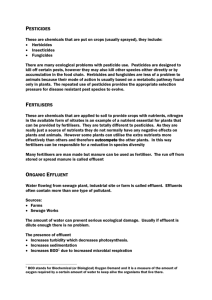

final factory effluent treatment plant

advertisement