Lab 09 - Drag Force

advertisement

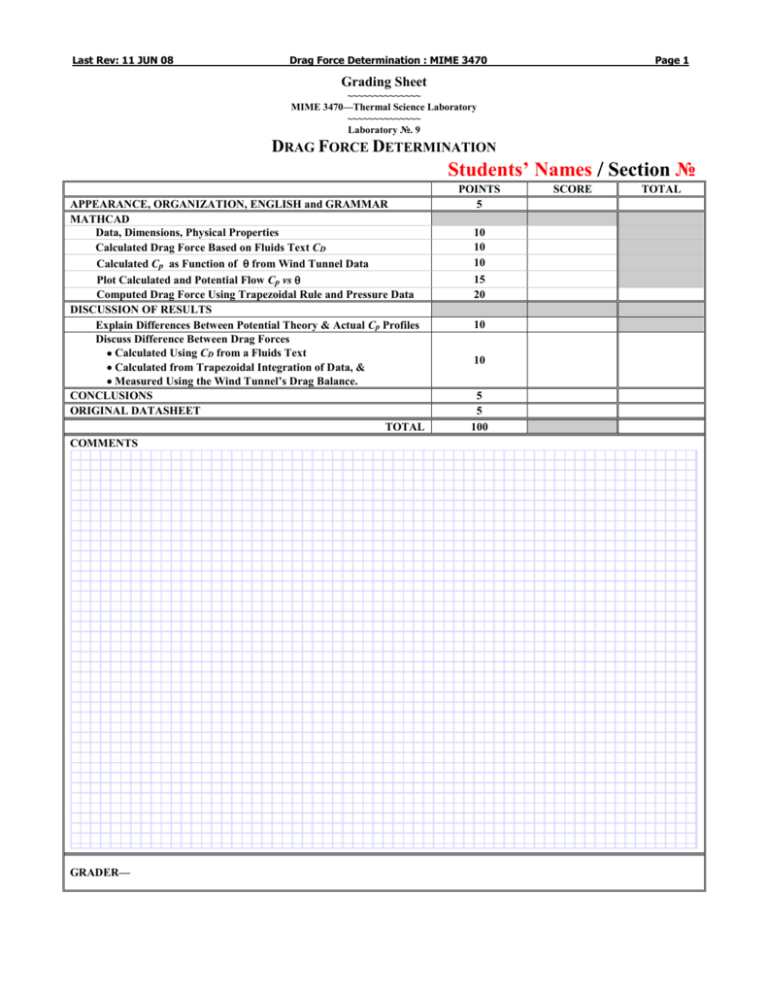

Last Rev: 11 JUN 08 Drag Force Determination : MIME 3470 Page 1 Grading Sheet ~~~~~~~~~~~~~~ MIME 3470—Thermal Science Laboratory ~~~~~~~~~~~~~~ Laboratory №. 9 DRAG FORCE DETERMINATION Students’ Names Section № APPEARANCE, ORGANIZATION, ENGLISH and GRAMMAR MATHCAD Data, Dimensions, Physical Properties Calculated Drag Force Based on Fluids Text CD Calculated Cp as Function of from Wind Tunnel Data Plot Calculated and Potential Flow Cp vs Computed Drag Force Using Trapezoidal Rule and Pressure Data DISCUSSION OF RESULTS Explain Differences Between Potential Theory & Actual Cp Profiles Discuss Difference Between Drag Forces Calculated Using CD from a Fluids Text Calculated from Trapezoidal Integration of Data, & Measured Using the Wind Tunnel’s Drag Balance. CONCLUSIONS ORIGINAL DATASHEET TOTAL COMMENTS d GRADER— POINTS 5 10 10 10 15 20 10 10 5 5 100 SCORE TOTAL Last Rev: 11 JUN 08 Drag Force Determination : MIME 3470 MIME 3470—Thermal Science Laboratory ~~~~~~~~~~~~~~ Laboratory №. 9 Page 2 one to determine the drag force from an experimentally measured distribution. A typical pressure distribution is shown in Figure 2. DRAG FORCE DETERMINATION ~~~~~~~~~~~~~~ LAB PARTNERS: NAME NAME NAME SECTION № EXPERIMENT TIME/DATE: NAME NAME NAME TIME, DATE ~~~~~~~~~~~~~~ OBJECTIVE–To measure the pressure distribution around a circular cylinder placed in a transverse air stream and calculate the drag force based on the local pressure measurements. To compare the measured pressure distribution and drag force with the values predicted by the potential flow theory, and to identify the limitations of that theory. INTRODUCTION–The theory of fluid flow around a smooth cylinder dates back to 19th-century hydrodynamics. The potential flow theory presented here predicts the velocity and pressure distributions about the circumference of a circular cylinder immersed in a fluid stream. The same theory predicts the lift and drag forces on the cylinder and can be applied to airfoils in modern aircraft and turbomachinery applications. In the ideal potential theory for this experiment, the fluid is assumed to be inviscid and incompressible. The flow at large distances from the immersed body is assumed to be uniform. In keeping with the above assumptions, the flow is irrotational. When the fluid encounters a smooth surface it is assumed to slip tangentially, flowing without friction or separation along the surface; the fluid neither penetrates the surface nor leaves a gap. This condition is sufficient to yield a unique solution to the governing flow equations. This boundary condition differs from the more realistic no-slip condition applied to viscous flows. Figure 1 shows a cross section of a circular cylinder of radius a in a potential flow from left to right. The fluid speed at large distances from the center is U and the corresponding static pressure is p. Note that the angle takes values from 0 to 2 radians and that the flow is symmetrical about the vertical and horizontal axes of the cylinder. Figure 2– Pressure Distribution Around a Circular Cylinder Placed in a Real-Fluid Uniform Flow. The length of the arrow at any point on the cylinder surface, in Figure 2a, is proportional to the pressure at that point. Figure 2b is a plot of the pressure data from Figure 2a. The direction of the arrow in Figure 2a indicates that the pressure at the respective point is greater than the free-stream static pressure (pointing toward the center of the cylinder) or less than the free-stream static pressure (pointing away). Note the existence of a separation point and a separation region (or wake) (see Figure 3). U Figure 3 – Streamlines of Flow About a Circular Cylinder. Figure 1 —Circular Cylinder in an Ideal (Potential Theory) Flow The pressure in the back-flow (wake) region is nearly the same as the pressure at the point of separation. The general result is a net drag force equal to the sum of the forces due to pressure acting on the front half (positive pressures) and on the rear half (negative pressures) of the cylinder. To find the drag force, it is necessary to sum the horizontal pressure components at each point along the cylinder’s surface. POTENTIAL FLOW PRESSURE DISTRIBUTION ABOUT A CYLINDER For potential flow, the tangential velocity along the surface of the cylinder is given by (1) U s 2U sin For steady, inviscid, incompressible flow along a streamline, Bernoulli’s equation is valid. Further, since the gravitational field is conservative (i.e., does not change), it is justifiably ignored. By applying Bernoulli’s equation to Equation 1, it can be established without much difficulty that: p p Cp s (2a) 1 U 2 2 For real, viscous fluids, the fluid exerts a pressure on the front half of the cylinder in an amount that is greater than that exerted on the rear half. The difference in pressure multiplied by the projected frontal area of the cylinder gives the drag force due to pressure (also known as form drag as opposed to skin-friction or surface drag). Because this drag is due primarily to a pressure difference, measurement of the pressure distribution about the cylinder allows 1 4 sin2 (2b) where ρ and ps() denote the fluid density and the surface static pressure at angle , respectively. Cp is called the pressure coefficient or the Euler number. Observe that this coefficient is dimensionless, taking the value of 1 at both the forward and rearward stagnation points and a minimum value of –3 at = /2. U r 2U Last Rev: 11 JUN 08 Drag Force Determination : MIME 3470 Also, note from Figure 4 that the pressure coefficient is symmetric about both the x and y cylindrical axes. U y x p s p0 forth his boundary layer hypothesis in 1904. Again, this paradox is a result of the omission of the influence of viscosity. In a practical sense, the approach necessary to calculate the drag on the cylinder (or the drag coefficient) is to measure the pressure along the entire cylinder surface and perform the integration of Equation 3 using differential surface elements. If, for example, an experimenter wishes to represent the pressure distribution by making a large number of measurements (ps)i at discrete locations i separated by intervals of radians, the resulting calculation for the drag force per unit length of cylinder would be: N 1 U 2 2 FD i 1 The surface static pressure ps at = 0, is equal to the stagnation (or total) pressure, p0, of the flow. The stagnation pressure (the Bernoulli constant in this case) is p0 p 12 U 2 . The quantity 12 U 2 , is the dynamic pressure and is the kinetic energy per unit volume of the distant stream, while p is the static pressure of the distant stream. In this experiment, the student will measure the difference between p and ps()pressure (where ps(0) = p0, such that this difference is positive at the forward stagnation point) at various locations along the surface of a cylinder placed in a wind tunnel stream. In order to reduce the pressure data to the pressure coefficient Cp, the static pressure and the dynamic pressure of the approaching free stream are required. A manometer on the test bench will measure the difference in pressure, ps() – p. The dynamic pressure can be determined from the measured velocity of the free stream. DRAG AND LIFT FORCES–Since there are no viscous shear stresses (skin friction) in the potential model, the total force that the fluid exerts on the cylinder is obtained by integrating the static pressure force over the surface area A of the cylinder. The total force can be resolved into components parallel and perpendicular to the flow direction; they are called drag, FD, and lift, FL, respectively. In the present case they are horizontal and vertical components: p dA (3) p dA (4) A s x p s p s i 1 i 2 i i 1 cos rcyl Lcyl 2 (5) The cos term, in the Equation 5, generates the horizontal projection of the pressure force. Since the tunnel static pressure is assumed constant over the test section it is reasonable to replace (ps)i in the above equation with (ps)i – p. This is the actual differential pressure measured by the instrumentation in the lab and the p term will simply cancel out of any calculation of the drag force. The radius of the cylinder is rcyl and its length Lcyl. deg vod Figure 4 —Instantaneous Surface Pressure Coefficient vs. Angle FD Page 3 APPARATUS–The apparatus in this experiment consists of an open (as to a closed loop) wind tunnel with a 30cm diameter circular test section (see Figure 5). The cylinder almost entirely spans this test section and has a single pressure tap which moves with the cylinder as it is rotated. The test section itself has a static pressure tap at its underside for measuring the wind tunnel static pressure. A differential pressure transducer (manometer) is connected between the cylinder’s total pressure tap and the tunnel’s static pressure tap. The pressure tap on the surface of the cylinder is a small pinhole that is connected to a tubing connector that runs along the axis of the cylinder. Inlet Inlet flow flow straighteners straighteners Nozzle le Test section Diffuser Diffuser Fan Fan Cylinder Cylinder INLET FLOW STRAIGHTENERS NOZZLE FAN DIFFUSER TEST SECTION and FL A s y Due to the double symmetry discussed in connection with Figure 4, both FD and FL obviously are zero for a cylinder in potential flow. It is practical to conclude that there is no lift on a cylinder placed in a transverse air stream; but, the prediction that there is no drag is not easy to accept, and, in fact, it should not be. The inviscid flow assumption in the theory allows for complete pressure recovery along the rear side of the cylinder. This does not happen in real flows as will be seen from the measurements made in the laboratory. Even less obvious is the fact that under the potential flow assumption, FD = 0 independent of body shape! This outcome, referred to as D’Alembert’s paradox, was a major point of contention of 19th-century hydrodynamics until Ludwig Prandtl set Figure 5 - The Experimental Setup. CYLINDER–A hollow, plastic cylinder 25.4mm in diameter and 292mm long spans the breadth of the wind tunnel test section. The cylinder can be rotated on its axis from one angular position to another by hand. The angular position of the pressure tap relative to the tunnel’s longitudinal axis is measured by means of a 360o protractor located on the wind tunnel frame just below the cylinder. A pointer is fastened on the threaded bar that supports the cylinder, indicating the angle of rotation of the cylinder with respect to the stagnation streamline that corresponds to zero degrees on the protractor. MANOMETER–A differential manometer with a range of 0 to 2inH2O is used to measure the pressure differences. Last Rev: 11 JUN 08 Drag Force Determination : MIME 3470 PROCEDURE 1. The experiment is performed at a constant speed near 40mph. 2. Rotate the cylinder pointer to a protractor reading of = 0o. 3. Record the pressure difference reading at = 0o. 4. Rotate the cylinder pointer to = 5o and record the pressure difference again. 5. Continue taking readings in 5o increments for a total of 37 readings. 6. After all data have been taken, turn off the wind tunnel. FOR THE REPORT Calculations and Results 1. Calculate the drag force D FD 1 C DU 2 A 2 where, CD – drag coefficient selected from a plot of CD vs. Re (see data sheet), U = U, the free-stream velocity, A – is the area of the cylinder projected on a plane normal to the flow direction, ρ – is the air density. Page 4 2. Calculate Cp as a function of angle (Equation 2a). Note, if the value of Cp at the forward stagnation point is not equal to 1, scale all values of ps i p such that (Cp)0 = 1. 3. Plot calculated Cp vs. for the wind tunnel speed. Also calculate the potential theory value of Cp (Equation 2b) and plot it on the same graph. 3. Use Trapezoidal integration (see Appendix A) to compute the drag force on the cylinder based on the pressure difference measurements (see Equation 5). Discussion of Results 1. Explain the differences between the potential theory and actual profiles of Cp. 2. Discuss the difference between the drag force calculated using the CD from a fluids text (Item 1 above), calculated from Trapezoidal integration of data (Item 3 above), and the drag force measured using the wind tunnel’s drag balance. Last Rev: 11 JUN 08 Drag Force Determination : MIME 3470 ORDERED DATA, CALCULATIONS, and RESULTS Page 5 Last Rev: 11 JUN 08 Drag Force Determination : MIME 3470 DISCUSSION OF RESULTS Explain differences between potential theory and actual Cp profiles Answer Discuss difference between drag forces 1) calculated using CD from a fluids text, 2) Calculated from Trapezoidal integration of data, and measured using the wind tunnel’s drag balance. Answer CONCLUSIONS Page 6 Last Rev: 11 JUN 08 Drag Force Determination : MIME 3470 APPENDICES APPENDIX A—TRAPEZOIDAL INTEGRATION Page 7 Last Rev: 11 JUN 08 Drag Force Determination : MIME 3470 Page 8 APPENDIX B—DATA SHEET FOR DRAG FORCE EXPERIMENT Time/Date ____________________________ DATA Lab Partners ____________________________ Cylinder diameter (______) ____________________________ Cylinder length (______) ____________________________ Ambient temperature (°____) ____________________________ Air Speed, U (_____) ____________________________ Measured Wind Tunnel Drag. (_____) i () 0 5 10 15 20 25 30 Surface Pressure Measurements ps i p (inH2O) 35 40 45 50 55 60 65 70 75 80 85 90 95 100 105 110 115 120 125 130 135 140 145 150 155 160 165 170 175 180