my.final report2

advertisement

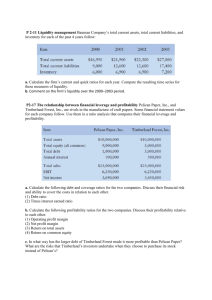

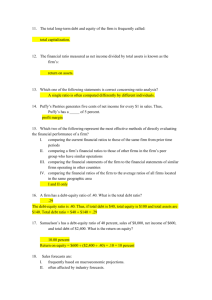

A PROJECT REPORT ON “STUDYING THE IMPACTS OF DEBT ON THE PROFITABILITY AND LIQUIDITY OF THE KRISHNA MARUTI LIMITED” KRISHNA MARUTI LIMITED SUBMITTED TO: Kurukshetra University, Kurukshetra in the Partial Fulfillment for the Degree of Master in Business Administration (Session 2008-20010)-MBA-3rd Semester Under Supervision of : Submitted By ; Ms.Shilpa Chawla RICHA NANDA Faculty,MBA D/o Sh. ASHOK NANDA Univ. Reg No. :04- DGY-611 Univ. Roll No. Institute Roll No, 1133/08 Tilak Raj Chadha Institute of Management and Technology (TIMT) (Affiliated to Kurukshetra University, Kurukshetra & Approved by AICTE) M.L.N.College Educational Complex, Yamuna Nagar-135001 (Haryana) Ph. 01732-220103, 234110. Fax: +91 -1732- 220103. E-mail: info@timt.ac.in , Web Site: www.timt.ac.in //DECALARATION// I hereby certify that the work which is presented in this Summer Training Project Entitled as:- “STUDYING THE IMPACTS OF DEBT ON THE PROFITABILITY AND LIQUIDITY OF THE KRISHNA MARUTI LIMITED” in partial fulfillment of the requirements for the award of the Degree of Masters in Business Administration (MBA), Kurukshetra University, Kurukshetra, is a authentic record of my original work carried out during the period from 20 June 2009 to 4 August 2009. I have not submitted the matter embodied in the project report for the award of any other degree. Place: Date: Richa Nanda D/o Sh. Ashok Kumar Nanda Unv. Reg No :04-DGY-611 Unv. Roll No.: Institute Roll No.: 1133/08 ACKNOWLEDGEMENT Perseverance, diligence, inspiration and motivation have always played a key role in the triumph of any venture. In the present world of walloping competition, a project is likely to apocalypse a nexus between theoretical knowledge and practical working. First of all, I would like to thank the paramount power, the ultimate impeccable creator, the almighty God, who is the one who has always directed me to work on the right path of my life. With his grace, this project could become a reality. “STUDYING THE IMPACTS OF DEBT ON THE PROFITABILITY AND LIQUIDITY OF THE KRISHNA MARUTI LIMITED”. Any accomplishment requires the effort of many people and this work is not different .Firstly, I would like to extend my sincere thanks and gratitude to Mr. SAHANI (Executive Director, operations) KRISHNA MARUTI LTD. ,GURGAON for his able guidance, regular counseling, keen interest and constant encouragement, without which the project would not have brimmed to fruition. I am extremely grateful to Dr. VIKAS DARYAL (DIRECTOR), Ms. GARIMA GUPTA H.O.D. (TIMT) and my research guide also, for their helpful attitude, regular coaching and inspiration. I owe my sincerely thanks to all employees of KRISHNA MARUTI LTD., for their support given to me time to time. Also, I would like to thank all my friends and family members for their support given to me time to time. I don’t have words to express my thanks; nonetheless, my heart is full of gratitude for the favors received by me from every person. EXECUTIVE SUMMARY The prime objective of my study was to study the impact of increasing debt on the profitability and liquidity of the company. I also took the help of ratio analysis in my study to know about the financial position of the company. The first section includes introduction to Krishna Maruti Ltd. The successive chapter introduces us with the project, gives proper definition to the problem, objectives of the study, significance of undertaking this project and defines the limitations and scope of the study. The third section briefs us about the way of carrying out the research methodology, which in turns tells about the sampling, data collection methods, field work, analysis and interpretation etc then is given the results and findings devised out of the research project. The bibliography and annexure follow this. I hope that this report will prove o be useful for the management to carve out the proper solutions put forth. CONTENTS TABLE OF CONTENTS Topic Page No. 1) Introduction 2) Profile of the study i) Justification of the study 3) Objectives of the Study 4) Literature Review 5) Research Methodology and Analytical tools a. Sampling and Sampling Design b. Data Collection c. Analytical Tools -Statistical tools d. Hypothesis Testing e. Limitations of the Study 6) Observations of the study 7) Results and Discussions/ Findings 8) Recommendations, Policy Implications 9) Bibliography 10) Annexure Indian Automobile Industry Indian Automobile Industry Indian automobile industry has come a long way to from the era of the Ambassador car to Maruti 800 to latest M&M Xylo. An industry is highly competitive with a number of global and Indian companies present today. It is growing at a pace of around 18% per annum for the last five years and is projected to be the third largest auto industry by 2030 and just behind to US & China, according to a report. The industry is estimated to be a US$ 34 billion industry. Indian Automobile industry can be divided into three segments i.e. two wheeler, three wheeler & four wheeler segment. Two wheeler segments enjoys 75% market share of automobile industry, followed by passenger vehicles with the 16% share of market. Three wheeler segments have merely 4% share in domestic market. The domestic two-wheeler market is dominated by Indian as well as foreign players such as Hero Honda, Bajaj Auto, Honda Motors, TVS Motors, and Suzuki etc. Maruti Udyog and Tata Motors are the leading passenger car manufacturers in the country. And India is considered as strategic market by Suzuki, Yamaha, etc. The major players have not left any stone unturned to be global. Major of the players have got into the merger activities with their foreign counterparts. Like Maruti with Suzuki, Hero with Honda, Tata with Fiat and latest Mahindra with Renault. In two-wheeler segment, motorcycles have the major share, Hero Honda, the leading bike manufacturer has more than 50% share in two-wheeler segment, followed by Bajaj Auto. In passenger car segment, Maruti Suzuki contributes the 52% market share, with complete monopoly over the small car segments. M&M enjoy the 42% market share in Multi Utility Vehicle in domestic market. The automobile industry in India — the ninth largest in the world with 2008 production of over 2.3 million cars and commercial vehicles — is one of the fastest-growing global automotive industries. A number of domestic companies, as well as the growing multinational investment, has led to rapid increases in automobile production. Following economic liberalization in India in 1991 the Indian automotive industry has demonstrated sustained growth as a result of increased competitiveness and relaxed restrictions. The monthly sales of passenger cars in India exceed 150,000 units. History REVA, known as G-Wiz in Europe, is the world's largest selling car. electric Tata Nano is the least expensive car in production in the world. The price is about Rs. 100,000 (US$2,500). Maruti Suzuki's A-Star vehicle during its unveiling in Pragati Maidan, Delhi. AStar, Suzuki's fifth global car model, was designed and is made only in India. An embryonic automotive industry emerged in India in the 1940s. Following the independence, in 1953, the Government of India and the private sector launched efforts to create an automotive component manufacturing industry to supply to the automobile industry. However, the growth was relatively slow in the 1950s and 1960s due to nationalization and the license raj which hampered the Indian private sector. After 1970, the automotive industry started to grow, but the growth was mainly driven by tractors, commercial vehicles and scooters. Cars were still a major luxury Japanese manufacturers entered the Indian market ultimately leading to the establishment of Maruti Udyog. A number of foreign firms initiated joint ventures with Indian companies. In the 1980s, a number of Japanese manufacturers launched joint-ventures for building motorcycles and light commercial-vehicles. It was at this time that the Indian government chose Suzuki for its joint-venture to manufacture small cars. Following the economic liberalization in 1991 and the gradual weakening of the license raj, a number of Indian and multi-national car companies launched operations. Since then, automotive component and automobile manufacturing growth has accelerated to meet domestic and export demands. Timeline of Indian automobile industry: 1897 First Person to own a car in India - Mr Foster of M/s Crompton Greaves Company, Mumbai 1901 First Indian to own a car in India - JamshedJi Tata 1905 First Woman to drive a car in India - Mrs. Suzanne RD Tata 1905 Fiat Motors 1911 First Taxi in India 1924 Formation of traffic police 1928 Chevrolet Motors 1942 Hindustan Motors 1944 Premier Automobiles Limited 1945 Tata Motors 1947 Mahindra & Mahindra Limited 1948 Ashok Motors 1948 Standard Motors 1974 Sipani Motors 1981 Maruti Suzuki 1994 Rover Company 1994 Mercedes-Benz 1994 General Motors India - Opel brand launch 1995 Ford Motor Company 1995 Honda Siel Cars India 1995 REVA Electric Car Company 1995 Daewoo Motors 1996 Hyundai Motor Company 1997 Toyota Kirloskar Motors 1997 Fiat Motors (Re-Entry) 1998 San Motors 1998 Mitsubishi Motors 2001 Škoda Auto 2003 General Motors India - Chevrolet brand launch 2005 BMW 2007 Audi 2009 Land Rover and Jaguar Industry Today Following India's economic liberalization in 1991, the automobile industry was opened for 100 percent foreign direct investment. A surge in the country's economic growth rate and purchasing power has fueled a 17% annual growth rate in the Indian automobile industry since 1991. The automotive industry generates direct and indirect employment to about 13.1 million people as of 2006-07. The automotive parts and cars exports has grown at an annual rate of 30% per year in the 21st century. However, the India's share of the overall global automotive industry remains low as of 2007. Increased competitin amongst automobile manufacturers provides for a variety of competitive options for the consumer. India was one of the largest manufacturers of tractors in the world in 2005-06, when it produced 293,000 units. India produced 65 Million tyres during FY 2005-06. India's tyre production meets domestic demand, as well as are exported to over 60 countries. Outlook India’s car market has emerged as one of the fastest growing in the world. The number of cars sold domestically is projected to double by 2010, and domestic production is skyrocketing as foreign makers are setting up their own production plants in India. The government’s 10-year plan aims to create a $145 billion auto industry by 2016. According to McKinsey & Company, the automotive sector’s drive for lowering costs will lead to outsourcing. The global automotive industry's sourcing from emerging markets will reach $375 billion by 2015, up from $65 billion in 2002. McKinsey thinks India can capture $25 billion of this export potential. Out of 400 Indian suppliers, 80 percent are ISO 9000 certified — the international standard for quality management. Most of India's current automobile production meets domestic demand. Forecasts predicts sales of 4.2 Million four-wheel automobiles in India by 2015. But, several manufacturers are now focusing on exports, and a diverse range of automotive components are now built and exported from India. India's passenger vehicle exports are forecast to rise from 170,000 in 2006 to 500,000 in 2010. Exports Hyundai i20, one of the most widely exported cars solely made in India. India has emerged as one of the world's largest manufacturers of small cars. According to New York Times, India's strong engineering base and expertise in the manufacturing of low-cost, fuelefficient cars has resulted in the expansion of manufacturing facilities of several automobile companies like Hyundai Motors, Nissan, Toyota, Volkswagen and Suzuki. In 2008, Hyundai Motors alone exported 240,000 cars made in India. Nissan Motors plans to export 250,000 vehicles manufactured in its India plant by 2011. Similarly, General Motors announced its plans to export about 50,000 cars manufactured in India by 2011. India automobile companies, mainly Maruti Suzuki, Tata Motors and Mahindra, have been aggressively expanding their overseas market too. Prominent India-made automobiles which are widely exported include: Maruti Suzuki - exports Suzuki Alto, Maruti 800, Maruti Omni, Maruti Wagon-R and Zen Estilo Hyundai Motor Company - exports Hyundai Santro, i10, Hyundai Getz, i20 and Hyundai Accent - 42% of its India production Tata Motors - exports Tata Safari, Tata Novus and Tata Xenon Mahindra & Mahindra Limited - exports Mahindra Scorpio and Mahindra Xylo In addition to Bangalore-based REVA, which currently is the only company actually selling EVs today, electric cars made in India includes: Mahindra & Mahindra: Four-seat model by 2010. Tata: 2008-2009 (Also possibly a compressed air car). Ajanta Group: clockmaker with plans for low-cost EV. Tara: Low-cost EV less than a Tata Nano. Hero Electric: 2013 Electric car. The list of foreign cars sold in India as CBU is given below: A Maruti 800 assembled at Gurgaon, Haryana, India. Audi: Audi A4, Audi R8, Audi A6, Audi A8, Audi TT, and Audi Q7. BMW: BMW 7 Series, BMW X5, BMW X3, BMW M3, BMW M5, and BMW M6. Land Rover: Range Rover and Range Rover Sport. Nissan: Teana and X-Trail. Porsche: Porsche 911, Porsche Boxster, Porsche Cayenne, and Porsche Cayman. Rolls Royce: Rolls Royce Phantom. Toyota: Land Cruiser Prado VX. Volkswagen: Volkswagen Jetta, Volkswagen Passat, and Volkswagen Touareg. Volvo: Volvo XC90 and Volvo S80. LamborghiniLamborghini Gallardo and Lamborghini Murciélago Production facilities in India Ashok Leyland: Ennore, Chennai, Tamil Nadu; Hosur, Tamil Nadu (3 plants) Audi: Aurangabad, Maharashtra. BMW: Chennai, Tamil Nadu. Bajaj Auto Ltd: Akurdi, MIDC Pimpri-Chinchwad, Pune, Maharashtra Caparo : Chennai, Tamil Nadu. Chevrolet: Halol, Gujrat. Daimler : Chennai, Tamil Nadu. Fiat: Pune (Ranjangaon), Maharashtra. Ford: Chennai, Tamil Nadu. Force Motors: Pune, Maharashtra General Motors: Talegaon Dabhade (Pune), Maharashtra Hindustan motors: Chennai, Tamilnadu, and Kolkata, West Bengal. Honda: Greater Noida, Uttar Pradesh. Hyundai: Chennai, Tamil Nadu. John Deere (Tractor): Sanaswadi (Pune), Maharashtra Kinetic Motor Company Limited: M.I.D.C., Pimpri-Chinchwad Pune, Maharashtra Mahindra: Nashik, Maharashtra; Kandivali, Maharashtra; Igatpuri, Maharashtra; Zahirabad, Andhra Pradesh; and Haridwar, Uttarakhand. Mercedes-Benz: Pune, Maharashtra. Mitsubishi: Thiruvallur, Chennai, Tamil Nadu. Renault-Nissan: Chennai, Tamil Nadu. Škoda: Aurangabad, Maharashtra Suzuki: Gurgaon, Haryana, and Manesar, Haryana. TAFE Tractors : Chennai, Tamil Nadu. Tata: Lucknow, Uttar Pradesh; Pimpri-Chinchwad (Pune) Maharashtra; Jamshedpur, Jharkhand; Haridwar, Uttarakhand and Sanand, Gujarat. TVS Motors, Chennai, Tamil Nadu. Toyota: Bangalore, Karnataka. Volkswagen: Talegaon Dabhade (Pune), Maharashtra Volvo Trucks: Bangalore, Karnataka Indian Automobile Industry -2008 All the major auto companies enjoyed the high growth ride till the mid 2008. But at the end of the year, industry had to face the hard truth and witnessed the fall in sales compared to last year. In December 2008, overall production fell by 22 % over the same month last year. Global recession has hit the Indian auto industry, India is strong and growing industry but the impact of recession is evident now on industry as sales & growth of automobile companies have declined. Passenger Vehicles segment registered negative growth. One of its supporting facts is that the sales in December 2008 for passenger vehicles fell by 13.86% over December 2007. Maruti- the leading car manufacturer, registered 10% fall in sells (56293 units), as compared to December’07 (62,515 units). But interestingly, Hyundai motors, the second largest car maker of country, registered a growth in sells, with the help of export; Hyundai Motors reported 19% growth. Two Wheelers registered minor growth of 1.85 % during April – December 2008. However, Two Wheelers sales recorded 15.43 percent fall in December 2008 over the same month last year. In two wheeler segment, Hero Honda has witnessed 10% fall (215,931 units in Dec 2008) in sales as compared to December 2007 (240,532 units). Bajaj Automobile has registered 33% fall in its over all two wheeler sells, compared to last year. The company has reported 37% negative growth in bike sells. Although the year 2008 saw a record launches of new products of various categories. Maruti launched A Star, its new small segment car. Honda Motors launched the new version of Honda city, its best selling sedan, also Civic Hybrid. Hyundai motor was not also far behind, in the end of the year, Hyundai launched its much awaited sedan i20. In Bikes segments, this year was full of happening. Yamaha introduced its two new hi-end models YZF & R15. Suzuki Motorcycle India also launched its legendary bike Hayausa & Intruder in Indian market. Introduction To Krishna Maruti KRISHNA MARUTI LIMITED KML entered the auto interior manufacturing business with a single product (seating system for Maruti 800 CC Car) in year 1994. Krishna Maruti Ltd. (KML) was incorporated in year 1994 as an ancillary to Maruti Udyog Ltd. (MUL), for the supply of Car seats. KML is joint venture between Mr. Ashok Kapur, MUL, and Suzuki Motor Corporation and has technical collaboration with SNIC of Japan for seat design and manufacturing. The state of the art plant is located at Delhi-Jaipur Highway, Narsinghpur Gurgaon (Haryana), and spread over an area of five acre. The installed capacity of plant is 4,000,000 seat set per annum. Today Krishna Group has six plants for a different range of car interiors like door trims, Roof Head liners, Rear view mirrors, Sheet metal components and auditorium seats all are located in Gurgaon. (Please see Annexure). Total group outlay is Rs. 6500 Million. Today KML manufacture 8 different products with over 100 different models. KML came into the existence, when there were established seat manufacturer for supplies to Maruti. We strived hard to prove ourselves better than others and today we got the distinction as the most favored supplier to MUL, and enjoying 59% of MUL seating business, which is much more than any other competitor who were in business before we came into business. KML has been the proud recipient of following five major awards from MUL, at last year vendor conference. Best VA/VE award Best Overall performance award Best effort of Cost reduction award Best effort for vendor up gradation award KAIZEN award Nevertheless, Satisfied with most delighted customer like, MUL, KML never looked back, relaxed but kept on revising and achieving set targets, KML achievements in the area of quality, Cost, Delivery, has become a benchmark for others industries. KML has also achieved following quality certificates. TS16949 ISO 14000 OHSAS 18000 Deming award Pursuing towards TQM. Over the past few years, KML has been upgrading software design tools, prototyping facilities, testing equipments and above all engineering and design skills for better prepared for the Challenge of AFTA, WTO and Trade Globalization. Our engineers have been working together with our technical partners to upgrade their skills and technical knowledge. The backbone of Krishna group is its corporate R&D center, established with an investment of Rs. 100 million and has distinction as a approved lab by govt. of India, capable of conducting tests as per Japanese standards, European Homologation. EEC/ECE, JASO & JIS. ISO 14001, environment certificate serves to show that KML is committed to being a responsible corporate citizen by ensuring that we take heed to minimize and where possible eliminate, environment unfriendly substance. Major customers are Maruti Udyog Ltd., Honda Siel, GM, FORD and HREC (STU). KML are India's First Total Auto Interior Group of Companies manufacturing all the requirements of auto interiors including Seating Systems, Rear View Mirrors, Head Rest Assemblies, Arm Rest Assemblies, Seat Trims (Covers), Injection Moulded Door Trims, Roof liners & Moulded Carpets. KML reached all this in short span of time because KML firmly practice ' 6 - F' principle throughout the organisation: Focused: Focus towards customer delight, engineering infrastructure, cost consciousness and continuous improvements through '5 - S', 'Kaizens', Quality Circle Meetings and Suggestion Meetings. Fast: Fast system & technological up - gradation and implementation. Flexible: Flexible towards customer requirements. Friendly: Creating friendly environment among customer, employees & vendors. Firm: Firmly adhering to laid down policies & procedures & Fun: Achieving the targets in stipulated time. In order to be a leader in its field, a strong centralized R & D Center (first of its kind in country) was established with an investment of $ 1.5 Million. This center is the best in the country and is recognized by the Department of Scientific & Industrial Research, Ministry of Science & Technology, Govt. of India.This center is capable of not only testing as per International Standards but can also issue Test Certificates to other Seat manufacturers. This test center can also perform test for non - Automotive components for Endurance & Repeatability. HISTORY OF KML It was in 1993 when Mr. Ashok Kapur started Krishna Maruti Ltd. seat division, a joint venture to supply car seats to Maruti Udyog Ltd. Since then he has never turned back and believes in only looking ahead. It is the hard work and perseverance of 13 years & a brain of an architect who knows how to build a high rise on a solid platform that has paved the way for The Krishna Group. Today the existence of Krishna group with 8 manufacturing plants, infrastructure company, media, floor & furnishing, tours & travels are the best example of his never dying approach of diversifying in the age of competition. Mr. Kapur's philosophy of putting the customer first has paid of handsomely & now Krishna group is one of the youngest diversified group which is going to touch a turnover of INR 10 billion (1000 crore) by next year. His son, Mr.Sunandan Kapur teamed up with him in 1999. Since then he has been responsible for various companies under The Krishna Group and is currently in-charge of a newly acquired company called SKH Metals Ltd. Mr. Kapur has been honored 3 times consequently by his customers for best overall performance. School of innovation management, Tokyo has honoured Mr. Kapur by passing on his teachings to the new graduates. His desire to prioritise quality perfection laid our seating division to not only win the Deming Award but also to become the world's first & youngest seating company to have this honour. 1994-1995 - Established Krishna Maruti Ltd., a joint venture between Ashok Kapur & Associates, Maruti Udyog Ltd., and Suzuki Motor Corporation to manufacture automotive seats in technical collaboration with SNIC Co. Ltd. of Japan. 1996-1997 - Established Krishna Toyo Ltd., a joint venture between Ashok Kapur & Associates and Toyo Ltd. to manufacture automotive mirrors in technical collaboration with Toyo Ltd. of Japan. 1997-1998 - Established Krishna Pads Ltd., a joint venture between Ashok Kapur & Associates and Krishna Maruti Ltd. to manufacture automotive head rests and PolyUrethane (PU) products. 1997-1998 - Established Research & Development (R&D) center as per European Homologation. 1998-1999 - Established Krishna Trims Ltd., a joint venture between Ashok Kapur & Associates and Krishna Maruti Ltd. to manufacture automotive seat trims. 1999-2000 - Established Krishna Maruti Ltd. - Door Trim Division, in technical collaboration with Suzuki Kasei of Japan (formerly Ohta Sheet) to manufacture injection moulded door trims. 2000-2001 - Established Krishna Maruti Ltd. - Roof Headliner Division. 2002-2003 - Established Krishna Grupo Antolin (P) Ltd., a joint venture between Krishna Maruti Ltd. and Grupo antolin to manufacture roof headliners in technical collaboration with Grupo Antolin of Spain. Established Krishna Quinette Galley, a joint venture between Ashok Kapur & Associates and Quinette Galley to manufacture auditorium & cinema seats in technical collaboration with Quinette Galley of France. 2004-2005 - Acquired Mark Auto Industries Ltd. (now SKH Metals Ltd.), a joint venture between Ashok Kapur & Associates and Maruti Udyog Ltd. to manufacture fuel tank, front suspension, and metqal parts in technical collaboration with Fatuba of Japan, Okamoto of Japan, and Magnetti Marelli of Italy. Established SKH Auto Components Ltd. through a merger of Krishna Trims Ltd. and Krishna Pads Ltd. Established Krishna Maruti Ltd. - Moulded Carpet Division. The journey towards perfection is still on.... KML philosophy Krishna Group take a turn for better in totality .Smaller , fewer, lighter , shorter, & beautiful. Maxim quality & minimize expenses. KML corporate philosophy is "RESPECT FOR INDIVIDUAL". Their employees, are their greatest assets. Their future growth depends greatly upon excellence in human resource management and evelopment. Their offer equal growth opportunities across the Organisation. Company provides conducive environment for employee's growth, by providing training and exposure for overall development with a view to make them able to shoulder added responsibilities. Krishna have a friendly work atmosphere in the day-to-day working. All family members are free to collaborate and communicate, and maintain a smooth and steady rhythm of work with full commitment. Board of Directors Testing facility The R & D Center has been established with the aim of bringing innovation in seating systems by incorporating latest principles in seat design. KML is the first seating manufacturing company in the country to establish such an advance facility. This center was established with an investment of $ 1.5 Million. This center is capable of conducting tests as per European Homologation (EEC/ECE/FMVSS) and Japanese Standards (JASO) on not only automotive seating systems but also on other components wherein repeatability and endurance life has to be ascertained. The test rigs are certified by Vehicle Certification Agency (VCA) of UK. The center is recognised by the Department of Scientific & Industrial Research, Ministry of Science and Technology, Govt. of India. The set - up includes Vibration Test Rig, Free Flight Impact Test Rig and Static/Dynamic Strength Test Rig. The software used for these Rigs produces precise waveforms e.g. Sine, Triangular, Square and Ramps. Products Of Krishna Maruti We are known for our innovative products and advanced technology which have been significant factors in our growth. Our continued focus on quality, craftsmanship, execution and global benchmarking are key elements of our way of doing business. We have expertise in manufacturing the following products: Automobile Seats Seating Systems Rear View Mirrors Head & Arm Rests Seat Trims Auditorium Seat Injection Moulded Door Trims Roof liners KML started its operations with only 1 model and a production capability of 40 sets/day. Toady we manufacture 16 different models. Krishna Maruti Limited has a production capacity of 400,000 Seating Systems/ annum. Presently Krishna Maruti Limited produces 16 different Variants of seating systems of following Models: BALE ESTEEM , WAGON R, ZEN, OMNI, MARUTI 800cc & ALTO. Krishna Maruti Limited has capabilities to Manufacture Seating Systems as an OE to potential customers for thei range of products Company produces a range of Outside & Inside Rear View Mirror Assemblies for Maruti Udyog Limited and Honda Siel Cars India Limited. With 35% OE market share, Every Fifth Indian Car has Rear View Mirror Assembly manufactured by Krishna Toyo Limited. The range can easily be extended to suit the requirements of other Auto Manufacturers. The Joint Venture agreement between Ashok kapur & Associactes and Toyo Industries Co. Ltd. was signed on 20th day of Dec. 1995. The Commercial production started in September 1996. Toyo Limited is Japan's Third largest Mirror Manufacturer and caters to 90% of Suzuki's total requirements in Japan. Toyo has manufacturing facilities in Thailand and Indonesia as well. toyo's Five decade of Experience in field of Auto Mirror have been incorporated at all levels and at all stages. All facilities required for ensuring the Quality of Input Parts and Products have been provided. Facilities for testing Mirror Assemblies as per International Standards are available. Very specialized test are conducted at Toyo's Facility in Japan. All the Components, Parts & Products are productionised after due approval from Toyo's Q.C, Japan. Krishna Pads Limited uses NC Controlled Puromat High - Pressure Foaming Machine for its foaming application for producing Head Rest & Arm Rest Assemblies for all models of Maruti's Car. Krishna Pads is working towards acquiring ISO 9002 certification in this year. Towards this end, all quality/work procedures have been implemented and are being strictly followed. Headrest defeletion test and impact tests are conducted regularly to ensure compliance as per statutory required performance parameters of seats. As a Backward Integration Exercise, Krishna Pads Limited (KPL) was established in Year 1996. Krishna Maruti Limited holds 10% equity in the company. This company manufactures Head Rest and Arm Rest Assemblies and is the single source for Krishna Maruti Limited. Krishna Pads Limited is India's Largest Manufacturer of Head Rest & Arm Rest Assemblies. This Krishna Maruti Limited promoted Company to manufacture Seat Trims (Cover) was established in Year 1996. Krishna Maruti Limited holds 10% equity in the company. Krishna Trims Limited is India's Largest Seat Cover Manufacturing Company. State of art cutting & stitching machines are used to manufacture products The Company has a manufacturing capacity of 200,000 Set per annum. Krishna Trims Limited is catering Krishna Maruti Limited's total requirement of trims. KPL provides these items for the following cars : Standard 800 Omni Van HR Zen Esteem Wagan R Baleno Trim being a most important component for quality seat, KML decided to establish Krishna Trims Limited for ensuring supply of high quality trims. Working on Group Quality Policy, KTL sends its team on regular basis to SNIC Company - Japan for training. Experts from SNIC Company - Japan are invited regularly to KTL for imparting training into designing Cutting & Stitching patterns for Trims to team at KTL. It was this effort that resulted in KTL acquiring ISO 9002 certificate within 1 year of its inception. Krishna Quinette is a 50:50 Joint Venture Company of Krishna Maruti Limited with Quinette Gallay of FRANCE. Quinette Gallay is the World Leader in the field of Auditorium Seats with over 70% of its total production servicing the Export Business. Quinette Gallay has presence in all the 6 Continents and installations in over 50 Countries. Krishna Quinette produces special seating system for auditorium applications. The company started its Commercial Operations since July 2003. Company produces a range of seating systems for auditorium applications. Krishna Quinette offers Sliding, Rocking, Tip-up and Fixed Seats with many options of Armrests, Cup Holders & Quilting Patterns. Some of the models being offered by Krishna Quinette in India are:Action BR Action Club Action Udine Europa Slider Metz West Palm Beach The Joint Venture agreement between Krishna Maruti Limited and Quinette Gallay of FRANCE was signed on 31th day of Jan 2003. Quinette Gallay of France has fifty years of experience, is now amongst the world leader in the field of activity. Quinette has manufacturing plant on 22000 sq mtr plot located in the suburbs of Paris. A design department utilizing both CAO/DAO data processing equipment. The use of modern method, machinery and equipment. A reliable and prompt after sales service and, on top of all, a well trained and competent work force, able to cope with the many variable challenges offered. KRISHNA QUINETTE Installations PVR MGF Main Stream Gurgaon PVR MGF Europa Gurgaon PVR Plaza Delhi PVR Forum Main Stream Bangalore PVR Forum Europa Bangalore Wave Cinemas Noida Wave Cinemas Lucknow Wave Cinemas Gold Lounge Lucknow Sahara Shahar Lucknow Rajshri Lucknow Novelty Lucknow Movie Talkies Mumbai Manipal Academy of Higher Education Scientific Conventional KGMU - Lucknow Centre at PVR Hyderabad PVR Mumbai This division manufacturers: Door Trims Roof Headliners Carpets For producing Injection Moulded Door Trims, we have Toshiba's (Japan) 1300 Tonne Machines and for the Assembling of various plastic parts together, we use Branson's (USA) Ultrasonic Welding Process. For our Roofliners, we have Meyer's (Germany) Lamination Machine & Thermoforming Machine. We are the only Indian Company to use Twin Head Robotic Water - Jet Cutting Machine from ABB - IR Sweden. The company is all set to use its specialty in Injection Molding for producing components for White Good Industry. In line with our vision to become India's First Single Stop Solution for Complete Auto Interiors, this division was established .For producing Door Trims, this division has Technical Collaboration with OHTA SHEET of Japan. The main objective of this division is to produce: Door Trims Roof Headliners Carpets This division incepted in June 1999. In Line with company philosophy of doing the projects without cost or Time overrun this project was completed within a record time of 66 days and production was started on 67th day (18th December 2000). This division has helped its customer in Cost Reduction by successfully localizing of Door Trims & Roof Headliners for Wagon R and Alto. The Door Trim manufacturing facility has been established with Technical Collaboration with M/s OHTA SHEET of Japan. This agreement was signed on 7th April 1999. OHTA SHEET is one of the leading Auto Interior Company of Japan and is in the business of manufacturing Door Trims, Roof Headliners & Moulded Carpets. OHTA SHEET is one of the Biggest Suppliers of Door Trims to Suzuki Motor Corporation in Japan . As per the Technical Collaboration Agreement OHTA SHEET provides the total Know - How right from the selection of Raw Materials, Machines, Manufacturing Process and testing Facilities. In line of Vision of becoming a World Class Manufacturing Company the Philosophy of TQM is followed through - out. The Organisation implements the best of Manufacturing and Management Techniques since inception. KML - DTD works on the principal that 'Customer is God'. For us Quality is the Way of Life. The Company is committed to Quality and Customer Delight in terms of Total Quality, Cost & Delivery i.e. Right Quantity, Right Price & Right Place. KML - DTD is working progressively towards QS 9000 and is hopeful of achieving the same within this year. The division was setup in July 2000 & the machines for lamination & thermofoaming was commission in December 2000. The commercial production started in Feb 2001.This plant can manufacture 2,00,000 Roof Headliners of various models per year. For Lamination of Substrates, Fully Automatic & Continuous Lamination Machine from Meyer - Germany is used. The Machine is capable of laminating upto five different materials together in a single operation. For moulding the Laminated Substrates into the required shape, the Thermoforming Press is used. This Press is High Capacity Single Acting Hydraulic Machine with advance controllers governing accurate controls over required parameters for consistent results.. Outsourcing At Krishna the basic raw materials used are : Polyurethane raw materials to produce moulded cushion pads -Polyols & Isocynates. CRCA sheet metal components. Tubular lengths of various sizes. Water soluble black paints & pre treatment chemical. PVC fabrics. Laminated polyester & cotton fabrics. Wire Spring Polypropylene for injection moulded components. Hardware items. Various industrial consumables like mig wire, adhesives, safety items, spot welding electrodes etc. Seat adjuster mechanism assemblies. Seat recliner mechanism assemblies. Rear seat lock assemblies. Automotive fabric. Treads. Substrate for roof headliner(rigid foam). Mirror sheets. Felt for moulded carpet. Needle punch fabric for moulded carpet. CRCE sheet. Non - woven fabric Fasteners for various sizes. Quality Company has been certified as ISO 9002 in year 1996 by TUV Bayran and QS 9000 in Year 1997 by AV Vincotte, Belgium. Towards our quest to become a World Class Company, we at KML commenced the TQM Mission jointly organized by CII and MUL since 1998. At Krishna Maruti Limited we are totally committed to Quality Standards set by our customers. Our line rejection is less than 500 PPM and we have achieved Zero MARU 'A' Defect. Kaizen and 5 S principals are followed at all levels through the organization. Krishna group offers a very challenging work culture with emphasis on developing individual's creativity. Krishna group is the leader in its field of operation and has joined hands with World leaders in their respective fields: a)Suzuki Motor Corporation - Japan. b)SNIC Company Limited - Japan (Seating Systems). c)Toyo Industries Company Limited - Japan (Rear View Mirrors) d)Ohta Sheet Company Limited - Japan (Door Trims) In order to develop and manufacture world-class product the best machines and tooling are there in the company. Individuals who look for a bright & promising career with Krishna Group please PROFILE OF THE STUDY DEBT PROFILE OF THE COMPANY Total Debt raised by KML: 2005 – Rs. 338938569 2006 – Rs. 454092269 2007 – Rs. 715018431 2008 – Rs. 996820254 Division of debt into secured and unsecured debt Year Total Debt Secured Debt Unsecured Debt 2008 996820254 969967830 13426212 2007 715018431 693138323 21880108 2006 454092269 423658613 30433656 2005 338938569 295062090 43336479 Sources of secured and unsecured debt raised by the company RATIO ANALYSIS ( Ratios related with the Profitability and Liquidity of KML) FINANCIAL ANALYSIS Financial analysis is the process of identifying the financial strengths and weaknesses of the firm and establishing relationship between the items of the balance sheet and profit & loss account. Financial ratio analysis is the calculation and comparison of ratios, which are derived from the information in a company’s financial statements. The level and historical trends of these ratios can be used to make inferences about a company’s financial condition, its operations and attractiveness as an investment. The information in the statements is used by Trade creditors, to identify the firm’s ability to meet their claims i.e. liquidity position of the company. Investors, to know about the present and future profitability of the company and its financial structure. Management, in every aspect of the financial analysis. It is the responsibility of the management to maintain sound financial condition in the company. RATIO ANALYSIS The term “Ratio” refers to the numerical and quantitative relationship between two items or variables. This relationship can be exposed as Percentages Fractions Proportion of numbers Ratio analysis is defined as the systematic use of the ratio to interpret the financial statements. So that the strengths and weaknesses of a firm, as well as its historical performance and current financial condition can be determined. Ratio reflects a quantitative relationship helps to form a quantitative judgment. STEPS IN RATIO ANALYSIS The first task of the financial analysis is to select the information relevant to the decision under consideration from the statements and calculates appropriate ratios. To compare the calculated ratios with the ratios of the same firm relating to the pas6t or with the industry ratios. It facilitates in assessing success or failure of the firm. Third step is to interpretation, drawing of inferences and report writing conclusions are drawn after comparison in the shape of report or recommended courses of action. BASIS OR STANDARDS OF COMPARISON Ratios are relative figures reflecting the relation between variables. They enable analyst to draw conclusions regarding financial operations. They use of ratios as a tool of financial analysis involves the comparison with related facts. This is the basis of ratio analysis. The basis of ratio analysis is of four types. Past ratios, calculated from past financial statements of the firm. Competitor’s ratio, of the some most progressive and successful competitor firm at the same point of time. Industry ratio, the industry ratios to which the firm belongs to Projected ratios, ratios of the future developed from the projected or pro forma financial statements NATURE OF RATIO ANALYSIS Ratio analysis is a technique of analysis and interpretation of financial statements. It is the process of establishing and interpreting various ratios for helping in making certain decisions. It is only a means of understanding of financial strengths and weaknesses of a firm. There are a number of ratios which can be calculated from the information given in the financial statements, but the analyst has to select the appropriate data and calculate only a few appropriate ratios. The following are the four steps involved in the ratio analysis. Selection of relevant data from the financial statements depending upon the objective of the analysis. Calculation of appropriate ratios from the above data. Comparison of the calculated ratios with the ratios of the same firm in the past, or the ratios developed from projected financial statements or the ratios of some other firms or the comparison with ratios of the industry to which the firm belongs. INTERPRETATION OF THE RATIOS The interpretation of ratios is an important factor. The inherent limitations of ratio analysis should be kept in mind while interpreting them. The impact of factors such as price level changes, change in accounting policies, window dressing etc., should also be kept in mind when attempting to interpret ratios. The interpretation of ratios can be made in the following ways. Single absolute ratio Group of ratios Historical comparison Projected ratios Inter-firm comparison Different parties are interested in knowing about the various ratios of the company. The following are various parties and their related interest: Investors To help them determine whether they should buy shares in the business, hold on to the shares they already own or sell the shares they already own. They also want to assess the ability of the business to pay dividends. Lenders to determine whether their loans and interest will be paid when due Managers might need segmental and total information to see how they fit into the overall picture Employees information about the stability and profitability of their employers to assess the ability of the business to provide remuneration, retirement benefits and employment opportunities Suppliers and other businesses supplying goods and materials to other businesses will read their accounts to see that they don't have problems: after all, any supplier trade creditors wants to know if his customers are going to pay their bills! Customers the continuance of a business, especially when they have a long term involvement with, or are dependent on, the business Governments and their agencies the allocation of resources and, therefore, the activities of business. To regulate the activities of business, determine taxation policies and as the basis for national income and similar statistics Local community Financial statements may assist the public by providing information about the trends and recent developments in the prosperity of the business and the range of its activities as they affect their area Financial analysts they need to know, for example, the accounting concepts employed for inventories, depreciation, bad debts and so on Environmental groups many organisations now publish reports specifically aimed at informing us about how they are working to keep their environment clean. Researchers researchers' demands cover a very wide range of lines of enquiry ranging from detailed statistical analysis of the income statement and balance sheet data extending over many years to the qualitative analysis of the wording of the statements GUIDELINES OR PRECAUTIONS FOR USE OF RATIOS The calculation of ratios may not be a difficult task but their use is not easy. Following guidelines or factors may be kept in mind while interpreting various ratios are Accuracy of financial statements Objective or purpose of analysis Selection of ratios Use of standards Caliber of the analysis LIMITATIONS OF RATIO ANALYSIS Differences in definitions Limitations of accounting records Lack of proper standards No allowances for price level changes Changes in accounting procedures Quantitative factors are ignored Limited use of single ratio Background is over looked Limited use Personal bias CLASSIFICATIONS OF RATIOS The use of ratio analysis is not confined to financial manager only. There are different parties interested in the ratio analysis for knowing the financial position of a firm for different purposes. Various accounting ratios can be classified as follows: 1. Traditional Classification 2. Functional Classification 3. Significance ratios 1. Traditional Classification It includes the following. Balance sheet (or) position statement ratio: They deal with the relationship between two balance sheet items, e.g. the ratio of current assets to current liabilities etc., both the items must, however, pertain to the same balance sheet. Profit & loss account (or) revenue statement ratios: These ratios deal with the relationship between two profit & loss account items, e.g. the ratio of gross profit to sales etc., Composite (or) inter statement ratios: These ratios exhibit the relation between a profit & loss account or income statement item and a balance sheet items, e.g. stock turnover ratio, or the ratio of total assets to sales. 2. Functional Classification These include liquidity ratios, long term solvency and leverage ratios, activity ratios and profitability ratios. 3. Significance ratios Some ratios are important than others and the firm may classify them as primary and secondary ratios. The primary ratio is one, which is of the prime importance to a concern. The other ratios that support the primary ratio are called secondary ratios. The various groups will be interested in different ratios: Interest Group Ratios to watch Investors Return on Capital Employed Lenders Gearing ratios Managers Profitability ratios Employees Return on Capital Employed Suppliers and other trade creditors Liquidity Customers Profitability Governments and their agencies Profitability Local Community This could be a long and interesting list Financial analysts Possibly all ratios Environmental groups Expenditure on anti-pollution measures IN THE VIEW OF FUNCTIONAL CLASSIFICATION THE RATIOS ARE 1. Liquidity ratio 2. Leverage ratio 3. Activity ratio 4. Profitability ratio We will discuss in details the Liquidity and Profitability Ratios as these are relevant to my study. 1. LIQUIDITY RATIOS Liquidity refers to the ability of a concern to meet its current obligations as & when there becomes due. The short term obligations of a firm can be met only when there are sufficient liquid assets. The short term obligations are met by realizing amounts from current, floating (or) circulating assets The current assets should either be calculated liquid (or) near liquidity. They should be convertible into cash for paying obligations of short term nature. The sufficiency (or) insufficiency of current assets should be assessed by comparing them with shortterm current liabilities. If current assets can pay off current liabilities, then liquidity position will be satisfactory. To measure the liquidity of a firm the following ratios can be calculated Current ratio Quick (or) Acid-test (or) Liquid ratio Absolute liquid ratio (or) Cash position ratio (a) CURRENT RATIO: Current ratio may be defined as the relationship between current assets and current liabilities. This ratio also known as Working capital ratio is a measure of general liquidity and is most widely used to make the analysis of a short-term financial position (or) liquidity of a firm. Current assets Current ratio = Current liabilities Components of current ratio CURRENT ASSETS CURRENT LIABILITIES Cash in hand Out standing or accrued expenses Cash at bank Bank over draft Bills receivable Bills payable Inventories Short-term advances Work-in-progress Sundry creditors Marketable securities Dividend payable Short-term investments Income-tax payable Sundry debtors Prepaid expenses (b) QUICK RATIO Quick ratio is a test of liquidity than the current ratio. The term liquidity refers to the ability of a firm to pay its short-term obligations as & when they become due. Quick ratio may be defined as the relationship between quick or liquid assets and current liabilities. An asset is said to be liquid if it is converted into cash with in a short period without loss of value. Quick or liquid assets Quick ratio = Current liabilities Components of quick or liquid ratio QUICK ASSETS CURRENT LIABILITIES Cash in hand Out standing or accrued expenses Cash at bank Bank over draft Bills receivable Bills payable Sundry debtors Short-term advances Marketable securities Sundry creditors Temporary investments Dividend payable Income tax payable (c) ABSOLUTE LIQUID RATIO Although receivable, debtors and bills receivable are generally more liquid than inventories, yet there may be doubts regarding their realization into cash immediately or in time. Hence, absolute liquid ratio should also be calculated together with current ratio and quick ratio so as to exclude even receivables from the current assets and find out the absolute liquid assets. Absolute liquid assets Absolute liquid ratio = Current liabilities Absolute liquid assets include cash in hand etc. The acceptable forms for this ratio is 50% (or) 0.5:1 (or) 1:2 i.e., Rs.1 worth absolute liquid assets are considered to pay Rs.2 worth current liabilities in time as all the creditors are nor accepted to demand cash at the same time and then cash may also be realized from debtors and inventories. Components of Absolute Liquid Ratio ABSOLUTE LIQUID ASSETS CURRENT LIABILITIES Cash in hand Out standing or accrued expenses Cash at bank Bank over draft Interest on Fixed Deposit Bills payable Short-term advances Sundry creditors Dividend payable Income tax payable 2. PROFITABILITY RATIOS The primary objectives of business undertaking are to earn profits. Because profit is the engine, that drives the business enterprise. Net profit ratio Return on total assets Reserves and surplus to capital ratio Earnings per share Operating profit ratio Price – earning ratio Return on investments (a) NET PROFIT RATIO Net profit ratio establishes a relationship between net profit (after tax) and sales and indicates the efficiency of the management in manufacturing, selling administrative and other activities of the firm. Net profit after tax Net profit ratio= Net sales Net Profit after Tax = Net Profit (–) Depreciation (–) Interest (–) Income Tax Net Sales = Income from Services It also indicates the firm’s capacity to face adverse economic conditions such as price competitors, low demand etc. Obviously higher the ratio, the better is the profitability. (b) RETURN ON TOTAL ASSETS Profitability can be measured in terms of relationship between net profit and assets. This ratio is also known as profit-to-assets ratio. It measures the profitability of investments. The overall profitability can be known. Net profit Return on assets = Total assets Net Profit = Earnings before Interest and Tax Total Assets = Fixed Assets + Current Assets (c) RESERVES AND SURPLUS TO CAPITAL RATIO It reveals the policy pursued by the company with regard to growth shares. A very high ratio indicates a conservative dividend policy and increased ploughing back to profit. Higher the ratio better will be the position. Reserves & surplus to capital = Reserves& surplus Capital (d) EARNINGS PER SHARE Earnings per share is a small verification of return of equity and is calculated by dividing the net profits earned by the company and those profits after taxes and preference dividend by total no. of equity shares. Net profit after tax Earnings per share = Number of Equity shares The Earnings per share is a good measure of profitability when compared with EPS of similar other components (or) companies, it gives a view of the comparative earnings of a firm. (e) OPERATING PROFIT RATIO Operating ratio establishes the relationship between cost of goods sold and other operating expenses on the one hand and the sales on the other. Operating cost Operation ratio = Net sales However 75 to 85% may be considered to be a good ratio in case of a manufacturing under taking. Operating profit ratio is calculated by dividing operating profit by sales. Operating profit = Net sales - Operating cost Operating profit ratio = Operating profit Sales (f) PRICE - EARNING RATIO Price earning ratio is the ratio between market price per equity share and earnings per share. The ratio is calculated to make an estimate of appreciation in the value of a share of a company and is widely used by investors to decide whether (or) not to buy shares in a particular company. Generally, higher the price-earning ratio, the better it is. If the price earning ratio falls, the management should look into the causes that have resulted into the fall of the ratio. Price – Earning Ratio = Market Price per Share Earnings per Share Capital + Reserves & Surplus Market Price per Share = Number of Equity Shares Earnings before Interest and Tax Earnings per Share = Number of Equity Shares (g) RETURN ON INVESTMENTS Return on share holder’s investment, popularly known as Return on investments (or) return on share holders or proprietor’s funds is the relationship between net profit (after interest and tax) and the proprietor’s funds. Net profit (after interest and tax) Return on shareholder’s investment = Shareholder’s funds The ratio is generally calculated as percentages by multiplying the above with 100. Ratios Of KML LIQUIDITY RATIO 1. CURRENT RATIO (Amount in Rs.) Current Ratio Year Current Assets Current Liabilities Ratio 2005 383222867 253066203 1.51 2006 384183841 255701566 1.50 2007 518352735 340425415 1.52 2008 981970741 688935052 1.42 2. QUICK RATIO (Amount in Rs.) Quick Ratio Year Quick Assets Current Liabilities Ratio 2005 200637827 253066203 0.79 2006 179181676 255701566 0.70 2007 196523103 340425415 0.58 2008 457150547 688935052 0.66 3. ABOSULTE LIQUIDITY RATIO (Amount in Rs.) Absolute Cash Ratio Year Absolute Liquid Assets Current Liabilities Ratio 2005 17293347 253066203 6.7 2006 1598190 255701566 6.2 2007 1738793 340425415 0.5 2008 1581744 688935052 0.2 PROFITABILITY RATIOS GENERAL PROFITABILITY RATIOS 4. NET PROFIT RATIO (Amount in Rs.) Net Profit Ratio Year Net Profit After Tax Income from Sales Ratio(%) 2005 21919419 1415228253 1.5 2006 29675318 1457487364 2.1 2007 30091531 1872953336 1.6 2008 83901327 3460757092 2.4 5. OPERATING PROFIT (Amount in Rs.) Operating Profit Year Operating Profit Income From Sales Ratio 2005 1415228253 2006 1457487364 2007 1872953336 2008 3460757092 6. RETURN ON TOTAL ASSETS RATIO (Amount in Rs.) Return on Total Assets Ratio Year Net Profit After Tax Total Assets Ratio(%) 2005 21919419 841446948 2.6 2006 29675318 996622755 2.9 2007 30091531 1053968849 2.8 2008 83901327 1643477509 5.1 7. RESERVES & SURPLUS TO CAPITAL RATIO (Amount in Rs.) Reserves & Surplus To Capital Ratio Year Reserves & Surplus Capital Ratio 2005 152430709 54300000 2.8 2006 182106027 3.5 2007 212197558 54300000 54300000 292829576 54300000 5.4 2008 3.9 OVERALL PROFITABILITY RATIOS 8. EARNINGS PER SHARE (Amount in Rs.) Earnings Per Share Year Net Profit After Tax 2005 21919419 2006 No of Equity Shares Ratio 4.1 29675318 5430000 5430000 2007 30091531 5430000 5.5 2008 83901327 5430000 15.4 5.5 14. RETURN ON INVESTMENT (Amount in Rs.) Return on Investment Year Net Profit After Tax Share Holders Fund Ratio (%) 2005 21919419 206730709 10.6 2006 29675318 236406027 12.5 2007 30091531 266497558 11.3 2008 83901327 347192576 24.2 BALANCE SHEET & P&L ACCOUNT Balance sheet 2008 2007 2006 2005 54000000 54300000 54300000 54300000 292829567 212197558 182106027 152430709 969967830 693138323 423658613 2950620090 b)Unsecured Loans 13426212 21880108 30433656 43336479 3)Deferred Tax Liability 90658186 74537038 54637691 45107053 1421181804 1056053027 745135987 590236331 SOURCES OF FUNDS 1) Share capital a)Capital b)Reserves & Surplus 2) Loan Funds a)Secured loans TOTAL APPLICATION OF FUNDS 1)Fixed Assets a)Gross Block 1373378562 1206374464 888991905 789600274 b)less : depreciation 527895377 461633635 413246467 423492469 c)Net Block 845483185 744740629 475744628 366107805 d)Capital Work In Progress 232671238 61820220 118507580 72007622 e)Preoperative Expenses Pending 22273037 ------- ------- ------- 2)INVESTMENTS 25014360 69480680 19147689 19147680 11105 10049 27673 115149 a)Interest Accrued 364984656 194784310 128679827 137256202 b)Inventories 455568803 194032428 177583486 183344480 1570639 1728744 1570517 17178198 159835538 127797204 76322338 45328828 671551795 329421414 247794086 239221600 17383257 11004001 7907580 13844603 293035689 177927321 128482275 130156664 2704295 2084178 3253824 2816560 1421181804 1056053027 745135987 590236331 2006 2005 3)CURRENT ASSETS LOANS & ADVANCES c)Sundry Debtors d)Cash & Bank Balances e)Loans & Advances LESS: Current Liabilities & Provisions a)Current Liabilities b)Provisions Net Current Assets 4)MISCELLANEOUS EXPENSES TOTAL PROFIT & LOSS ACCOUNT PARTICULARS 2008 2007 INCOME Turnover Less : Excise Duty Net Sales Add : Other Incomes TOTAL 4345858766 2531564274 1900930309 1858778891 885101678 658610938 443442945 443550638 3460757092 1872953336 1457487364 1415228253 165317436 88671206 63728019 62350512 3626074528 1961624542 1521215383 1477578765 EXPENDITURE Cost Of Materials Personnel Expenditure Financial Charges Other Expenses Depreciation Miscellaneous Expenses Written Off TOTAL PROFIT BEFORE TAX 2947670855 1513611425 1140192525 1053982898 224255639 160813185 136784980 128649899 89982381 53862177 29071944 22975964 166160070 114697924 115261944 150336804 66544087 57992081 52924251 76912287 935668 2222871 2800066 2697140 3495548700 1903199663 1477035700 1435554992 130525828 58424878 44179683 42023772 Current Tax 26669080 6600000 3965700 18435000 Deferred Tax 17804588 19899347 9530638 1669353 2050833 1744000 1008027 ------- 100000 90000 ------- ------- Net Profit After Tax 83901327 30091531 29675318 21919419 Profit Brought Forward 92387557 62296026 32620709 19231159 176288884 92387557 62296027 41150578 Fringe Benefits Wealth Tax Profit Carried to Balance Sheet Objectives Of The Study Primary objectives : To study the impact of debt (bifercated into secured and unsecured debt) raised during 2005-2008 on profitability of the firm. To study the impact of debt (bifercated into secured and unsecured debt) raised during 2005-2008 on liquidity of the firm. Secondary objectives : To study the financial position of the company. To study the various ratios of the company in the year 2005 to2008. THEORITICAL FRAMEWORK CONSTRUCT Impacts of debt rose during 2005-2008 on the profitability and liquidity of the company. VARIABLES Independent Variable: Debt (bifercated into secured and unsecured debt). Dependent Variable: Profitability, Liquidity. Literature Review CONCEPTUAL LITERATURE CONCEPTUAL LITERATURE is that which relates with concepts & theories. Help from different books should be taken for different concepts & theories. EMPIRICAL LITERATURE Empirical literature consists of study made by others in the same field. PUBLISHED DATA IN NEWSPAPER BOOKS & MAGAZINES AVAILABLE DISCUSSION WITH PEOPLE OF ORGANIZATION The literature review includes the academic books, internet access etc. 1. Donald R. Cooper and Pamela S. Schindler1, “Business Research Methodology” Eighth Edition’ Tata McGraw Hill Publishing Company Limited, New Delhi. Chapter 3, Page 82, 86, 87. Chapter 4, Page 101,102 (helped in research design) 2. Kothari C.R., “Research Methodology Methods and Techniques”2 (Second Edition) New Age International Publishers, Ansari Road, Daryaganj, New Delhi-110002. Chapter 4, Page 55-58. Chapter 6, Page 95,100,111. (Methods of data collection, collection of data and collection of secondary data” are referred before the data collection”.) 3. Jain, ,T.R., and Aggarwal, Dr. S.C., “Statistics For M.B.A”3,VK publication, PP1-3 Part b, , 2nd Edition ,PP 131-134 Part (“Correlation” is studied to use these test in study.) 4. “Gupta S.P.””STATISTICAL METHODS”. The information regarding the statistical tools and their limitations in different fields the research is given in this section. This section explains why to use regression and what are the situations in which regression can be used and what is the meaning of regression. Statistics”, 30th edition, “Sultan Chand & sons” (page no: 378-418). 5. Statistical Methods- Sultan Chand Publication The information regarding the statistical tools and their limitations in different fields the research is given in this section. This section explains why to use trend analysis and what are the situations in which regression can be used, and what does regression means 6. Maheshwari S.N “Management accounting & financial control” the information regarding the mean of inventory capital management. The basic idea to take that Project I have got from this book” (page no134-145). 7. Khan M.Y. & Jain P.K. “Financial Management” the information regarding the inventory management etc.,”Financial Management”,3th edition(page no-4.75). 8. Beri G.C. - Marketing Research 3rd edition: This book helped in understanding the different research designs and statistical tools used here. 9. Chandra Parshant,” Financial Management”5th edition,(pageno-82-83) 10. “Jain T.R. & Aggarwal S.C” Statistics for MBA, V.K. Publication(Page no.59-88) 11. Patel Rashna( 2002),“ India’s strengths –Tremendous sourcing centers”, Home Fashion , Servewell Printers, Mumbai, Vol-1, No.1,pp-08-09. 12. Gupta S.P. and Gupta M.P., “Business Statistics”4, Twelth Edition, Sultan Chand and Sons Publications. PP 237-241,628-629 (test hypotheses testing). 13. Murray R. Spiegel, “Theory and Problem of Statistics”5, Third edition, Tata Mc Graw Hill Publication, Chapter 12, Pg No.45-48 (correlation and regression) 14. khan and Jain,” FInancial Management”, ed 2003., McGraw Hill Publishing Co. Ltd NEW DELHI10 15. Leopold A. Bernstein & John J. Wild 1, “Analysis of Financial Statements” , Revealed application of special cash flow adequacy ratio& comparative financial analysis. 16. Wachonicz Jr. John M. & Van Horme James C. “Financial Management” ed. 1993. (PHI) Eight Edition , Mumbai11 17. Annual Report 2005-06 of Chinar Textiles Industries Limited “The balance sheet and profit & loss account of Chinar Textiles Industries Limited. And corporate governance is an integral element of the company’s value system, management ethos and other business practice”. 18. Annual Report 2006-07of Chinar Textiles Industries Limited15, “The information regarding the balance sheet and profit & loss account for the year 2006-07.” Research Methodology RESEARCH METHODOLOGY Research is a systematic and continuous method of defining a problem, collecting the facts and analyzing them, reaching conclusion forming generalizations. Research is defined as “a scientific & systematic search for pertinent information on a specific topic”. Research is an art of scientific investigation. Research is a systemized effort to gain new knowledge. It is a careful inquiry especially through search for new facts in any branch of knowledge. The search for knowledge through objective and systematic method of finding solution to a problem is a research. THE RESEARCH PROCESS: 1 OBSERVATION Broad area of research interest identified 3 PROBLEM DEFINITION Research Problem Delineated 4 THEORETICAL FRAMEWORK 5 GENERATION OF HYPOTHESES Variables clearly identified and labelled 2 PRELIMINARY DATA GATHERING Interviewing Literature Survey 7 DATA COLLECTION, ANALYSIS AND INTERPRETATION 6 SCIENTIFI C RESEARCH DESIGN 8 DEDUCTION Hypotheses substantiated? Research question answered? NO Yes 9 Report writing 10 Report Presentat ion 11 Manager ial decision making So we should consider the following steps in research methodology12: Problem statement Research design Sample design Data collection Organization Of Data Presentation Of Data Analysis and Interpretation of data PROBLEM STATEMENT The research problems, in general, refers to sum difficulty with a researcher experience in the contest of either a particular or a theoretical situation and want to obtain a salutation for same. The present report has been undertaken to know the impact of debt raised during 2005-2008 on the profitability and liquidity of KML. RESEARCH DESIGN A research is the arrangement of the conditions for the collections and analysis of the data in a manner that aims to combine relevance to the research purpose with economy in procedure. In fact, the research is design is the conceptual structure within which research is conducted; it constitutes the blue print of the collection, measurement and analysis of the data. As search the design includes an outline of what the researcher will do from writing the hypothesis and its operational implication to the final analysis of data. The design is such studies must be rigid and not flexible and most focus attention on the following; What is the study about? Why is the study being made? Where will the study be carried out? What type of data is required? Where can be required data be found? What period of time will the study include? What will be sample design? What techniques of data collection will be used? How will the data be analyzed? In what style will the report be prepared? Research Design can be categorized as12: TYPES OF RESEARCH DESIGN EXPLORATORY RESEARCH DESCRIPTIVE & DIAGONOSTIC RESEARCH DESIGN EXPERIMENTAL RESEARCH DESIGN The present study is descriptive in nature, as it seeks to discover ideas and insight to bring out new relationship. Research design is flexible enough to provide opportunity for considering different aspects of problem under study. It helps in bringing into focus some inherent weakness in enterprise regarding which in depth study can be conducted by management. SAMPLING & SAMPLING DESIGN: A sample design is a definite plan for obtaining a sample from the sampling frame. It refers to the technique or the procedure that is adopted in selecting the sampling units from which inferences about the population is drawn. Sampling design is determined before the collection of the data. Several decisions have to be taken in context to the decision about the appropriate sample selection so that accurate data is obtained and efficient results are drawn. Following questions have to be considered while sampling design What is the relevant population? What is the parameter of interest? What is the sampling frame? What is the type of sample? What sample size is needed? How much will it cost? RESEARCH DESIGN: Research design involves a series of rational decision making benefits at each point from such sophisticated design to ensure accuracy, confidence and commensurate with large investment of resources. Purpose of study: Exploratory Descriptive Hypothesis testing The purpose of my study is descriptive. A descriptive study is undertaken in order to ascertain be able to describe the characteristics of variables of interest in a situation. It is also hypothesis testing also. Because studies that engage in hypothesis testing usually explain the nature of certain relationship or establish the difference among groups or independence of the two or more factors in the situation. Types of investigation: Establishing Casual relationship Correlation Group differences, ranks etc. Type of investigation in my study will be correlation. Because my main motive is to check whether there is significant relationship between the debt raised and profitability and liquidity of the company. So investigation type will be correlation type. Extent of researcher interference in study: Minimal: studying events as they normally occurs Manipulation and/or control and/or simulation The extent of research interference in my study will be minimal. I’ve to just collect and analyze the data for findings. There will be no need for simulation tests etc. Study setting: Contrived Non-contrived Measurements and measures: Operational definition Items (measures) Scaling Categorization Coding Units of analysis (population to be studied) Individuals Dyads Groups Organization Machines etc. The units of analysis or the population that will be studied in my research will be the balance sheet, P&L account, cash flow statements, etc. Sampling design: It is a definite plan for obtaining a sample from sampling frame. It is determined before collection of data. Sampling size for my study will be the data of last four years i.e from 2005 to 2008. Time horizon: One shot (cross sectional) Longitudinal The time horizon for my study is the four years time period. Data collection method: Primary data Secondary data Interviewing Questionnaires Observations Unobtrusive methods. My data collection is based on secondary data i.e. from websites, books, prowess, company’s balances sheets, etc. Data analysis Feel for data Goodness of data Hypothesis testing For data analysis mostly the hypothesis testing will be used. By using SPSS Software it will be performed. Statistical tools will also be used. Analytical tools will also be used. Hypothesis Testing With the help on ANNOVA we will use the following hypothesis Null Hypothesis: there’s no significant impact of secured debt on profitability of the company. Alternate Hypothesis: there’s significant impact of secured debt on profitability of the company. Null Hypothesis: there’s no significant impact of unsecured debt on profitability of the company. Alternate Hypothesis: there’s significant impact of unsecured debt on profitability of the company. Null Hypothesis: there’s no significant impact of secured debt on liquidity of the company. Alternate Hypothesis: there’s significant impact of secured debt on liquidity of the company. Null Hypothesis: there’s no significant impact of unsecured debt on liquidity of the company. Alternate Hypothesis: there’s significant impact of unsecured debt on liquidity of the company. Analytical and Statistical Tools Correlation 1) Between secured debt and liquidity Correlations secured_debt secured_debt Pearson Correlation Liquidity 1 Sig. (2-tailed) .000 N Liquidity ** .860 2381826856 2.E9 ** 1 Pearson Correlation .860 Sig. (2-tailed) .000 N 2381826856 2.E9 **. Correlation is significant at the 0.01 level (2-tailed). High degree of correlation exists between secured debt and liquidity of the company i.e. 86%. 2) Between unsecured debt and liquidity Correlations Liquidity Liquidity Pearson Correlation unsecured_debt 1 Sig. (2-tailed) N unsecured_debt Pearson Correlation ** .324 .000 2.E9 2381826856 ** 1 .324 Sig. (2-tailed) .000 N 2.E9 2381826856 **. Correlation is significant at the 0.01 level (2-tailed). Low degree of correlation exists between unsecured debt and liquidity of the company i.e. 32.4%. 3) Between secured debt and profitability of the company. Correlations secured_debt secured_debt Pearson Correlation profitability ** 1 .891 Sig. (2-tailed) .000 N profitability 2381826856 2.E9 ** 1 Pearson Correlation .891 Sig. (2-tailed) .000 N 2381826856 2.E9 **. Correlation is significant at the 0.01 level (2-tailed). High degree of correlation exists between secured debt and liquidity of the company i.e. 89.1%. 4) Between unsecured debt and profitability of the copany Correlations unsecured_debt unsecured_debt profitability 1 .378 Pearson Correlation Sig. (2-tailed) N profitability .000 2381826856 2.E9 ** 1 Pearson Correlation .378 Sig. (2-tailed) N ** .000 2381826856 2.E9 **. Correlation is significant at the 0.01 level (2-tailed). Low degree of correlation exists between unsecured debt and profitability of the company i.e. 37.8%. ANOVA 1) Let null hypothesis be that there is no significance effect of secured debt on the profitability of the company. b ANOVA Model 1 Sum of Squares df Mean Square Regression 1.908E15 1 1.908E15 Residual 5.431E14 2 2.716E14 Total 2.451E15 3 F Sig. 7.026 .118a a. Predictors: (Constant), secured_debt b. Dependent Variable: profitability As the level of significance is greater than 0.05, we reject our null hypothesis and accept our alternate hypothesis i.e. secured debt effects the profitability of the company. 2) Let null hypothesis be that there is no significance effect of unsecured debt on the profitability of the company. ANOVA Model 1 Sum of Squares df Mean Square Regression 3.018E14 1 3.018E14 Residual 2.149E15 2 1.075E15 Total 2.451E15 3 F Sig. .281 a .649 a. Predictors: (Constant), unc b. Dependent Variable: profit As the level of significance is greater than 0.05, we reject our null hypothesis and accept our alternate hypothesis i.e. unsecured debt effects the profitability of the company. 3) Let null hypothesis be that there is no significance effect of secured debt on the liquidity of the company. ANOVA Model 1 Sum of Squares df Mean Square Regression 9.956E18 1 9.956E18 Residual 4.396E18 2 2.198E18 Total 1.435E19 3 F Sig. .167a 4.530 a. Predictors: (Constant), secured debt b. Dependent Variable: Liquidity As the level of significance is greater than 0.05, we reject our null hypothesis and accept our alternate hypothesis i.e. secured debt effects the liquidity of the company. 4) Let null hypothesis be there is no significance effect of unsecured debt on liquidity. ANOVA Model 1 Sum of Squares Regression Df Mean Square 9.373E17 1 9.373E17 Residual 1.341E19 2 6.707E18 Total 1.435E19 3 F Sig. .140 a. Predictors: (Constant), unc b. Dependent Variable: liquid As the level of significance is greater than 0.05, we reject our null hypothesis and accept our alternate hypothesis i.e. unsecured debt effects the liquidity of the company. .744a MULTIPLE REGRESSION 1) Multiple Regression between secured debt, unsecured debt and liquidity of the company. b Model Summary Std. Error of the Model R R Square a 1 .833 Adjusted R Square .694 Estimate .081 2.09628E9 a. Predictors: (Constant), unsecured_debt, secured_debt b. Dependent Variable: Liquidity Coefficientsa Standardized Unstandardized Coefficients Model 1 B (Constant) Std. Error -2.356E9 2.900E9 secured_debt 6.055 4.226 unsecured_debt 2.045 113.104 a. Dependent Variable: Liquidity Coefficients Beta t Sig. -.812 .566 .830 1.433 .388 .010 .018 .988 2) Multiple Regression between secured debt, unsecured debt and profitability. Model Summaryb Model R 1 R Square .887a Adjusted R Square .787 Std. Error of the Estimate .362 2.28304E7 a. Predictors: (Constant), unsecured_debt, secured_debt b. Dependent Variable: profitability a Coefficients Standardized Unstandardized Coefficients Model 1 B (Constant) Std. Error -1.147E7 3.159E7 secured_debt .081 .046 unsecured_debt .253 1.232 a. Dependent Variable: profitability Coefficients Beta t Sig. -.363 .778 .853 1.767 .328 .099 .205 .871 Reliability Analysis Cronbach’s alpha is most commonly used reliability coefficients, which is based on the average correlation of items within a test if the items are standardized. If the items are not standardized, it is based on the average covariance among the items. Because Cronbach’s alpha can be interpreted as a correlation coefficient, it ranges in value from 0 to 1. Reliability Statistics Cronbach's Alpha N of Items .045 4 Here the value of our Cronbach’s alpha is 4.5% which is less then 5% I means that our data is reliable. Limitations Except the supreme power, the Almighty, no one is impeccable and prowess enough to accomplish anything without any faults and limitations. A research is no exception. No study is devoid of certain shortcomings. Some problems encountered in this study are under mentioned: Time Constraints: Time was a bit short to fathom into the depth of the study. But still all efforts to the best possible extent have been made to collect the data. Data collection Constraints: Since data used is secondary in nature, this poses the constraints on the validity and reliability of the data. Secrecy of Internal Data In today’s day the companies are very sensitive regarding their internal data, this proved a hindrance to my study. Period of Analysis Sample size of four years was taken by me i.e. from 2008-2009 which was sufficient but a bigger sample would have helped to reach too more precise findings. Findings Recommendations