Design for Assembly (DFA) Lecture Notes

advertisement

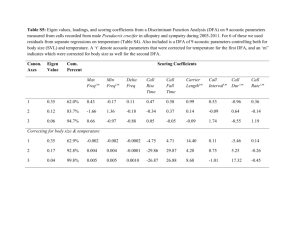

6.1 Introduction to Design for Assembly (DFA) 6.1.1 Background DFA is perhaps one of the most effective techniques to reduce production cost and certainly the most established methodology in concurrent engineering. The basic concepts are mostly a collection of common sense rules that are often neglected in the design process. DFA applies to any product that requires assembly: automotive parts and systems, electronics, toys, appliances, etc. DFA attracted strong industry interest when G. Boothroyd and P. Dewhurst (University of Rhode Island) systematized the methodology in the late 70's. Other researchers include R. Sturges at Westinghouse (now at Virginia Tech.) and a group at Hitachi's Production Engineering Research Laboratory (PERL). By the mid 80's, DFA received overwhelming industry response. Boothroyd and Dewhurst along with others developed a PC-based program and a handbook to review an assembly design. Whereas these quantification methods are effective in trade analysis of different designs, the basic concepts and design guidelines remain very important at the layout design stage. The fundamental concept is to design the product so that it is easy to assemble. The important thing to remember: apply DFA design rules to early layout designs! Also, keep in mind that we should look at the compatibility between assembly methods and designs. Boothroyd and Dewhurst have published design rules that apply to manual and automatic assembly. The method calculates normalized assembly time. Their programs are effective but tend to be tedious and time consuming. Many companies consider DFA to be most effective in training designers to incorporate assembly concerns. In ME317, we introduce a simplified method derived from R. Sturges’ Westinghouse methodology. 6.1.2 Pertinent Factors in DFA: • • • • Number of Parts Handling of Parts (Reach distance, orientation, part size and weight) Part Insertion (Direction, fixture) Part tie-down (fasteners, fastening process) Note that there are other concerns such as assembly costs related to product variation. Simply put, if designers can qualitatively simulate or “walk through” the assembly process of their designs, they will come out ahead significantly in assembly cost and quality (reduced defect rate). 6.1.3 DFA101: The Basic DFA Rules CAUTION--DFA is not always perfect!!!: Interpret GOOD as "desirable for assembly" and BAD as "undesirable for assembly." You must also consider other life-cycle issues such as tooling costs, component complexity, service needs, and product variety that are explored in later lectures. 6.1.3.1. Number of parts for each sub-assembly If the following does not apply and the parts are separate => combine parts. 1) The part moves relative to all other parts already assembled? 2) The part must be of a different material. 3) The part must be isolated from all other parts already assembled. 4) The part must be separate from all other parts already assembled, because otherwise, necessary assembly or disassembly of other parts would be impossible. Three Pieces Bolt Washer One Piece Spacer Cold Headed Fastener Figure 6.1.1 Minimize number of parts 6.1.3.2 Ease of handling. Manual assembly 1) If your hand can enclose the part, it is too small to handle easily -- BAD 2) If two hands are needed to handle the part, it will delay assembly and present handling difficulties -- BAD 3) If the part has sharp corners, it presents a hazard to the worker -- BAD Robotic assembly 1) If the part is slippery, we may need a special gripper -- POOR 2) If the part is fragile, we may need force sensing to prevent the gripper from damaging the part -- BAD Avoid flexible parts. Figure 6.1.2 Avoid flexible parts Avoid tangly parts Figure 6.1.3 Avoid tangly parts Provide tool access Figure 6.1.4 Provide tool access 6.1.3.3 Ease of Insertion 1) Direction of insertion from: Above (straight line) -- EXCELLENT Side (straight line) -- GOOD At an angle (not straight) -- BAD Bottom -- VERY BAD Figure 6.1.5 Minimize number of insertion angles 2) If the part is self-aligning (chamfers, holes, etc.) -- EXCELLENT Figure 6.1.6 Use recesses or bosses to locate components 3) If alignment is by arrows, labels, or matching colors -- GOOD 4) If there are no features to align the part properly -- BAD 6.1.3.4 Fastening Methods Velcro -- EXCELLENT Snap-on -- VERY GOOD Tab -- GOOD Screw -- VERY BAD (higher penalty depending on quantity and variation) Permanent - BAD (application of glue/cement/weld/solder slows down assembly) Figure 6.1.7 Use integral fasteners 6.1.4 Assembly Sequence Diagram One of the most effective ways to enhance product design for ease of assembly is to plan the assembly process in advance. To facilitate this advance planning, we encourage designers to use the following diagram to qualitatively "walk through" the assembly process. This procedure in itself forces the designers to identify cost-driving assembly tasks and steps that may lead to defects. We view this diagram as an essential document to the evaluation of assembly difficulties. A fishbone style diagram for describing the assembly sequence, such as the one shown in Figure 6.1.8, is extremely effective in promoting the advanced planning of the assembly process. The diagram also promotes DFA by forcing the engineers to identify assembly difficulties and to come up with remedies. In fact, the identification of the assembly sequence is the first step in any DFA methodology. The modified Westinghouse method presented in the next section will also assume that you have completed the assembly sequence diagram. One can characterize each assembly step by indicating fixturing needs (the symbol “F”), reorientation (circular arrow), and insertion directions (straight and rotational arrows). This information feeds directly into the DFA worksheet for computing assembly ratings. The diagram can include other symbols indicating time penalty factors addressed on the next page. We recommend engineers to include at least the fixturing, reorientation, and insertion angle information. These symbols will facilitate the rapid evaluation of assembly difficulty. Handle Core Cap Cap F Tip F Handle Core Tip Assembly Figure 6.1.8 Assembly sequence diagram for a mechanical pencil 6.1.4.1 Guide to Creating an Assembly Sequence Diagram 1) Start with the part that other parts attach to (usually fixtured). 2) Parts that attach directly are shown with a slanted arrow. 3) Denote special operations with icons next to the arrows. F Fixture Rotation (flip assembly or screwing action) Straight-down attachment Attachment at an angle Attachment from below Attachment from the side Other icons may be defined if necessary. 4) A sub-assembly consists of a separate tree that attaches to the main assembly. Le ft Carriage Base Drive Gear 1 F PC Board Drive Gear 2 F Power S u pply Motor Pape r Tray Le ft Carriage S ubassembly Drive Roller Right Carriage Frame IBM Proprinter Assembly Sequence Diagram Platten Pape r Guide Te nsion S haft Drive S crew and Motor Eccen tric S h aft and Print He ad Tail S haft Ribbon Drive Gear 1 Ribbon Drive Gear 2 Roller S haft Roller Tractor Drive Ass'y Roller Guide S ubassembly Paper Width Adjuster (2) Keypad Ribbon F Fixture Rotation (flip assembly or screwing action) Straight-down attachment Hood Attachment at an angle Knob Attachment from below Cove r Attachment from the side Printe r Asse mbly Figure 6.1.9 Assembly sequence diagram for the IBM Proprinter 6.1.5 Assembly Evaluation: The Modified Westinghouse Method While there are several DFA methods available, we feel that many are unnecessarily complex and require too much time to complete. For the Stanford DFM class, we have developed a simplified version of the Westinghouse methodology. We sincerely appreciate the help of Dr. Martin Hinckley of Sandia National Labs in proposing the simplification. Professor Bob Sturges, one of the original developers of the Westinghouse Methodology and now at Virginia Tech., also gave us advice. Table 6.1.1 shows the worksheet used to compute the assembly times. A step by step guide to the Westinghouse method is shown below the chart. One can determine the assembly time penalty for each column using Table 6.1.2. One can easily create a spreadsheet to perform the computation in Table 6.1.1, and further combine it with Table 6.1.2. The DFA data came from: Sturges, R.H. and Kilani, M. 1992. Towards an Integrated Design for an Assembly Evaluation and Reasoning System. Computer Aided Design. Vol. 24, No.2. pp. 6779. Westinghouse Design for Assembly Calculator. The two major evaluation measures: assembly rating (AR) and part efficiency (PE): AR (Assembly Rating) is a normalized measure that compares the total assembly time with a reference time of 2.35 seconds per part. Hence AR of 1 indicates that the design is quite good from ease of assembly viewpoint. As penalty time increases, AR decreases. AR = 2.35 x Number of Parts / Total assembly time. PE (Part Efficiency) compares the total number of parts with the theoretical minimum number of parts. The theoretical minimum is calculated based on the designer’s response to the factors cited in 6.1.3.1. PE=1 is good, less than one encourages elimination of parts. PE = Theoretical Minimum / Number of Parts. Table 6.1.1 Assembly Evaluation Worksheet A hand. cond. Part/Operation Description 1 Handle 2 Core 3 Cap 4 Flip sub-assy 5 Tip 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 21 22 23 24 25 26 27 28 29 30 B C D E F G H I J K L siz e thick. insert. end to inset. insert. insert. fastn. fastn. time/ no. of align. end direc. cond. clear. proc oper. reps. align. (T op) (Nrep) 0.1 0.25 1 0.6 2.25 4.2 1 0.4 0.25 1 0.6 0.25 1 3.5 1 0.4 0.25 1 0.6 0.9 1 4.15 1 2.25 2.25 1 0.1 0.25 1 0.6 0.25 4 6.2 1 5 TOP Step Step Step Step 1: 2: 3: 4: Draw the Assembly Sequence Diagram List Parts & operations in order (left column) Enter times from Estimated DFA Time Chart Sum time p er part/op er. in column K Enter no. of repetitions for each operation in col. L Enter K*L in col. M Step 5: Enter a 1 in col. N if a part was inserted during operation Enter a 1 in col. O if part or operation can be eliminated Step 6: Calculate Summary Statistics M repet. time K*L 4.2 3.5 4.15 2.25 6.2 20.3 TAT N O insert eliminate part? part? 0 = no, 1 = y es 1 0 1 0 1 0 0 0 1 0 4 NUP Summary Statistics NUP 4 = number of unique parts TOP 5 = total no. of operations TAT 20.3 = total assembly time NP 4 = no. of parts = sump rod.(L,N) Tavg 4.06 = avg time/op eration = TAT/(sumRep) Pmin 4.0 = min # parts = NP - sumprod.(L,N,O) AR 0.463 = Assembly rating = 2.35 * NP /TAT PE 1 = Part Effciency = Pmin/NP Table 6.1.2 Assembly Time Chart (Modified Westinghouse method) Use this table to select operation time (in seconds) for each part or assembly operation. Enter the time into the Modified Westinghouse Assembly Evaluation Worksheet. If the condition does not apply, leave the entry blank (default is zero seconds). If special conditions apply, enter the corresponding time penalty into the worksheet. A. B. HANDLING Handling Condition Time Condition 0.5 heavy 1.0 delicate 1.5 nests/tangles 2.0 tweezers required 3.5 other tools required 6.0 severe nest/tangle G. Size Time 0.6 0.4 0.1 0.0 note: H. Part Size < 2mm 2 - 6mm 6 - 12mm > 12mm time x 2 if insert. orientations < 4 C. Thickness Part Thickness < 0.5mm 0.5 - 2mm > 2mm time x 2 if insert. orientations < 4 Time 0.5 0.2 0.0 note: D. Orientation about Insert. Axis Time Insertion Orientations 1.50 1 (subtle feature) 1.00 1 (obvious feature) 0.25 2 or more E. End to End Alignment Time End Insertion Orientations 1.5 1 (subtle feature) 1.0 1 (obvious feature) 0.5 2 or more 1 F. 2 3 INSERTION Insertion Direction Time Condition 0.6 down 1.4 from the side 1.7 diagonally or twist/turn/tilt 2.0 up Insertion Conditions Time Insertion Condition 1.25 constrained motion 1.35 temporary hold down 1.50 two hands 2.25 rotate or fixture 6.00 flexible Time 0.25 0.90 1.60 Insertion Clearance Insertion Clearance large small very small Time 0.0 1.0 2.5 4.0 5.0 6.0 Fastener Time Fastener Type washer pin retaining ring screw nut rivet I. J. Fastening Process Time Time Fastening Process 1 snap or press fit 3 bending or crimping 4 screwing 5 polymer weld or stake 7 solder 9 weld or braze 11 adhesive = ° end-end sw it ch OK swit ch not OK 4 or more Number of Insertion Alignments (insertion axis perpendicular to page) End to End Insertion Alignments Two allowable orientations compared to only one 6.1.5.1 Guidelines for Assembly Time Chart: Modified Westinghouse Method HANDLING A. Handling Condition Handling conditions apply to special cases, the default is 0 seconds. These times can be added when more than one condition applies. 0.5 1.0 heavy delicate 1.5 nests/tangles 2.0 3.5 tweezers required other tool required 6.0 severe nest/tangle More than 4.5 kg (10 lbs.) Parts prone to break, scratch, bend, crinkle, parts with sharp edges for example: shims, foils, brittle materials. Parts supplied to operator in bulk and requires simple manipulation to separate it from other parts in the container, for example: retaining ring, sticky parts. Part cannot be inserted without the use of other tools, for example: pliers, wrench. Parts supplied to operator in bulk and requires considerable manipulation to separate it from other parts in the container, for example: cable, coil springs. B. Size Size is the largest dimension of the rectangular solid that can enclose the part, default is 0 seconds. (see diagram) 0.6 0.4 0.1 time x2 < 2 mm 2 - 6 mm 6 - 12 mm if insert. orientat. <4 (< .08 in.) (.08 - .25 in.) (.25 - .5 in) If less than four possible orientations about axis of insertion then multiply time penalty by two. C. Thickness Thickness is the smallest dimension of the rectangular solid that can enclose the part, default is 0 seconds. (see diagram) 0.5 0.2 time x2 < 0.5 mm (< 0.02 in.) 0.5 – 2 mm (0.02 – 0.08 in.) if insert. orientat. <4 (see Size) thickness size D. Orientation About Insertion Axis The number of orientations (about the axis of insertion) a part may have where it can still be properly inserted. (see diagram below) 1.50 1 (subtle feature) 1.00 0.25 1 (obvious feature) 2 or more One correct orientation where asymmetric feature is not very noticeable One easily recognizable orientation More than one correct insertion orientation. (screws, pins, rectangular pieces) E. End to End Alignment The number of end to end orientations a part has where it can still be properly inserted. A part with two end-to-end orientations can be inserted upside down (see diagram below). 1.50 1 (subtle feature) 1.00 0.5 1 (obvious feature) 2 or more One correct orientation where asymmetric feature is not very noticeable One easily recognizable orientation More than one correct insertion orientation. in serti on a xi s en d to end ori enta tion orientations about insertion axis 1 >4 end to end orientations 2 1 INSERTION F. Insertion Direction The insertion direction refers to the direction the part will be inserted. If more than one direction applies, the times may be added. 0.6 1.4 1.7 2.0 down from the side diagonally or twist/turn/tilt up G. Insertion Conditions 1.25 constrained motion 1.35 temporary hold down 1.50 2.25 two hands rotate or fixture 6.00 flexible Operator’s access limited by fixturing or other parts. Part will stay in place only if supported until another subsequent part is added. fixture-fixturing operation precedes insertion of part rotate- re-orientation precedes insertion of part Requires extra manipulation during insertion, or does not stay in place when released. H. Insertion Clearance 0.25 0.90 1.60 large small very small 10-50 % 1-10 % <1% I. Fastener Time 0.0 1.0 2.5 4.0 5.0 6.0 washer pin retaining ring screw nut rivet % = 100% (A-B) / B B A J. Fastening Process Time When inserting a part, if these fastening processes apply, use the corresponding time. 1.0 3.0 4.0 5.0 7.0 9.0 11.0 snap or press fit bending or crimping screwing polymer weld or polymer stake solder weld or braze adhesive