OCR Document - ReEnergy Holdings

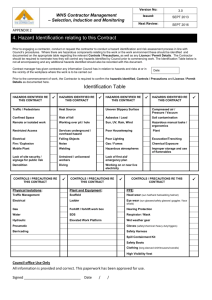

advertisement