4.0 Dioxin Dispersion Modeling

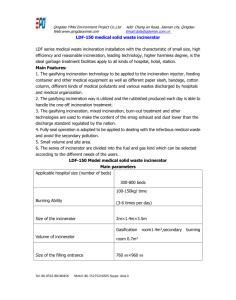

advertisement