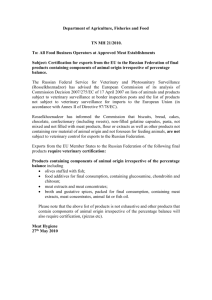

VET 604.400.026 - EFTA Surveillance Authority

advertisement

EFTA SURVEILLANCE AUTHORITY GOODS DIRECTORATE Brussels, 4 March 2002 Doc. No: 02-2387-D Ref. No: VET 604.400.026 FINAL REPORT FROM A MISSION CARRIED OUT IN NORWAY FROM 7 MAY TO 11 MAY 2001 CONCERNING LIVE POULTRY AND POULTRY MEAT Please note that the comments to the factual content from the Norwegian Authorities have been included in the body of the text or as footnotes as bold italic print. In addition statements with regard to measures taken to remedy deficiencies have been included as an addendum. ______________________________________________________________________________________________ _ Rue de Trèves 74, B-1040 Brussels, Tel: (+32 2) 286 18 11, Fax: (+32 2) 286 18 00 E-mail: registry@surv.efta.be Homepage: www.efta.int Page 2 1. Introduction 1.1. Country visited 1.2. Dates of mission 1.3. Composition of mission team 1.4. Legal basis for the mission 1.5. Objective of the mission 1.6. Background of the mission 1.7. Sites visited during the mission 1.8. General comment 2. Structure of the Competent Authority and short description of the poultry industry 2.1. Summary description of the Competent Authority 2.2. General information on the poultry industry in Norway Page 3 3 3 3 3 3 4 4 4 4 4 5 3. Description of the system and findings 3.1. Approval procedures for poultry meat establishments 3.2. Veterinary supervision of establishments 3.3. Own checks 3.4. Pre-slaughter health inspection and post mortem inspection 3.5. Use of immersion chillers 3.6. Training programmes for company auxiliaries and staff 3.7. Trade in meat – trace back – meat export 3.8. Veterinary supervision of poultry farms and hatcheries 3.9. Veterinary supervision during transport and at the slaughterhouse concerning animal welfare 3.10. Veterinary control of zoonoses 3.11. Welfare of laying hens kept in battery cages 5 5 6 8 10 12 12 12 13 4. Action taken during, at the end and after the mission 17 5. Conclusions 5.1. – 5.8. The different issues included in the scope of the mission with regard to the production of fresh poultry meat. 5.9. Veterinary supervision during transport and at the time of slaughter regarding animal welfare. 5.10 Veterinary control of hatcheries 5.11 Veterinary control on zoonoses 5.12 Veterinary control on the animal welfare of laying hens in battery cages. 18 6. Recommendations to the authorities of Norway 7. Addendum 20 21 14 15 16 18 19 19 19 19 Page 3 1. Introduction 1.1. Country visited Norway 1.2. Dates of mission 7 to 11 May 2001 1.3. Composition of the inspection team The inspection team was comprised of two officials from the EFTA Surveillance Authority and one observer from the Food and Veterinary Office (FVO) of the European Commission. 1.4. Legal basis for the mission The legal basis for the mission is the acts laid down in the following points in Chapter I of Annex I to the EEA Agreement: Point 6.1.2 (Council Directive 71/118/EEC on health problems affecting trade in fresh poultry meat as amended). Point 9.1.3 (Council Directive 88/166/EEC laying down the minimum standards for the protection of laying hens kept in battery cages). Point 1.1.1 (Council Directive 89/662/EEC concerning veterinary checks in intraCommunity trade with a view to the completion of the internal market). Point 4.1.4 (Council Directive 90/539/EECon animal health conditions governing intra-Community trade and imports from third countries of poultry and hatching eggs). Point 5.1.2 (Council Directive 91/628/EEC on the protection of animals during transport). Point 7.1.8 (Council Directive 92/117/EEC concerning measures for protection against specified zoonoses and specific zoonotic agents in animals and products of animal origin in order to prevent outbreaks of food-borne infections and intoxications). Point 9.1.2 (Council Directive 93/119/EEC on the protection of animals at the time of slaughter or killing). Point 1.2.74 (Council Decision 98/139/EC laying down certain detailed rules concerning on-the-spot checks carried out in the veterinary field by Commission experts in the Member States). 1.5 Objective of the mission The objective of the mission was to assess compliance in Norway with the requirements of the above mentioned Acts in particular in relation to: Approval procedure for poultry meat establishments. Veterinary supervision of slaughter hygiene, establishments and live animal health inspections and post-mortem inspections. Veterinary supervision of poultry farms. Veterinary supervision of the protection of animals during transport and at the time of slaughter and of the protection of laying hens in battery cages. Supervision and checks on trade in poultry meat with particular attention to controls at origin and destination and the documentation. Control of zoonoses, in particular control of salmonella in poultry. Page 4 1.6 Background of the mission This mission is included in a series of missions to the EFTA States in order to verify a correct and uniform application of the requirements of the acts referred to in Chapter I of Annex I to the EEA Agreement. 1.7 Sites visited during the mission Two integrated poultry slaughterhouses (slaughtering, cutting and cold storing). One cutting plant integrated into a meat products establishment. Two hatcheries, one for broilers and one for layers. Two farms, one for broilers and one for hens kept in battery cages. The Norwegian Veterinary Institute including its unit for epidemiology and the Norwegian Zoonosis Centre. Three municipal food control authorities (Kommunalt næringsmiddeltilsyn, KNT) and the official veterinarians (OVs) employed by them to supervise the approved establishments. One municipal laboratory for salmonella examination. The central Competent Authority (CA) for veterinary public health and the central CA for animal health and animal welfare. Four local animal health officers (District Veterinarians, DVs). Three regional veterinary officers. 1.8 General comment The description in Chapters 2 and 3 of the structure and systems of veterinary supervision is based on information from the CA in Norway. 2 Structure of the CA and short description of the poultry industry 2.1 Summary description of the CA Central level The Norwegian Food Control Authority (Statens næringsmiddeltilsyn, SNT) is responsible for approving and listing the poultry meat establishments. It is also responsible for supervising them from a veterinary public health point of view. The SNT’s staff members are responsible for fresh meat, meat products and poultry meat establishments. The Norwegian Animal Health Authority (Statens Dyrehelsetilsyn, SDT) is responsible for approval, listing and supervision of farms and hatcheries regarding animal health and animal welfare. Local level The KNTs are required by law to employ OVs to perform the control of the approved poultry meat establishments. The DVs, who belong to the SDT, are performing supervision and control of animal health and animal welfare on farms, breeding farms and hatcheries. For more detailed description of the organisation of the CA reference is made to Chapter 6 in the EFTA Surveillance Authority report (Doc. No. 01-1795-D), which is available on it’s homepage: www.efta.int. (The report will be found by the following steps: EFTA Surveillance Authority/Publications/Veterinary issues-Control matters/11 May 2001. Final report of a mission to Norway from 27 November to 1 December 2000…) Page 5 A Zoonosis Centre is organised within the Norwegian Veterinary Institute, although its activity is also on behalf of the Norwegian Public Health Institute. There are two full time and two part time (20%) veterinary scientists and one part time (60%) office staff employed at the Centre. There is a counselling board with ten representatives: Norwegian Veterinary Institute, the Norwegian Public Health Institute, SNT, SDT, The Public Health Authority, The Agricultural Authority, KNT, The Veterinary College, The Public Health Research Institute and the Consumers Council respectively. The Centre was established to collect, analyse and present epidemiological data on zoonoses and zoonotic agents in Norway in order to prevent the spread of zoonoses through feed, food, live animals and animal products. Finally, communication and information to all interested parties including the consumers is a central task. Furthermore it is to act as a bridge in the cooperation between the professional environment and the different national authorities. 2.2 General information on the poultry industry in Norway in the year 2000 There are nine poultry slaughterhouses approved in accordance with Article 6 of Council Directive 71/118/EEC as amended. Six of these are integrated with cutting plants and cold stores. There are two establishments approved in accordance with Article 7 of the Directive (limited capacity). The poultry industry in Norway has one major operator, which is a co-operative owned by farmers. The co-operative owns the only breeding station in Norway for broilers. The breeding station is importing day old chickens from Scotland every 13 weeks. The cooperative also owns five of the nine slaughterhouses, the major poultry meat cutting and production plant, which is handling more than 50% of the poultry meat produced annually in Norway. There is rarely import of poultry products from other EEA States. The production of fresh poultry meat was 24-25.000 tons. The rearing is done on about 500 farms, mostly in the regions north and east of Oslo (the counties of Hedmark and Østfold) and in the regions around Trondheim and Stavanger. The breeding and production of layers are mainly done in the Stavanger region. The eggs are produced on about 3700 farms all over the country with a concentration of about 600 farms is in the Stavanger region. The production of eggs was about 25.000 tons. 3 Description of the system and findings 3.1 Approval procedures for poultry meat establishments Legal basis Regulation of 21 March 1995 nr 265 on hygiene and control etc relating to the production and placing on the market of fresh poultry meat. 3.1.1 Description of the approval procedure An official application form/evaluation form has been prepared by SNT to ensure a harmonised evaluation of establishments at the local level. The establishments submit an application to the local KNT. KNT gives the establishment scores according to the degree of fulfilment of legal requirements. The KNTs OVs evaluate the establishments applying for approval. Based on their evaluation, the KNT makes a statement, recommending or not recommending SNT to approve the establishment. The completed application form is then sent to SNT for evaluation. Page 6 3.1.2 The application form, maps and documentation, the general information about the establishment and the letter from KNT describing the establishment, are evaluated by senior veterinary officers in SNT before an approval is given. If an establishment is approved, it is assigned an approval number. Findings, observations There was no apparent cooperation in general between the SNT and SDT in the poultry area. None of the veterinary officers in SNT or SDT have poultry meat establishments as their main responsibility1. There are no internal routines in SNT to inspect or audit the performance of the KNTs and the poultry meat establishments before approval is given2. The inspection team was informed about two slaughterhouses (for ducks and turkeys), which were approved with limited capacity (Article 7 of Council Directive 71/118/EEC), but did not appear on any official list for approved establishments3. 3.2 Veterinary supervision of poultry meat establishments Legal basis §13 in the Meat Production Act of 10 January 1997 No. 9. Document of 27 October 1997 containing the delegations given SNT from the Ministry of Agriculture. Document of 8 July 1999 No. 866 containing the control activities administered by SNT. § 4 in the Act on Food Control of 19 May 1933 No. 3. Document of 29 April 1988 No. 312, containing delegations given to SNT by the Ministry of Health and Social Affairs. Regulation of 17 February 2000 No. 251 on the delegation of powers to KNTs concerning food control. Instructions and administrative provisions sent in circular letters (Rundskriv) to specify how certain tasks related to supervisory/control activity are expected to be performed by official control personnel. 3.2.1 Description of the system Central level Supervisory guidelines (Tilsynsveilederen) in order to aid the KNTs in supervising/controlling approved establishments. 1 It was held by the Norwegian Authorities in their letter received 3 August 2001 that one of their Senior Veterinary Officers has poultry meat establishments as part of her main responsibility. 2 It was held by the Norwegian Authorities in their letter received 3 August 2001 that, when SNT during the handling of applications for approval find that KNTs evaluations/recommendations are insufficient, or if establishments not fulfilling legal requirements are recommended approved by KNT, establishments are to be visited by official veterinarians from SNT before further handling of the application received. 3 It was held by the Norwegian Authorities in their letter received 3 August 2001 that only one of the two slaughterhouses mentioned was actually approved for limited capacity production at the time of inspection (Holte Gås og And approved 28.02.2000) and that this establishment was missing from the official list, but is now included. It was also held that the other establishment mentioned (Svehaugen) was approved for export 16.11.2000. Page 7 To ensure a harmonised control and supervisory system, SNT arranges seminars where both the local and central authorities are present. Focus is on calibration according to practical supervision/control, and interpretation of legal requirements. SNT also audits the individual KNTs on a regular basis. Local level The OV or an auxiliary conduct the inspection/control of poultry meat. The cutting plants are inspected daily, either by the OV or an auxiliary. The official inspectors make written reports after each visit in the establishments. These reports include observations made on the particular day of inspection, and are addressed to the owner of the establishment. The functioning of the quality control system of the establishments is continually monitored and evaluated (frequent controls), and results and conclusions regarding hygiene checks (e.g. cleaning of utensils and surfaces, bacteriological quality of meat and water quality) are to be included in the reports. Hence these reports include information regarding the inspectors’ overall impression of the establishment at a given time. If there are major faults or shortcomings, decisions are made to ensure correction and fulfilment of legal requirements. In addition to “on the spot” inspections, establishments are audited annually. After audits the establishments are provided with audition-reports. These documents are provided to the administration of the establishments and contain descriptions of the observation items in great detail. KNT also reports annually to SNT about the individual deficiencies and shortcomings found in the establishments. These facts are provided to SNT electronically via an internal interconnecting data-system (Sedon-PC). Every quarter the KNTs also report to SNT about the results of the poultry meat inspections. Findings, observations The inspection team found that: SNT had not inspected or audited the KNTs visited with respect to the correct application of the requirements of the poultry meat legislation, which seems to be due to shortage of staff. The staff was not sufficiently trained as, in particular, the live animal control system was generally deficient, in one place non-existent, and indications that, even when knowing, violations of the rules were accepted by SNT without action being taken (notes from telephone conference between the different KNTs and SNT 6 September 2000). The OVs visited were not supervising: o the use of the health marks o the poultry meat going in and out of the establishments o the own check systems to see to if they were operating properly, in particular concerning correct registration and follow up of deficiencies. Severe hygiene deficiencies, which had not been noted by the OVs, such as: o The control of the cleaning was not functioning in any of the establishments visited. o The reports from the OVs to the owners did not cover all relevant aspects, which should be covered by an inspection. o Water was used without being proven potable. Regarding more specific issues the mission team made the following observations: Page 8 Structure and lay out o The structures of the poultry meat establishments were deficient from two points of view. Firstly, rooms were missing, such as rooms for wrapping and packaging and rooms for ingredients (meat products requirement), or were too small for the scale of the operations taking place. Secondly, the lay out for the flow of products and personnel was such that there were ample risks of cross contamination in all establishments visited. Installation and equipment o There were unprotected overhead installations, which were difficult to clean in all establishments visited. o Equipment and machinery on the slaughter lines that were not designed, constructed or adjusted to avoid contamination, cross-contamination and splashing was in use. o Hand washing facilities, knife sterilisers and boot washers were missing in some places. o Wastewater was not always positively ducted and gratings were missing on drains. Maintenance and cleanliness o Although maintenance plans were in place, the maintenance of the establishments was varying. o Cleanliness was varying, and the control of the cleaning was not functioning in any of the establishments visited. Operational hygiene o Packaging was taking place in cutting rooms without these being large enough or in rooms where different incompatible operations were carried out. o Products were regularly not protected as wrapping was often loose or not solid enough, and the packaging was not protecting the poultry meat during handling, storage and transport. o Cutting was not well organised, poultry was brought for cutting without being properly eviscerated, the flows of products were bad, the rooms overcrowded and offering systematic cross contamination risks in the establishments visited. Knives and other equipment were not frequently enough cleaned and sterilised. o The handling of offal and waste was not well organised and clearly separated from handling of products. o Separation between clean and unclean operations was in general insufficient. o Crates were used for waste and products without any indication of the purpose. Crates were also reused without being cleaned and disinfected. o In a number of rooms there was accumulation of condense water, which could contaminate exposed products. 3.3 Own checks 3.3.1 Description of the system The presence of an own check system is one of the key-criteria to be present before approval is recommended by KNT. Page 9 Documentation regarding the own check system is to be kept by the establishment for at least two years and the records have to be available to the OV whenever he/she asks for them. Findings, observations Water quality control was not properly supervised as o initial analyses were not done and sometimes updated drawings of the internal distribution system and a numbering of all the taps were missing. o All required parameters were not examined and monitoring was not done on samples taken from representative taps. o Clear indications of contamination of the water were not reacted upon by the OVs. o Supply of water not in accordance with the Water Directive (Council Directive 80/778/EEC) was also accepted without reaction4. Pest control systems were in place. o However, follow-ups were not done, even when clear signs of pest activities were noted. o In one establishment visited there was no link between the pest control registrations, the maintenance plan and the daily supervision of the establishment in the sense that drains were not covered with gratings, doors were left open waste was accessible to pests on the outside of the premises. Temperature control systems were in place. o However, the performance did not enable the OV to check that the requirements of the Directive were being met at all times as the frequency of registrations was not readable on the x-axis of the graphs presented. It was not always guaranteed that the temperatures measured were the real temperatures as a system including proof of calibrated instruments being used to guarantee correctness was sometimes missing. Health certificates of staff were in place. o However, they were not always required in advance of employment and o they were not always correctly worded5. 4 Control of the cleaning was never effectively performed and followed up. Training of staff was not always involving the OV during preparation and performance. In the final meeting Norway was asked to provide written assurances within one week that the requirements concerning potable water supply were complied with as soon as possible. Such assurances were submitted. 5 It was held by the Norwegian Authorities in their letter received 3 August 2001 that routines making sure health certificates are in place in advance of employment are now in place in all establishments visited. Page 10 3.4 Pre-slaughter health inspection and post mortem inspection 3.4.1 Description of the system Pre-slaughter health inspection The Norwegian authorities did not provide a description of the live animal health check system. Post mortem inspection All poultry carcasses and the organs from the birds are inspected visually, and if necessary palpated, directly after slaughtering. When the gut is removed prior to post-mortem (PM) inspection, the whole organ set from at least 5 % of the group of birds, sent to be slaughtered from one individual owner is to be controlled separately. If an auxiliary during the PM inspection reveals an abnormal carcass, that particular carcass is to be contained. On a random basis the contained carcasses will have to undergo further examination by the OV. After examination the OV decides upon whether or not all arrested carcasses are unfit for human consumption. The OV is obliged to register the results of the AM and PM during the slaughtering process. The OV can decide if further testing is necessary, for example bacteriological testing and residue control testing, in order to decide if the carcasses are unfit for human consumption or not. If unfit for human consumption, the OV is obliged to dispose the carcasses and keep a record of this. All results regarding condemned carcasses are to be reported to SNT on a quarterly basis. The OV is obliged to be physically present in the establishment during the PM inspection, but he/she can choose to delegate the act of PM inspection to an auxiliary (under his/her power, responsibility and supervision). Under the supervision and observation of the OV, the establishment’s personnel are allowed to assist in the PM inspection. This personnel is then obliged to prepare the birds for the PM inspection, and assist the OV when he/she is performing PM inspection if necessary. If the OV considers the assistance unsatisfactory the PM inspection has to be discontinued. The OV is obliged to check a minimum of 300 poultry carcasses per day. This is a legal requirement although the birds have already undergone PM inspection performed by auxiliaries. Page 11 Findings, observations Pre-slaughter health inspection It is stated in Article 56 of the Norwegian poultry regulation that the flocks for slaughter should be supervised according to detailed ruled issued by the Ministry of Agriculture. Such rules have never been issued. The only written statements presented to the mission team were in a letter, dated 23 June 1995 from the Ministry to the regional veterinarians and DVs, which was handed over to the mission team in the final meeting. o In this letter the Ministry assesses the minimum supervision of holdings producing more than 20.000 chickens, 15.000 ducks and 10.000 hens and turkeys a year to be two times per year. o The letter is also expressing the view that it is the owner who does the AM control. o The link between the veterinary supervision as a prerequisite for the owner’s declaration is not established in this letter, nor is it clarified that the inspection to be done by the official veterinarian performing the live animal health check on the farm before signing the certificate, which follows the flocks for slaughter, shall comprise the details written in point 27 of Chapter VI of Annex I to Council Directive 71/118/EEC as amended. Pre-slaughter health inspections were severely deficient as o the OVs at one of the slaughterhouses visited did not ask for the information required or take action to establish the correct system of information. o In the holding for broilers that was visited, the DV did not examine all the details of the flock records, which are required and the owner did not keep copies of the own declarations for the flocks that he sent for slaughter. o In one of the slaughterhouses visited the own declarations were incomplete. In the other one they were missing. o Statements were given that the holdings delivering flocks for slaughter to one of the slaughterhouses were not under supervision of a DV and that this could also be the case in other slaughterhouses. In the final meeting Norway was asked to provide written assurances within one week that the requirements of pre slaughter health inspections were complied with. Such assurances did arrive, see later in the report. Page 12 Post mortem inspection The post mortem inspection system was deficient as: The body cavities of the birds were not examined. Only a limited number and not all the relevant diagnoses as noted in point 53 a) of Chapter IX of Annex I to Council Directive 71/118/EEC as amended, were used when taking decisions after post-mortem examinations. The auxiliaries were taking decisions. The system, describing that only 5% of the birds should be examined together with the viscera, is incorrect. 300 birds, including the viscera and the body cavities, were not examined at random from each consignment after the completion of the post-mortem inspection. 3.5 Use of immersion chillers 3.5.1 Description of the system Immersion chillers are forbidden in Article 33 of the Norwegian poultry regulation and are not used in Norway. 3.5.2 Findings, observations No immersion chillers were observed in the establishments visited. 3.6 Training programmes for company auxiliaries and staff 3.6.1 Description of the system The OV can be assisted by auxiliaries. 3.6.2 The auxiliaries, who can be company staff or officials, must complete a course and pass an exam approved by SNT. The auxiliaries, who are employed by the companies, are operating independent of the establishment. Findings, observations The training programme for the auxiliaries that had been in use until now was not meeting the requirements of Annex III to Council Directive 71/118/EEC as amended, however, plans were submitted that indicated an improvement during 2001. 3.7 Trade in meat – trace back – meat export 3.7.1 Description of the system The points of incoming and outgoing transport of fresh poultry meat and poultry meat products are to be identified as a critical control points (CCP). At these points the establishments check if labelling (health mark), commercial documents, wrapping and temperature are according to legal requirements. To be able to verify to the OV that checks actually have been carried out, the establishments write down the results of the own checks. This written documentation is to be controlled and signed by the OV at a regular basis. Fresh poultry meat and poultry meat products are to be followed by documentation during transport, stating the amount of poultry meat under transport, identification of the establishment where the poultry meat was last handled, and a description of the transported products. Commercial documents/hygiene certificates and the goods under transport are to be controlled at arrival in the receiving establishment. Page 13 Only poultry meat products labelled according to the regulations are allowed to be stored or processed further at arrival. The commercial documentation/hygiene certificates have to be kept by the establishment for at least a one-year period in case of controls/supervision by the OV. There are no procedures regulating the printing of labels and wrapping material bearing the health mark. The OV is responsible for controlling the use of health marks in the establishments (including labels on the wrapping material if this includes the health mark). This means having the stamp used in his possession, allowing the auxiliaries to operate the stamp only when in use. The OV is also to be in charge of the use of labels and wrapping-material when this is bearing the health mark. This means only allowing the establishment to use this when under his/her control/supervision. 3.7.2 Findings, observations The commercial documents appeared to be marked with the official health mark including the approval number. In none of the establishments visited OV’s were supervising the use of the health mark. In none of the establishments visited was the OV supervising poultry meat going into and out of the establishment. There was no information about export of poultry meat from Norway. 3.8 Veterinary supervision of poultry farms and hatcheries 3.8.1 Description of the system Legal basis § 56, 57 and 58 of Regulation of 21 March 1995 nr 265 on hygiene and control etc relating to the production and placing on the market of fresh poultry meat. 3.8.2 6 Regulation of 31 January 1995 nr 107 on monitoring and control of the occurrence of Salmonella in live animals. This regulation requires that the local veterinary officer shall notify the local food control authority and the official doctor whenever the test show presence of Salmonella which can constitute a threat to public health. Findings, observations All supervision of the poultry farms and hatcheries were done by the DVs. They were restricting their performance of inspections according to the funds made available to the specific issue. It was not up to the DVs to prioritise in relation to the need for supervision6. The inspections performed were not always complete. There was no requirement to have a control of the microbiological quality of the health status and in one of the hatcheries visited no such controls were performed. It was held by the Norwegian Authorities in their letter received 3 August 2001 that it should be noted that the DV’s are given budgetary means to follow-up the legislation based on their own judgements and priorities in addition to the funds made available for routine inspections/specific issues given priority by the Central Unit of the Animal Health Authority. Page 14 Two of the DVs visited were part-time practitioners in the same area and the same holdings as they had official duties and their impartiality could therefore be questioned. The cooperation between the DVs and the OVs at the slaughterhouses was almost non-existent. The farm was only visited two times a year due to budgetary restrictions. The DV’s presence at the Authority’s inspection was the first visit this year to this farm. The inspection team was also informed that this year would be the first year when all the visits foreseen in the legislation will be performed according to the legislation. All relevant checks were not done i.a. the feed was not checked, as there were no instructions from the Ministry of Agriculture as foreseen in Article 56 of the Norwegian poultry regulation and the DV therefore had made his own certificate. A copy of the own declaration from the farm to the slaughterhouse was not kept at the farm. 3.9 Veterinary supervision during transport and at the slaughterhouse concerning animal welfare. 3.9.1 Description of the system The authorised stunning method used for poultry is electrical current provided through a waterbed. Details regarding this stunning method are given in the regulation on animal welfare in slaughterhouses. The OV and the auxiliaries carry out the supervision regarding animal welfare at the time of slaughter. If serious shortcomings or minor shortcomings occur repeatedly without being corrected, the regional veterinary officer has the power to suspend the approval given to the slaughterhouse. Guidelines on animal welfare in slaughterhouses were about to be issued and the latest copy of the draft was handed over at the initial meeting. Findings, observations Some uncertainties regarding the compliance with the transport requirements in southern Norway were observed. In northern Norway there is no poultry slaughterhouse. The northernmost slaughterhouse is the one in Ytterøy about 100 km north of Trondheim. Spent hens from northern Norway, where there are about 100.000 of them, were said not to be transported to southern Norway for slaughter, but killed and sold or disposed of as waste on the farms. Animal welfare during stunning and bleeding was observed by the inspection team to be satisfactory although it was unclear (not documented) to what extent and by which means this was controlled by the OVs. Page 15 3.10 Veterinary control of zoonoses The legal basis § 65 and 71 in Regulation 21 March 1995 nr 265 on hygiene and control etc relating to the production and placing on the market of fresh poultry meat, §17 in Regulation 10 April 1995 nr 368 on the monitoring and control of the occurrence of Salmonella in fresh meat and fresh poultry meat. 3.10.1 Description of the system The DV is obliged to report on any verified occurrence of zoonoses to the Norwegian Animal Health authority. The OV is obliged to notify SNT, the Norwegian Health Authority and the Norwegian Veterinary Institute if Salmonella is found in poultry meat and poultry meat products. If the finding of Salmonella is considered a threat to public health, the official local or regional doctor is to be notified according to § 4 in the Act of 5 August 1994 nr 55 on prevention of contagious diseases and § 9 and 10 in Regulation 31 January 1995 nr 107 on monitoring and control of the occurrence of Salmonella in live animals. The DV is obliged to notify the SNT when Salmonella is detected in live animals. If the Salmonella is considered a threat to public health, the official local or regional doctor is to be notified according to § 4 in the Act of 5 August 1994 nr 55 on prevention of contagious diseases. The DV is also obliged to ensure that slaughterhouses, dairies and other food establishments concerned are notified according to § 4 and 13 in Regulation 6 March 1995 nr 237 on prevention, control and eradication of animal diseases and zoonoses. Any veterinary practitioners that suspect or verify a case of contagious animal disease are obliged to notify the SDT. If suspected or verified cases of contagious animal disease are considered a risk to public health, the DV is obliged to notify the official local or regional doctor and the KNT. The official report on zoonoses from 1999 shows the results of the supervision of zoonoses. Findings, observations Question marks remain as to the efficiency and reliability of the procedures in place for the general surveillance by the Department of Epidemiology or in the Zoonosis Centre, as procedures were observed to o include extensive sampling by the companies and the owners, not frequent enough by officials, o provide uncertain traceability to the individual flocks, o include long and slow routes for sending and examining samples, o include exceptionally long reporting times, o include vague organisational rules creating hesitant information procedures. Page 16 3.11 Welfare of laying hens kept in battery cages 3.11.1 Description of the system There are no particular routines described for how and when the DVs should visit the holdings, however according to § 6 of the Regulation of 15 October 1982 the following set of events is foreseen to take place: Before new constructions are set up the owner contacts the DV and sends over drawings etc. for information and comments. When the building is finalised it is inspected and approved by the DV before being taken into use. In addition the following supervision takes place: The local animal welfare council visits the holdings every third or fourth year. The DV inspects the holdings every second year depending on the budgetary resources available. 3.11.2 Findings, observations There were no written routines for the controls to be performed and the DV had no equipment for the purpose. The regularity of visits was depending on allocation of designated budgetary resources and not on professional parameters or internal prioritisations within the geographical and operational domain of the DV. The Norwegian application of the rules was more favourable for the animals than required. Page 17 4. Action taken during, at the end of and after the mission At the final meeting, the mission team required urgent information, within one week at the latest, about the actions taken by Norway on the following two issues: 1. That the requirements concerning the live animal health check system were as laid down in Chapter VI of Annex I of Annex B to Council Directive 71/118/EEC as amended. 2. That the requirements concerning the use of potable water in the establishments were as laid down in point 6 and 7 of Chapter I of Annex I to Council Directive 71/118/EEC as amended. The following documentation, indicating corrective actions taken after the visits, was received at the final meeting: Copy of a letter from KNT Elverum to the poultry meat establishment requiring action to be taken to keep the temperature in poultry meat on max +4 ºC. Copy of a letter from KNT Elverum to the poultry meat establishment requiring action to be taken to use only potable water. Copy of a letter from KNT Stavanger to the SNT that from 14 May all flocks for slaughter at the establishment in question will be accompanied by an owner’s declaration. The following informal documentation was received on 31 May 2001 in E-mail from SDT enclosing two documents: One unsigned copy of a letter from the central office of the SDT to the regional veterinarians asking them to see to it that the DVs inform the broiler rearers within their areas of responsibility that all flocks sent for slaughter from 4 June 2001 must be followed by a veterinary health certificate, which must not be older than three days on delivery at the slaughterhouse. One model of such a veterinary health certificate. A formal letter confirming SDT’s commitment was received 5 June 2001. Page 18 5. Conclusions 5.1. The competent authority 1. The cooperation between SNT, which is the Competent Authority and the SDT, which was in charge of the inspections of live animals, was not functioning as pre-slaughter health inspections could not be assured as foreseen in Chapter VI of Annex I to Council Directive 71/118/EEC as amended. 2. SNT did not have enough information available about the application of Council Directive 71/118/EEC as amended in the different KNTs. Moreover, the system of supervision of the KNTs implemented by SNT was general and had not been covering the KNTs with particular reference to the application of the Directive. 5.2 Approval procedure for poultry establishments. The procedure for initial approval of poultry meat establishments is satisfactory except that establishments are not always seen in operation before the final approval. 5.3 Veterinary supervision of establishments. 1. The SNT and SDT do not have sufficient staff and sufficient cooperation to guarantee the veterinary supervision of the establishments as required by Council Directive 71/118/EEC as amended. 2. The number and seriousness of the deficiencies found in the establishments visited regarding structure and lay out, installations and equipment, maintenance and cleanliness and in particular operational hygiene indicated that the supervision was not efficient and that corrective actions were not properly enforced. 5.4 Own checks. 1. The visited establishments had systems covering the most relevant issues. 2. The controls of the water, of the cleaning, of temperatures, of pests and of the health certificates of the staff were not performed as required. Thus the own check systems were not functioning properly and corrective actions were often missing. 5.5 Use of potable water. The requirements for potable water were not met. 5.6 Pre-slaughter health inspection and post-mortem inspection. 1. Information about the live animals for slaughter was not always asked for by the OVs at the slaughterhouses. 2. Live animal health inspections did not always take place by the DVs and owners declarations were not always sent to the slaughterhouse in advance of sending flocks for slaughter. 3. The post-mortem inspections were deficient as auxiliaries are taking decisions and OVs do not carry out all the required checks. 5.7 Training programmes for company auxiliaries and staff. 1. The company auxiliaries are given the same training as the official auxiliaries. 2. The general training of staff is not always properly organised, as the OVs are not always involved in the establishing and the performance of the programme. 5.8 Trade in meat – trace back – meat export. 1. The use of health marks is not supervised by the OVs. Page 19 2. The flow of products in and out of the establishments is not supervised by the OVs. 5.9 Veterinary supervision during transport and at the time of slaughter regarding animal welfare. 1. Veterinary supervision of the transports was not clearly documented to guarantee compliance with the transport rules. 2. The supervision at the time of slaughter of the stunning and the bleeding was acceptable although it was not documented. 5.10 Veterinary control on hatcheries. The control of the hatcheries did not include control of the cleaning. 5.11 Veterinary control on zoonoses. 1. The activity of the epidemiological unit in the Veterinary Institute and the Zoonosis Centre was not organised in a way to identify any deficiencies of the requirements in the approved zoonosis plan. 2. Procedures for sampling and reporting were, on a regular basis, extremely impractical and slow although it was stated that another procedure would be enforced in case of positive findings. 5.12 Veterinary control on the animal welfare of laying hens kept in battery cages. Veterinary supervision of the animal welfare of hens kept in battery cages was done, however a completely functioning control system did not seem to be in place. Page 20 6. Recommendations to the authorities of Norway To send to the Authority, within two months of the receipt of the final report, a plan and timetable giving details of the actions taken and planned to address all the following recommendations: 1. To improve the co-operation between the two competent services SNT and SDT, both on the central and the local level to improve the level of information with a view to defining and managing the tasks regarding the application of Council Directive 71/118/EEC as amended. 2. To ensure that all the establishments approved and listed according to Council Directive 71/118/EEC as amended are still satisfactorily in compliance as required in the Articles 6.1 and 7.1 of Council Directive 71/118/EEC as amended. 3. To ensure that live animal health control is performed according to the requirements of Chapter VI of Annex I to Council Directive 71/118/EEC as amended. 4. To ensure that post-mortem control is performed and decisions taken according to the requirements of the Chapters VIII and IX of Annex I to Council Directive 71/118/EEC as amended. 5. To ensure that the establishments’ own checks and the veterinary supervision is performed according to the requirements of Article 6 and Chapter XI of Annex I to Council Directive 71/118/EEC as amended. 6. To ensure that the water used in the establishments is controlled to be in compliance with the requirement of points 6 and 7 of Chapter I Annex I to Council Directive 71/118/EEC as amended. 7. To ensure that the health marks are used in the establishments as required in Chapter XII of Annex I to Council Directive 71/118/EEC as amended, with particular reference to point 65. 8. To ensure that fresh poultry meat is protected as required in points 70, 71, 72 and 73 of Chapter XIV of Annex I to Council Directive 71/118/EEC as amended. 9. To ensure that hatcheries have a microbiological quality control of the health status as required in point B.2.(f) of Chapter II of Annex II to Council Directive 90/539/EEC. Page 21 7. Addendum to the mission report The Norwegian Authorities informed the Authority in a letter dated 23 July 2001 about the factual content of the draft report and the measures already taken to remedy the deficiencies in the draft report. In addition to the comments to the factual content, which is included as footnotes to the relevant points in the report, the Norwegian Authorities have made the following statements to the point of the report indicated: 3.4.1 Regarding pre-slaughter health inspection and post mortem inspectionfindings and observations Pinpoint 1: It is stated in Article 56 of the Norwegian poultry regulation that the flocks for slaughter should be supervised according to detailed rules issued by the Ministry of Agriculture. Such rules have never been issued. As mentioned under point 4 in the report, an informal E-mail was received 31 May 2001 from the SDT enclosing two draft documents, one letter to the regional veterinarians and one health certificate. A formal letter received 5 June 2001 confirmed the E-mail. In addition it was stated from the Norwegian Authorities in their letter received 3 August 2001 that information and instructions regarding immediate measures taken to improve the live animal control had been given by the Central Unit to the Regional Veterinary Officers in letters dated 21 June and 17 July 2001 and that the instructions differed slightly from those communicated by E-mail and that they would be effectuated from 1 August 2001.