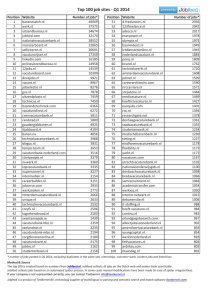

XRT Mirror Inspection Procedure - Osservatorio Astronomico di Brera

advertisement

DOCUMENT: XRT-OAB-PR-002 ISSUE: 2 SUBJECT: Post TVAC test XRT Mirror Inspection DATE: 8th July 2004 PREPARED BY: G. Tagliaferri CHECKED BY: O. Citterio APPROVED BY: G. Chincarini SIGNED BY: XRT Mirror Module Osservatorio Astronomico di Brera XRT FPCA Tony Abbey University of Leicester XRT Lead David Burrows Penn State University Observatory I and T Manager Mark Edison Spectrum Astro Quality Assurance Terry Fletcher Spectrum Astro Instrument Module I and T Manager Joanne Baker GSFC Contamination Control Diane Day Swales …………………………… date: …………. …………………………… date: …………. …………………………… date: …………. …………………………… date: …………. …………………………… date: …………. …………………………… date: …………. …………………………… date: …………. CHANGE RECORD ISSUE 0 1 2 3 4 5 DATE 25 May 2004 31 May 2004 8 July 2004 CHANGE Draft Issue 1 Issue 2 DISTRIBUTION University of Leicester Space Research Centre Penn State University Physics and Astronomy Osservatorio Astronomico di Brera Tony Abbey, Tim Stevenson, Alan Wells Swales Aerospace Diane Day, Brian Kittle Spectrum Astro Mark Edison, Terry Fletcher NASA Goddard Space Flight Center Renan Borelli, Oren Sheinman, Joanne Baker, Pat Izzo Dave Burrows, Joe Hill Sergio Campana, Guido Chincarini, Oberto Citterio, Gianpiero Tagliaferri APPLICABLE DOCUMENTS XRT Requirements Document, XRT-PSU-015 NFI Door Deployment Test Procedure, 1143-ET-M42685 XRT Contamination Control Plan, XRT-PSU-030 1.0 SCOPE OF DOCUMENT This document specifies the steps to be carried out for the XRT Mirror inspection after Swift has completed its Environmental Tests including TVAC and Acoustics. The inspection will be performed while Swift is mounted on the Ransome table and after the XRT Door Deployment on the primary side. It is assumed this procedure will only be run from the NFI Door Deployment Test Procedure. 1.1 Motivation to Inspect the Mirrors It has been recognised that, after the Acoustic Test is performed on the Swift satellite, it is necessary to check the glued connections that are fixing the 12 mirror shells inside the grooves on the spider arms. According to the qualification test performed on the X-ray optics at the unit level, we do not expect that these connections will have been damaged by the Observatory Environmental Tests. However, we know that very strong vibrations can damage them (from the development tests carried out for the Jet-X project). In this case, the quality of the X-ray image could be altered and the on-ground calibration will no longer be valid. In the worst case, the glue may be completely removed and the HEW could degrade from ~18 to ~30 arcsec at 1.5 keV while the effective area could be reduced by 30-50% due to the mirror contamination from the debris. Thus, although the glued connections have been qualified to a much higher level of stress and we do not expect them to be damaged, it is nevertheless important for the complete control of the hardware and of the mission to re-evaluate their status post environmental testing and before launch. 1.2 How the Inspection will be performed For a full evaluation of the mirror status it would be necessary to perform a new X-ray calibration campaign. To this end we would need to take the Swift satellite to an X-ray calibration facility, send X-ray photons through the X-ray mirrors and evaluate their performance again. Clearly this is not possible. Thus, we will evaluate the status of the glued connections via a visual inspection. In this way we will assess the status only of the glued connections on the front spider, because the rear spider will not be visible. Given that the connections are the same and that the stresses transmitted to the two spiders will be very similar (the Mirror Module is fixed to the Spacer at its centre at an equal distance from the two spiders), it is reasonable to assume that the connections on the rear spider will be in the same state as those on the front spider. Figure 1: This schematic shows the set-up for the mirror inspection. The satellite distance from the ground and its orientation are only indicative, in order to give an idea how the test will be carried out. 1.2 Inspection Requirements To perform the mirror inspection we need a digital camera (optical zoom 8 or better, or lens with ~200 mm focal length, and 5 to 8 Megapixels), a tripod and a lamp to illuminate the spider arms and the glued connections (see the set-up sketched in Figure 1). We also need a lap-top or desk computer to transfer the images to properly evaluate them. The lamp must be adjusted to have a uniform illumination without shadows on the spoke side to be photographed. The flash of the camera must be kept off to protect the Solar Cells on the front of the Inner Baffle. The lamp must be placed about 5º-10º out of the optical axis to avoid photons passing through the optics by two reflections on the active surface of the mirrors. A UV-blocking filter, blocking wavelengths below 350 nm, should also be put in front of the lamp to avoid fixing any particulates on the mirror surface. Figure 2 shows how the pictures are expected to look for a good evaluation of the glued connections. This picture was taken with a Nikon camera Coolpix 5700 at optical zoom 8x. The connections, made with a blue, coloured glue, are clearly visible and from zooming in on the various parts it is possible to evaluate their status. In this picture only one side of a spider arm is shown, clearly we need to take a pictures on both sides. This will then need to be repeated for all 12 arms of the front spider. Moreover, in order to make sure that all 12 arms are checked, we need to fix a zero point on a reference arm (e.g. the one nearer to the Star Tracker or any other reference point that can be used for this purpose). The Digital camera and lamp will be moved to the position to which pictures of the reference arm can be taken, from there on pictures of the next arm will be taken moving always in the same direction (either clockwise or counter-clockwise) in order to take pictures of all 12 spider arms. The pictures will be numbered from 1 to 12, altogether 2x12 pictures need to be taken for each side of the spider arms. Figure 2: This photograph, taken in the same configuration foreseen for the inspection after TVAC and Acoustic Tests, shows the blue glued connections on one side of a spider arm (2 spider arms are visible). 1.2 Inspection Procedure Minimum 30 minutes photo set up time will be required prior to beginning test. The XRT Door will be taped shut while the set-up is performed. One hour is planned for the photography with the XRT Door open. 1. Mount a single 250 watt quartz lamp above and as close as possible to the barrel of a 200mm lens. The front of the lamp should be approximately ¾ inch forward of the lens first surface. TC ____________ 2. Set up camera on tripod approximately 7 ft above floor in front of XRT. TC ____________ 3. Align the optical axis of the lens with the optical axis of the XRT as a starting position. 4. Position the front of the lens 36.5 inches from the front of the telescope. Front of lens to glue joint will be 64 inches. TC ____________ 5. Perform steps 6 and 7 if a lamp intensity less than 250 Watts is necessary. If not continue at step 8. 250 Watts?_________ TC ____________ 6. Plug the lamp into a Variac 7. Adjust the Variac to lower the lamp wattage. TC ____________ TC ____________ 8. Attach a 2B ultra violet cut off filter to the front of the lamp. Insure lamp and filter have adequate ventilation. QA ___________TC ____________ 9. Set up a lap top PC close to the camera position. TC ____________ 10. Attach a flashcard reader to the computer USB port. The computer will have a version of Adobe Photoshop or software capable of viewing TIFF images. TC ____________ 11. Place a 512 megabyte image card into the camera. 2 image cards will be used. Labelled A and B TC ____________ 12. Adjust camera as follows: a. ISO = 125 b. exposure control = manual c. metering = spot d. white balance = tungsten e. format = TIFF f. timer = 5 sec g. anti-mirror = on h. aperture = f 22 TC ____________ 13. Verify no more than four people total are in the SCA and only two people with in the vicinity of the Observatory (Door Technician and Photographer) TC ____________ 14. Establish the reference spider arm. See Figure 3 and mark (use TAM Baffle as a reference point) TC ____________ 15. Make test exposures a. turn on lamp b. focus lens on a spider arm c. adjust shutter speed d. make three exposures at different shutter speeds. e. turn off lamp 16. Give image card to test director for evaluation on the PC. 17. Adjust exposure and camera position as directed by the test director. TC ____________ 18. Make additional exposures as required for approval by the test director. 19. Begin photography of both sides of 12 spider arms, moving in a clockwise direction. Mark up Figure 3 with a number corresponding to the position of the photograph and record in Table 1 with the number corresponding to the exposure. TC ____________ 20. Photograph 3 spider arms on the card A. 21. Give image card to test director for inspection and saving images to the computer. 22. Continue photography with second image card B. 23. Repeat steps 19 through 22 until all spider arms have been photographed. TC ____________ 24. Tape XRT Door Closed TC ____________ 25. Verify photographs of all Glued connections are adequate for Glued Connection evaluation QA _________TC ____________ 26. Secure from test and break down equipment when directed by the test director. TC ____________ Figure 3 provides a drawing of the mirror with the TAM baffle as a reference point. This drawing will be used to mark up with numbers correlating to each picture and documented in Table 1. Figure 3: This Drawing shows the mirrors mounted on the spacer and the TAM baffle to be used as a reference point. This drawing is to be marked up to correlate with the image numbers documented in Table1. 1.3 Evaluation of the results If from the inspection of the pictures taken on both side of the 12 spider arms, no cracks or evidence of damage is seen on the glued connections and no blue particulate is seen spread on the surfaces around the connections, then we will declare that the optics glued connections have passed the Observatory Level Environmental Test without visible damage. Instead, if from the picture inspection, we find that there damage evident to the glued connections, the implication will be that there is a high probability that during the launch the glued connections will get loose and blue glue debris will probably be spread on the various surfaces of XRT (including the mirrors). As a result the XRT image quality could be much worse (HEW~30 arcsec or worse) and the effective area reduced (up to a factor of 2). In any case, given that the mirror shells are constrained inside the grooves carved on the spider arms, there will be no damage to the hardware and XRT will still be fully functional although at a lower efficiency and quality (however, one should consider the possibility that some pieces of glue fall down on the Focal Plane Camera Door). Of course, the on-ground calibrations will not be valid any more and one will have to rely only on in-flight calibrations. At this point the Swift PI (and Executive) will have to decide if the mission will go ahead in any case. The same considerations will apply if, from the pictures inspection, we find that the glued connections have completely come apart. It must be stressed, however, that the results obtained during the Qualification Test performed on the X-ray optics give us strong confidence that no problems should have arisen IF the level of the Acoustic Test were kept at the expected limits. Position Number as Marked Card A or B in Figure 3 Image Name/ Number