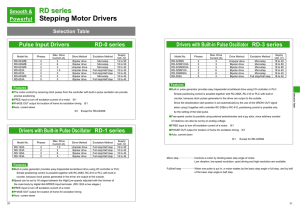

STEPPING DRIVER XDM-70

advertisement

STEPPING DRIVER XDM-70 Features: 1: High performance, cost-effective 2: Supply voltage up to DC:80V 3: Output current up to 7.0A 4: Pulse input frequency up to 300 KHz 5:Pure-sinusoidal current control technology 6: TTL compatible and optically isolated input 7: Automatic idle-current reduction 8:15 selectable resolutions, up to 25,600 steps/rev 9: Suitable for 2-phase and 4-phase motors 10: Support PUL/DIR and CW/CCW modes 11: Short-voltage, over-voltage, over-current and over temperature protection 12:151*98*49(mm) Introduction: The XDM-70 is a high performance microstepping drivers based on pure-sinusoidal current control technology. Owing to this advanced technology, the driven motor can run with smaller noise, lower heating, smoother movement and have better performance at higher speed than most of the drivers in the markets. It is suitable for driving 2-phase and 4-phase hybrid stepping motors. Applications Suitable for a wide range of stepping motors, from NEMA size 17 to 43. It can be used in various kinds of machines, such as X-Y tables, labeling machines, laser cutters, engraving machines, pick-place devices, and so on. Particularly adapt to the applications desired with low noise, low heating, high speed and high precision. Electronic Specifications (Tj=25℃) : XDM-70 parameters Min Typical Max Unit 1.7 Output current - 7.0 A Supply voltage +24 +68 80 VDC Logical signal current Pulse input frequency Isolation resistance 7 10 16 mA 0 - 300 KHz MΩ 500 Pin Assignment and Description Control Signal Connector P1 pins Pin functions PUL+ PUL- DIR+ DIR- ENA+ ENA- Details Pulse signal: In single pulse(pulse/direction) mode, this input represents pulse signal, effective for each rising or falling edge(set by inside jumperJ1);4-5V when PUL-HIGH,0-0.5V When PUL-LOW. For reliable response, pulse width should be longer than 1.5 μ s. Series connect resistors for current-limiting when +12v or +24v used. DIR signal: In single-pulse mode, this signal has low/high voltage level, representing two directions of motor rotation; For reliable motion response, DIR signal should be ahead of PUL signal PUL signal by 5 μ s. at least.4-5V when DIR-HIGH,0-0.5V when DIR-LOW. Please note that motion direction is also related to motor-driver wiring match. Exchanging the connection of two wires for a coil to the driver will reverse motion direction. Enable signal: This signal is used for enable/disabling the driver. High level(NPN control signal, PNP and Different control signals are on the contrary, namely Low level for enabling.) for enabling the driver and low level for disabling the driver. Usually left UNCONNECTED(ENABLED) Power connector P2 pins Pin function DC DC A+,A- B+,B- Details Power supply,24-80VDC,Including voltage fluctuation and EMF voltage Motor Phase A Motor Phase B Microstep Resolution Selection Microstep resolution is specified by 5, 6, 7,8 DIP switches as shown in the following table: Microstep Step/rev(for 1.8 SW5 SW6 SW7 SW8 degree motor) 2 400 OFF ON ON ON 4 800 ON OFF ON ON 8 1600 OFF OFF ON ON 16 3200 ON ON OFF ON 32 6400 OFF ON OFF ON 64 12800 ON OFF OFF ON 128 25600 OFF OFF OFF ON 5 1000 ON ON ON OFF 10 2000 OFF ON ON OFF 20 4000 ON OFF ON OFF 25 5000 OFF OFF ON OFF 40 8000 ON ON OFF OFF 50 10000 OFF ON OFF OFF 100 20000 ON OFF OFF OFF 125 25000 OFF OFF OFF OFF Current Setting Ref current Peak current SW1 SW2 SW3 1.70A 2.40A ON ON ON 2.43A 3.08A OFF ON ON 3.17A 3.77A ON OFF ON 3.93A 4.45A OFF OFF ON 4.71A 5.14A ON ON OFF 5.50A 5.83A OFF ON OFF 6.25A 6.52A ON OFF OFF 7.00A 7.2A OFF OFF OFF Notes: Ref current table on the screen printing is used for the users of the XDM-70 to refer. Due to motor inductance, the actual current in the coil may be small than the dynamic current setting, particularly under high speed condition. Typical connections Mechanical Specifications ATTN:IRENE YANG TEL:0086-755-25323725