Development of a Virtual Reality Based Driving Simulator

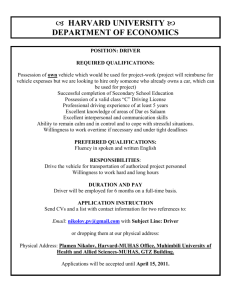

advertisement

Driving in a Virtual World H. S. Kang Faculty of Mechanical Engineering Universiti Teknologi Malaysia M. K. Abdul Jalil* Faculty of Mechanical Engineering Universiti Teknologi Malaysia Musa Mailah Faculty of Mechanical Engineering Universiti Teknologi Malaysia Abstract This paper discusses the experience of developing a fixed-base driving simulator. The simulator developed in this research project if fixed-based and is intended to provide a platform for vehicle-related research in the future such as vehicle system development, human factor studies, and vehicle safety research A driving simulator enables the reproduction of the actual driving environments in a safe and tightly controlled environment. The driving simulator for this research is developed using PC-based workstations that are capable of producing high fidelity graphics at reasonable cost. The VR-based simulator gives a driver on board the impression that he drives an actual vehicle by predicting vehicle motion caused by the driver input and feeding back the corresponding visual, motion, audio and proprioceptive cues to the driver. This research is intended to provide a test bed for simulating driving related task using virtual reality technology. Keywords: Vehicle Dynamic Model, Virtual Reality, Visual Database. 1 Introduction The term ‘Virtual Reality’ or VR has been used to describe a wide range of applications in computer graphics and human-computer interaction, some of which have little connection with the term’s original meaning. A virtual reality, or as we normally refer to as virtual environment, is a system which allows a user to feel immersed in a computer-generated environment. VR technology has been widely used in engineering and scientific visualization due to its ability to create a life-like simulation. A virtual driving simulator is a virtual reality device that allows its user to feel a life-like experience of driving an actual vehicle. The driving simulator is effectively used for studying the interaction of a driver and vehicle and for developing new vehicle systems. During the design of an automobile, detailed mockups of the interior are built to study the design and evaluate the ergonomic issues. However, these physical prototypes are expensive, time consuming, and difficult to modify. It is more effective to use a virtual prototype replacing the physical mockup for the design and analysis aspects such as layout and packing efficiency, visibility of instruments, controls and mirrors, reachability and accessibility. ------------------------------------*e-mail: kasim@fkm.utm.my A driving simulator is needed to enable the analysis on driving characteristics, and interaction between visual database and vehicles. Recent development of powerful desktop computer workstations can now support the computational requirement of small to mediumscale driving simulators. Many factors should be carefully considered in developing and applying full-scale driving simulators effectively, such as constructions costs, application areas and target performance. A prototype simulator, down-scaled, yet consisting of all the necessary subsystems can be used effectively for evaluation of the factors mentioned above and design of the full-scale simulators. The driving simulator for this research is developed using PC-based workstations that are capable of producing high fidelity graphics at reasonable cost. The VR-based simulator gives a driver on board the impression that he drives an actual vehicle by predicting vehicle motion caused by driver input and feeding back the corresponding visual, audio and proprioceptive cues to the driver. This research project provides the initial groundwork for future research development of driving simulator in Malaysia. The long-term objective of this research is to provide a test bed for simulating driving related task and for virtual environment technology research in the country. This paper describes a first research attempt to develop a static base driving simulator based on virtual environment technology to create an immersive driving environment for the simulator user. The knowledge gained from this project will be further used to develop a full-scale driving simulator for automotive and transport safety research in Malaysia. 2 Related Work Research related to the development and application of driving simulator is not new. Driving simulators, having their roots on flight simulators in the early 1900s [Repa and Wierwille 1976], have begun to appear in primitive forms in the 1970s. With the advent of computer technologies, Daimler-Benz launched a high-fidelity driving simulator in 1980s [Drosdol and Panik 1985], which created wide interests throughout the world. Since then, many automotive makers and research institutions worldwide have developed their own simulators. There are various level of complexity of driving simulators ranging from a simple static base simulator to the most advanced simulator that are capable of simulating the dynamic motion and scenes of an actual vehicle. Various institutions and companies have developed driving simulators for research purposes including National Advance Driving Simulator (NADS), Leeds Advanced Driving Simulator (LADS) [Bailey et al. 1999], and the Swedish National Road and Transport Research Institute. A typical advanced driving simulator, such as NADS in Iowa, normally consists of a visual system, angular and translational motion systems with 6 DOF, vehicle cab system, control feel system, auditory system, and vehicle dynamics. An advanced simulator is capable of producing a high fidelity simulation output. However the construction cost of this system is very high. On the other hand, a static base simulator is inexpensive and may be sufficient for applications that do not require very highfidelity simulation. These simulators have several advantages over comparable vehicle testing: safety, reproducibility of the vehicle model and its simulated surroundings, ease of data acquisition and the convenience of changing vehicle models and simulated surrounding in software rather than test hardware. The disadvantages are that the information gained through driving simulation may be misleading if the simulator does not provide an appropriate analog to the simulated scenario, and high fidelity driving simulation is sometimes far more expensive than vehicle testing [Gruening et al. 1998]. There are also companies that are involved in construction and supply of driving simulators such as AutoSimTM from Norway. The only setback of a ready-made system is that it may not fulfill a very specific research requirement that needs high level of equipment customization. Therefore, for fundamental research purposes, developing a simulator from scratch is much preferred. The VRbased driving simulator developed in this research will lay the groundwork for future research in transport safety, vehicle design and ergonomic evaluation, intelligent vehicle highway systems and driver education and testing. or higher would be considered ideal. At 10 frames per second, the image will be at least 0.1 seconds behind the simulation and usually much more because most image generators require a frame to cull the visual database and another frame to draw the database. The larger delays are tolerable for the sound and instrument commands, and so the technical requirements for these cues are relatively easily achieved [Allen et al. 1998]. 3.3 Real-time Computation of Vehicle Dynamic Model (VDM) The Vehicle Dynamics Model (VDM) is a mathematical model that provides the vehicle responses during maneuvering at different road condition in the virtual world. An important constraint on the vehicle dynamic model is that it needs to run at least as fast as real time. The ability to run in real time depends on the integration time step and the complexity of the dynamic model. The integration time step is an upper limit on the wall-clock time available to numerically integrate across one time step. If a car model does not include a bounce degree of freedom for tires, it should run well at about 100 Hz or with a time step of 0.01s [Gruening et al. 1998]. 3.4 3 This section discusses the key issues in developing a typical vehicle driving simulator. These issues are centered around creating a realistic simulation environment that closely matches the actual driving scenes. 3.1 Visual Database Rendering Burden Visual database is one of the major components of any driving simulator. A realistic driving scene is crucial to provide user with the sense of realism. However, the quality of visual database is always limited by the capacity of the rendering engine. Therefore, the development of the visual database must include the optimization aspect of the graphics. An important part of the visual database is the description of the surface the vehicle drives on. This may be modeled using polygonal road descriptions that are also used in visual system, grid posts that are fit with splines, and analytical road segments that are connected together to form the road surface [Artz 1995]. The visual database typically provides position and orientation of the road texture description. The terrain model includes a visual database which provides the desired level of realism. An effective way of producing a detailed image, without using too much computer power, is by having different pictures of the same object. When an object is close, it is very detailed and when it is far away, it has almost no detail [Martin and Jessica 2002]. 3.2 Fidelity of Vehicle Driving Simulator Issues in Developing Vehicle Driving Simulator Simulation Frame-rate The frame rate is more important than the graphical acuity. Too large graphical delays mean a great risk of the driver getting dizzy even if the screen has good acuity. According to Gruening et al. [1998], rates of 10 frames per second is often quoted as the minimum necessary for a sense of immersion, while a rate of 30 Hz The accuracy of a driving simulator depends on the computational capability to create graphic scenes with sufficient detail, resolution, accuracy, luminance, contrast, and frame rate to provide a dynamic display with enough quality and temporal response with closed and open loop driving tasks and maneuvers [David and Allen 1995]. It is important that the graphical scene is rendered from the driver’s viewpoint. The direct part of the sight is about 60 30 [Gruening et al. 1998]. A mid-level simulator typically has a large screen graphical display to portray the out window roadway environment. The forward field of view should have a lateral subtended angle from the driver’s eye-point of at least 50-60 degrees, to provide for adequate cueing and representation of driving scenarios [David and Allen 1995]. 4 Components of Vehicle Driving Simulator A typical driving simulator normally consists of four main components: a simulation of the physics of the vehicle model and the road surface; a simulation of the surrounding environment, including other vehicles and their surroundings; a system that enables the operator to interpret the state of the model, such as its video and audio displays; and its control devices, such as steering wheel, brake pedal, and throttle [Gruening et al., 1998]. A good mid-level simulator should have a large roadway scene display typically comprising of animated computer graphics. It may have a motion system or fixed base. It should have a dedicated cab with a steering feel system with interactive controls and displays, a parametrically configurable vehicle dynamics model, and a data acquisition system, [David and Allen, 1995]. The driving simulator developed in this research project is considered a low-cost version. It is a PC-based system with fixed base. It consists of several major components: the visual database system, the vehicle dynamics model, the driving cab system, and the communication or interface module. 4.1 System Architecture The setup of the driving simulator developed in this research is shown in Figure 1. The simulator consists of a static base driving cab with projected visual on a wide screen display to simulate the driving environment, and the visual and audio database. The simulator is controlled and operated on two personal computers connected by Ethernet. The driver on board the simulator controls the driving tasks using steering wheel, brake pedal and accelerator. These controllers feed signals to the simulation system using TCP/IP network protocol. The first PC acts as the graphic rendering engine and the second PC manages the signal transfers between the rendering engine and the simulation controllers, such as the steering wheel, the accelerator and the brake pedals. The distribution of the tasks into two different PC’s is necessary to ensure that the driving simulation is done in real-time. The visual scenes are projected on a wide-angle screen using two LCD projectors that are connected to the second PC that controls the visual rendering. The visual scenes can also be run on two flat panel LCD monitors. Stereographic glasses can also be used to immerse the simulator user in a virtual environment to produce a sense of realism while driving in the virtual scenes. Figure 2 illustrates the hardware architecture of the driving simulator in our research. A driving simulator is primarily an operator-in-loop device, so provisions to measure and record driver behavior in general, and driver response and performance in particular are essential in a mid-level facility [David and Allen 1995]. The cockpit or the driving cab consists of a half-cut car to give the simulator user the actual feel of driving an actual vehicle. The simulation controller consists of a steering wheel, an acceleration pedal, and a brake pedal that are connected to sensors (22mm 1W conductive plastic servo mount potentiometers). The NI-DAQ PCI 6024E I/O adapter board receives these data and passes them to a MATLAB program in the server computer where the vehicle dynamic model (VDM) is computed. Figure 1 Functional Diagram of the Driving Simulator 4.2 Data Flow in Driving Simulator Figure 3 illustrates the data flow chart of the driving simulator. The input data to the I/O data acquisition board are the steering angle, sw , throttle displacement, T and brake pedal displacement, B respectively. The NI-DAQ PCI 6024E I/O adapter board receives these data and passes them to a MATLAB program in server computer that computes the vehicle dynamic model (VDM) output such as the vehicle’s surge ( X ), sway ( Y ), and yaw ( ). These output data computed from the VDM are then sent to the client computer using TCP/IP socket. The output data from the vehicle dynamic model computed by MATLAB are used to simulate the driving actions in the virtual environment. The visual database of the virtual driving environment, which is located on the client computer, was developed using WorldToolKit (WTK) programming language. WTK consists of functions written in C language that makes the process of linking the visual database and the network system easy. Figure 2 Hardware Architecture in Driving Simulator Figure 3 Data Flow Chart of Driving Simulator The visual database developed for this project is based on the roadmap of Universiti Teknologi Malaysia (UTM) campus. The road surface amplitude (road input) matrix, Z u will be detected by WTK internal virtual sensory system and fed back to the server computer through TCP/IP socket. The Suspension Response Dynamic model will then compute the reaction and response of the vehicle body from the static equilibrium position, Z b , pitch angle, , and roll angle, . These data will be returned to the client computer in one step delay to modify the orientation of vehicle body with respect to its virtual road profile. 4.3 The visual scene rendering includes full texturing, shading, fog, and lighting effects to create a realistic driving environment. The visual system is capable of producing high-resolution simulation environment which spreads across two computers or projected screens. A set of stereographic glasses can be used to view the visual scene to give the user a sense of immersiveness while driving in the virtual environment. Figure 4 shows a sample of the driving scene developed in this research. Visual Database The environment surrounding a driving simulator includes all the geometric representations which support both interaction between the vehicle simulation and its surroundings, autonomous and nonautonomous agents. These agents typically include virtual vehicles which influence the driving task. The mathematical description of the environment is called the visual database [Gruening et al. 1998]. In this research, the visual database was developed using PC based rendering engine. The visual database system generates high fidelity driving scenes that can be displayed on multiple display systems that simulate the driver’s view when a vehicle is in motion. The visual system is composed of a highspeed graphics accelerator running on Intel Pentium 4, 2 GHz processor. The virtual driving scenes for this project are based on the roadmap and landscape of Universiti Teknologi Malaysia. The scenes were generated using WorldToolKit (WTK) software that consists of functions written in C language that supports virtual environment development and control. The toolkit includes facilities for real-time rendering and animation, and extensive functions for the creation and management of 3D graphic objects and external sensors. Figure 4 The UTM Campus Virtual Driving Scenes The computer-generated environment or visual scenes can be divided into three parts: static universe, dynamic objects, and the interior of the driver’s vehicle. The static environment includes roads, trees, buildings, and other elements that remain stationary during the simulation. The dynamic objects can be controlled independently and can react to the motion of the user’s vehicle such as traffic lights. The virtual driving environment is controlled by a steering wheel, accelerator and brake pedal that provide the driver’s input to the simulator. The models used in developing the visual database were created using AutoCAD, 3D Studio and neutral file formats (NFF), which are readable by WTK. These simulation models, as shown in Figure 4, were then arranged in a hierarchical order in WTK environment, which is called scene graph. The scene graph is the structure that holds all of the current elements of the scene, such as geometries, lights, fog, and positional information. Figure 5 illustrates the structure of the scene graph in the visual database. The universe refers to the created virtual world in WTK. It contains all the WTK objects including geometries, sensors, lights, viewpoints, serial ports, and paths. Under the universe, there is a scene graph ancestry known as root node. The scene graph is an ordered collection of nodes, in the form of a directed acyclic graph, which holds hierarchical scene data. in the memory. In this research project, most of the static objects in the visual database are minimally rendered using large polygon size. For example, a visible facet of a building containing window frames and wall are created using single polygon with wall textures image mapped on the polygon. Another technique that is used to enhance the graphic rendering speed is the use of level-of-detail (LOD) concept. A group of objects can be classified under a single node or object called LOD node. LOD node is a specialized ‘switch’ node that selects its currently active child automatically based on its distance from the viewpoint. LOD node can be used to dynamically select between a set of different representations, each of which is a different level of detail. For example, suppose the simulator driver passes close to a building and then recedes into the distance. WTK allows us to specify the distance at which the LOD node could “swap in” a new or less expensive representation. As the driver recedes into the distance, simpler models (which require less and less computational effort to process) are progressively swapped in, freeing up memory and system resources. The maximum number of frame rate supported by WTK is 30 Hz. However, the frame rate depends on the capabilities of rendering machine. The current rendering frame rate is around 25 frame rate per second (fps), which is higher than the minimum necessary value of 10 fps proposed by Gruening et al. [1998] for a sense of immersion. We can increase the frame rate setting if the driving simulation is conducted in a more powerful rendering machine to minimize the total delay of visual display. Figure 5 The Structure of Scene Graph The scene graph of the virtual driving simulator consists of three elements under the root node: the light nodes, geometry nodes, and transformation nodes. The light nodes contain the lighting information to illuminate some or all of the geometries in virtual scene. The geometry nodes include static geometries files loaded into WTK using WTK’s file import function and dynamic geometries created within WTK at the polygon and vertex levels. The transformation nodes contain positional information associated with geometries and lights read in from a file, and dynamic positional information created and managed within WTK. It describes where particular elements (geometries and lights) should be placed in the scene, either in relation to another object, or in relation to the scene as a whole. The scene graph provides a very powerful scene structure for real-time 3D simulation. Specifically, scene graph provides the hierarchical framework for easily grouping objects together spatially using parent-child relationship. This is essential for maintaining performance in scenes that contain many individual objects. Because objects can be grouped together in a positional hierarchy, the scene graph can be used to easily construct and maintain efficient simulations that contain individual moving parts. WTK calculates which parts of the scene (or scene graph) are visible from the current viewpoint, and quickly rejects non-visible geometry before drawing begins. The graphic rendering speed depends on the complexity of the models in front of the user viewpoint, for instance the number of polygons used to create the models and the texture mapping applied to these models. We implement this method to reduce the graphical rendering burden To improve the fidelity and realism of driving scenario, the real pictures of UTM buildings were mapped on the virtual objects. This method can reduce the number of polygon used in the virtual objects compared to drawing it directly in three dimensional. Hence, the memory used in the graphical rendering can also be reduced. Figure 6 shows the virtual buildings modeled by this method. 4.4 Network Data Transmission The Transmission Control Protocol/Internet Protocol (TCP/IP) was employed as the data transmission protocol. This protocol is reliable because it is a connection-based protocol and requires the establishment of a session before data is transmitted between two computers. TCP is designed to ensure that all packets sent by a computer are received on the other end. TCP packets are delivered to Socket. A Socket is a connection between two computers in a TCP/IP network that sends or receives packets of data across a network. Sockets are highly useful in client-server models [James and Joe 1994].. The TCP client socket was created as an additional part in the WTK programming structure and the TCP server socket was constructed as a part of MATLAB C-MEX program [The MathWorks 2002]. By creating the client socket, it connects the virtual reality programming to the server, and receives the data computed from MATLAB vehicle dynamic model. In order to establish a socket connection to transfer these data, the client creates a socket and connects it to the server. On the server side, once the server socket is created, it is bound to a specific endpoint and told to listen indefinitely for an attempt by the client to connect. The server socket then accepts the requests of the client for connection. Once the communication channel between these two machines is established, the server will send the vehicle dynamic output data. Client socket will receive these data and process them in WTK to control the virtual environment driving simulation. The SIMULINK integration time step is preset to 0.01s in the Vehicle Dynamic Model blocks. To do this, the MATLAB CMEX S-function file is used rather than the M-file S-function because the M-file S-function tends to cause the MATLAB interpreter to be called at each time step and slows down the overall simulation speed [The MathWorks 2002]. A C MEX-file that defines an S-function block provides the information of the model to SIMULINK during the simulation. As the simulation proceeds, SIMULINK, the ODE solver, and the MEX-file interact to perform specific tasks including defining the initial conditions and block characteristics, computing derivatives, discrete states, and outputs. steering rack. In our research, we concentrate on the 6 DOF orientations of the sprung mass (car body) that affects the driver’s viewpoint directly. The vehicle dynamic model (VDM) is simulated in MATLABSIMULINK program in the server computer as demonstrated in Figure 7. The VDM is divided into two vehicle dynamic blocks; the Handling Dynamic Model and Suspension Response Model; and a SIMULINK S-function block that contains a network communication TCP/IP port for data interface with client computer. SIMULINK interacts with a C MEX-file S-function by invoking callback methods that the S-function implements. Each method performs a predefined task, such as computing block outputs, required to simulate the block whose functionality the S-function defines. SIMULINK defines in a general way the task of each callback. The S-function is free to perform the task according to the functionality it implements. Figure 7 Vehicle Dynamic Model Blocks 4.5.1 Handling Dynamic Model Figure 6 Building with Photo Texture Mapping 4.5 Vehicle Dynamic Model (VDM) The driving simulator does not have a physical drive line. Instead the vehicle, its mechanical components and their behaviour are described in a computer model. This model simulates the vehicle dynamics in detail and in high update rates [Martin and Jessica 2002]. The complexity of the vehicle dynamic model is usually related in a straightforward way to the number of degrees of freedom (DOF) of the vehicle [Gruening et al. 1998]. The model describes a drive line and a steering system, to enable the driver to move forward and control his direction in the simulated world. Good models of wheel suspension and steering servo-unit are important for a realistic vehicle model. To include all parameters of interest, the model often needs something like 15 DOF [Martin and Jessica 2002]. There are typically 6 degree of freedom (DOF) for the sprung mass, 4 DOF for the wheel velocities, 4 DOF for the wheel suspension travels and last DOF for the position of the The vehicle Handling Dynamic Model of the driving simulator is based on a linearized handling model. On the simulator hardware, the driver manipulates the cockpit and provides three input values into the system: the steering wheel angles, sw , the throttle displacement, T , and brake pedal displacement, B . These input values acquired by potentiometers (sensors) are sent to the MATLAB Handling Dynamic block after being converted into steering input, , throttle torque, TP , and braking torque, TB respectively. The handling model will simulate the behaviours of the actual vehicle handling system. The steering input, controls the direction of the vehicle manoeuvring, and the throttle torque, TP , and braking torque, TB are combined to achieve the vehicle velocity, V . By using the inertial reference frame XY shown in Figure 8, the coordinates X and Y of the centre of mass G of the vehicle and the yaw angle between x and X axes are expressed as generalized coordinates [Genta 1997]. Figure 8 Reference Frame of the Vehicle Motion From Figure 8, the velocities components u and v from vehicle velocity, V and its sideslip angle, can be expressed in terms of: u V cos v V sin (1) (2) The equations of motion with respect to time are arranged in matrix form as: cos X sin Y sin u cos v The forces derived from the quarter-car model on the vehicle front left side (with subscript fl ) are the suspension spring force, Fs , damping force Fd , spring effect force caused by tire, Ft , and tire damping force Fdt : (3) where the is the vehicle yaw angle. By finding the derivatives with an integration step, the coordinates X and Y of the vehicle centre of mass and the yaw angle can be obtained. 4.5.2 Figure 9 Quarter-Car Model Suspension Response Dynamic Model Fsfl k fl (Z ufl Z sfl ) Fdfl C S ( Z ufl Z sfl ) Ftfl ktfl (Z rfl Z ufl ) (5) (6) Fdtfl C St ( Z rfl Z ufl ) k (4) (7) refers to the spring stiffness, C S is the damper Vertical dynamic effects play a major part in vehicle handling which involve tyre normal loads, vertical terrain inputs, and heaving motion due to the suspension between the sprung and unsprung masses [Allen and Rosenthal 1994]. Suspension systems are used to isolate the vehicle’s sprung mass from road irregularities to achieve acceptable ride quality and to control load transfer in order to maintain direction stability [Allen and Rosenthal 1994]. where In our project, we derived all the forces affecting the vehicle suspension system from a quarter-car model, and later expanded these results into a full-car model to determine the vehicle body displacement from the static equilibrium position, roll angle and pitch angle. The full car model is shown in Figure 10. The displacement of sprung mass can be determined by examining the forces acting on the vehicle body. From the results of the quarter-car model, the general forces acting on the vehicle suspension system are front-left force, F fl , front-right force, F fr , A two degree of freedom quarter-car model was used to examine the forces that exist in the suspension system. The tyres are considered as massless springs while both the unprung and sprung masses are taken into account. This model holds well for natural frequency of the unsprung mass of up to 30-50Hz [Genta 1997]. Figure 8 provides a schematic illustration of the quarter-car model. the vehicle suspension system are: damping coefficient, k t is the tyre stiffness, C St is the tyre damping coefficient, Z u is the displacement of unsprung mass from the static equilibrium position, Z s is the displacement of the sprung mass from the static equilibrium position, and Z r is the height of the road surface on a reference level. rear-left force Frl , and rear-right force Frr and the displacement of sprung mass (the car body in this case) on each side, Z sfl , Z srl , Z sfr ,and Z srr . Finally, the equations of motion of Zb F fl F fr Frl Frr mB (8) a a ( F fl Frl )( ) ( F fr Frr )( ) 2 2 I XX b b ( Frl Frr )( ) ( F fl F fr )( ) 2 2 I YY References (9) (10) ALLEN, R.W. AND ROSENTHAL, T.J. 1994. Requirements for Vehicle Dynamic Simulation Models. SAE Paper 940175. ALLEN, R.W., THEODORE, J.R., BIMAL, L.A., DAVID, H.K., FRITZ, G.A., JEFFREY, R.H. AND JEFFREY, P.C. 1998. A Low Cost PC Based Driving Simulator for Prototyping and Hardware-In-The-Loop Applications. SAE Paper 980222. ARTZ, B.E. 1995. An Analytical Road Segment Terrain Database for Driving Simulation. Conference Proceedings DSG 95. BAILEY, A.C., JAMSON, A.H., PARKES, A.M. AND WRIGHT, S. 1999. Recent and Future Development of the Leeds Driving Simulator. Presented at DSC99, Paris. DAVID, H.W. AND ALLEN J.C. 1995. A Survey of Mid-Level Driving Simulators. SAE Paper 950172. DROSDOL, J. AND PANIK, F. 1985. The Daimler-Benz Driving Simulator, SAE Paper 850334. ENGIEERING ANIMATION Reference Manual, Release 9. INC. 1999. WorldToolKit GENTA, G. 1997. Motor Vehicle Dynamic. World Scientific Co. Pte. Ltd. JAMSON, A.H., PARKES A.M. AND WRIGHT, S. 1999. Recent and Future Development of the Leeds Driving Simulator. Presented at DSC99, Paris. Figure 10 Full-Car Model where Z b is the displacement of the vehicle body from the static equilibrium position, is the pitch angle, is the roll angle, a is the track length, b is the distance from front axle to rear axle, m B is the mass of vehicle, I XX is the moment of inertia in xdirection, and I YY is the moment of inertia in y-direction. 5 Conclusion A low-cost yet effective static base simulator has been developed using virtual-reality technology. This project has laid the groundwork for the development of a full-scale driving simulator to be used for road safety and vehicle related research. The ongoing research work involves the development of a more realistic visual database system, an advanced vehicle dynamic model and integration of audiovisual effect. Future development will also include a motion base integration into the existing system to simulate the dynamic response of a vehicle in motion. 6 Acknowledgement This research project has been supported and funded by the Ministry of Science, Technology and Environment (MOSTE) under the IRPA grant 03-02-06-0087EA001 (vot 74123). MARTIN, J AND JESSICA, N. 2002. A Survey of Driving Simulators and their Suitability for Testing Volvo Cars. Chalmers University of Technology. NATIONAL HIGHWAY TRAFFIC SAFETY ADMINISTRATION AND THE UNIVERSITY OF IOWA. 2002. NADS: National Advanced Driving Simulator, The Most Sophisticated Driving Simulator in the World. REPA, B. AND WIERWILLE, W. 1976. Driver Performance in Controlling a Driving Simulator with Varying Vehicle Response characteristics, SAE Paper 760779. THE MATHWORKS, INC. 2002. Writing S-Functions, Version 5. JAMES, M., AND JOE, L. 1994. TCP/IP Networking: Architecture, Administration and Programming. New Jersey: PTR Prentice Hall.