3 DLS Getting Started_rev2.0

advertisement

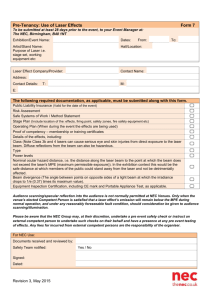

DIODE LASER SPECTROSCOPY GETTING STARTED OVERVIEW of the INSTRUMENT INITIAL SETUP FIRST EXPLORATIONS www.teachspin.com Rev 2.0 11/09 I. Overview of the Instrument (See the Apparatus Section 5 for details.) A. The Laser TeachSpin’s robust and reliable grating stabilized laser is both temperature and current regulated. When the grating is in place, it provides optical feedback that retroreflects the laser light to create an external cavity that stabilizes the laser to run at a controllable wavelength. A piezo stack, mounted in the grating support, allows the grating position to be modulated by an applied voltage. The laser temperature, laser current and piezo stack modulation are determined by individual modules of the Laser Diode Controller. A Plexiglas cover over the laser provides isolation from air currents and protects the knobs used to adjust the angle of the grating from accidental changes. There are two holes in the cover to allow the laser beam to exit undisturbed both with and without the diffraction grating in place. (The grating can be removed to study the way the laser behaves without grating stabilization.) B. The Detectors Your apparatus is supplied with three photodiode detectors. The detectors contain current to voltage converters. The detector response is linear when the voltage output signal is between 0 and -11.0 Volts so you want to make sure you are no where near the -11.0 saturation voltage. A switch on the back of the detector allows you to change the gain setting from 10 MΩ to 333 Ω in ten steps. The detectors have separate signal and power cables. Three DETECTOR POWER plugs are on the front panel of the controller. You can send the detector signal directly to an oscilloscope or to the DETECTOR MODULE of the Controller. C. The Absorption Cell Assembly The absorption cell assembly consists on an outer glass cylinder, an insulation layer, a heater assembly, a “cold-finger”, a thermocouple to monitor the temperature and the gas filled Rb cell itself. The cold-finger is a small piece of metal that fits over a small protrusion on the side of the cell. Because the metal is a good conductor and stays cooler than the cell, any excess rubidium will condense in the protrusion, rather than on the windows of the cell. The heater is both powered by and monitored from the controller. D. The Magnetic Field Coils The magnetic field coils are a Helmholtz pair which produces a uniform field at the Rubidium cell. They are used in experiments such as Resonant Faraday Rotation and Zeeman Splitting and must be powered by an external power supply. The Absorption Cell Assembly in mounted at the center, even when they are not in use. E. The Controller While almost all functions of the apparatus are controlled by the modules on the front on the Laser Diode Controller, the potentiometer used to set the laser temperature is on the back, to prevent accidental changes. The laser temperature determines the lasing frequency and will be set at the factory. The temperature should be touched only if, for some reason, a check of the Laser Temperature Set Point indicates it has been altered or the diode itself is changed. 3-1 Rev 2.0 11/09 The Modules – starting from the right DETECTOR/LOW PASS/DC LEVEL: This module provides power for three detectors and offers two detector inputs and a series of Monitor options. You can look at either detector or a combined signal. PIEZO CONTROLLER: This controls the piezo modulation, which determines the way the angle of the grating is changed and thus the change or “sweep” of the laser frequency. It includes a monitor output. RAMP GENERATOR: This provides a bipolar variable amplitude and frequency triangle wave which can be used, via the RAMP OUTPUT connection, to modulate either or both the piezo stack and the laser current. The resulting changes in the grating angle and current produce the variation or “sweep” of the laser frequency. The RAMP GENERATOR module can supply a wide range of frequencies and amplitudes. The SYNC OUTPUT connection for the oscilloscope is located in this module. CELL TEMPERATURE: The cell temperature is both set and monitored through keys on the LED display. It has been configured by TeachSpin. In case it is accidentally reset, see the Apparatus section for detailed help. CURRENT: The current module controls the current to the laser. It houses a modulation input so that the current can be ramped along with the piezo stack and an attenuator to control the degree of modulation. MONITORS: This set of connectors and indicators, located on the lower part of the cell temperature panel, provides a place to monitor, as a voltage, the set point temperature of the laser as well as the actual temperature and current. The indicator lights indicate the temperature of the laser in reference to the set point. F. TV and Camera The TV and camera will be used to observe both the light coming from the laser and the Rb fluorescence in the vapor cell. While invisible to our eyes, the 780 nm light can be detected by the camera and seen on the TV. G. The Optics and Connectors Your Diode Laser Spectroscopy system comes with a whole collection of bases supports, mirrors, polarizers, neutral density filters and beam splitters which can be combined in a wide variety of ways to do a wide range of experiments that is limited only by your imagination. II. Initial Setup – What to do first (This may take one or two hours.) These instructions will help you set up and align your laser for the first time. When you have carried out these detailed steps, your laser will be tuned to the Rubidium resonance lines. Once aligned, it is unlikely that the laser will need any more than minimal tweaking. A. Unpacking and Setting Up the Laser 1. The room used for your diode laser should be able to be closed to other users, first so that you can dim the room lights, but most importantly so you can have absolute confidence that no stray laser beams can escape and potentially cause harm to anyone. 3-2 Rev 2.0 11/09 2. Unpack the various components from their shipping containers and place everything on a table with plenty of room to work. 3. Place the Controller at one end of the optical breadboard. (we find it easier to put the controller and laser on the right side of the board – the laser connection is behind the left end of the controller.) 4. Mount the laser on one end of the breadboard so that the beam will go across the board. (Before making placing the laser head on the board or making connections to it, ground yourself to remove electrostatic voltages.) 5. Remove the protective plug from the laser head 9-pin D-connector. Connect the laser to the controller using the 9-pin D-cable provided, which plugs into the back of the controller. 6. Make sure the laser power switch (located on the left side of the controller, on the front) is in the off position. Then plug in the laser controller power cord and turn on the main power switch (located in the back, near the power cord). B. Setting up the Absorption Cell Assembly – the cell takes a while to get to optimum temperature so you want to have it heating up while you do other things. 1. Slide the Absorption Cell Assembly into the Magnetic Field Coils and secure it. 2. Place the assembly on the breadboard so that the laser beam will go through the cell. Put it eight inches or so away so that you have room to work between it and the laser. 3. Connect both cables from the cell assembly to the back of the controller. You will notice that the polarity of the banana plug heater wires does not matter. The polarity of the blue thermocouple connector, however, does matter. It will only plug into the blue receptacle one way. 4. When the power is turned on, the Cell Temperature controller (LED display on front panel) will first reset and then display the cell temperature. In five or ten minutes the cell temperature will be close to its factory established set-point temperature of 50 C.* You may check and/or change the cell temperature set-point as follows: a) Press the leftmost button on the cell temperature controller. It is marked by a circular arrow. The temperature controller will read SP1. b) Press the rightmost button on the cell temperature controller. The cell set-point temperature (in degrees C) will now be displayed. c) You can press the up/down arrow buttons to change the set-point. Start with a temperature of 50 C. d) Press the rightmost button. The display will read SP2 e) Press the leftmost button twice. The display will read RUN momentarily, then it will read the cell temperature. f) The cell temperature should read near the set-point after several minutes. You may proceed with the next step before the final temperature is reached. The Cell Temperature controller is not critical to operation of your diode laser. It merely improves the signal strength by increasing the rubidium density in the cell. See Theory section for a plot of Rb pressure versus temperature. * A starting temperature of 50 °C was chosen to give a nice strong absorption signal (about 90%). Once you become familiar with the system you may want to work at a lower temperature. 3-3 Rev 2.0 11/09 Trouble shooting: If the controller is not working as described please refer to the Apparatus section of the manual under Cell Temperature Controller for how to configure and set your controller. It is possible your controller became reset during shipping or by a student (the ever-present scapegoat). C. Starting up the Laser Operating note: The diode laser frequency depends on temperature. If not set correctly, you may not be able to get your laser to tune to the Rb resonance lines. The optimal temperature was determined at TeachSpin and is recorded on the data sheet. 1. Check the Diode Laser temperature: a) Use a voltmeter to read the TEMPERATURE SET-POINT in the MONITORS section of the controller chassis. This voltage should equal the Temperature Set-point recorded on the data sheet shipped with your laser. If it does not, adjust the 10-turn potentiometer on the back of the chassis to obtain the correct set-point. b) Make sure the LASER TEMPERATURE INDICATOR lights are both off. If either of these is on, then the laser temperature has not yet reached its set-point temperature. With a voltmeter connected to the LASER DIODE TEMPERATURE pin jacks, you may monitor the laser temperature. 2. PUT ON SAFETY GOGGLES. Your laser typically runs with an output optical power of 10-30 mW, all concentrated into a narrow, intense beam. Staring directly at the Sun sends about 1 mW into your eyes, and this is already enough to cause permanent eye damage. To make matters worse, the laser light has a wavelength close to 780 nm, which is nearly invisible. Practice proper laser safety – anyone that is in the room and can see the laser, should wear safety goggles when the laser is on. 3. Set the laser CURRENT potentiometer fully counterclockwise (low current) then turn the LASER POWER switch on. D. Aligning the Laser 1. Locate the IR viewing card. The sensitive area of the IR card is a dull orange color. This contains a polymer that absorbs UV light from the ambient lights in the room, especially fluorescent lights. The polymer molecules are then excited into a metastable state, and incident IR light from the laser can induce a transition that emits visible light. (Note the IR card will not work well if the room lights are off for an extended period.) The IR card allows you to “see”(actually locate) the laser beam even when you are wearing your protective goggles, since the goggles do not block the visible light emitted by the polymer. 2. Hold the IR card at the laser output (the hole in the plastic cover of the laser) while you turn up the laser CURRENT knob. You will need to turn the knob 3-4 turns before the beam becomes detectable on the card. 3-4 Rev 2.0 11/09 3. Set up the TV and Assemble the TV camera: a) Put the TV monitor near the controller and set it up to display camera image. b) Connect the power cable of the camera to the 12V power supply provided, and connect the camera output cable to the TV monitor. You should see an image on the monitor. D C ra C me a C c) Place the TV camera, mounted on an optical post, into a post holder. Then the camera can conveniently be placed on the optical table with the laser and other optical components. Buisness Card in Card Holder Figure 1. External Cavity Alignment Operating note: The camera lens can be focused over a broad range of working distances, from infinity to as close as a few centimeters. The focus is adjusted by turning the lens. Do NOT shine the laser beam directly into the TV camera, for this may damage the CCD sensor. 4. Place a business card in the Neutral Density Filter holder and locate it so that it intercepts the laser beam see Figure 1. Focus the TV camera on the card. Dim the room lights and turn the laser current to zero. Now increase the current while watching the TV monitor. You will see a light spot that becomes slightly brighter as you increase the current. Your diode laser is below threshold, it is not lasing, but only acting as an LED. As you continue to increase the current you will observe a sudden brightening of the beam spot and the appearance of a speckle pattern characteristic of lasing. Adjust the current so that the laser is just above threshold. You can measure the laser current with a voltmeter. A diode current of 50 mA. will give 5.0 Volt output on the LASER CURRENT in the MONITORS section. You can compare your measured value with the threshold current recorded on your data sheet. A lower threshold current represents better optical alignment. Do not be concerned if your threshold current is slightly higher than that recorded on your data sheet. You will align the cavity in the next few steps after which you can measure the threshold current again. 3-5 Rev 2.0 11/09 Note: Your laser was shipped with the laser aligned. It many cases it will need little if any adjustment. The following steps will allow you to check the alignment and optimize it, if necessary. 5. Look at the laser head itself. You will see two knobs protected by the plastic cover. The upper or top knob controls vertical alignment. The lower or side knob provides a wavelength selective horizontal alignment. Before beginning your alignment, it is important that you have read the first section of this manual Diode Laser Physics. It will be much easier to follow the procedure if you have some idea of the physics behind these adjustments. This may be the most difficult procedure you will need to follow in this experiment. For the uninitiated it is very easy to totally misalign the laser, which can be both frustrating and time consuming. If you are not familiar with diode laser adjustment, we ask that you follow each step closely. If you have trouble or do not observe what is described in a given step, do not go on to the next step! We have tried to anticipate possible problems and direct you to the solution. We also do not want to make you overly timid by this statement. Alignment of the external laser cavity is something that any experimental physicist can accomplish. You will need to become facile in the alignment, not only because your students may misalign the cavity, but also because eventually your diode will burn out, and you will have to replace it. This will involve an alignment of the cavity, starting from scratch. Figure 2: Picture showing TOP and SIDE Knobs used to align grating. Allen wrench is shown in Side Knob. 3-6 Rev 2.0 11/09 6. Vertical Alignment: Remove the plastic cover from the laser and set the current so that the laser is just above threshold. Adjust the TOP knob while watching the laser spot on the card using the TV camera. Keep track of where this knob started, and DO NOT TURN THE KNOB MORE THAN ONE HALF TURN. You may find it useful to use the 5/64” Allen wrench placed in the back of the knob as a position indicator. It is also easier to make small adjustments of the knob by using the long arm of the Allen wrench as a lever. You should see the laser spot change in intensity as the TOP knob is turned. If you rotate the TOP knob very slowly, you will notice that the bright “region” actually changes from bright to dim. These are modes of the laser. You should be able to distinguish six to ten of these modes, with fewer modes when the current is just above threshold. You are seeing different longitudinal modes in the external cavity defined by the grating and back facet of the diode. As you turn the top knob you are not only changing the grating angle but also the external cavity length. You have changed the cavity length by one half wave length when you move from one bright peak to the next. You will need to have to set the current just above threshold to see this clearly. This may involve a few iterations of setting the TOP knob to give an intensity maximum and then adjusting the laser current. Figure 3, at the right, shows an oscilloscope trace of the intensity of the laser as the TOP knob is adjusted. It will give you an idea of how the brightness of the spots you are seeing is varying. It is hard to tell the middle ones apart. For best alignment leave the laser in the middle of this vertical mode pattern as best you can. It is not necessary to sit right on one of the mode maxima, but only near the center of the mode pattern. The correct mode maximum will be set later with the side horizontal adjustment knob and piezo voltage. Note that finger pressure on the knob also changes the grating alignment, so remove your fingers often during this adjustment. If you find it difficult to turn the knob with a light touch, then you can use the Allen wrench placed in the back of the knob as a lever for adjustment. It is not critical for operation of your laser that you achieve near perfect vertical alignment of the grating. You will get adequate laser performance by simply turning the TOP knob to the intensity maximum. However, it has been found that the better the alignment the better the operation of the laser. Better operation being defined as wider mode-hop-free scans. If you are not able to see any change in laser intensity as you adjust the Top knob then STOP! Do not continue. Most likely both the SIDE and TOP knobs have both been moved by accident or during shipping. Please refer to “Aligning the external cavity” in the Apparatus section of the manual. 3-7 Rev 2.0 11/09 Operating note : The TOP and SIDE knobs are used to align the grating with respect to the diode. The lines on the grating run vertically. Figure 2 shows the diode laser with the cover off and the 5/64” Allen wrench placed in the SIDE knob. The first order diffraction from the grating is directed back into the diode. The zero order reflection from the grating is the light you observe leaving the laser. The TOP knob rotates the grating about an axis that is parallel to the table top. Turning the TOP knob changes the vertical angle of the light diffracted from the grating. But to first order it does not change the wavelength of the light that is diffracted back into the laser. The SIDE knob rotates the grating about an axis that is perpendicular to the table top. Turning the SIDE knob does changes the wavelength of the light that is diffracted back into the diode. E. Setting up to Observe Rubidium Fluorescence 1. Remove the index card and position the Rubidium Absorption Cell Assembly so that the laser beam passes through the center of the cell. You may use the IR viewing card to trace the path of the beam. CCD Camera Side Hole Rb Cell Cell Heater ND Filter Holder with Viewing Screen (Beam Block) Field Coils Figure 4. Setup for Observing Rubidium Florescence 2. Point the camera so it looks into the Rb cell from the Side Hole in the cell heater. If you place the camera up on the base of the cell holder you can position the camera so that it abuts the glass holder surrounding the Rb cell. It may also be helpful to dim the room lights since you will be looking for the fluorescence light emitted by the Rb atoms. 3. Set up the two channel oscilloscope that you will use for these experiments. Run a BNC cable from the RAMP OUTPUT of the RAMP GENERATOR module to an oscilloscope. Run a second cable from the RAMP GENERATOR SYNC. OUTPUT to the ‘scope trigger. Observe the output on the ‘scope as you adjust the RAMP GENERATOR settings. 3-8 Rev 2.0 11/09 4. Use The RAMP GENERATOR and PIEZO CONTROLLER to Set the Frequency Sweep a. Turn the ramp amplitude down and connect the RAMP OUTPUT from the oscilloscope to the modulation input connection on the PIEZO CONTROLLER MODULE. This is a good place to use one of the short BNC cables that came with the system. b. Connect the MONITOR OUTPUT of the PIEZO to Channel 1 of the oscilloscope. Turn the piezo OUTPUT OFFSET knob to zero. (The OUTPUT OFFSET changes the DC level of the monitor output. It does not change the voltage applied to the piezo stack. This control is used when locking the laser to an absorption feature and is not needed here.) c. Set the ramp generator frequency to about 10 Hz. Turn the piezo ATTENUATOR knob to one (1). Set the ramp generator AMPLITUDE knob to ten (10) and use the DC OFFSET knob of piezo controller to produce a large-amplitude triangle wave that is not clipped at the top or bottom. The piezo MONITOR OUTPUT should have a signal that runs from about 3 volts to about 8 volts. Operating note: The PIEZO CONTROLLER drives a small piezoelectric stack that moves the optical feedback grating. This scans the laser frequency (see the Diode Laser Physics section of this manual for more on how this works). CURRENT CELL TEMPERATURE RAMP GENERATOR PIEZO CONTROLLER DC OFFSET FREQUENCY RANGE .5 .4 .3 .2 100 mA Full Scale .4 Laser Temperature Indicator .6 .2 .8 0 MONITORS Laser Diode Temperature 1 .7 .8 .9 .1 1 1 0.1 10 0.8 100 1k 0.4 30us 10us min. 1.6 0 Multiplier 2 6 8 2 3 1 .4 2 4 .6 2 .8 0 10 AMPLITUDE Temperature Set Point 0 5 OFFSET RAMP SYNC. OUTPUT OUTPUT 0 1 ATTENUATOR MODULATION + 10ms 10 DC OFFSET 5 10 20 50 1 3 1 _ Laser Current INPUT 2 30 GAIN _ 0 5 OUTPUT OFFSET MONITOR 2 6 4 8 0 10 6 2 8 0 10 LASER DIODE CONT (Laser Saftey Goggles Require BALANCE OUTPUT DETECTOR INPUTS To Oscilloscope Chan. 1 To Oscilloscope Trigger Figure 5: Modules showing connections for setting the frequency sweep. 3-9 20 4 Below Set Pt. INPUT 5 15 100 GAIN + .2 MONITOR 1 FINE COARSE 100V Full Scale DC LEVEL 30ms 0.1s TIME CONSTANT 4 Above Set Pt. 0.3ms 1ms 0.1ms 3ms MONITOR 1.2 Reset 4 LOW PASS 10k 0.01 Frequency (Hz.) 2 ATTENUATOR MODULATION .6 DETECTOR DETECTOR POWER Rev 2.0 11/09 F. Actually Finding the Rb Fluorescence, Initial Horizontal Adjustment 1. Set the laser current to the value listed on your data sheet. You will need to connect a voltmeter to the LASER CURRENT MONITOR to accurately set the current. If the horizontal grating position has not been changed much during shipping or because of accidental adjustment, then you will see a flashing streak of light within the cell on the TV monitor. This is rubidium fluorescence. Atoms of Rb in the cell, absorb laser light at the atomic resonance frequency and re-emitting it in all directions. If you do not see any fluorescence, do not despair. You only need to make a slight adjustment of the SIDE knob. 2. Put the 5/64” allen wrench (hex key) in the back of the SIDE knob and use it as a rotation marker. Remember the starting position of the wrench; you could even draw a little picture in your lab book. While you observe the TV screen looking for the fluorescence flash, slowly rotate the SIDE knob first one way and then the other. You should not need to rotate it more than one half turn in either direction. 3. If still no fluorescence is observed, then return the SIDE knob to the starting position, and adjust the current in 3mA increments (about 1/3 of a turn) both above and below the Laser current recorded on you data sheet. At each new current setting rotate the SIDE knob again, so that you don’t lose your position, always return the knob to its starting position before changing the laser current. If you do NOT see any fluorescence, first repeat the above steps again, doing them with care. You might have someone else go through the steps as well. It’s easy to miss some detail and thus not observe fluorescence. In particular check the laser temperature, the vertical alignment, and make sure you are sweeping the piezo.* 4. If you still see no florescence then you can try making bigger excursions in the grating angle with the side knob (plus and minus one whole turn). It may be that the Cavity became grossly misaligned during shipping, refer to section A4-2. in the appendix for details on aligning the external cavity. 5. Once you see the florescence flash move the SIDE knob so that the florescence is always visible. Now adjust the laser current to make the florescence as bright as possible. G. Observing the Absorption Spectrum Using a Photodiode Detector 1. Connect a Photodiode Detector (PD) cable to the DETECTOR POWER output of the laser controller, and connect the Photodiode Detector output BNC to Channel two (2) of the oscilloscope. Set the Channel two (2) input coupling to DC, the gain to 5 Volts/div, and the vertical position so that ground is in the middle of the oscilloscope display. The signal from the Photodiode Detector is negative and saturates at about -11.0 volts. If you are uncomfortable observing a negative going signal, you can always use the invert function on your ‘scope. * You can check that the piezo is actually moving by doing the following. With the Ramp generator connected to the Piezo modulation input, turn the AMPLITUDE of Ramp to zero, change the ramp frequency to about 3 kHz. And then increase the AMPLITUDE. You should be able to hear the piezo vibrate. WARNING: Do not leave the piezo running at high frequency and amplitude for a long time. It will cause heating and damage to the piezo. 3 - 10 Rev 2.0 11/09 2. Put the Photodiode Detector in place to intercept the laser beam coming through the Rb cell. You can move the PD for alignment. You will have to adjust the Gain on the back of the PD. Make sure that the beam is hitting the sensor and bolt the photodetector down. Operating note: In the present configuration there is a very high intensity beam (power per unit area) going through the Rb cell. This much power “saturates” the transition, resulting in very little total absorption of the beam. 3. Attenuate the Signal Reaching the Detector a) Assemble the glass neutral density filter in a fixed mirror holder and place it in a post holder. Please refer to the Optics section in the Apparatus Chapter of the manual if you are unfamiliar with putting optical components into mounts. b) Place the attenuator between the laser and the Rb cell (not between the cell and photodiode). Adjust the PD Gain so you can observe something on the ‘scope showing that light is hitting the PD. For the best performance you want the PD Gain to be as high as possible without saturating the PD. This keeps the noise from the PD at a minimum. The PD gain changes in 1,3,10 steps, a signal level of 2 to 6 volts is reasonable. Block the beam with your hand to convince yourself that the PD is detecting the transmitted laser light. You should see a ‘scope signal that looks something like this: Figure 6: Upper trace (Channel 1) shows piezo monitor signal. Lower trace (channel 2) shows Detector output. Note that signal is “negative going” so absorption features appear as spikes. 3 - 11 Rev 2.0 11/09 4. Interpreting the Oscilloscope Signals a) The upper trace shown in Figure 6 is the piezo monitor, which shows the voltage on the piezoelectric stack as a function of time. The lower trace is from the photodiode, showing absorption dips due to the Rb vapor. Because we have a negative going signal, these appear as spikes. If the laser scanned “perfectly” in frequency (that is no mode hopping), you would see just some fraction of the Rb absorption spectrum. The energy levels of 85Rb and 87Rb and the Doppler broaden spectrum are show below: Figure 7: Energy level Diagrams Figure 8: Doppler broadened spectrum b) The absorption dips in your trace are interrupted by various “mode hops” – when the laser frequency jumps suddenly. Refer to the Diode Laser Physics section for a discussion of mode hops. Observe how the signal changes when you vary the laser current and the piezo drive parameters. Please explore the parameter space. H. Horizontal Modes, Final Horizontal Adjustment 1. Adjust the laser current and piezo voltage so that a “nice” absorption spectrum is centered on the oscilloscope. This takes a little practice. As with the vertical adjustment, there are also horizontal modes. These modes are slightly different, in that turning the horizontal move through two or three of these modes by changing the piezo DC LEVEL voltage. a) Place the 5/64” allen wrench (hex key) in the back of the SIDE knob with the long arm of the allen wrench sticking out at about a 45° angle. (See picture at step 15). You will use the allen wrench as a lever to gently move through the horizontal modes. b) Watch the oscilloscope display as you gently push on the end of the allen wrench. You should be able to identify six to eight modes in which the Rb absorption is still visible on the oscilloscope. You want to set the Side knob in the middle of this mode pattern. c) You might notice that the modes at the ends have a shorter and more erratic scan over the Rb absorption. You do not need to make an exact adjustment with the Side knob as the Piezo DC OFFSET voltage can be used to fine tune to the mode. With proper alignment and laser current adjustment you should be able to set a scan that covers the first three lines in the absorption spectrum (87b, 85b, and 85a as shown in Figure 9). 3 - 12 Rev 2.0 11/09 Figure 9: Scan showing first three absorption lines 2. You may notice a few “extra” features at the ends of a scan right before a mode hop. These feature look like (and are) replicas of the strong 85b and 87b absorptions and appear near where you would expect to find the 87a absorption. The “extra” features are associated with relaxation oscillations in the diode laser. (See Diode Laser Physics Section). By reducing the laser current and adjusting the Piezo DC LEVEL, you should be able to get a nice scan showing the 85a and 87a features. This is shown in Figure 10. Figure 10: Scan improved by adjustments to laser current and piezo DC level. 3 - 13 Rev 2.0 11/09 I. Using Simultaneous Current and Piezo Modulation to produce a larger scan range without mode hops. (See the Diode Laser Physics section for an explanation.) 1. Set the laser CURRENT ATTENUATOR knob to zero. Attach the BNC splitter “F” connector to the RAMP OUTPUT on the RAMP GENERATOR. Plug one BNC from the RAMP OUTPUT to the MODULATION INPUT of the PIEZO CONTROLLER, and the second BNC from RAMP OUTPUT to the CURRENT MODULATION INPUT. 2. Turn the ramp generator amplitude up to maximum, and watch what happens when you turn up the current attenuator knob. With some tweaking you should be able to produce a full trace over the Rb spectrum. The oscilloscope invert function has been used to show the trace in what “looks” more like an absorption spectrum in the Figure 11. Note the correspondence to the expected atomic Rb spectrum shown in Figure 8 Figure 11: Expanded Scan Showing Four Absorption Lines Operating point: The depth of the lines depends on the length of the Rb cell and the atomic density, the latter depending on cell temperature. You can explore this by changing the cell temperature. 3. You can see in the above that the background intensity changes considerably with the scan. This is because you are now scanning the laser intensity (via the current) together with the laser frequency (via the piezo). You can correct for this effect in a number of ways. One way is to digitally record a spectrum with the cell in place, and then record a second spectrum with the cell removed, and finally divide the two signals in software. This has the advantage that only a single photodetector is needed, but the disadvantage that the two traces are not recorded simultaneously. Another way to accomplish this is by using a second photodiode, as in the following layout. 3 - 14 Rev 2.0 11/09 Detector 2 to (-) INPUT CCD Camera Photodiode Detector ND Filter Holder with Gelatin Filters Rb /5 50 Photodiode Detector Side Hole 0 Cell Cell Heater S. B. Detector 1 to (+) INPUT Glass ND Filter Field Coils Figure 12: Apparatus set up to use two detectors J. Using Two Photodiode Detectors to Compare a Beam directly from the Laser to one that has passed through rubidium vapor 1. You will need to place the 50/50 Beam splitter in a mirror mount. Please refer to the Optics section in the Apparatus Chapter of the manual if you are unfamiliar with putting optical components into mounts. 2. With this experimental configuration you will detect two simultaneous signals, one with and one without the Rb absorption, and then subtract the spectra. You will use the Detector electronics on the Laser Diode Controller. To Oscilloscope Chan. 1 DANGER CURRENT CELL TEMPERATURE RAMP GENERATOR PIEZO CONTROLLER Laser Saftey Goggles Required for Everyone in Lab .3 .2 100 mA Full Scale .4 .8 0 MONITORS Laser Temperature Indicator .6 .2 ON Laser Diode Temperature 1 MODULATION .6 .7 .8 .9 .1 1 10 0.8 100 1k 30us 10us min. 1.6 10k 0.01 0 Multiplier 2 6 8 0 10 AMPLITUDE Temperature Set Point 0.3ms 1ms 0.1ms 3ms 1.2 0.4 2 3 1 .4 4 .6 2 1 3 .8 1 0 5 OFFSET RAMP SYNC. OUTPUT OUTPUT 0 1 ATTENUATOR MODULATION 15 10 DC OFFSET 5 10 20 2 50 5 _ 25 30 GAIN Laser Current INPUT 0 5 OUTPUT OFFSET MONITOR OUTPUT BNC "F" To Oscilloscope Trigger GAIN 2 6 4 8 0 10 6 2 8 0 10 LASER DIODE CONTROLLER (Laser Saftey Goggles Required) BALANCE DETECTOR INPUTS From PD 2 DETECTOR POWER From PD 1 Figure 13: Controller Modules showing connections for using two photodiode detectors 3. Connect the BNC from the Photodiode Detector 1 to the right most (-) DETECTOR INPUT. (This will invert the signal from PD 1 so that absorptions will show as dips.) Set the BALANCE knob above the (-) INPUT to 1.0 (fully CW). Set the GAIN to 1. Connect a BNC Cable from the MONITOR connector above the gain triangle to Channel 1 on the ‘scope. 3 - 15 OUTPUT 4 Below Set Pt. INPUT 20 100 + .2 + 10ms 1 FINE COARSE 100V Full Scale DC LEVEL MONITOR 30ms 0.1s TIME CONSTANT Reset 4 LOW PASS MONITOR 4 Above Set Pt. OFF 1 0.1 Frequency (Hz.) 2 ATTENUATOR LASER POWER .5 .4 Class 3B Laser 780 nm. 80mW CW DETECTOR DC OFFSET FREQUENCY RANGE Rev 2.0 11/09 Change the BALANCE knob and observe the effect on the ‘scope. Position a second Photodiode Detector to intercept the beam that has been split off by the Beam Splitter. Connect the power cable of the detector to one of the open ports. Connect the BNC from Photodiode Detector 2 to the (+) or left most DETECTOR INPUT. Set the BALANCE knob above the (+) INPUT to 1.0 (fully CW) and turn BALANCE knob above the (-) INPUT to 0. Adjust the Gain on the back of Photodiode Detector 2 for a “good” (2-6 volts) level signal on the ‘scope and position the photodiode for a maximum signal. Now increase the BALANCE knob above the (-) INPUT to 1.0 and adjust the BALANCE to get a spectrum like the one is Figure 14. Figure 14: Trace for Channel 1 only showing the combined signal from the detectors. Subtracting the signals removes the effect of “ramping” the current. The beams reaching both detectors are varying at the same rate and the BALANCE controls are used compensate for any difference in intensity. The trace shows an excellent correspondence to the expected spectrum, with all four Rb absorption dips on a flat background. Note, however, that the subtraction technique does not immediately give an absolute measurement of absorption, while the digital method does. Operating note: You should always be wary that zero light on a photodiode may not correspond to zero voltage output. You can check this by simply blocking the beam and noting the voltage 3 - 16 Rev 2.0 11/09 K. All Finished At this point the initial alignment is complete, and you are ready to move on to the more sophisticated spectroscopy experiments. You may need to realign the grating feedback from time to time, following the above procedures. If not disturbed, however, the alignment will likely be stable for months. L. Shutting Down If you are not using the laser for a few hours for some reason, you can you can leave the controller on. Then the diode laser and the Rb cell will stay at their operating temperatures and be ready to go when you need it. BUT TURN THE LASER CURRENT OFF. You should turn the laser current down, and the laser power switch off, whenever you leave the lab. This is a safety precaution, plus it will prolong the life of your laser. With use the diode laser will eventually burn out and need to be replaced, so leave the laser itself off when not in use. It’s okay to leave the ramp generator and piezo controller on and running at whatever setting you wish (for examples, the settings determined above). You can also leave the Rb cell temperature at whatever setting you wish. Then these will be set up when you want to use the laser – just turn on the laser power switch and turn up the current. After the laser warms up briefly, you should have essentially the same spectrum you had when you turned the laser current off. We do not recommend leaving the controller on overnight and unattended even if the laser current has been turned off. 3 - 17 Rev 2.0 11/09 III. Observing Saturated Absorption A. The Optical Plan There are countless ways in which the optics could be configured to do observe the Saturated Absorptions Spectrum (SAS of Rubidium. A complete diagram of the configuration we will guide you in building is shown below in Figure 1. (A different layout is used in the lab notes from Caltech which are at the end of this manual.) Detector 2 to (+) INPUT Detector 1 to (-) INPUT Photodiode Detector Photodiode Detector CCD Camera M BS irr 0 or 2 /5 50 Rb Cell /9 10 M 0 irr 1 BS or Glass ND Filter Figure 1. Complete SAS setup B. Some Basics Before We Begin 1. Keep the beam height above the table constant as you bounce the beam off the mirrors. Since the center of the absorption cell and the laser are 4” (10 cm) above the table top, the beam should be there also. You can use the viewing card to check the beam height. Place the viewing card in the neutral density beam holder so that the marked line matches the top of the holder. Now, set the height so that the top edge of the holder, and thus the center of the viewing card, is 4 inches above the tabletop. 3 - 18 Rev 2.0 11/09 2. When placing optics, try to start with the beam centered in the optic. This gives you maximum adjustment range before the beam “walks off” the end of the optic and you have to reposition the mount. 3. When using the optical mounts to hold beam splitters, observe that there are two possible configurations of the mount. When looking at the mount from above, the upper adjustment screw can be placed on the right or the left. If placed on the wrong side, the support for the upper adjustment screw will block the transmitted beam. The upper screws are shown with a blackened edge in the figures below. To change orientations, you must remove the mount from the post and use the orthogonal mounting hole. 4. Spend a bit of time planning your optical layout before you start. 3 - 19 Rev 2.0 11/09 C. Placing the Components Now that you have completed the Initial Setup and have observed the Doppler broadened absorption spectrum of Rubidium you are ready to look for saturated absorption. 1. Make sure you have two mounted mirrors, a 10/90 and a 50/50 beamsplitter assembled. 2. Reconfigure the apparatus you have been using into the layout shown in Figure 2. (This is only part of the complete SAS setup. We’ll add the rest later.) BE SURE TO HAVE A BEAM BLOCK IN PLACE AS SHOWN Detector 2 to (+) INPUT Detector 1 to (-) INPUT Photodiode Detector Rb Cell CCD Camera Photodiode Detector /9 10 0 Beam Block BS Glass ND Filter Figure 2. Start of SAS setup with 1O wedged beam splitter in place We have used the 1O wedged beam splitter which yields two reflected beams, one from each face. The small angle of the wedge causes the beams to diverge slowly so that both beams can travel through the cell to the two photodetectors. The second photodetector (PD) is not needed to “see” the SAS. It is used in the final electronic subtraction to remove the absorptive background signal. If you do not intend to use this electronics “trick,” you can leave the second detector out of the setup. Position the PD’s to maximize the signal level from each. 3 - 20 Rev 2.0 11/09 Monitoring the output of the Detectors, you should observe the now familiar Rb absorption spectrum on your ‘scope. 3. Now, add the two turning mirrors to the setup, as shown in Figure 3. Move the Beam Blocker to the new location shown. Detector 2 to (+) INPUT Detector 1 to (-) INPUT Photodiode Detector irr or 2 Photodiode Detector Rb Cell CCD Camera M Beam Block 0 r1 BS o irr /9 10 M Glass ND Filter Figure 3. Turning mirrors added to setup. D. Understanding the Functions of the Beams We are now ready to add the important 50/50 beam splitter as shown in Figure 4. But first let’s talk about the motivation for all the beams flying around. The initial 10%/90% beamsplitter has generated two weak 'probe' beams, and you've seen that each of them, passing through the cell to a photodetector, is a probe of the transmission of the cell. But the stronger beam transmitted through the 10/90 beamsplitter has now been brought around to the far side of the cell, and is ready to be sent through the cell, in the opposite direction of the probe beams, and overlapping one of the two probe beams inside the cell. (You want to overlap the beam going to Detector 1.) The stronger beam is called the 'pump' beam, and what it 'pumps' is the atoms being probed by only one of the two probe beams. Because we are using a 50/50 beamsplitter, only half the pump beam is sent through the cell, and only half of the probe beam gets through to the photodetector, PD1. The important function of the 50/50 BS, however, is to create the desired anti-parallelism of the pump beam and one of the probe beams. 3 - 21 Rev 2.0 11/09 There are two fine points to observe in Figure 4. First note the upper adjustment knob on the 50/50 BS mount is on the side such that the probe beam can pass through the mount. You should also observe that the mount is placed such that the beam going to Detector 1 passes through the 50/50 beam splitter, but the beam going to Detector 2 misses both the beam splitter and the edge of the mount that is holding the BS. With the 50/50 beam splitter in place, we are ready to align the strong pump beam so that it is anti-parallel to the weak probe beam going to detector 1. (You may want to read the appendix that has a short discussion of the algorithm used to position a beam in space.) Remove the glass ND filter from the beam path. This will make it easier to see the two beams. Use the IR viewing card to observe the beams at position 1 which is right before the probe beam goes through the 50/50 BS. The IR viewing card has a circular hole on its backside so that you can observe beams from both directions. Use the adjustment screws on Mirror 1 or 2 to overlap the two beam spots at position 1. Detector 2 to (+) INPUT Detector 1 to (-) INPUT Photodiode Detector Photodiode Detector M BS irr 0 or 2 /5 50 IR viewing card position 1 Rb Cell CCD Camera Over lap these two beams IR viewing card position 2 /9 10 M 0 or 1 BS irr Glass ND Filter Figure 4. Aligning pump and probe beams. 3 - 22 Rev 2.0 11/09 Now, move the IR viewing card to position 2 (between the Rb cell and the 10/90 BS). Use the adjustment screws on the 50/50 BS mount to overlap the two beams at this position. It is very likely that the strong pump beam will not be visible at position 2 initially. You may have to loosen the screw that secures the post on the 50/50 BS and rotate it till you can find the beam. If all else fails and you cannot get the beams to overlap easily, you can temporarily move the Rb cell and magnet off to the side so that you can trace the pump beam path from the 50/50 BS. Once the beams are overlapped at position 2, move back to position 1 and check the beams. Again use the mirrors to overlap the beams here. After a few iterations, you should be able to get the pump beam and one of the probe beams overlapping in space and antiparallel in direction. Now replace the glass ND filter (and the Rb cell, if you removed it) into the beam path. Look at the absorption signal on the oscilloscope. Expand the scale so that you can observe the two large absorption features. If your beams are close to being aligned, you will start to see some sharp spikes within the broad absorptions. See Figure 5. These “spikes” indicate that the ability of the rubidium atoms to absorb photons from the probe beam has been diminished; more light from the probe beam is actually reaching the detector. This is because atoms which, in the past, would have absorbed the probe beam photons are already in the excited state because they have absorbed photons from the “pump” beam. You may now try to maximize the size of these spikes by tweaking the adjustment screws on the mirrors and the 50/50 BS. (a) (b) Figure 5. Observation of SAS features (a) Beams are partially overlapped and some SAS signal is visible (b) Signal after tweaking of mirrors and 50/50 beamsplitter. If you are “too” good at this alignment, the two beams may be so perfectly anti-parallel that the strong pump beam comes through the cell and, bouncing off the 10/90, is reflected back into the laser. When this happens, the laser will no longer scan through the spectrum continuously, but in a series of steps. You may observe a spectrum that looks like that shown 3 - 23 Rev 2.0 11/09 in Figure 6. This feedback is undesirable, but it does show that you have perfected the alignment of the two beams. Now you can slightly misalign the two beams such that the feedback does not corrupt the smooth scan of the laser. You may have noticed that the Caltech lab notes show an opto-isolator right after the laser. The opto-isolator will stop this feedback from getting into the laser, but it is not essential for operation of the system. Another technique to reduce feedback is to put more ND filters in the beam path. An added filter attenuates the reflected beam twice, once on the way out and again on the return trip. Figure 6. When the anti-parallelism is too close to perfect, there is feedback into the laser that corrupts the frequency sweep. The ‘staircase’ appearance of the absorption profile is the indication of this. If you have set up the second photodetector, you will now be able to use an electronics “trick” to isolate the SAS features. To preview this capability, send the two photodetector signals to the two channels of an oscilloscope, and adjust things until you can see what's similar about the two signals, and what's different. Now you are ready use the detector electronics section of your electronics box to isolate that difference. (You will be subtracting out most of the broad absorption signal.) Put the signal from Detector 1 into the minus input and that from Detector 2 into the plus input of the detector section of the electronics box. Attach the monitor output to the ‘scope. Set the plus balance control to zero and the minus balance control to one and observe the signal from Detector 1 on the ‘scope. Adjust the gain on Detector 1 so that you have a large signal (several volts) but not so large as to saturate the detector (maximum signal less than 10 volts). Now, set the plus balance to one and the minus balance to zero and observe the signal form Detector 2. It will be inverted, with negative voltage values. Again adjust the gain of Detector 2 for a signal level that is comparable to that seen by Detector 1. Because the beam going to Detector 2 is not attenuated by the 50/50 beam splitter, the gain needed on Detector 2 will be less than that of Detector 1. (Typically Detector 1 needs a gain setting of 1.0 MΩ and Detector 2 a gain of 330 kΩ.) 3 - 24 Rev 2.0 11/09 Now set both balance knobs to one and then reduce the balance on the larger signal so that the Doppler broadened background is removed. This subtraction is never perfect, so there will always be some residual broad absorption signal remaining. You may now raise the gain setting on the difference signal and bring the SAS spikes up to the volt level. You are now ready to record some beautiful SAS traces. (a) Figure 7. SAS traces with background subtraction. (a) Rb87 F=2 and Rb85 F=3 (b) Expanded view of Rb87 F=2. (b) It is interesting to study these signals as a function of the intensity in each of the beams. The above traces are power broadened. To observe the narrowest linewidths, you will have to work at very low optical power levels in both the pump and the probe beams. You can use neutral-density filters to attenuate the beams. You will also need to darken your room to minimize ambient light falling into your photodetectors. 3 - 25 Rev 2.0 11/09 IV. Aligning a Michelson Interferometer Mirror 2 Photodiode Detector Mirror 1 50:50 Beam Splitter Pick-off portion of strong beam 0 /9 10 BS Figure 1: Overview of un-equal arm Michelson. Find a spot on the table to lay out the Michelson interferometer (MI). You must use the filter holder to hold the 50/50 Beam Splitter (BS). A mirror mount will not allow the beam to come in and exit from all four directions. This complicates the alignment as one can only make coarse adjustments of the 50/50 BS. Keep Mirror 1 as close to the 50/50 BS as possible. Use a wedged or flat piece of glass as the 10/90 BS to pick off a fraction of the laser beam. Now look at Figure 2 below. We will use a business card with a hole punched in it to observe the reflected beam from each of the mirrors. Adjust the business card and card holder so that the incoming beam goes through the hole. Use the CCD camera to observe the beam reflected from the mirror. Adjust the mirror to send the out going beam back through the same hole. Do this for both mirrors as shown in Figure 2. 3 - 26 Rev 2.0 11/09 Mirror 1 D C ra C me a C 50:50 Beam Splitter D C ra C me a C Business Card w/ hole in Card Holder Mirror 2 Mirror 50:50 Beam Splitter Business Card w/ hole in Card Holder Figure 2: Use a business card with a hole punched in it to roughly align two mirrors. 3 - 27 Rev 2.0 11/09 Mirror 1 Business Card in Card Holder Mirror 2 Mirror Mirror C CC am D er a 50:50 Beam Splitter Mirror 1 Business Card in Card Holder Mirror 2 Mirror Mirror C CC am D er a 50:50 Beam Splitter Figure 3 Iterative procedure to get two beam co-linear. Now move the Card holder to the position shown in Figure 3. (Upper) You should see two beams on the card, one from each mirror. With the card holder close to the 50/50 BS adjust mirror 2 to make the two beams over lap. Then move the card holder to a position far from the 50/50 BS (a few feet, 1/2 meter or so.) Again, you should see two beams, now adjust mirror 1 to make the beams overlap. Go back to the near position and repeat. In a few iterations, you should start to see some fringes appear in the overlapped area of the two beams. You will not see any fringes if the laser is scanning its wavelength, so turn off the wavelength scan during this part of the operation. (Set the Ramp Generator attenuator to zero.) Once you see some fringes you can still repeat the above steps a few more times. If done correctly the fringe spacing should become larger as the alignment approaches optimum. Gently pushing on one of the mirror mounts should cause the fringe pattern to change. Now put a photodiode in the beam and restart the laser scan. You should be able to see some nice periodic modulations of signal from the photodiode. I find that a contrast ratio of 10% is about the best I can do. (minimum intensity is 10 % of maximum intensity.) Other tips: Remove the glass Neutral density filter from the laser beam when doing the alignment. This will help make the beams easier to see. You will have to replace the filter when you want to make scans. Feed back from the interferometer can get back into the laser and corrupt the scan. If this is a problem adding more attenuators after the glass neutral density filter will help. 3 - 28 Rev 2.0 11/09 V. Appendix – Making Beams Collinear Two points define a line, iterative procedure to align a laser beam to a “line in space”. The pictures are only for aligning in one dimension. The process is shown in the Figures 1 – 4 below. The objective is to get the laser beam, the narrow line, to be collinear to the “line in space” represented by the darker dashed line. The angles have been exaggerated to make it easier to see what is going on. 1. With the viewing card near to mirror M2, adjust angle of mirror M1 until the laser beam is intersecting with the desired “line in space”. See Diagrams 1 and 2. 2. Now, move the viewing card to a distance far away from M2, as shown in Diagram 3. 3. Adjust the angle of mirror M2 so that laser beam again intersects the “line in space”. You will notice that this makes the alignment at the first position, near M2, off a bit. 4. Now move the viewing card back to position shown in Diagram 1 and repeat. You will probably have to repeat the process several times to get the beam where you want it. (That’s iterative for you!) The closer the viewing card is to M2, the faster this procedure converges. You might ask where the “line in space” that you are trying to match comes from. It could be another laser beam or, perhaps, a desired beam path defined by two irises. 3 - 29 S. B. S. B. M irr or 0 /5 50 0 /5 50 M irr or Rev 2.0 11/09 IR Viewing Card Line to match Line to match Line to match 3.) S. B. S. B. 0 /5 50 M irr or 2.) 0 /5 50 M irr or 1.) Line to match IR Viewing Card 4.) IR Viewing Card IR Viewing Card 3 - 30