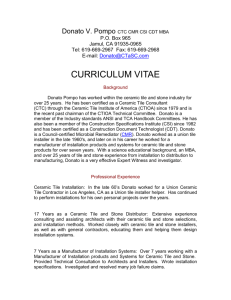

Ceramic Tile

advertisement

Ceramic Tile In order for the layman to better understand what is a ceramic tile, the best place to start is with a definition for the word "ceramic." This word is derived from the Greek "Keramikos," which literally translated means "of the earth." A modem definition of ceramic would therefore be, products made from naturally occurring earth (clays) which are shaped and then permanently hardened by heat. When referring to a ceramic tile floor, we are, therefore, using the word ceramic in a generic sense, to describe the fact that the floor is paved with a burnt clay- based product, without being specific about what type of ceramic tile has been used. There are many methods and numerous combinations of clays and auxiliary raw materials used to produce tiles with widely varying properties. The properties, which are adjusted, include strength, porosity, color, size, surface texture and uniformity. With there being so many different types of ceramic tiles commercially available, it is very difficult to list them all individually, and as a result it is common to classify a ceramic tile by its porosity. Porosity and strength are generally inversely proportional, so a highly porous tile will be less resistant to abrasion than a vitrified tile would be. In order to make a highly porous tile useable in situations where it would be vulnerable to staining, a topical glaze can be applied before the firing process to create an impermeable barrier to contamination. These glazes are usually colored to produce a decorative finish and can also be a high gloss or a matte luster. The use of a high gloss tile is generally confined to walls, as their use on floors would result in a floor with a high risk of slip and fall accidents. Glazed tiles are regularly used in flooring applications but the glazes are normally of the matte, slip-resistant type. Another advantage in the application of a glaze to a ceramic base is that it allows the use of clays, which would under other circumstances be rejected because of their poor fired color. This is advantageous because it holds down the cost of the finished product. Modem Italian floor tiles are produced by the "monocottura" (once-fired) method, using a red burning clay base covered with a colored glaze. Both clay and glaze is fired at the same time, bringing down the manufacturing costs and promoting a strong bond between the glaze and the ceramic base. Technological advancements made in the manufacture of ceramic tiles have provided the manufacturers with the ability to produce a finished product which so closely mimics natural stone that it is extremely difficult to be able to decipher the difference between the man made products and the real thing. The ceramic tile manufacturers have been very quick to realize that providing a product, which looks like natural stone but has the strength and durability of a ceramic, is a winning combination. This is because most ceramics are chemically resistant to both strongly acidic and strongly alkaline chemicals. They are also generally harder wearing than most natural stone used in flooring applications (including granite) and so are resistant to scratching and wear patterns. It is, therefore, obvious that the use of ceramic tiles in flooring applications will continue to grow at the expense of natural stone.