Application of Computers in Process Control

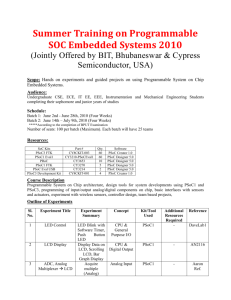

advertisement

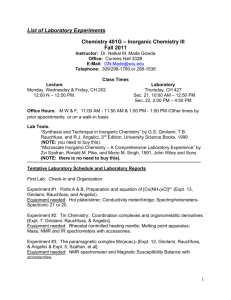

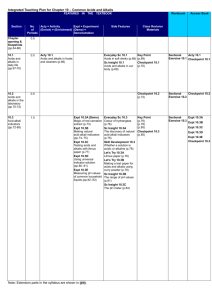

Purdue University Calumet School of Technology Course Syllabus ECET 46200 – Application of Computers in Process Control Credits and Contact hours: Credit 4, Class 3, Lab. 3, Contact Hours 6 Instructor’s or Course Coordinator’s Name: Akram Hossain Text Book, Title, Author and Year: Process Control Instrumentation Technology, Curtis D. Johnson, Latest Ed., Prentice-Hall Introduction to the Course: a) Catalog Description (2010-2011 Academic Catalog): Application of computers to control industrial processes. Study of continuous- and descrete-time control algorithms; digital signal processing; and system control concepts applied to process control. b) Prerequisites: ECET 21700 or Consent of the course coordinator or course instructor. c) Required course. Specific Goals of the Course: a) Course Learning Objectives: Upon completion of this course, the student should be able to: 1. Understand discrete-state process control 2. Understand Control strategies: process characteristics, control modes, composite control modes 3. Understand Digital and analog controllers, computer in process control and control softwares 4. Analyze control loop characteristics: control system configuration, multivariable control system 5. Analyze stability of a control system 6. Able to model a simple mechanical or an electrical system 7. Perform process control loop tuning: feedback, feedforward and cascade control. 8. Apply computer based hardware and software tools for process control (NI’s LabVIEW Software Tools) 9. Apply statistical process control techniques for quality assurances (Statit Express QC) 10. Apply statistical process control techniques to determine process capability (Statit Express QC) b) Criteria 3 Student Outcomes: This course covers items a, b, c, d, f, g, h & j in ABET Criteria 3. Course Delivery Methods (check all that apply): X Lecture X Laboratory X Projects Page 1 of 2 ECET 46200 – Application of Computer in Process Control Factors Used to Determine the Course Grade (check all that apply): X Quizzes X Exams X Homework X Lab Reports X Class participation X How final grade is determined as follows: Several inputs will be used to evaluate students' performance in the course. The letter grade for completion of this course will be based on several input factors. Among them following: 4 to 6 "pop" quizzes 3 Scheduled Examinations Scheduled Final Examination Homework 100 points 300 points 200 points 100 points Laboratory Class Project Attendance 200 points 200 points 100 points Brief List of Topics to be Covered: 1. Introduction to Industrial Process Control Systems (Review) 2. Discrete-State Process Control and Control Strategies 3. Controller Principles (1) Process Characteristics (2) Control System Parameters (3) Control Modes (4) Composite Control Modes 4. Digital Controllers (1) Computer in Process Control (2) Controller Hardware and Software 5. Direct Computer Control Hardware and Software (NI’s LabVIEW Software Tools) 6. Control Loop Characteristics (1) Control System Configurations (2) Multivariable Control System (3) Stability of Control System (4) Process Control Loop Tuning (5) Transient Responses 7. Mathematical Modelling of Mechanical system (1) Concepts of Analogus System (2) F-V and F-I Analogy (3) Transfer Function of Simple Spring-Mass System 8. The Stability of Process Control Systems (1) Concept of Stability (2) Stability Criterions (3) Frequency Response (4) Controller Tuning 9. Concepts of CAM Operation (1) Concept of Inertia (2) Inertia Ratio, Inertia mismatch between load and the motor 10. Cascaded Control and Feedforward Control and Adapted Control System 11. Statistical Process Control ( Statit Express QC Software Tools) (1) Statistical Process Control Techniques (2) Control Charts (3) Process Capability Analysis 12. Course instruction may add or substract course topics based on the current need of the Mechatronics Engineering Technology program. 13. Discussion on CCST (Certified Control Systems Technician) tests offered by ISA (The Instrumentation, Systems, and Automation Society). How ECET graduates can take them? Lab Experiments: EXPT#1 EXPT #2 EXPT #3 EXPT #4 EXPT #5 EXPT #6 EXPT #7 EXPT #8 EXPT #9 EXPT #10 EXPT #11 EXPT #12 EXPT #10 EXPT #11 EXPT #12 EXPT #13 : Introduction to LabVIEW Software Tools and SCXI data acquisition system : Configuring SCXI chassis and testing of I/O data acquisition modules : LabVIEW basic programming structures : Designing passive filter using LabVIEW : Modelling of dynamic characteristics of DC motor : Experimenting with a monolithic temperature transducer using LabVIEW : Experimenting with a motion sensor using LabVIEW (Digital I/O) : Experimenting with a pressure transducer using LabVIEW (Analog I/O) : LabVIEW to develop a polynomial from a data set (curve fitting) : Modeling and Testing of a Mechanical System -pendulum system : Modeling and Testing of Electromechanical System – Servo Motor with Load : Modeling and Testing of Electromechanical System – DC Motor with Load : Varifying Stability Criterion of a Control System : Print reading of Drain Control Loop : Introduction to Statistical Process Control (SPC) (STAT QC Software Tools) : Application of SPC Tools for Process Control (STAT QC Software Tools) Page 2 of 2