CHM412 EXPERIMENT 2 sdf

advertisement

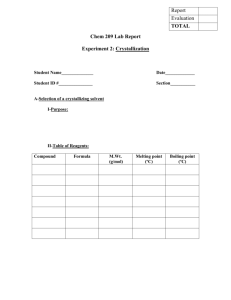

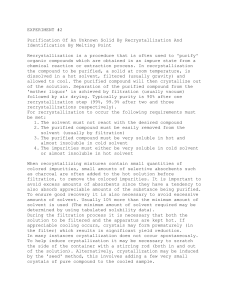

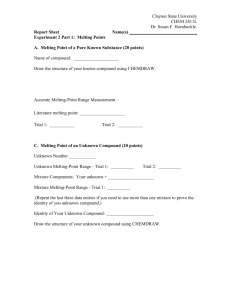

Page 1 of 3 CHM 412 EXPERIMENT 2 RECRYSTALIZATION AND MELTING POINTS Learning objectives: 1) Able to do recrystallization. 2) Melting point determination. Introduction Recrystallization is one of the techniques to purify small scale solid compound products in chemistry laboratory. It is very common to find that most of products from organic reactions are impure. The impurities are usually come from leftover reactants and side-products. Removal of the impurities is required before any further reaction on the compound, because impurities will be interfered with the further reaction that will be carried out. The first step for recrystallization is preparation of hot saturated solution; this will be obtained by dissolving the required solid in a minimum amount of hot recrystallization solvent. Solid impurities will be removed via gravitational filtration, and then the hot saturated solution will be slowly cooled down in order for the solid to precipitate out. The solvent used for the recrystallization will be the liquid that able to fully dissolved the solid in hot, partially dissolved the solid in room temperature and slightly dissolved it in cold. When the is solid formed and the solution turned to room temperature or after cool down in an ice-bath the mixture of solid and solvent will be filtered again under vacuum. At this stage the soluble impurities will be remained in the solution. For a simple determination of pure compound in a laboratory, melting points is normally used. A pure solid will give a melting range of 1-2oC, while impure compound will be showing rather a larger range for the melting temperature. Chemical: Acetanilide about 1-2 g Page 2 of 3 Apparatus 1 Erlenmeyer flask (100 ml), 1 hot plate 1 short stem/stemless gravity filter funnel, 1 beaker (100 ml), 1 filter paper, 1Buchner funnel 1Buchner flask 1 rubber hoses, A vacuum pump, A retort stand, 1 watch glass, 3 melting-point capillary tubes, 1 long piece of glass/plastic tube, A melting point temperature determining apparatus Procedure 1. Place about 1-2g of impure acetanilide in a 100 ml erlenmeyer flask. 2. Heat water to boiling (use a hot plate) and add a minimum amount of the hot water to dissolve the acetanilide and soluble impurities while continuously heating the mixture at the boiling point. 3. Continue to add hot water little by little until all the acetanilide dissolves. This is to prepare hot saturated solution. 4. Do not continue to add the solvent in attempts to dissolve the insoluble contaminants. 5. Note that the acetanilide will dissolve in hot water forming an oily layer. Add enough boiling water to dissolve the oil. 6. Using a short stem or stemless gravity filter funnel and fluted filter paper, filter the hot solution into a 100 ml sized beaker. Cool the clear filtrate gradually at room temperature and allow the compound to crystallize. Cool in ice bath to crystallize even more compound. 7. After about 30 minutes or when the amount of the solid more or about the same level of the solvent , collect the crystals in a buchner funnel. Try to rinse the crystals 2-3 times with the total of about not more than 20 ml ice cold water. 8. Transfer the crystals onto a watch glass and dry it in the oven. Page 3 of 3 9. To prepare a solid sample for a melting point determination, press the open end of a melting-point capillary tube down on the sample so that the sample is forced up into the tube. 10. Turn the tube upright position and drop it in a long piece of glass tubing to knock down the sample to the closed end. 11. Introduce the capillary into a melting point temperature determining apparatus and start heating. Watch the sample through the magnifier and when it starts to melt, note the temperature range over which it melts. Questions 1. Explain why the collected crystals in a recrystallization procedure were washed with cold water rather than warm water. 2. Why is the final product from recrystallization obtained by suction filtration rather than gravity filtration? 3. Although solid product is pure, why will it still have a melting range?