Bookbinding S and the Conservation of Books

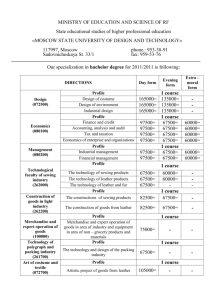

advertisement