Bernoulli Equation Lab: Fluid Mechanics Experiment

advertisement

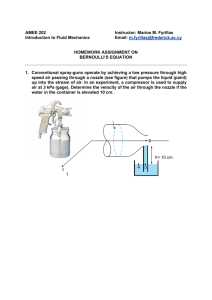

Intro to Fluid and Thermal Transport – ME 331 Laboratory Assignment #3 Bernoulli Equation Demonstration C. J. Kobus Figure 1 shows the apparatus used to investigate the validity of the Bernoulli equation when applied to the steady flow of water in a tapered duct. The apparatus consists of a clear acrylic duct of varying circular cross section, known as a Venturi. The duct has a number of side hole pressure tapings connected to a manometer bank, which allows the measurement of static pressure at 6 different sections. The apparatus is mounted on an Armfield hydraulics bench and flow control valves are used to control the flowrate through the Venturi. Figure 2 and Table 1 respectively show the positions (in mm) of the pressure tapings and the dimensions of the cross-sections. The duct has an upstream taper of 14o and a downstream taper of 21o. The objective of this experiment is to evaluate the validity of the Bernoulli equation when applied to a converging-diverging nozzle. Table 1 - Dimensions of the Venturi Cross-sections Tapping Position Diameter of cross-section (mm) Manometer Height A 25.0 h1 B 13.9 h2 C 11.8 h3 D 10.7 h4 E 10.0 h5 F 25.0 h6 1. 2. Photo from Armfield Hydraulics Bench and Accessories catalog : http://www.armfield.co.uk Schematic from Armfield “Bernoulli’s Theorem Demonstration, F1-15” Instruction Manual, Issue 4, September 2001. INTRODUCTION TO FLUID AND THERMAL ENERGY TRANSPORT - ME331 Assignment Specifications 1. Perform an experiment to measure the steady manometer deflections at the 6 pressure tapings for three inlet volume flowrates (1.0 gpm, 1.5 gpm, and 2.0 gpm). The manometer levels can be adjusted using a hand pump and an air bleed screw until they reach a convenient height. Start with the highest flowrate, record the steady manometer levels then repeat for the next lower flowrate. 2. Plot the static pressure deflection (hi-h6) as a function of position number, i, for the three flowrates. Discuss the effect of flowrate on the pressure drop through the duct. 3. Assuming steady and incompressible flow and using the conservation of mass equation, the velocity, Vi, at each tap location, i, can be determined from the volume flowrate as /A Vi i where Ai is the cross-sectional area at tap i. For each flowrate, calculate and plot these velocities (m/s) as a function of position number, i. 4. Using Bernoulli’s Equation for incompressible, inviscid flow and the manometer equation, derive an expression relating the velocity at each tap location to the manometer height measurements at a cross section and to the velocity at tap A. 5. Superimpose the velocities predicted by the Bernoulli equation on the plots from spec. #3. For tap A use the velocity determined using eq. (1). 6. Perform an uncertainty analysis on the velocity calculations from eq. (1) and show error bars on the plots. Perform a sensitivity analysis on the Bernoulli equation velocity predictions and include error bands on the plots. Assume the following accuracy for the direct measurements: diameter = ± 0.05 mm, manometer level = ±2.5 mm, flowrate = ± 3% f.s.f. 7. Compare the velocity predictions from the Bernoulli equation to those calculated using eq. (1). Discuss any discrepancies and comment on the agreement between your theoretical and experimental results. 8. A venturi is a device that is sometimes used to measure flowrate. The volume flowrate is determined by measuring the pressure difference between the upstream section and the throat of the nozzle. Using Bernoulli’s Equation for incompressible, inviscid flow, the manometer equation, and the conservation of mass equation, show that that the volume flowrate can be predicted by 1 2 d 52 d12 2 g (h1 h5 ) A5 , where A1 4 and A5 4 A 2 1 ( 5 A ) 1 Compare this prediction to your directly measured volume flowrates.