Solutions

advertisement

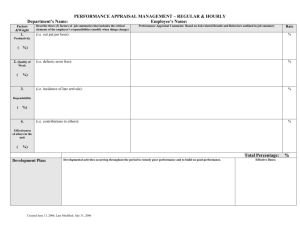

Solution 11 3. The composite index for quality costs for Midwest Sales shows a steady decrease in total quality cost down from $0.2358 to $0.1562/total sales dollars. Internal failure rates were reduced substantially, from $468.20 thousand in the first quarter to $166.40 thousand in the fourth quarter. External failure rates also showed substantial improvement since the first quarter, dropping from $280.80 thousand to $128.60 thousand in the fourth quarter. Increases in prevention and appraisal expenditures have apparently led to improvements in failure costs. The overall index fell by one-third (8 percentage points). Management should maintain or increase the level of prevention and appraisal in an effort to reduce quality costs, especially failure costs. (See spreadsheet Prob8-03.xls for more details). TOTAL SALES AND $THOUSANDS QUARTERLY QUALITY COSTS 1 2 3 Total sales External failure Internal failure Appraisal Prevention Total Quality Cost 4,120.00 280.80 468.20 194.20 28.40 971.60 4,206.00 208.20 372.40 227.70 29.20 837.50 4,454.00 142.80 284.40 274.40 50.20 751.80 INDEX OF QUALITY COSTS AS A % OF SALES 1 Qtr. 2 Qtr. 3 Qtr. External failure Internal failure Appraisal Prevention Total Quality Cost % Total Sales/Base 4 4,106.00 128.60 166.40 266.20 80.20 641.40 4 Qtr. 6.82 11.36 4.71 0.69 23.58 4.95 8.85 5.41 0.69 19.91 3.21 6.39 6.16 1.13 16.88 3.13 4.05 6.48 1.95 15.62 100 102.09 108.11 99.66 Midwest Sales, Inc. - Cost of Quality Index 25 Percent of Sales 20 15 10 5 Total Quality Cost Internal failure 0 1 Qtr. External failure 2 Qtr. 3 Qtr. Quarters 10. 4 Qtr. Appraisal Prevention Spreadsheet data and the Pareto chart (see Prob8-10.xls for details) for Repack Solutions, Inc. show that the company is spending too much on appraisal and internal failure cost and too little on prevention. Checking boxes, machine downtime, and packaging waste need immediate improvement in order to have the greatest impact on quality costs, since they constitute almost 82% of quality costs. However, it should be done with caution, since “checking boxes” represents appraisal costs designed to screen out poor quality and prevent it from reaching the customer. REPACK SOLUTIONS, INC. QUALITY COST & PERCENTAGES Checking boxes Mach. downtime Pkg. waste Income. insp. Other waste Cust. complaints Error corrn. Qual. train. assoc. Improv. proj. Typo corrn. Quality planning Total Percent Cumulative % Cost 48.80 27.84 5.15 4.12 3.78 2.75 2.75 2.06 1.37 0.69 0.69 48.80 76.63 81.79 85.91 89.69 92.44 95.19 97.25 98.63 99.31 100.00 710000 405000 75000 60000 55000 40000 40000 30000 20000 10000 10000 1455000 Quality Cost Category Appraisal Int. Fail. Int. Fail. Appraisal Int. Fail. Ext. Fail. Int. Fail. Prevent. Prevent. Int. Fail. Prevent. Percent Cumulative % 60.00% 120.00% 50.00% 100.00% 40.00% 80.00% 30.00% 60.00% 20.00% 40.00% 10.00% 20.00% 0.00% C he c M ki n ac g h. bo do xe w s Pk nti g. me In w co as m te O e. i t h C e nsp us r . t. wa co st m e Q Er pla ua ro i nt l. r c s t Im rai orr pr n. n. a o Ty ve sso po me c. co nt Q rrr p ro ua ec j . li t tio y pl ns an ni ng 0.00% Cumulative Percent Percent Within Defect Category Repack Solutions, Inc. Defect Categories Note that costs could also be classified by aggregating them into the four categories of internal and external failure, prevention and appraisal costs, instead of the above categories. 12. For HiTeck Tool Company, the largest costs are internal failure (56.6%) and appraisal (27.1%). More must be done in quality training, a component of prevention (currently 7.8%), if failure, appraisal, and overall quality costs are to be controlled. External failure costs are 8.6% of quality costs, so screening methods are working fairly well. Note that the above proportions are fractions of the total quality costs of $ 247,450. Quality Cost Categories Cost Elements Proportion APPRAISAL Costs Incoming test & inspection Inspection Test Laboratory testing Design of Q.A. equipment Material testing & insp. Insp. equipt. & calibration Formal complaints to vendors Setup for test & inspection Laboratory services 7500 25000 5000 1250 1250 1250 2500 10000 10750 2500 Cost Elements Costs Subtotal $ 67000 0.271 Subtotal Proportion PREVENTION Quality training Quality audits Maintenance of tools and dies Quality control admin. Writing proced. & instr. 0 2500 9200 5000 2500 $ 19200 0.078 INTERNAL FAILURE COSTS Scrap Rework Correcting imperfections Rework due to vendor faults Problem solving - prod. engrs. 35000 70000 6250 17500 11250 $140000 EXTERNAL FAILURE COSTS 0.566 Adjustment cost of complaints Total costs 21250 $ 21250 $247,450 0.086