TUGAS_AAS

advertisement

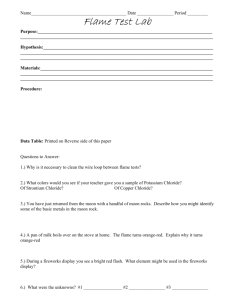

TUGAS KIMIA ANALITIK III Oleh KHAERUL HATTA ( 105 05 092 ) RIZKI ANSHARI ( 105 05 093 ) ASTUTI TRIJAYANTI ( 105 05 094 ) HUMAILA RIZQI ( 105 05 096 ) TRIWIDIANSYAH ( 105 05 097 ) WERDI ISNA RETNOWATI ( 105 05 098 ) PROGRAM STUDI KIMIA FAKULTAS MATEMATIKA DAN ILMU PENGETAHUAN ALAM INSTITUT TEKNOLOGI BANDUNG 2007 TUGAS KIMIA ANALITIK AA-6300 Next Generation Double Beam Atomic Absorption Spectrophotometer (SHIMADZU) Atomic Absorption for the New Century Features High-throughput Dynamic Beam Management System Ensures long-term stability with low noise level Provides the highest level of sensitivity for trace-level analysis (Direct determination Flame: Pb, 0.1ppm; Furnace: Pb, 0.3ppb) Dual-Detector System with Dual Background-Correction Function Ensures maximum sensitivity and accurate background correction at all wavelengths Easy selection process provides optimum method for meeting analysis objectives Burner Height and Gas Flow Rates are Automatically Set for Each Element and Matrix Ensures maximum sensitivity and superior detection limits Enables continuous measurement WizAArd Software - A Match for this Electronic Records Era The newly developed "WizAArd" (Windows-based 32bit) software is much easier to understand and use, with a parameter editing function that enables conditions to be changed rapidly and comprehensive data processing functions. It provides a high level of electronic records security functions for compliance purposes: Manage user login ID names and passwords Manage authority restrictions according to user level Electronic signatures and audit trail functions have been equipped as standard QA/QC functionality as required by the U.S. Environmental Protection Agency (EPA) has been improved Hardware validation software is also standard. Switch Smoothly Between Flame and Furnace - Without Tools Simply remove the burner head and put in place the furnace section. A single autosampler can be used for both flame and furnace, which negates the need to prepare the autosampler for each analysis method. Comprehensive Flame Analysis Highly Sensitive and Stable Flame Analysis The High-Throughput Dynamic Beam Manager System developed uniquely for the AA-6300 automatically sets the photometric system to optical double beam for flame measurement, and to electrical double beam for furnace measurement. Furthermore, the optical system has been designed to produce its maximum performance in each of the measurement methods through the optimal adjustment of the light beam, highspeed operation digital filter, and employment of optical components. Flame Analysis under Optimal Conditions at All Times The AA-6300 conducts measurements by automatically setting the optimal conditions for not just the gas flow rates, but also for the burner height for each element at all times. Detailed methods - including the burner height - can be saved in files as measurement conditions, making it possible for anyone to conduct optimal measurements at any time. Safe Flame Measurement The following safety mechanisms have been incorporated. Safe ignition/extinction sequence Flashback prevention through the gas pressure monitor Prevention of raw gas release when the flame dies out Burner misuse prevention Automatic flame extinction in a power failure Safety inspection support provided by software, and a self-diagnostics function that determines whether the system safety mechanisms are in working order Comprehensive Furnace Analysis Highly Sensitive and Stable Furnace Measurement Unique control of the gas flow inside the graphite tube at atomization (Patent 2067563) ensures high sensitivity measurement - among the best in the world. Combining a high-sensitivity optical sensor with a digital temperature control system enables temperature control with a high degree of precision over the entire temperature region from drying to atomization. By employing the electronic controller, the flow rate of the inner gas can be controlled precisely in 0.01L/Min units. Furnace Analysis under Optimal Conditions at All Times With a sophisticated autosampler, a maximum of 4 reagents (such as the diluent, standard solution, sample, matrix modifier) can at first be mixed and then injected (without mixing as well). The system can be set to automatically dilute and repeat the measurement if the calibration curve concentration is exceeded. Safe Furnace Mechanisms Cooling water flow rate monitor (Ar) gas pressure monitor Over-current prevention device (double checked with the breaker and the optical sensor) Furnace block cooling check Specifications AA-6300 Wavelength range 185 to 900 nm Automated wavelength selection Mounting Aberration-corrected Czerny-Turner mounting, Number of grating groove:1800 lines/mm, Forcal length: 298mm Bandwidth 0.2 0.7 0.7(Low) nm (4 step automatic switching) Detector Photomultiplier (short wavelengths), semiconductor (long wavelength) No. of lamps mounted 6 lamps, 2 user-selected lamps can be illuminated at the same time (1 for measurement, 1 warming up for next measurement) Photometric Mode Flame: Optical double beam. Furnace: Electrical double beam Background Correction High-speed self-reversal method (BGC-SR), high-speed deuterium lamp method (BGC-D2) Lamp Mode Emission, Non-BGC, BGC-D2 Burner Type Air-cooled premix type Burner Head Made of titanium, 10cm slot (the 5cm slot for high temperature flames is optional) Nebulizer Pt-lr capillary with teflon orifice and ceramic impact bead (Hydrofluoric acids can be used) Chamber Polypropylene Positioning Control Automatic search for the optimal burner height, automatic adjustment of vertical position, manual adjustment of back and forth position Gas Control - Flow Control Unit Fuel gas, support gas, automatic flow rate setting (0.1L/min step), automatic search for the optimal gas flow rate Safety Measures Safe ignition/extinction sequence Automatic extinction in a power failure Flashback prevention through gas pressuring monitoring Burner misuse prevention Prevention of raw gas release when the flame dies out Ignition Push ignite button Software Software based on Microsoft WindowsTM Dimensions & Weight 835 (W) x 460 (H) x 545 (D) mm, 70 kg (not including the flue, protruding parts) Power Requirements AC100V±10% (no sudden voltage fluctuations) 230VA, 50/60HZ Ambient Temperature and humidity range Temperature: 10 ~ 35°C Humidity: 20% ~ 80% (less than 70% when temperature is greater than 30°C) Part Number: Description: BUCK 205AAS Atomic Absorption Spectrophotometer Detailed Product Information The 205 Advantage The Buck Scientific 205 AAS uses a unique burner system to get more sample to the flame, which results in more signal and better sensitivity. We use an impact bead nebulizer to get an efficient generation of a fine aerosol of sample solution. The short path spray chamber permits difficult solutions containing organics or high dissolved solids to be aspirated with superb precision and minimal instabilities. To take advantage of this enhanced signal, we designed an optical layout that provides the highest throughput of any commercially available spectrophotometer. Our very simple straight line optical path uses a monochromator with a single reflector mirror. This cuts down on the amount of light loss often associated with models having 10 or more mirrors. Because of this the Buck 205 AAS can detect far-UV elements, such as arsenic and selenium, with ten times greater sensitivity. • Internal microprocessor and software can identify samples, perform statistical analysis and graphically display calibration curves. • Dual lamp power, one for warm up • High throughput "Stable Beam" optical system • Modulated HCL power supply to cancel DC emission from flame • Digital readout for absorbance, emission, direct concentration, lamp currents and PMT voltage • Autozero, curve correction, integration and high gain damping features • Bandpass resolution from 0.2 - 0.7 - 2.0nm • Burner safety interlock system for nitrous oxide/acetylene flame operation • High sensitivity detection using quartz PMT detector • Analog and digital output for chart recorders/PC data systems • Compact design saves bench space Wavelength Range: 190 to 900nm Burner/ Nebulizer: Accuracy: ±0.2nm Integration: User selectable times from 0.5 to 10 seconds for Stabilized readings. Precision: ±0.1nm Calibration: Automatic, weighted least squares fit to 1st, 2nd, 3rd, or 4th order functions, up to 8 points. Monochromator / Optics: Power Supply: 250mm Ebert Mount 0.2, 0.7, 2.0nm bandpass to cover analytical wavelengths for use on atomic absorption and emission measurements Display: 16 line backlit liquid crystal display for all text & graphics Output Modes: LCD Display, IEEE Parallel port for dot matrix printer, RS-232 Serial Port 600 lines/mm high efficiency grating 100-240V.A.C. operating range, 50/60HzAC,<100 watts Polypropylene spray chamber with premix burner and high efficiency adjustable nebulizers (SS or Pt/Ru), Titanium burner heads for Air/Acetylene, Argon/Hydrogen and nitrous Oxide/Acetylene operation Hollow Cathode Lamp: Dimensions: 39" x 11" x 12" Dual HCL modulated power supply, 0 to 25mA peak Weight: 50 lbs. (80 lbs. shipping) WFX-110 /120/130 AAS Spectrometer Atomic Absorption Spectrophotometer (QUALITESTTM) Features High sensitivity, simple and safe operation, low analytical cost, ensured by the patented flame analysis technique (patent No. ZL9210560.7) adopting oxygen-rich air-acetylene flame as the substitution for nitrous oxide-acetylene flame for high temperature element analyses. The flame temperature of the oxygen-rich flame is adjustable continuously between 2300~2950℃. (Only for WFX-110) Fully automated microcomputer controlled operation 1. Automatic wavelength peaking for quick and precise operation. 2. Automatic spectral bandwidth selection. 3. Automatic hollow cathode lamp changeover. 4. Automatic instrument parameter setting, including light source power supply, photomultiplier high voltage supply and background correction energy balance. 5. Automatic signal measurement and data processing. Fast sampling, photo-electric conversion, noise smoothing, integration, curve fitting, background correction and data display can all be done automatically. Easy and flexible WINDOWS operating system, with multi-windows processing technology to observe the signal profile, the measured results and the calibration curve at the same time. Various analytical programs, data, signals and graphics can all be stored for later use. Fully sealed optical system, keeping the optical elements clean and dry and ensuring long-term high-energy throughput. Optimum vibration-absorbing mechanism, ensuring good mechanical stability of the optical system, reducing vibration interference in graphite furnace operation. Two background correction systems, deuterium arc background correction system (with high performance deuterium arc lamp) and S-H background correction system (only for WFX-110/120) to realize background correction at all wavelengths. Perfect safety protection measures, alarm and automatic safety protection to fuel gas leakage, air pressure deficiency and abnormal flame extinction; spray chamber made of explosion-proof material, all-titanium burner and explosion-proof stopper for flame analyses; alarm and protection function to argon pressure deficiency, insufficient cooling water supply, over-heating and overcurrent etc. in graphite furnace analyses. Multi-analytical functions, providing flame AA, graphite furnace AA, and hydride AA analysis and flame emission analysis. Specifications Wavelength range Wavelength accuracy Resolution Baseline stability Main Specification Background correction Lamp turret Hollow Cathode Lamps Lamp current adjustment Lamp power supply mode Optical System Detection and Data Processing System Monochomator Grating Focal length Blazed Wavelength Spectral Bandwidth Detector Software Analytical method Repeatable measurement 190-900n ±0.5nm better than 0.3nm 0.005A/30min The D2 lamp background correction capability at 1A is better than 30 times. The S-H background correction capability at 1.8A is better than 30 times. (for WFX-120/110) 6-lamp turret (WFX-110/120), 4-lamp turret (WFX-130) Automatic adjustment and display. Wide pulse current: 0~25mA, Narrow pulse current: 0~10mA. (WFX-110/120) Powered by two pulses (wide and narrow) simultaneously in WFX110/120; square-wave pulse in WFX-130. Single beam, Czerny-Turner design grating monochromator 1800 l/mm 277mm 250nm 0.1nm, 0.2nm, 0.4nm, 1.2nm Photomultiplier with high sensitivity and wide spectral range. Ms-WindowsTM operating system Working Curve Method (1st order and 2nd order fitting), Standard Addition Method. Maximum 20 times of repeat measurement, automatic calculation of Condition reading Result printing Burner Flame Analysis Spray chamber Nebulizer Position adjustment Protection for gas system mean value, standard deviation and relative standard deviation. With model function Measurement data and final analytical report printout. 10cm single slot all-titanium burner for Air-C2H2 flame(WFX110/120/130); 5cm single slot all-titanium burner for oxygen-rich flame (WFX-110). All-plastic spray chamber. High efficiency glass nebulizer with metal sleeve. Adjusting mechanism for vertical, horizontal positions and the rotation angle of the burner. Fuel gas leak protection, abnormal flame extinction alarm, air-pressure deficiency protection and explosion-proof device. Automatic Cu: Characteristic concentration≤0.05mg/L, Detection limit≤0.006mg/L; Flame ignition Normal Air-C2H2 flame Characteristic Concentration and Oxygen-rich Air-C2H2 flame (only Ba: Characteristic concentration ≤ 0.22mg/L Detection Limit for WFX-110) Hydride generation Hg: detection limit≤0.5ug/L Power Supply 220V, 200W Dimensions 1020 (L) x 492 (W) x 537 (H) mm Weight Unpacked 80kg PEMBAHASAN Setiap perusahaan pembuat perangkat Atomic Absorption Spectrophotometer memiliki kelebihan dan spesifikasi tertentu atas produknya. Dalam tugas ini akan dibahas perbandingan 3 perangkat AAS yang dikeluarkan oleh 3 perusahaan yang berbeda. Untuk lebih jelasnya, dapat dilihat pada tabel perbandingan di bawah ini : No Spesifikasi Tipe Alat AA 6300 BUCK 205 AAS WFX-110 /120/130 1. Rentang Panjang Gelombang 185-900 nm 190-900 nm 190-900 nm Pengukuran 2. Jumlah Lampu 6 2 6 3. Monokromator Double beam 250 mmEbert Single beam Mount 4. Detektor Photomultiplier Photomultiplier & semiconductor 5. Nebulizer Pipa Pt-Ir (Dapat Pt-Ru Terbuat dari menganalisis kaca dengan HF) lapis logam diluarnya 6. Burner 5 cm dan 10 cm Titanium titanium 7. Ukuran berat alat dan 5 cm dan 10 cm titanium 835 (W) x 460 975 (L) x 275 (W) 1020 (L) x 492 (H) x 545 (D) x 300 (H) mm, (W) x 537 (H), 80 mm, 70 kg 25 kg kg Dari ketiga jenis produk AAS ini, masing-masing memiliki kelebihan dan kekurangan. Berdasarkan spesifikasi diatas, dapat dijabarkan beberapa kelebihan dan kekurangan alat-alat tersebut. AAS tipe AA-6300 ini memliki rentang pengukuran 185-900nm yang berarti daerah pengukurannya menjadi lebih luas lagi dibanding kedua alat yang lain , yang hanya memliki rentang pengukuran panjang gelombang 190-900 nm. Dengan rentang pengukuran yang lebih luas, maka semakin banyak jenis sampel yang dapat dianalisis. Jadi dari spesifikasi ini, AAS tipe AA-6300 yang paling baik. Untuk produk AAS tipe AA-6300 dan WFX-110/120/130, memilki 6 lampu yang terpasang sekaligus, sehingga memudahkan analis dalam menganalisis macam-macam logam dalam waktu yang singkat. AAS tipe Buck 205 hanya memiliki 2 lampu sehingga tidak lebih hemat waktu dibandingkan alat yang lain. Monokromator yang digunakan pada AA-6300 adalah jenis double beam yang dapat mengatasi intensitas lampu yang tidak stabil sehingga pengukurannya menjadi lebih akurat. Namun, harganya lebih mahal dibandingkan dengan WFX-110/120/130 yang hanya menggunakan single beam. Harganya lebih mahal karena alat yang menggunakan double beam memerlukan perangkat tambahan dibandingkan dengan alat yang menggunakan single beam. Pada AAS tipe AA-6300, detektor yang digunakan ada 2 macam, yakni photomultiplier untuk pengukuran panjang gelombang pendek dan detektor semikonduktor untuk panjang gelombang panjang. Sedangkan AAS tipe WFX110/120/130 hanya dilengkapi 1 jenis detektor saja, yakni photomultiplier sehingga untuk panjang gelombang yang panjang tidak dapat dideteksi. Sedangkan alat ketiga, AAS tipe Buck 205 tidak diketahui jenis detektor yang digunakan sehingga tidak dapat dibandingkan. Dari data ini, dapat diketahui AA-6300 memiliki kelengkapan detektor dibandingkan kedua alat lain. Nebulizer yang digunakan pada tipe AA 6300 adalah pipa kepiler yang terbuat dari Pt-Ir, komponen Teflon dan keramik sedikit dan beberapa menggunakan HF. Perbandingan lainnya adalah ukuran dan berat dari perangkat AAS, semakin compact dan ringan perangkatnya, maka semakin mudah perangkat tersebut untuk dirawat. Dari ketiga alat di atas dapat diketahui bahwa tipe Buck 205 AAS yang paling memenuhi kriteria tersebut. Tipe AA-6300 juga dilengkapi dengan autosampler yang memudahkan dalam hal pengukuran banyak larutan. Selain itu, tipe ini juga dilengkapai dengan stabilitas alat yang baik sehingga dalam beroperasi tidak mengeluarkan bunyi yang memekakan telinga. Masalah keamanan menjadi jaminan utama dalam perangkat tipe ini, dengan adanya pengendali gas yang digunakan dan pencegahan adanya penyalahgunaan pembakar. Penilaian terhadap ketiga alat ini tidak dapat dilakukan dengan sangat terperinci karena informasi yang diberikan dari setiap alat berbeda. Menurut kami, semakin lengkap informasi alat tersebut maka akan semakin baik karena konsumen akan mampu memilih alat sesuai keinginannya dengan informasi yang jelas tersebut. KHAERUL HATTA ( 105 05 092 ) : 90 RIZKI ANSHARI ( 105 05 093 ) : 90 ASTUTI TRIJAYANTI ( 105 05 094 ) : 90 HUMAILA RIZQI ( 105 05 096 ) : 90 TRIWIDIANSYAH ( 105 05 097 ) : 90 WERDI ISNA RETNOWATI ( 105 05 098 ) : 90 Range Nilai 0 - 100