industry. It is estimated that onehalf of Nebraska’s work force depends on agriculture and the many related industries involved in all phases of the food and fiber chain from production to marketing for their employment. The majority of the manufacturers are located in the Eastern and Southeastern regions of the state. The Western and Northwestern regions of the state are rural areas and are sparsely populated with scattered clusters of commerce centers. At Figure 3.1.a are Companies by MEP Field Region. Also, at Figure 3.1.b is the Number of Companies by SIC Code For our MEP Field Regions. The second largest manufacturing industry in Nebraska is the production of industrial machinery, with 13,000 employees, or 11 percent of total manufacturing employment. It is followed by the manufacture of electronic equipment with 10,600 employees, and printing and publishing with 9,700 employees. Because of the wide variety of products manufactured by the firms in the client base, there is no “typical” manufacturing client for MEP services. The average company in the target market sells to regional markets and produces in small lots. However, there are some small and medium sized companies that do sell to national and international markets as well. Food processing accounts for 48.1% of total Nebraska exports, followed by industrial machinery at 11.7%, and electronic equipment at 6.2% of total Nebraska exports. 3-1 3-2 3-3 3.1.1 Learning about SMEs: Nebraska uses a diversified approach to learn about SMEs in its regions. We gather information from Target Research completed by the Research Division of the Department of Economic Development in cooperation with outside consultants and partners. The target research is underway once again and will be completed in the fall of 2000. The Business Retention and Expansion Survey is a one-on-one survey completed in cooperation with NEDA and the Nebraska Diplomats. The survey process is outlined in Figure 3.1.1. The survey reaches 400 firms yearly and is aligned with the Quarterly Business Survey completed by NICA and the University of Nebraska. A list of information sources is as follows: Surveys (BRE), focus groups, and other formal market research activities; Client assessments, one-on-one site engagements (staff, diplomats); NMEP workshops, seminars, including evaluations; NMEP Interactions via phone, fax, e-mail and internet; Manufacturers listserve (NEBMAN); Contact with stakeholders and partners including State Chamber, CC, NEDA, Diplomats, industry associations; Input from NMEP board members; pilot workshops, seminars for NICA members Discussions with other MEP centers; Industry publications, NPPD research, NIST research and performance data; Staff participation in professional affiliations. Research staff analysis Market analysis for targets—fpc, etc. 3.1.2. Segmenting NMEP’s Market: Our basic analysis includes establishing relevant SME segments by the number of companies within SIC clusters, the size of those industries, the areas of growth industries, those in transition and their level of importance to the economy. Dun and Bradstreet provides segmentation data complied by geographies, SIC code, number of employees and management. NMEP analyses these data along with regional economic performance and trends, critical needs and competitive factors to establish corollary data from the targeted industry study. A Quarterly Business Survey gives us information on wages, salaries, growth and expansion. The Business Retention and Expansion Survey gives us information on problems which need addressing in the SME community. Our focus on Value-Added Agriculture, metal fabrication, machinery, and electrical manufacturing, while addressing regional needs of all manufacturers is supplemented by: Adaptation of the Michael Stone analysis for targeting 1027 of 2100 manufacturers in the state; Targeting research (Nebraska Utilities, NIFA, NEDA, Diplomats, Chambers, DED, UN). 3.1.3. Evaluation/Improvement of Market Analysis NMEP constantly collects, analyses and updates all important factors to better define its markets and to keep pace with regional and business changes. The FileMaker Pro database is maintained and updated frequently to reflect new information. The leadership team confers with industry experts and leaders, and customers to identify emerging trends. New services are developed utilizing a process of data analysis, client feedback, feasibility, cost/benefit ratios, market potential, impact potential and our delivery capacity. Our exchange of information and review of the services occur in: 3-4 Management and staff meetings; Strategic planning meetings. 3-5 3-6 Our strategic areas for growth are Value-added agriculture, Metal Fabrication, Machinery, and Electronics. 3.2 3.2.1 Customer Relationship Management Relationship Management The Customer Agent model is the foundation for client success, regional economic impact and NMEP’s reputation and viability. Our customer agents work with their SMEs to integrate their services into their planning processes. Assessments are utilized to establish competitive strategies and identify strengths and weaknesses. Customer Agents educate clients about the range of available services and resources. Before beginning, the long-term implications of a project are reviewed with the client along with recommendations for continuous improvement. 3.2.2. Customer Satisfaction To measure customer satisfaction and project impact, our MEP has signed up in the pilot test of a new NIST national survey service. In addition, our projects are surveyed within six months. To insure quality and real world relevance of projects, a Nebraska Industrial Competitiveness Alliance representative will audit program projects and results. Client satisfaction starts at the beginning of a project by aligning business expectations with their needs. Throughout the project, CAs keep track of expectations. NMEP uses formal surveys in Value-added Agriculture projects mailed to clients in the three months following completion of the project. We also use repeat business as an indirect measure of client satisfaction and analyze, monitor, and respond to trends to ensure maximum satisfaction. Referral and testimonials on specific projects further indicate the level of confidence and satisfaction with core service areas. 3.2.3 Customer Access Management NMEP has provided multiple avenues for clients to access or communicate with staff: Regional offices in Scottsbluff, Grand Island, Hastings, Columbus, Lincoln and Omaha; 1-800-MEP4MFG; Fax, Phone, E-mail, internet, listserve, cell phones; CIO Award for Excellence on our Website Direct mail, broadcast fax; and, A standard operating procedure for handling inquiries from clients ensures a timely response. 3.2.4 Customer Contact Administration Administrative processes are automated through the Filemaker Pro database. All customer data from initial contact to proposal writing to project close are available to staff through access to the database. The financial manager compares the invoice request with the original contract to ensure accuracy before mailing an invoice. Invoices are mailed within the week in which the request was placed. To ensure the continuing relationship with the client, the: Customer Agent as project manager; Disputes on billing, contract administration and all other contact by CA. 3.2.5 Complaint Management 3-7 Any performance-related negative comment from any client at any time trigger a review process. The leadership team rigorously reviews complaints for root cause and appropriate action. We respond to complaints within 24 hours. We encourage direct action from CAs on complaints, however no complaint can be closed out without the Director’s approval. Our high Customer Satisfaction Rate has generated little use of the complaint process. 3.2.6. Evaluation/Improvement of Relationship Building Customer relationship management is subject to ongoing review and improvement. Measure such as: Repeat business; Positive referrals; Complaints; Surveys; are all Tracked by Filemaker Pro. We pay special attention to satisfaction levels and trends, repeat business, and growth in project size when developing new services, operating plans, and customer relationship strategies 3-8 Chapter 4 CENTER PERFORMANCE INFORMATION AND ANALYSIS 4.1 Performance Measurement Information In an effort to link significant business determinants with our goals and objectives, NMEP continually collects data and information pertinent to our marketplaces and operations. The collection of data and information is guided by the following criteria: Logistics of current strategies; Operational efficiency; Customer/employee satisfaction; Impact by center services; and, Market research and penetration. 4.1.1 Key Performance Information Figure 4.1.1 displays the data and information NMEP collects and analyzes regularly in each business aspect, and their responsible party and key users: 4.1.2 Developing Data As an entity of the State of Nebraska, NMEP is required to process financial data in accord with the NAIS accounting system for State of Nebraska. The State uses a Cash basis fund accounting system. We accomplish this through the 1997 passage of Legislative Bill (LB) 659 which establishes NICA as a division of the Department of Economic Development. Headquarters staff in Lincoln are responsible for validating, assembling, and controlling the data submitted to the NAIS system for processing. This arrangement provides for a structured control environment for processing financial transactions. NMEP utilizes Access and Excel to perform billing and maintain accounts receivable. Additionally, Access and Excel tracks income and expenses and generates reports that cannot be generated through the NAIS system. NMEP performance is tracked relative to our goals. Annual performance reviews are conducted. In addition, the following metrics are reported monthly, and monitored yearly: program development, marketing, events, meetings, research and development, training, administration, personal and projects. A graphic and worksheet sample of the Nebraska MEP TimeLog Summary is included in 7.5 and our MEP Staff Roster is found in CP-4. The NMEP has implemented the Filemaker Pro database. Several types of information are being collected. Some information is gathered in order to track the progress being made in reaching clients and explaining our MEP services. For this purpose, workshop information, contact reports, speaking engagements and other forms of general information sharing are collected. Field staff who visit firms and engage the firm in discussions on productivity issues record the information into the Filemaker Pro database. Monthly reports are forwarded to the Director for inclusion in the quarterly report to NIST. Certain data elements will be collected from all firms. These include company name, address, primary and secondary SIC codes, whether the firm engages in defense contracting, county, number of employees, types of activities for projects—e.g. business management, CAD/CAM, market development, 4-1 plant layout, etc. A third type of information helps to allocate staff time among projects. The Contract Resource Plan and Scope of Work forms track the use of staff to projects. 4-2 Figure 4.1.1 Key Performance Measurement Regularly Collected and Reported Service/Product Delivery Survey Response Rate Survey Satisfaction Rate** Number of Clients Reporting positive impact** Impact-Sales** Impact-Material** Impact-Inventory** Impact-Other** Impact-Jobs Created** Impact-Jobs Retained** User Frequency NICA, NOC, CA, HQ NICA, NOC, CA, HQ NICA, NOC, CA, HQ NICA, NOC, CA, HQ NICA, NOC, CA, HQ NICA, NOC, CA, HQ NICA, NOC, CA, HQ NICA, NOC, CA, HQ NICA, NOC, CA, HQ M M M M M M M M M NOC, CA, HQ NOC, CA, HQ NOC, CA, HQ NOC, CA, HQ NOC, CA, HQ NOC, CA, HQ NOC, CA, HQ NOC, CA, HQ NOC, CA, HQ Q M Q M M M Q Q Q NOC, CA, HQ NOC, CA, HQ NOC, CA, HQ NOC, CA, HQ W M M M Comparative New Projects** Number of Clients** Number of Prospects** Number of Field Staff** Number of Adm. Staff** Number of Tech. Staff** Projects by SIC Code** Projects by Region** Projects by Size of SME** Financial Revenues** Expenses** In-kind Match** Cash Match** Operational Number of Contacts** NOC, CA, HQ M Number of Projects** NICA, NOC, CA, HQ Q Project Hours** NOC, CA, HQ M Project Revenue** NICA, NOC, CA, HQ Q Start Date NOC, CA, HQ M Close Date NOC, CA, HQ M Events/Participants/Companies** NICA, NOC, CA, HQ Q Third Party Projects** NICA, NOC, CA, HQ Q Job Training NOC, CA, HQ M ED Financing NOC, CA, HQ M Staff Hours by category NOC, CA, HQ M Project Hours** NICA, NOC, CA, HQ Q SMEs Served** NICA, NOC, CA, HQ Q Percentage of SMEs in targeted areas** NICA, NOC, CA, HQ Q Key: NICA (Nebraska Industrial Competitiveness Alliance); NOC (NICA Operating Committee); CA (Customer Agent); HQ (NMEP Operating Staff); W (Weekly); M (Monthly); Q (Quarterly); and, **Operating Plan. 4-3 Field staff have been trained in the usage of FileMaker Pro by Operations Director Dave Wright and reporting and evaluation by NIST/MEP Regional Manager Janice McClintic. In addition, the NMEP benefits from integration with the Department of Economic Development with Financial statements audited annually by State of Nebraska. 4.1.3 Comparative Performance Information In most cases, benchmarking data will also be gathered—sales, inventory, material and labor costs, plant size, equipment, and organization date. Benchmark data will provide a basis for measuring the impact of the improvement project. We regularly review our performance against other Centers through: Benchmarking against national centers by NIST/MEP; Benchmarking against regional centers by NIST/MEP; and, Benchmarking against centers of comparable size by NIST/MEP. 4.2. Performance Analysis 4.2.1. Analysis by senior leaders We manage the key performance metrics incorporated in the strategic plan and operating plan. These metrics summarize the numerous operational activities we analyze and track associated with the center. The leadership team regularly assesses performance and capabilities relative to the goals, plans and changing business needs of SMEs. Although activity based cost analysis has not been employed in the NMEP, steps toward this task are being developed. 4.2.2 Key Processes and Activity Information Analysis of performance data results in projections that are used to evaluate trends: Favorable trends recognized and shared with staff; Unfavorable trends are prioritized for corrective action. 4.2.3 Evaluate/Improve Systems NMEP continues to focus on the operational needs of the Customer Agents. These needs drive the improvements to the Filemaker Pro database system. Customer Agents and Administrative Staff jointly evaluates our information system. 4-4 Chapter 5 CENTER WORKFORCE PRACTICES AND WORK ENVIRONMENT 5.1 Work Practices and Organization Pursuant to the reorganization of the operational format of the MEP service delivery system, the Customer Agent has been identified as the primary need to move the program to a new level of service delivery. The role of the Customer Agent can then be detailed as follows: The Customer Agent (CA) serves a fixed group of customers, while the group does not need to be geographically continuous, logic would suggest that this would be the most efficient way to implement the mission of the CA. Positions have been filled across Nebraska. The CA must possess overall knowledge of manufacturing operations in a general sense, but need not have a specific manufacturing discipline or background to be successful. Field staff call upon firms in their area on a systematic basis. 1027 firms in Value-added Agriculture, Metal Fabrication, Machinery and Electrical with between 10 and 199 employees will receive priority over larger firms. The number of firms in this group vary greatly among service regions: Central (207), Metro (374), Mid-Plains (50), Northeast (94), Southeast (246), Western (56). 5.1.1 Work and job organization Our NMEP is organized in a Statewide network of field offices (6) within seven regions. The location of offices is shown in CP-3. CA focus; All six of the CAs are managed by the Center Director; NMEP service delivery capability organized in a matrix by region and function (CP-4); Marketing manager, service delivery directors have responsibility for generating awareness and leads; Administrative staff does financial management, information systems, management and reporting. 5.1.2 Performance Management System Employee success is recognized at Customer Agent team meetings each month. Performance evaluation built upon annual performance goals. Performance is reviewed internally and with the NOC and NICA/NMEP in their quarterly meetings. Performance of Center reviewed by NICA/MEP semiannually. Our Center goals are focused on impact and revenues. Compensation is capped by the State of Nebraska. 5.1.3 New Hires Our recruiting and hiring plan is directed toward obtaining high-performance employees by determining need from our operational goals and objectives. Recruiting is done on a team basis through the NOC. The jobs are posted in this fashion: Job description based on Job Profile completed by ACT WorkKeys; CA function is sales/customer relationship; Industrial experience is specific depending on needs of NOC; 5-1 5.1.4. Knowledge Building and Sharing We encourage internal and external communication to reinforce values, identification of issues, assessment of performance and recognition of success. Our communication includes: Integration of the Filemaker Pro and Website to improve communication and encourage collaboration; Collaboration encouraged through monthly meeting (fourth Tues.); Monthly NOC meetings; Weekly leadership team meetings; Staff participation in planning process; Annual review self-assessment by NIST/MEP; NIST/MEP working groups; Training/Report of training at monthly meetings; Train-the-trainer concept. 5.1.5 Evaluation and Improvement of Work Practices and Organization Customer service is the focus of our work practices and organization. The Leadership team has responsibility of driving continuous improvement. We are striving toward evaluation and improvement through: ISO 9000 Certification goal of July 1, 2001; Staff participation in Center Progress Report 5.2 Employee Education, Training, and Development 5.2.1 Education and training needs The NMEP evaluation process identifies the gaps in the needs of the organization, and provides professional development through company-reimbursed, employee chosen educational courses, as well as membership in professional organizations. Our strategic plan goal is to continue NMEP as a learning organization, and figure 5.2.1 is a model of this system. This requires investment in staff training, and requires: Publications, Coaching, feedback, Staff presentations, Skill-specific training, conferences, benchmarking; Training needs determined by WorkKeys Assessment; Annual performance reviews. 5.2.2 Education and Training Delivery Having staff that are trained to make effective calls on firms and have knowledge about manufacturing processes is critical to an effective program. Many staff members have participated in the annual Modernization Forum training sessions and special program meetings. Our staff have attended special training sessions on the Edgerton Quality Award, e-Commerce, ASQ’s ISO 9000-14000, Y2K, Theory of Constraints, Reporting and Evaluation and Lean Manufacturing. This training is specifically geared to improve the quality and proficiency of staff. Staff training is also included in the monthly staff meetings. These monthly meetings cover topics such as: a) record keeping, b) operating procedures, c) procedures for making contacts, sales techniques, d) 5-2 group dynamics, e) coaching techniques, f) evaluation procedures, and g) third party contracts. Because our staff has multiple backgrounds, cross training is provided to make certain that all staff are knowledgeable about the expertise that exists within the MEP organization. 5-3 5-4 Staff participate in the Mod-forum; WorkKeys “WIN” system; Filemaker Pro Training; NIST/MEP report training 5.2.3 Evaluating and Improving Education and training In accordance with 5.1, our evaluation and improvement activities, the Leadership team responsible for identifying key training needs. Training needs are discussed at the NOC team review. A procedure for evaluating education and training needs is in the development stage in the ISO 9000 process. 5.3 5.3.1 Employee Well-being and Satisfaction Enhancing the Work Environment Employees are hired by the State of Nebraska. All employees are given a: Defined benefit/retirement plan; Life Insurance; Medical/dental insurance; Vacation/Sick and personal days; and, A grievance resolution program. 5.3.2 Evaluation and Improvement of Employee Satisfaction Low turnover the last two years is an indication of employee satisfaction. ISO 9000 procedures include an: Annual performance review process; One-on-one meetings. 5-5 Chapter 6 CENTER PROCESS MANAGEMENT 6.1 Service and Product Offerings In identifying new service and product ideas we use the same vehicles mentioned in 3.1 for identifying SME needs. Target research, the Business Retention and Expansion Survey and the Quarterly Business Survey. A list of information sources is as follows: Surveys (BRE), focus groups, and other formal market research activities; Client assessments, one-on-one site engagements (staff, diplomats); NMEP workshops, seminars, including evaluations; NMEP Interactions via phone, fax, e-mail and internet; Manufacturers listserve (NEBMAN); Contact with stakeholders and partners including State Chamber, CC, NEDA, Diplomats, industry associations; Input from NMEP board members; pilot workshops, seminars for NICA members Discussions with other MEP centers; Industry publications, NPPD research, NIST research and performance data; Staff participation in professional affiliations. Research staff analysis Market analysis for targets—Food Processing, Metal Fabrication, Machinery, and Electronics. 6.1 New Products and Services (research listed in 3.1) The product and services development process has provided the Nebraska MEP access to a number of critical services for small- and medium-sized manufacturers, including: Engineering and Technology - provides the expertise in engineering functions such as manufacturing process analysis and improvement, Industrial and management systems engineering, manufacturing control systems, general test and evaluation planning including design qualification testing plus factory acceptance testing, and ISO 9000 and quality assurance system evaluation. The MEP also evaluates plant layouts, assess the need for equipment modernization, automation, robotics, evaluates energy consumption, water usage and conservation and waste and pollution prevention. Market Development- provides business and market development for manufacturers in the areas of operations plan development, business plan development, marketing plan development, export marketing assistance, financial analysis, marketing research, competitive industry analysis, media and promotion plan development, production layout-design, technical trouble shooting, start-up entrepreneurial assistance and human resource management review. Business Consulting and Financial Packaging - strategic planning, loan packaging, financial recovery, computer training, and rural development. Certain production issues such as vendor control, just-in-time delivery and writing procedures related to quality assurance are also being addressed by NBDC Technical Services - laboratory research assistance in test product manufacturing, sensory evaluation, short term customer processing, safety and shelf life evaluation, food engineering, packaging, food chemistry and biochemistry, microbiology and quality assurance, toxicology, biotechnology/bioprocessing, nutrition and other analytical services, food labeling, food sanitation and HAACP training assistance and extrusion. 6-1 Workforce Development - job profiling and training in manufacturing disciplines such as statistical process control, just-in-time manufacturing, team building, problem solving decision making, machine tool technology, computer aided manufacturing, die making, quality control and inspection, production machining, cylindrical and centerless grinding, fluid power, architectural drafting, engineering drafting, blueprint reading, geometric dimensioning and tolerencing, welding and automotive. 6.1.1 Defining and Describing Service Offerings NMEP defines and describes its service offerings through the use of product/service sheets, brochures, website sections, manuals, cases studies, seminars and workshops. Descriptions and defining methods include service descriptions, tools, methods of performance, potential benefits and measurements of success. Figure 6.1.1. is a graphic description of this process. 6.1.2. Selecting, Designing and Introducing New Services We are designing an ISO 9000 Formal process for identifying and verifying unrecognized need, determining its business potential, and subsequently developing, documenting, pilot testing and implementing a new service or product. Figure 6.1.2. is a graphic description of this process. Members of the NICA board are frequent attendees at the ModForum where they attend product seminars and workshops. The NICA board also is involved in the testing of products in Nebraska. 6.1.3 Improving Services/Product Mix We are designing an ISO 9000 Formal process for improving services and products for NMEP. Figure 6.1.3. is a graphic representation of this process. Products are identified by clients, surveys, service partners for the NMEP (the NICA Operating Committee) and the NMEP operations group. Services and products are reviewed by the NOC and Customer Agents at their monthly meetings, NICA/MEP at quarterly meetings, and at headquarters on a weekly basis. 6.2 Marketing Operations NMEP’s marketing activity seeks to make the center the best known provider of consulting services to target industries and manufacturers. The NOC, Clients and surveys provide marketing leads and appointments to our Customer Agents. Where appropriate, Customer Agents make calls, help define customer needs, prepare proposals, and close sales. As NMEP moves toward the education environment, Customer Agents are involved in the planning, design and marketing of our seminars and workshops. 6.2.1 Methods, Materials, Channels, Events NMEP uses a wide variety of techniques to build awareness, develop new business, and seek referrals. Tactics include targeted direct mail, newsletters, tradeshows, outreach events, websites, and public relations. Figure 6.2.1. is a graphic representation of the marketing activity process. NMEP uses a wide variety of techniques to create demand for our services. These include seminars and workshops, trade shows, newsletters, direct mail, sales letters, website presentations, and cooperative marketing with our NMEP partners. 6-2 To support these activities, NMEP maintains a database of all SMEs in Nebraska and all referral sources who are appropriate contacts for targeted mailings. This database was compiled from the Nebraska Manufacturers Directory, partner resources, and Dun and Bradstreet’s Marketplace. It is continually updated. 6-3 6-4 6-5 6-6 6-7 Customer Agents are encouraged to stay closely involved with the development and implementation of outreach activities. Customer Agents are often called on to deliver seminars and workshops or to identify the qualified speaker. Our operating plan calls for 70 workshops and 70 seminars. 6.2.2 Creating a Strong Marketing Awareness Within the Center NMEP does regular marketing and sales training for its staff. Some portion on each agenda at monthly Customer Agent meetings is dedicated to giving our staff the necessary tools to sell the organization and core services. NMEP’s most effective source of leads is referrals. Owners and managers of smaller firms conduct much of their business on the basis of trust and established relationships. Referrals come from: Current Clients Partners NOC Staff BRE Survey 6.3 Customer Engagement and Sales 6.3.1 Following Up on Leads Figures 6.3.1 and 6.3.2 provide a process map of the engagement/sales process. Both Customer Agents and our service providers follow on leads from SMEs. All regional centers have exceptional staff, and they are backed-up by business and technical consultants. All those involved in client engagements use FileMaker Pro to help automate tracking and follow-up. Customer Agents make entries into the FileMaker Pro system at every level to record and track progress. 6.3.2 Clear Project Proposals and Informed Expectations The center has worked hard to improve client assessment tools to facilitate identifying needs and defining an appropriate scope of work. Beyond the use of standard materials/techniques in engaging the client, the center is entering a near-term thrust to apply ROI analysis at the proposal development stage (as well as post-closure). 6.3.3 Evaluating and Improving the Engagement/Sales Process Customer Agents have the prime responsibility for pursuing new clients and repeat business. New client business is tracked with FileMaker Pro. Repeat business can be cross-selling or add-on contracts. A procedure is used to evaluate progress on projects and take corrective action, which may result in add-on projects. Repeat business could be training and techniques for cross-selling into other service areas where integration into the economic development is vital. Our leadership team reviews quantitative information and compares performance against objectives. The center also surveys clients regarding proposal credibility and value, Customer Agent skills, and follow-up response. We continue monthly meetings with the Customer Agents and NOC service providers, and weekly or daily calls is often necessary for closing a deal. 6-8 6-9 6-10 6.4 Service Delivery 6.4.1 Ensuring Field Staff Understanding and Customer Expectations NMEP has developed process flows for one-on-one projects, Figure 6.4.1. Customer Agents have ultimate responsibility for delivering one-on-one services, and are also project managers for seminars or workshops offered in their area. There are five things the CA must do in this process: hold an initial meeting to confirm scope of work and deliverables; confirm objectives and success criteria; develop a task milestone plan; implement service delivery; and, manage project completion tasks. 6.4.2 Auxiliary Tasks Other service delivery responsibilities include data entry into FileMaker Pro, project close out, client success stories, case studies, timely reporting of client and project concerns, and timely reporting of new customer ideas for products. 6.4.3 Tracking Projects in Real Time The center generally relies on in-process billing complaints to track progress in project delivery. 6.4.4 Evaluating and Improving Service Delivery Process Various methods are used to evaluate and improve the service delivery process. Customer satisfaction data is gathered through NIST Census Bureau surveys, Westat Surveys, and Food Processing Surveys. This data is summarized by the Operations Manager to determine if there are positive or negative trends in the quality of service delivery. Specific problems are addressed one-on-one by the Center Director. Monitoring performance against goals for service delivery serves as a benchmark from which to improve. FileMaker Pro provides good information to Customer Agents to plan their workload, assess their time commitment to projects, marketing, research and development, meeting, seminars and program development. 6.5 Support Services In the analysis of the Center’s performance, NMEP tracks, improves, and looks at data on areas such as collections from customers, collections from funding partners, and our overhead rate. Headquarters staff in Lincoln are responsible for validating, assembling, and controlling the data submitted to the NAIS system for processing. This arrangement provides for a structured control environment for processing financial transactions. The main users of this information are the NMEP Operations Committee, headquarters staff and NICA/MEP. NMEP utilizes Access and Excel to perform billing and maintain accounts receivable. Additionally, Access and Excel tracks income and expenses and generates reports that cannot be generated through the NAIS system. NMEP performance is tracked relative to our goals. Annual performance reviews are conducted. In addition, the following metrics are reported monthly, and monitored yearly: program development, marketing, events, meetings, research and development, training, administration, personal and projects. 6-11 This system allows NMEP to fulfill our responsibilities under the cooperative agreement with NIST/MEP. 6-12 6-13 The NMEP has implemented the Filemaker Pro database. Several types of information are being collected. Some information is gathered in order to track the progress being made in reaching clients and explaining our MEP services. For this purpose, workshop information, contact reports, speaking engagements and other forms of general information sharing are collected. Field staff who visit firms and engage the firm in discussions on productivity issues record the information into the Filemaker Pro database. Monthly reports are forwarded to the Director for inclusion in the quarterly report to NIST. Certain data elements will be collected from all firms. These include company name, address, primary and secondary SIC codes, whether the firm engages in defense contracting, county, number of employees, types of activities for projects—e.g. business management, CAD/CAM, market development, plant layout, etc. A third type of information helps to allocate staff time among projects. The Contract Resource Plan and Scope of Work forms track the use of staff to projects. 6-14 Chapter 7 CENTER PERFORMANCE Performance Trends and Comparisons This section exhibits NMEP’s progress in achieving our objectives of high performance in key areas of market penetration, revenue generation, client and regional impact, employee satisfaction and capacity utilization. Data for fiscal years have been annualized from July 1-June 30. FY99 is for six months. 7.1 Customer and Regional Impact Results NIST surveys for NMEP’s history from 1994-1998 as detailed in the following figures summarize customer impact from center services/products. The first Figure 7.1.1, combines NIST customer impact indicators (changes in sales, capital investment, productivity) and shows an upward trend to $16 million per year. Figure 7.1.2 is the employment impact, and shows an upward trend over the period to 700 jobs per year. In Figure 7.1.3 we see the trend of impact of projects, per client. And, in Figure 7.1.4 trends in job impact per client is shown. Figure 7.1.1 7-1 Figure 7.1.2 Figure 7.1.3 7-2 Figure 7.1.4 Job Impacts per Project/Client Nebraska MEP 46.3 50 45 40 35 30 Jobs 25 20 15 10 5 0.1 1.4 0.8 0 '95-'96 '96-'97 '97-'98 Program Year 7.2 Market Penetration Results 7-3 '98-'99 (First 6 months) The increasing trends in value-added work per company are revealed in this section. Figure 7.2.1 shows the level of the center’s SME population served with value-added work by company; and Figure 7.2.2 shows completed projects by company SIC code. Figure 7.2.3 reveals patterns of market penetration by size, Figure 7.2.4 by top project categories, and Figure 7.2.5 by first-time customers. 7.3 Financial Profile and Health NMEP’s financial performance has maintained a strong growth pattern, showing improvements in sales, overall efficiency and productivity. The following figures show our performance in program income growth, Figure 7.3.1, financial profile and health 7.3.2. 7.4 Customer Satisfaction We use testimonials to emphasize high client impact and surveys to collect satisfaction data. A recent pilot survey by Westat revealed that 83% of our clients were highly satisfied with our value-added services. In addition, in one of our target markets, food processing, we do surveys three months after completion of work. In the Food Processing surveys we receive an approval rating of 4.7 on a scale of 05. 7.5 Capacity Utilization and Operational Efficiency NMEP efforts have been constant in an effort to improve the effectiveness of administration. Figure 7.5.1 shows the timelog summary used to track center staff hours spent delivering services, marketing, events, meetings, staff training, administration, research and development, personal time, and program development time. From this record we are able to show trends in administrative hours, Figure 7.5.2; program development hours, Figure 7.5.3; and, event hours, Figure 7.5.4. Figure 7.2.1 7-4 Completed Projects vs. Size of Region Nebraska MEP 800 732 700 600 466 465 500 400 300 211 200 128 100 146 120 23 76 89 99 9 0 Western Mid-Plains Central Northeast Metro MEP/Community College Region Number of Firms Southeast Number of Completed Projects Figure 7.2.2 Summary of Project Impacts by Company SIC Category* Nebraska MEP SIC Category Companies Surveyed $ Impacts Job Impacts Food (20) 41 $9,027,000 601 Metal Fab. (34) 35 $5,338,250 118 Machinery (35) 30 $45,000 15 Non Mfg 27 $59,000 4 Electrical (36) 16 $315,000 0 Transportation (10) 10 $95,000 0 Wood (24) 6 $6,000 0 Primary Metal (33) 6 $40,000 6 Chemical (28) 5 $75,000 0 Instrument (38) 5 $85,500 0 Printing (27) 4 $0 4 Textile (22) 2 $70,000 0 Paper (26) 2 $300,000 0 *Only SIC categories with reported impacts are listed 7-5 Figure 7.2.3 Figure 7.2.4 7-6 Figure 7.2.5 Figure 7.3.1 7-7 7-8 Figure 7.3.2 Nebraska MEP Financial Profile and Health Fiscal Year 1994 1995 1996 1997 1998 1999 NIST Funding $892,190 $892,190 $892,190 $664,040 $346,885 $433,330 State Match Revenue Generated $892,190 NA $892,190 NA $892,190 $100,910 $1,119,960 $189,574 $693,770 $147,116 $877,270 $349,567 7-9 7-10 Figure 7.5.2 Figure 7.5.3 7-11 Figure 7.5.4 7-12 7.6 Employee Well-Being and Satisfaction We are developing measures and/or indicators of employee well-being, satisfaction, and motivation for our ISO 9000 project. Measures we do track are turnover, Figure 7.6.1. Figure 7.6.1 7.7 Other Significant Accomplishments Engineering and technical services, marketing and business services, and workforce development assistance are basic for NMEP. As we move towards a learning environment, we will continue to offer a number of new, higher value services, including Lean workshops, Red Flags for Manufacturing, ISO and Quality assistance. Figure 7.7.l shows the increasing trend in company attendance at NMEP events and Figure 7.7.2 depicts the growth in the number of client employees receiving training from NMEP. Although the bulk of our projects remain service to small manufacturers (Figure 7.2.3), our increase in revenue generation comes from medium-sized manufacturers. Figure 7.7.3 shows a trend towards service to medium-sized companies while we continue to maintain our goal of service to all manufacturers. 7-13 Figure 7.7.1 Figure 7.7.2 7-14 Figure 7.7.3 7-15