Use of confocal microscopes

advertisement

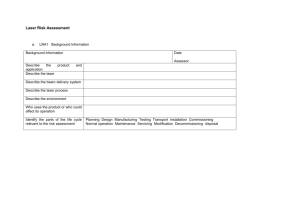

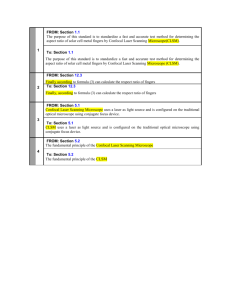

Risk Assessment IMS-MRL LASERS Describe the product and application Describe the Laser Date: 08/04/09 Name of Assessor: Margaret Blount The Departmental Microscopy Facility contains four lasers connected to the Zeiss LSM 510 META confocal microscope in room HR-36-04-150 and two lasers connected to the Zeiss Palm Microbeam Rel.4.2 in room HR-36-04-151. The Department also has a FACS analyser which incorporates two lasers, this is currently housed in the large laboratory on level 5, HR-35-05-120. The Zeiss LSM 510 META is attached to 4 lasers: 1. Ar/ML 458/477/488/514, Class 3B, 30mW 2. HeNe 594, Class 3B, 2mW 3. HeNe 633, Class 3B, 5mW 4. Diode 405, Class 3B, 50mW The Zeiss Palm Microbeam Rel.4.2 is attached to one laser: 1. Cutting laser – 355nm, pulse energy ≥90μJ, Class 3B: Laser class of system during normal operation is 1M. The FACS analyser is attached to two lasers: 1. Argon Ion 488 laser, class 3B, 15mW. 2. Diode laser 635, Class 3B, 10mw. The laser beams are delivered by a closed fibre optic system to the confocal head. In the confocal microscope the laser light is conducted via enclosed optical fibres into the META head and into the optical system of the microscope. In the Palm Microbeam, the laser is housed in a LaserUnit where the laser light is generated and focused whence it is conducted into the microscope via an enclosed microscope adapter. In the FACS analyser the lasers are housed in a separate compartment from the sample loading area and are only accessible by the manufacturer’s authorised engineers. Describe the Laser Process 533576247 Laser light is applied, through the microscope objective, to the sample. In the confocal microscope the laser beam scans the sample; In the microbeam the laser is used to cut areas of the sample via software operated by the user, using an image generated on the computer screen. In the FACS analyser the sample is aspirated into a chamber enclosed within the laser housing where it is subjected to laser illumination and fluorescence is detected by probes also within this housing. 1 Risk Assessment Describe the Environment The confocal system is in a dedicated, purpose-built room, 150, which is air conditioned. Access to the microscope is limited to trained users. The room itself is enclosed and air conditioned. It contains one fluorescence microscope and one confocal microscope, incorporating 4 lasers, two PCs. The Palm Microbeam is in a separate purpose built room, which contains the Palm Microbeam, a conventional light microscope and other small equipment. The FACS analyser is situated within the communal laboratory; it is not possible for users to access the laser beam. Who uses the product or could affect its operation? Underline the part(s) of the life cycle of interest 533576247 Authorised users (see appendix A for list of authorised users), maintenance staff (see appendix B for list of maintenance staff), service engineers Planning, Design, Manufacture, Testing, Transport, Installation, Commissioning, Normal Operation, Maintenance, Servicing, Modification, Decommissioning, Disposal 2 Risk Assessment Assessment Number: Assessed by: M.A. Blount STEP 1 List significant hazards Assessment Date: 08/04/09 Review Date: 08/04/10 STEP 2 List groups of List existing controls people who are at risk Activity/Facility Assessed: Microscopy and FACS Location: IMS-MRL, level 4 and 5 STEP 3 Are these What is the risk Actions Required controls OK? factor from (See over) these hazards? All Lasers are fully contained in cabinets. Only qualified service personnel are permitted to open these boxes. Instructions to this effect are contained in the local rules and are part of pre-use training required for authorisation. Yes Low Cooling system Laser cabinets are actively ventilated to external source. Integrity of system is checked by maintenance technician. System is serviced regularly (on contract) Yes Low Add to inspection checklist Explosion of mercury arc lamp Lamp is changed regularly after 300 hours by technician. Housing of lamp is designed to contain explosion. Adequate ventilation and contingency plan devised in case of emergency (set out in local rules) Yes Low Add to inspection checklist Equipment interconnections -Trip hazard and possible damage to equipment (e.g.fibre breakage) All optical guides and other equipment interconnections are kept out of the way. Yes Low Add to inspection checklist The Laser: Electric shock from high voltage power supply 533576247 3 Risk Assessment Assessment Number: Assessed by: M.A. Blount STEP 1 List significant hazards Assessment Date: 08/04/09 Review Date: 08/04/10 STEP 2 List groups of List existing controls people who are at risk Activity/Facility Assessed: Microscopy and FACS Location: IMS-MRL, level 4 and 5 STEP 3 Are these What is the risk Actions Required controls OK? factor from (See over) these hazards? Beam Delivery: Exposure to laser radiation, Class 3B, UV-A and visible wavelengths. UV-A – Short term – burns to skin Long term – premature cataracts in lens of eye. Associated with malignant melanoma in skin Visible – retinal hazard Laser beam is divergent when objectives in place All Beam delivery 1. Optical fibres encased in flexible metal coverings and are attached by screws on fixings at all points. They are routed behind the equipment. Only qualified service personnel are permitted to disconnect this equipment. 2. Beam contained within microscope optics – interlocked to prevent viewing laser through microscope optics. 3. Free air from objective to sample ≤1.0cm gap. Users instructed not to insert reflective material into beam path. Users may not alter the UV light source. Exposure is limited at the sample. Users are advised to block the UV light source by switching off or using filter when changing samples. Avoid exposure to UV as much as possible. Instructions contained in the 533576247 Yes Low 4 Risk Assessment Assessment Number: Assessed by: M.A. Blount STEP 1 List significant hazards Assessment Date: 08/04/09 Review Date: 08/04/10 STEP 2 List groups of List existing controls people who are at risk Activity/Facility Assessed: Microscopy and FACS Location: IMS-MRL, level 4 and 5 STEP 3 Are these What is the risk Actions Required controls OK? factor from (See over) these hazards? local rules and are part of pre use training required for authorisation. Exposure to laser beam when changing samples Interlock stops laser beam when condenser tilted back thus exposure is impossible during normal operation. Yes Low Yes Low Yes Low The Laser Process: Reflections of laser radiation from sample and metalwork Chemical hazards from samples 533576247 Users Users Light intensity at the process site is reduced. Viewing of sample and operation of microscope is via software controls on the computer screen at such an angle to the microscope that the user is unlikely to view any laser reflections in the unlikely event of a problem occurring. It is necessary to swing back the condenser assembly to change samples, this operates an interlock preventing inadvertent exposure to lasers emissions. Users are not permitted to change the objective lenses. Only microscope oil and ethanol are used. Exposure to the former is controlled by wearing gloves (see COSSH 5 Risk Assessment Assessment Number: Assessed by: M.A. Blount STEP 1 List significant hazards Assessment Date: 08/04/09 Review Date: 08/04/10 STEP 2 List groups of List existing controls people who are at risk Activity/Facility Assessed: Microscopy and FACS Location: IMS-MRL, level 4 and 5 STEP 3 Are these What is the risk Actions Required controls OK? factor from (See over) these hazards? form) Biological hazards from samples Users Refer to individual biological risk assessment Contamination All Ditto Small room - Risk of tripping or inadvertent damage to system due to overcrowding. Users The room is equipped and intended for a maximum of 5 people in normal circumstances, as explained during training. Use by inadequately trained users Users Environment & People: Prolonged use of equipment can result in eye strain and ergonomic hazards 533576247 Users All users must be authorised; before this can occur they must have received proper training. They must also sign a declaration that they have read the local rules. Ambient lighting kept as high as possible, restrict length of time using equipment, workstation designed for ease of use and fully adjustable chairs provided. Yes Low Yes Low Yes Low 6