Block 10 - Unit 5 - Diagnostic Ultrasound Imaging Calibratio

DIAGNOSTIC ULTRASOUND IMAGING CALIBRATION

General Ultrasound Knowledge

Other names

• Real-time scanners

• 2-D scanners

• Duplex scanners

• Echocardiographs

• Cardiac ultrasound imagers

• Vascular ultrasound imagers

Common uses

• Cardiology

• Diagnostic imaging

• Obstetrics and gynecology

• Ophthalmology

• Radiology

• Surgery

• Vascular lab

• Emergency department

Scope

• This procedure covers all diagnostic ultrasound scanners, including generalpurpose and dedicated systems

• This procedure does not cover nonimaging diagnostic ultrasound systems such as doppler blood-flow detectors and doppler fetal heart monitors

Test Equipment Required

Multipurpose phantom - comprehensively evaluate the performance of diagnostic ultrasound imaging systems with the following capabilities

• Dead-zone or ring-down

• Vertical and horizontal measurement calibration

• Focal zone

• Sensitivity

• Axial and lateral resolution

• Functional resolution

• Grayscale and displayed dynamic range

• Material

The phantom should be designed with a combination of monofilament line targets and tissue-mimicking cylindrical targets of varying sizes and contrasts

The monofilament line targets should have a diameter of 0.1 mm to 0.5 mm ±5% to optimize the displayed image at frequencies typically used on general-purpose scanners

Monofilament line targets with diameters of approximately 0.5 mm should be present to optimize the displayed image at the high ultrasound frequencies typically used on small-parts scanners

Doppler flow phantom - comprehensive evaluation of ultrasound scanners that incorporate continuous-wave, pulsed-wave, or color-flow Doppler capabilities with the following capabilities:

• Flow velocity

• Location of flow

• Directional discrimination

Material

The phantom can be either the tissue-mimicking type with one or more fluid-flow channels (containing a non-degradable blood-mimicking solution with calibrated reflecting targets) or the type that incorporates a moving string target within a fluid-filled container

The string phantom provides greater accuracy for flow velocity calibration

NOTE:

To check only basic Doppler operation, it is not necessary to use the calibrated Doppler phantoms described above

A less-costly blood-flow simulator may be purchased, or one may be constructed using a fluid pump and flexible tubing submerged within a fluid-filled container

In lieu of the nondegradeable blood-mimicking solution with calibrated reflecting targets, any echogenic fluid, such as a detergent-water solution, may be used

Blood flow simulator - for checking doppler ultrasound

ECG simulator

Leakage current meter

Ground resistance ohmmeter

Overview

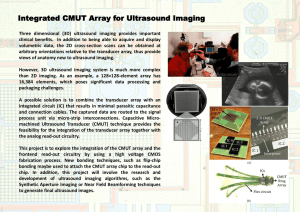

Ultrasounds typically provide 2-D images of soft tissue

Scanners also provide waveforms (M-mode)

Newer scanners have 3-D capabilities

Ultrasound refers to sound waves emitted at frequencies above the level of human hearing

For diagnostic imaging, frequencies ranging from 2 to 10 MHz are typically used

Ultrasound waves are mechanical vibrations that require a medium for transmission

Echoes are produced whenever the beam encounters an interface of different acoustic impedances, such as the soft-tissue/bone interface

Transducer

• Placed on the skin after an acoustic coupling gel is applied

• Converts an electrical signal into ultrasonic energy that can be transmitted into tissues

• Reconverts reflected signal into an electrical signal

Procedure

Note:

• Before beginning an inspection, carefully read this procedure and the manufacturer's instruction and service manuals

• Know how to operate the equipment and the significance of each control and indicator. Also review special inspection and preventive maintenance procedures or frequencies recommended by the manufacturer

Transducer Identification and Scanner Settings for Tests with the Multipurpose

Ultrasound Phantom (Record the Type, Serial #, Frequency, Settings, Power, Gain,

Dynamic Range, etc.)

Measurements

• Dead Zone - place the transducer over the dead zone line target group.

Determine the minimum distance (in mm) at which the scanner can resolve individual structures

• Axial resolution - place the transducer over one of the axial resolution line target groups. Determine the minimum reflector separation (in mm) along the axis of the transducer beam required to produce separate reflections

• Lateral resolution

Place the transducer over each lateral resolution line target group

Determine the minimum reflector separation (in mm) perpendicular to the sound path needed to produce discrete reflections

Because lateral resolution can vary with depth, multiple transducer locations should be used

Record the lateral resolution for each depth checked

If the transducer has adjustable transmit focus, verify its operation and perform each lateral resolution measurement in the respective focal zone, if possible

• Vertical Distance

Place the transducer over a vertical distance calibration line target group

Use the scanner's digital calipers and/or marker grids to determine the accuracy of linear measurements along the axis of the transducer beam at 20 mm and 100 mm measured distances

• Horizontal Distance

Place the transducer over a horizontal distance calibration line target group

Use the scanner's digital calipers and/or marker grids to determine the accuracy of linear measurements perpendicular to the sound path

On images produced by flat sequenced linear-array transducers, check at 20 mm and 60 mm measured distances, using any left to right location

On images produced by sector transducers, check at 20 mm and 60 mm measured distances, but at multiple left to right positions. If the transducer has adjustable transmit focus, perform measurements within the focal zone, if possible

• Doppler Calibration

If a calibrated Doppler ultrasound phantom is available, verify the accuracy of flow velocity, directional discrimination, and, if applicable, pulsed-Doppler gate positioning

Measurement parameters and display quality should not vary between inspections with the same transducer configuration, scanner settings, and technique

Operator Calibration - ensure operator calibrations are performed according to the manufacturers manuals

Other Checks

Accessories

Confirm the presence and condition of accessories (e.g., transducers and coupling gel)

Verify that expiration dates have not been exceeded

A copy of the instruction manual should be readily available to the operators

Chassis/housing

Examine the exterior of the scanner for cleanliness and general physical condition

Be sure that plastic housings are intact, that all hardware is present and tight, and that there are no signs of spilled liquids or other serious abuse

AC plug/receptacles

• Examine the AC power plug for damage

• Wiggle the blades to check for security

• Shake the plug and listen for rattles

• If damage is suspected, open the plug and inspect it

• For receptacles mounted on the scanner - verify the presence of line power, and insert an AC plug into each and check that it is held firmly.

Line cord

• Inspect the cord for signs of damage

• If damaged, replace the entire cord or, if the damage is near one end, cut out the defective portion

• Be sure to wire a new power cord or plug with the correct polarity

Strain reliefs

• Examine the strain reliefs at both ends of the line cord

• Be sure that they hold the cord securely

Circuit breaker/fuse

• If the scanner has a switch-type circuit breaker, check that it moves freely

• If the scanner is protected by an external fuse, check its value and type against that marked on the chassis

Cables

• Inspect any cables (e.g., transducer) and their strain reliefs for general condition

• Carefully examine cables to detect breaks in the insulation and to ensure that they are gripped securely in the connectors at each end to prevent rotation or other strain

• Verify that there are no intermittent faults by flexing electrical cables near each end and looking for erratic operation or by using an ohmmeter

Transducers

• Check the surface areas of ultrasound transducers for deterioration, cracks, or dents in the membrane

• Check the acoustic fluid of mechanically steered transducers; refill with the recommended fluid if air bubbles are present

Controls/switches

• Before changing any controls, check their positions

• If any settings appear inordinate (e.g., a gain control at maximum), consider the possibility of inappropriate clinical use or of incipient device failure

• Record the setting of those controls that should be returned to their original positions following the inspection

Physical condition

Secure mounting, and correct motion

Check that control knobs have not slipped on their shafts

Control fixed-limit stops, alignment, as well as positive stopping

Each control and switch performs its proper function

Indicators/displays

• Record the reading of an hour meter, if present

• During the course of the inspection, confirm the operation of all lamps, indicators, meters, gauges, and visual displays on the scanner

• Be sure that all segments of a digital display function

• Observe an image on the CRT display, and check its quality Also verify image quality of peripheral accessories

Audible signals (Confirm appropriate volume, as well as the operation of a volume control)

ECG - Using an ECG simulator, verify normal operation of ultrasound scanners configured for echocardiography, according to the following criteria:

• Baseline - constant thickness; horizontal and no vertical drift

• ECG waveform should be clearly visible, including the P wave and QRS complex

• 50/60 Hz noise should not be present

• Intervals between the timing marks displayed by the scanner should be consistent with the timing of the ECG simulator

![Jiye Jin-2014[1].3.17](http://s2.studylib.net/store/data/005485437_1-38483f116d2f44a767f9ba4fa894c894-300x300.png)