Flow of Manufacturing Activities - Sun Yat

advertisement

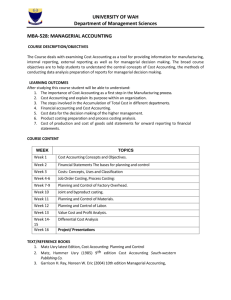

Task Team of FUNDAMENTAL ACCOUNTING School of Business, Sun Yat-sen University Lesson Notes Lesson 13 Managerial Accounting: Concepts and Principles Learning objectives 1. Describe the definition of managerial accounting. 2. Identify and explain the difference between managerial accounting and financial accounting. 3. Analyze different ways to classify costs. 4. Describe the flow of manufacturing activities. 5. Identify and explain job order cost accounting systems and process cost accounting systems 6. Analyze different methods of cost allocation Teaching hours Students major in accounting 0 hours Other students 6 hours Teaching contents Introduction The previous 12 chapters focus on the financial accounting topics. Please summarize the basic points of financial accounting: Users/ Time focus/ Emphasis/ Importance/ Subject focus/ Requirements. (1) Is the information provided by financial accounting enough for an enterprise to conduct its operation and management? (2) If not, how to satisfy this demand for the internal used information? (3) Have you ever heard “managerial accounting”? What is Managerial Accounting? Managerial accounting is an activity that provides financial and nonfinancial information to managers and other internal decision makers. It is quite important to planning, control, and decision making activities. Comparison between Managerial Accounting and Financial Accounting Managerial accounting and financial accounting can be compared as the following table: Financial Accounting Managerial Accounting 1. Users Investors, creditors, and other external users Managers, employees, other internal users 2. Time focus Historical perspective Future emphasis 3. Emphasis Objectivity Verifiability 4. Importance Precision of information Timeliness of information 5. Subject focus Summarized data for the whole organization Detailed segment reports of an organization 6. Requirements Structured and often controlled by GAAP Relatively flexible (no GAAP) and and Relevance for planning and control Task Team of FUNDAMENTAL ACCOUNTING School of Business, Sun Yat-sen University Cost Classifications Costs can be classified by relevance, behaviour, controllability, traceability, and function. Costs Classification by Relevance If costs influence a decision, we call them relevant costs, such as costs that are applicable to a particular decision, costs that should have a bearing on which alternative a manager selects, costs that are avoidable, future costs that differ between alternatives. If costs do not influence a decision, we call them irrelevant costs. Sunk costs means that all costs incurred in the past that cannot be changed by any decision made now or in the future. They are irrelevant, and should not be considered in decisions. For example: You bought an automobile that cost $30,000 two years ago. The $30,000 cost is sunk because whether you drive it, park it, trade it, or sell it, you cannot change the $30,000 cost. Out-of-pocket costs require future outlays of cash, they are associated with a particular decision, and are relevant for future decisions. For example: Considering the decision to take a vacation or stay at home, if you choose a vacation, you will only have travel costs (out-of-pocket costs). Opportunity costs means the potential benefit that is given up when one alternative is selected over another. For example: If you were not attending college or university, you could be earning $25,000 per year. Your opportunity cost of attending college or university for one year is $25,000. Costs Classification by Behaviour Cost behavior refers to how a cost will react to changes in the level of business activity. Fixed costs do not change when activity changes; variable costs change in proportion to changes in the volume of activity. Total fixed costs remains unchanged when activity changes within a relevant range. Fixed costs per unit decline as activity increases. Total variable costs change when activity changes. Variable costs per unit do not change as activity increases. Mixed costs contain a combination of fixed and variable costs. Step-wise costs remain fixed over limited ranges of volumes but increase by a lump sum when volume increases beyond maximum amounts. For example: additional production supervisors must be added when another shift is added. Costs Classification by Controllability Controllable costs vs not controllable costs depend upon the employee’s responsibilities. For example: A lower level manager may have control over overtime costs but not over the purchase of high-cost machinery. Costs Classification by Traceability Traceable costs are classified as (1) direct costs can be conveniently traced to a unit of product or other cost objective, for examples: salaries of production workers, salary of maintenance department employees; (2) indirect costs must be allocated to a unit of product or other cost objective, for examples: factory rent, factory light and heat, factory accounting costs. Costs Classification by Function Manufacturing costs are necessary and integral to the production of finished goods, for examples: direct labour, direct materials, and manufacturing overhead. Non-manufacturing costs are not integral to the manufacture of finished goods. For examples: selling and administrative expenses. Manufacturing costs can be further classified as (1) direct materials, materials that are clearly Task Team of FUNDAMENTAL ACCOUNTING School of Business, Sun Yat-sen University and easily identified with a particular product, for example: steel used to manufacture an automobile; (2) direct labour, labour costs that are clearly traceable to, or readily identifiable with, the finished product, for example: wages paid to an automobile assembly worker; (3) manufacturing overhead, all manufacturing costs except direct material and direct labour, that is , manufacturing costs that cannot be traced directly to specific units produced. For examples: indirect labour – maintenance, indirect material – cleaning supplies, factory utility costs, and supervisory costs. Manufacturing costs are often combined as follows: (1) prime cost, including direct material and direct labour; (2) conversion cost, including direct labour and manufacturing overhead. Non-Manufacturing costs (period costs) are expenses not charged to the product. (1) Selling costs, costs incurred to obtain customer orders and to deliver finished goods to customers —advertising and shipping; (2) Administrative costs, non-manufacturing costs of staff support and administrative functions —accounting, data processing, personnel, research and development. Discussions ABC company manufactures a portable radio designed for mounting on the wall of the bathroom. The following list represents some of the different types of costs incurred in the manufacture of these radios: 1) The plant manager's salary. 2) The cost of heating the plant. 3) The cost of heating executive offices. 4) The cost of printed circuit boards used in the radios. 5) Salaries and commissions of company salespersons. 6) Depreciation on office equipment used in the executive offices. 7) Depreciation on production equipment used in plant. 8) Wages of janitorial personnel who clean the plant. 9) The cost of insurance on the plant building. 10) The cost of electricity to light the plant. 11) The cost of electricity to power plant equipment. 12) The cost of maintaining and repairing equipment in the plant. 13) The cost of printing promotional materials for trade shows. 14) The cost of solder used in assembling the radios. 15) The cost of telephone service for the executive offices. Required: Classify each of the items above as product cost or period costs. Answer: 1) Product. 2) Product. 3) Period. 4) Product. 5) Period. 6) Period. 7) Product. 8) Product. Task Team of FUNDAMENTAL ACCOUNTING School of Business, Sun Yat-sen University 9) Product. 10) Product. 11) Product. 12) Product. 13) Period. 14) Product. 15) Period. Flow of Manufacturing Activities Flow of manufacturing activities can be listed as the following graph: (ppt page 25) Job Order Cost Accounting Systems and Process Cost Accounting Systems Job Order Cost Accounting Systems Here the production of products responds to special orders. It is quite flexible in the number of products they can produce, where jobs involving the production of more than one unit of product are called job lots. Please refer to ppt page 27 and page 28. Process Cost Accounting Systems Process cost accounting systems are used for production of small, identical, low-cost items, for example, mass produced in automated continuous production process. Here costs cannot be directly traced to each unit of product. Please refer to ppt page 30. To determine the cost of goods transferred from department to department and to finished goods, we need to calculate unit cost. Unit cost is computed by dividing the accumulated costs by the number of equivalent units produced in the period. Costs are accumulated for a period of time by process or department. Equivalent units is a concept expressing a number of partially completed units as a smaller number of fully completed units. For example: Three one-third full pitchers are equivalent to one full pitcher. Equivalent units may be different for material and labour and overhead at different stages of a process. Comparing Job Order and Process Production We can compare job order and process cost accounting systems as follows: Similarities: (1) Same objective, to determine the cost of products; (2) Same inventory accounts, raw materials, goods in process, and finished goods; (3) Same overhead assignment method, predetermined rate times actual activity Differences (job order systems vs process systems: (1) Custom orders vs Repetitive production; (2) Heterogeneous products vs Homogeneous offering; (3) Low output volume vs High output volume; (4) High flexibility vs Low product flexibility; (5) Low to medium standardization vs High standardization. Cost Allocation Based on the complexity from low to high, the methods of cost allocation can be classified as plant-wide overhead rate, two-stage cost allocation, and activity-based costing. Task Team of FUNDAMENTAL ACCOUNTING School of Business, Sun Yat-sen University Plant-wide Overhead Rate A single plant-wide overhead rate is relatively easy to use, but may result in inaccurate product costs. Two-stage Cost Allocation Two-stage cost allocation is more accurate method than plant-wide. Stage 1: Allocate service department costs to production departments. Service department costs are assigned to operating (or production) departments. Stage 2: Allocate production department costs to cost objects. Costs accumulated within operating (or production) departments are assigned to cost objects. Activity-based Costing Activity-based costing attempts to better allocate costs to the desired cost objects by focusing on activities consumed by the cost objects. Many activities within a department drive overhead costs. Products require activities. Activities consume resources. Activity-based Costing: Procedures The procedures include: (1) Identify activities that consume resources; (2) Assign costs to a cost pool for each activity; (3) Identify cost drivers associated with each activity; (4) Compute overhead rate for each cost pool, rate equals to estimated overhead costs in activity cost pool over to estimated number of activity units; (5) Allocate overhead cost, overhead rate times actual activity.. Activity-based Costing: Identifying Cost Drivers Most cost drivers are related to either volume or complexity of production. For example: purchasing, invoicing, quality inspection, product design. Three factors must be considered in choosing a cost driver: (1) Causal relationship; (2) Benefits received; (3) Reasonableness. The typical costs and cost drivers are listed as follows: Cost Cost Driver Materials purchasing Number of purchase orders Materials handling Number of materials requisitions Personnel Number of employees Equipment amortization Number of products produced or hours of use Quality inspection Number of units inspected Indirect labour in setting up Number of setups required equipment Activity-based Costing: Benefits The benefits of activity-based costing include: (1) More detailed measures of costs; (2) Better understanding of activities; (3) More accurate product costs for pricing decisions, product elimination decisions, and managing activities that cause costs. Certainly, benefits should always be compared with costs of implementation Case Study ABC Company acquired its factory building about 25 years ago. For a number of years, the company has rented out a small, unused part of the building. The renter's lease will expire soon. Task Team of FUNDAMENTAL ACCOUNTING School of Business, Sun Yat-sen University Rather than renewing the lease, ABC Company is considering using the space itself to manufacture a new product. Under this option, the unused space will continue to be depreciated on a straight-line basis, as in past years. Direct materials and direct labour cost for the new product is $45 per unit. In order to store finished units of the new product, the company will rent a small warehouse nearby. The rental cost is $1,800 per month. It will cost the company an additional $3,500 each month to advertise the new product. A new production supervisor, hired to oversee production of the new product, will be paid $2,500 per month. The company will pay a sales commission of $12 for each unit of product that is sold. Required: Complete the chart below (in the next page) by placing an "" under each column heading that helps to identify the costs listed to the left. You can place an "" under more than one heading for a single cost: for example, a cost may be a product cost, an opportunity cost, and a sunk cost; you would place an "" under each of these headings on the answer sheet opposite the cost. Opportunity Sunk cost Variable cost cost Fixed cost Product Selling and cost administration cost Rent on unused factory space depreciation Direct material + direct labour Rental cost warehouse of Advertising cost Supervisor’s salary Sales commissions Key points 1. definition of managerial accounting 2. cost classification 3. job order cost accounting systems 4. cost allocation Reading material 1. Charles T. Horngren, George Foster and Srilant Datar, Cost Accounting: A Managerial Emphasis (Tenth Edition), Prentice Hall Inc., 2000. 2. Anthony A. Atkinson, Rajiv D.Banker, Robert S. Kaplan, S. Mark Young, Management Accounting , Prentice Hall Inc., 2001.