objective - Ali & Sons

advertisement

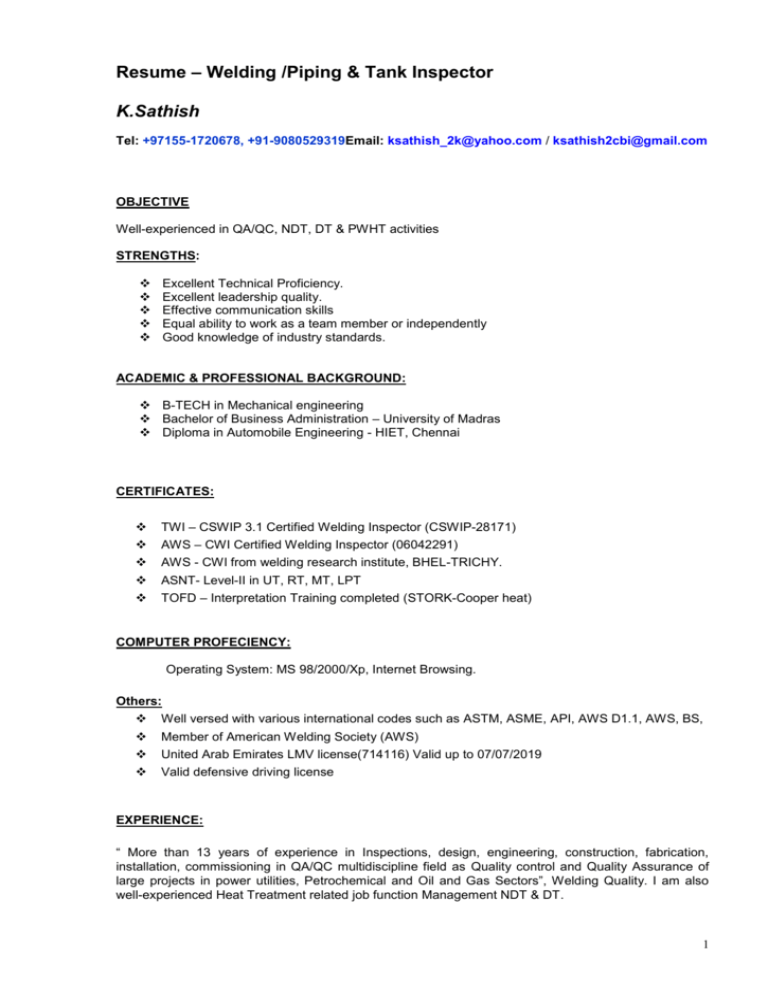

Resume – Welding /Piping & Tank Inspector K.Sathish Tel: +97155-1720678, +91-9080529319Email: ksathish_2k@yahoo.com / ksathish2cbi@gmail.com OBJECTIVE Well-experienced in QA/QC, NDT, DT & PWHT activities STRENGTHS: Excellent Technical Proficiency. Excellent leadership quality. Effective communication skills Equal ability to work as a team member or independently Good knowledge of industry standards. ACADEMIC & PROFESSIONAL BACKGROUND: B-TECH in Mechanical engineering Bachelor of Business Administration – University of Madras Diploma in Automobile Engineering - HIET, Chennai CERTIFICATES: TWI – CSWIP 3.1 Certified Welding Inspector (CSWIP-28171) AWS – CWI Certified Welding Inspector (06042291) AWS - CWI from welding research institute, BHEL-TRICHY. ASNT- Level-II in UT, RT, MT, LPT TOFD – Interpretation Training completed (STORK-Cooper heat) COMPUTER PROFECIENCY: Operating System: MS 98/2000/Xp, Internet Browsing. Others: Well versed with various international codes such as ASTM, ASME, API, AWS D1.1, AWS, BS, Member of American Welding Society (AWS) United Arab Emirates LMV license(714116) Valid up to 07/07/2019 Valid defensive driving license EXPERIENCE: “ More than 13 years of experience in Inspections, design, engineering, construction, fabrication, installation, commissioning in QA/QC multidiscipline field as Quality control and Quality Assurance of large projects in power utilities, Petrochemical and Oil and Gas Sectors”, Welding Quality. I am also well-experienced Heat Treatment related job function Management NDT & DT. 1 Job History 1) MOODY INTERNATIONAL in Abu Dhabi –NOV 2010 to Till date QA/QC Welding/Piping & Tank inspector (TPI for GASCO) Project- Gasco IGD Habshan 5, Habshan, Abu Dhabi Shell development inspections as per code API-650,620 Inspection of storage tanks during construction/maintenance & Refurbishment such as verification of foundation, bottom slope/ radius & check plumbness, peaking & banding, static hydro test, settlement check etc. Witnessing of all Destructive and Non-destructive testing. Review and Acceptance of Material Receiving inspection for Plates/Pipes, Fittings, Valves, Instruments, and vendor supplied Equipment’s Surveillance Inspection.(Fit up, Weld Visual, Welding consumables check and Monitoring of various welding process) Conduct routine surveillance inspection and monitoring of the NDE and Welding activities carried out on the Construction sites and Sub-Contractor’s workshops and confirm the implementation of all requirements of relevant Codes & Standards, Welding Specifications, and Method Statements. Inspect the quality of products / consumables / materials comply with requirements of established Standards & project Specifications. Ensure that all the utilized equipment and consumables are of the appropriate and approved/certified type and there are in a good status of maintenance and sufficient in number. Identify the correct welding procedure specification and verify the welders meet the WPS requirements and project specifications Monitoring the parameters is within the limits of approved WPS. Monitor Welder performance and conduct visual inspections of welds Radiographic film interpretation, in accordance with applicable code and project specification Inspection of consumable store to verify electrode baking and holding temperature, relative humidity including consumable control and issue. Ensure Sub contractor maintaining the proper records and it meets job requirements specification. Witness and Inspect Sub-Contractor during qualification of welders and procedures in accordance with applicable codes and specification Issuing and resolving Non Conformances, taking corrective & preventive actions for all construction activities of the project Make sure the Inspection & Test Plan of each activity is fulfilled and “hold points” of the company's team are completed in due time. Coordinate and supervise welding inspectors’ teams during activities. Review of NDT reports, PMI reports, Ferrite test reports and PWHT charts in accordance with approved procedures and codes. Ensure these activities meet Line class and project specification requirements Review and prepare punch lists for Hydrostatic/Pneumatic Test Packs. Actively participate in maintaining and upgrading of this documentation in compliance with Codes, Standards, Project Specifications and industry best practices. Witnessing of Hydrostatic/Pneumatic tests. Review / comment Hydro Test Packs, Spool release Documents and other project technical documentation, including Sub-Contractor’s NDE and Welding documents. Actively participate in maintaining and upgrading of this documentation in compliance with Codes, Standards, Project Specifications and industry best practices. Audit and inspect equipment such as welding machines, NDT equipment’s etc. Advice and assist Sub-Contractors in maintaining and upgrading their equipment to ensure high quality job. Monitor the construction process to ensure performance meets job quality and design requirements in accordance with Company procedures and international standards Interpretation of construction drawings, scope of works, established standards and specifications applicable to the projects. Inspects Sub-Contractors workshops/construction sites and report / advice any problem concern regarding HSE in particular for NDE and welding activity. 2 2) TECNICAS REUNIDAS in Abu Dhabi –March 2009 to August 2010 QA/QC Welding/Piping & Tank Inspector (In Borouge 2) Project- Borouge 2 , Ruwais, Abu Dhabi JOB Responsibilities Shop floor inspection and testing of fabrication of pressure vessels, Pipes, Pipelines, exchangers and storage tank etc. The implementation of the site Quality Plan and all procedures and specification concerning the inspection of the project. Shell development inspections as per code API-650,620 / BS7777 for double wall storage tank. Co-ordination of Quality inspection matters liaising with sub-contractor management and work force. Monitoring and ensuring that the appropriate consumables being distributed to welders in order to make sound weld. Inspection of dissimilar metal joining such as stainless steel to carbon steel. Qualification & performance monitoring of welding personnel. Monitoring of various welding process like GTAW, SMAW, FCAW & SAW. Inspection of storage tanks during construction/maintenance & Refurbishment such as verification of foundation, bottom slope/ radius & check plumbness, peaking & banding, static hydro test, settlement check etc. Witness the tests such as vacuum test, diesel penetration test, measurement accuracy test, UT, PT, MPI & Oil tests of tank bottom plate and shell. Witnessing of hydro test & pneumatic test of tanks, piping. Preparation/maintaining of QA/QC document such as, welding sequence & Erection, Hydro test procedure, Test package for pneumatic & hydro test for tank & piping. 3) CB&I (Chicago bridge & Iron Compnay) in Abu Dhabi- Jan 2006-Sep 2008 QA/QC Welding/Piping & Tank Inspector Project- Gasco 3rd NGL Project, Ruwais, Abu Dhabi JOB Responsibilities Review and Acceptance of Material Receiving inspection for Plates/Pipes, Fittings, Valves, Instruments, and vendor supplied Equipments. Shell development inspections as per code API-650 / BS7777 for double wall storage tank Initiating, recommending and assisting in providing effective solution to such problems that may arise concerning visual inspection, magnetic particle testing, inspection, and liquid penetrant testing inspection. Ensuring Quality Standard and Procedures are maintained. Inspection on welding (check joint fit up, seam orientation, plate or pipe no, heat no, alignment, visual inspection & numbering and preparation of Inspection reports & NDT progress chart for storage tanks & pipelines Fully responsible for Radiographic interpretation. Conducting/Witnessing Welder qualification test and issue certificates. Monitoring of various welding process like GTAW, SMAW, FCAW & SAW. Inspection of storage tanks during construction/maintenance & Refurbishment such as verification of foundation, bottom slope/ radius & check plumbness, peaking & banding, static hydro test, settlement check etc. Perform line checking/prepare and check official test pack prior to release for hydro testing by ensuring that all welding inspection and NDT activities affecting the quality of welds contained in each piping spools of an isometric have been completed and accepted. Witnessing of hydro test & pneumatic test of tanks, piping and preparation of test certificates. 3 4) Metal Scan Inspection Services in India – Sep 2003- Nov 2005 as QA/QC Inspector JOB Responsibilities Fully responsible for Radiographic interpretation Initiating, recommending and assisting in providing effective solution to such problems that may arise concerning visual inspection, magnetic particle testing, inspection, and penetrant testing inspection. Witnessing of all Destructive and Non-destructive testing at various sites for different clients... Monitoring all types of process documentation required for fabrication, erection and commissioning etc. Preparation of QA/QC procedures for various clients Conducting/Witnessing Welder qualification test and issue certificates. Supervision of Welding, Pre-heat and PWHT of weld. Ensuring Quality Standard and Procedures are maintained Review and Acceptance of Material Receiving inspection for Plates/Pipes, Fittings, Valves, Instruments, and vendor supplied Equipments Development and implementation of inspection checklist and report/format. Witness the tests such as vacuum test, diesel penetration test, measurement accuracy test, UT, PT, & MPI tests of tank bottom plate and shell. Surveillance Inspection.(Fit up, Weld Visual, Welding consumables check and Monitoring of various welding process) Co Ordination of all Destructive and Non-destructive testing at various sites for different clients. 5) Bailey Hydropower Pvt Ltd in India – May 1999- July 2003 as Quality Control Engineer JOB Responsibilities Inspection of hydraulic cylinders, mobile components, bearings and valves. Co Ordination of all Destructive and Non-destructive testing. The job involves daily inspection of fabricated pipes and structures, welding inspection, quality control, Radiographic Film interpretations etc. Reviewing and verifying inspection and NDT reports and witnessing Activities as per quality control plan. Painting inspections and quality control. Ensuring that all codes, standards and Specifications requirement are strictly adhered during Execution. Initiating, recommending and assisting in providing effective solution to such problems that may arise concerning visual inspection, magnetic particle testing, inspection, and penetrant testing. Preparations of inspection reports, and all sorts of inspection and NDT activities and conducting audits on internal system. 4 PERSONAL DETAILS: Permanent Address : 27/23, yogeswaran cross street, Madipakkam, Chennai. Tamilnadu, India, Pin--600091 Telephone in India : +91-9941980038, +91-9080529319(Res) +91-9884242003 Age & DOB : 34 Years, 23 / Feb /1978 Sex / Marital Status : Male / Married Languages Known : English, Tamil & Telugu Pass Port Details : Number Date of Issue Date of Expiry Place of issue : : : : H7732513 13/09/2009 12/09/2019 Abu Dhabi Declaration I do hereby declare that above furnished details are true to the best of my knowledge, Place: Date: Sathish. K 5