A Word document is available here

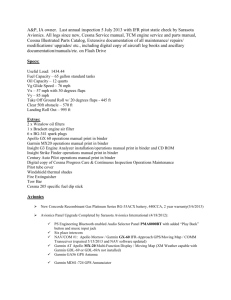

advertisement

Manufacturer and model: Cessna Aircraft Co. A185F. Date: May 28, 2010. Aircraft total time since new: 827.5 hours. Aircraft disassembled and transported for complete refurbishment as follows: FUSELAGE: Floats removed and wheel gear temporarily installed. Paint stripped from fuselage, door frames and door edges. All interior panels, insulation and headliner removed. Windshield replaced with new LP Aero 316CMB windshield w/o center strip (STC SA4741NM). All side windows replaced with new LPAero units. All new seals installed on both doors and all windows. Ski brackets permanently removed. Fuel shutoff valve r & r - inspected and lubricated. Fuel drain valve @ accumulator tank replaced (STC SA2272CE). Excess/unused wires removed from fuselage. All new shockmounts installed in instrument panel. Overvoltage light replaced. Cessna SK185-27 installed (stabilizer jack access kit). Trim screwjacks removed, disassembled, cleaned, inspected, lubricated, reassembled and reinstalled. Left outboard seat rail replaced. Compass diaphragm and gaskets replaced and refilled with fluid. Replaced rusted hardware a/r in spar bearing blocks. Spar carry-through inspected internally with borescope - no corrosion found. Hoisting rings and tailwheel spring sandblasted, inspected, primed, painted and reinstalled. New grommets installed around hoisting rings. Old ELT and antenna removed. New Artex ME406 ELT c/w whip antenna installed per manufacturer's instructions. Right cowl flap hinge replaced. Both cowl flaps adjusted per Cessna service manual. Both fuel drain valves in belly replaced with new Saf-Air SA82 drain valves. All new seat roller washers installed on both front seats. New SCAT hose installed to defroster, lt. radio cooling and both rear seat vents. New 4509 sealed beam installed in taxi light. Diode installed on starter solenoid and ignition switch lubricated per AD93-05-06. Auxiliary fuel pump (electric) replaced with fresh overhauled 4140-00-17 unit s/n 55370. Cabin roof cleaned inside and inspected. No corrosion found. Zinc Chromate primer applied. New insulation installed in cabin roof. Headliner repaired and reinstalled. Door frames and door edges prepped, epoxy primed and painted original brown (F5130J tinted). All new Vantage Plane Plastics interior panels installed and dyed original brown. Individual #3 and #4 (center) seats and brackets installed per Cessna 185 Parts Manual. (Removed serviceable from C-FHOP). All new Airtex seat upholstery installed. All seat belts and shoulder harness re-webbed. Hoses replaced @ tee in fuel vent/return line above headliner front right side. All new stainless camloc cowl fasteners installed. Complete new fuel strainer assembly installed. Exchange overhauled 4140-00-17 electric fuel pump installed. Cont'd. Page 2 of 3. ENGINE: All fluid hoses replaced FWF. #3, #4 and #6 cylinders overhauled (channel chrome) and reinstalled c/w new rings and gaskets. Internal inspection for corrosion of crankcase and accessory case carried out with borescope and visually. No corrosion found. All new baffle seals installed. Baffles repaired a/r. Baffles stripped, prepped, primed , painted white and reinstalled. Muffler shroud repaired. New M2381U Slick ignition harness installed (weathered). All new intake hoses installed on engine. J9534-20 alternator shock mount replaced. New alternator belt installed. New throttle control installed (MCC299505-0501). New mixture control installed (MCC299507-0401). New 0750137 ground strap installed on rt. rear engine shockmount. Engine mount sanded, inspected, primed and repainted. Broken engine control bracket p/n 0750195-12 welded. Engine controls rigged per Cessna 185 service manual. Correct hardware installed on engine and prop controls per AD 86-24-07. F & M C6LC-S full flow oil filter adapter and 48108 oil filter installed per STC SE09356SC. All new SCAT hoses installed FWF. New BA8103-1 air filter installed. Fuel manifold valve repaired at A.T.C. and reinstalled. Fuel control unit repaired at A.T.C. and reinstalled. New R-646212-23A7 fuel pump s/nB09KA174R installed. Fuel pump pressure checked per Cessna service manual. WINGS: Wings removed from fuselage. Flaps, ailerons and control cables removed from wings. All paint stripped from wings, flaps and ailerons and inspected. Ailerons balanced in accordance with Robertson SB#20 (per AD83-17-06). Both wing tips replaced. Both fuel cells replaced with new (FFC 1200065-3 and 1200065-4). Robertson kit rigged per manufacturer's instructions. All moving parts in wings inspected and lubricated. New Eagle CMS-2 fuel drain valves installed in both wing fuel tanks (STC SA01380CH) New aileron carry through cable installed. McFarlane MCSK100 flap roller wear washers installed (STC SA01074WI) S1450-3S10-032 flap wear washers installed per Cessna SEB95-3. Flap buttons replaced a/r. New cotter pins installed in all aileron hinges. RH aft fuel tank outlet replaced with new p/n 0720007-7 outlet. EMPENNAGE: Empennage removed from fuselage. All paint stripped from empennage and inspected. New tips (2) installed on horizontal stabilizer. Replaced center and upper rudder hinge bearings. Replaced outer and middle elevator hinge bearings on both elevators. Beacon bulb replaced. Page 3 of 3. PROPELLER: Propeller overhauled at Leavens Aviation and reinstalled. All paint stripped from spinner and spinner bulkhead, inspected, prepped, primed and repainted. FLOATS: All covers removed Floats leak tested Covers reinstalled Floats and rigging and floats cleaned and inspected. and resealed a/r. using all stainless hardware. repainted with Amerlock 400AL epoxy paint. GENERAL: New Gill G35 battery installed. Aircraft prepped, primed with DuPont 2580CR epoxy primer and painted with Nason 2K urethane: N7817IB matterhorn white; 143IB maroon; 43523IB silver metallic. All controls balance checked per Cessna 185 service manual and Robertson instructions. Aircraft reassembled with new hardware and rigged per Cessna 185 service manual and Robertson STOL instructions. Stainless screw kit installed. EDO 597-3430 floats reinstalled and rigged per manufacturer's instructions. New water rudder direct cables installed on both sides. Water rudder pulleys replaced a/r. New 0742016 water rudder steering springs installed. Independent inspection carried out on all flight and propulsion controls that were affected by this work. Airworthiness directives researched and complied with. Aircraft ground run and prop governor adjusted.