(HSE) induction - Hydro Tasmania

advertisement

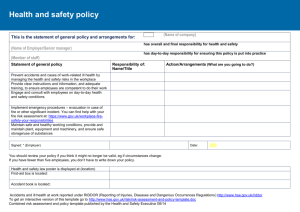

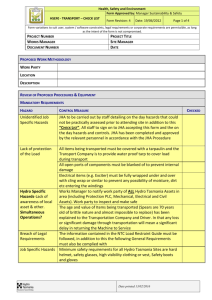

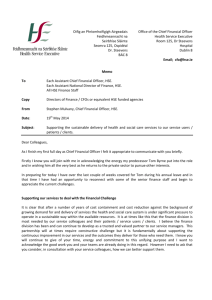

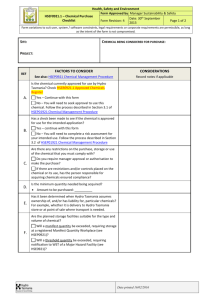

HSE HSEREF0602.1 Health safety and environment (HSE) induction guide (Level 2) Date: March 2013 Title: Approver: Hydro Tasmania Standard Health safety and environment (HSE) induction guide Document Owner: Date Created: Manager, Sustainability & Safety Date Approved: Date Effective: Version 2 HSE team March 2013 March 2013 March 2013 HSE Health, Safety & Environment – HSE Induction Guide (Level 2) Revision 1 CAUTION: Printed Document is Uncontrolled Print Date: 06/03/2016 ‘Each of us needs to understand and apply the principles of good safety and environmental management in our daily work. I hope you will carry this commitment to safety and sustainability with you both on and off the job.’ Chief Executive Officer HSE Health, Safety & Environment – HSE Induction Guide (Level 2) Revision 1 CAUTION: Printed Document is Uncontrolled Print Date: 06/03/2016 Contents 1. 2. 3. 4. 5. 6. Welcome 4 1.1 Purpose statement 4 1.2 Objectives of the health, safety and environment (HSE) induction 4 1.2.1 Modes of delivery 4 1.2.2 Completing the induction 5 HSE Overview 6 2.1 HSE policies and commitments 6 2.1.1 Hydro Tasmania values 6 2.1.2 Health and safety committment 7 2.1.3 Environmental policy 8 2.1.4 Sustainability code 9 2.2 HSE management system 10 2.3 Cardinal rules 12 2.4 Breaches and disciplinary action 12 HSE awareness, training and competency 13 3.1 HSE training 13 3.1.1 First aid training 13 3.2 Hydro Tasmania induction levels 14 3.3 Site access 14 3.3.1 Personal protective equipment (PPE) 14 3.3.2 Hazardous and restricted areas 15 3.3.3 Visitors 16 3.4 High risk licences 16 3.5 HSE communication and consultation 16 Legal and other requirements 18 4.1 Health and Safety 18 4.1.1 Legally defined workplace roles 18 4.2 Environment 19 4.2.1 Environmental impact assessments and management plans 19 Hazard identification and risk management 20 5.1 Basic risk management approach 20 5.2 Hazard identification and risk management tools 21 Fitness for work 23 6.1 Alcohol and other drugs 23 6.2 Transmissible infections and diseases 23 6.3 Work hours and fatigue management 24 6.4 Smoke free workplace 24 6.5 Occupational health 24 HSE 7. Health, Safety & Environment (HSE) Induction Guide (Level 2) Revision 1 CAUTION: printed document is uncontrolled Print Date: 06/03/2016 6.5.2 Electromagnetic fields (EMF) 25 6.5.3 Managing employee health and well-being 25 6.5.4 Rehabilitation 26 27 7.1 Work permits 27 7.1.1 Permit to work (PTW) system 27 7.1.2 Excavation, drilling, civil works 27 Energy isolation 28 7.2.1 Locking rules 28 Specific hazards 30 8.1 Hazardous substances 30 8.1.1 Chemical handling 30 8.2 Hazardous environments 30 8.2.1 Safety signs 30 8.2.2 Working alone, or in isolated or remote area 31 8.2.3 Working in or near water 31 8.3 8.4 8.5 9. 25 Operational controls 7.2 8. 6.5.1 Manual handling 8.2.4 Working at heights 32 Electrical safety 32 8.3.1 Electrical work competency requirements 32 8.3.2 Live work 32 8.3.3 Electric shock 33 Tools and mobile equipment 33 8.4.1 Compressed air safety 33 8.4.2 Power tools 33 Travel and transport 34 8.5.1 International travel 34 8.5.2 Domestic travel 34 8.5.3 Road safety 34 Management of contractors and suppliers 36 9.1 Hydro Tasmania responsibilities 36 9.2 Contractor / supplier responsibilities 36 10. Incident management and emergency response 37 10.1 Incident management 37 10.2 Emergency preparedness 37 10.2.1 Evacuation 38 10.3 Incident and emergency response equipment 11. Notes 38 39 Page iii of 38 HSE 1. Health, Safety & Environment – HSE Induction Guide (Level 2) Revision 1 CAUTION: Printed Document is Uncontrolled Print Date: 06/03/2016 Welcome Welcome to the Hydro Tasmania Group’s health, safety and environment (HSE) induction (level 2) guide. This induction must be completed by all Hydro Tasmania Group employees and any contractors or sub-contractors performing work on Hydro Tasmania-controlled sites. The Hydro Tasmania Group, here-after referred to as Hydro Tasmania, includes the entities trading as Hydro Tasmania, Entura and Momentum. 1.1 Purpose statement The HSE induction guide is designed to provide information to employees, contractors and sub-contractors of Hydro Tasmania. This guide describes the minimum HSE requirements to be able to work on our worksites, which have been designed to establish consistent safe work, and sound environmental management practices within Hydro Tasmania. The information contained in this guide is sourced from Hydro Tasmania’s Health, Safety and Environmental (HSE) Management System. All Hydro Tasmania Group employees, contractors and sub-contractors are required to complete this induction and a site-specific (level 3) induction as a minimum. Further training may be required to work in specific or hazardous areas (such as power stations, switchyards or the Tasmanian Wilderness World Heritage Area). 1.2 Objectives of the health, safety and environment (HSE) induction The HSE induction has three main objectives: 1. To outline the unique health, safety and environmental aspects and impacts of Hydro Tasmania work sites and activities; 2. To introduce you to the safety and environmental planning tools and procedures used at Hydro Tasmania. 3. To enable you to meet your responsibility for managing the health, safety and environmental impact of yourself and others on the worksite; and 1.2.1 Modes of delivery This induction can be delivered using several methods, providing the competency of inductees can be effectively assessed. Examples of delivery techniques are: This document and the assessment are worked through face-to-face with the trainee(s) at an agreed time; This document is studied by the trainee prior to arriving on site; an assessment is then arranged as part of the on-site induction prior to the commencement of work; or Classroom-based training and assessment. You will be assessed on your understanding of and your ability to use the available health, safety and environmental resources. The assessment is competency-based and you must achieve a mark of 100% to successfully complete the training. Page 4 of 38 HSE 1.2.2 Health, Safety & Environment (HSE) Induction Guide (Level 2) Revision 1 CAUTION: printed document is uncontrolled Print Date: 06/03/2016 Completing the induction Proof of successful completion of this induction is required to work for Hydro Tasmania and you need to keep a record of completion with you at all times when working at Hydro Tasmania field sites. This may be a validated training record in an Australian Electricity Supply Industry Passport, a validated Hydro Tasmania induction card, a copy of the signed competency assessment. In addition an electronic record of HSE level 2 induction is maintained by HR. Upon successful completion of the HSE induction assessment and before you can start work, you must also complete a formal site specific induction (level 3) with the Hydro Tasmania representative for each site that you will be working on. You may also be required to sign on to a Hydro Tasmania Permit to Work. If you are unsure about whether you need to sign onto a Permit to Work, ask your Hydro Tasmania representative. Page 5 of 38 HSE 2. Health, Safety & Environment – HSE Induction Guide (Level 2) Revision 1 CAUTION: Printed Document is Uncontrolled Print Date: 06/03/2016 HSE Overview 2.1 HSE policies and commitments Hydro Tasmania is committed to ensuring our staff and contractors have a safe place to work, and strives to achieve positive outcomes for the environment and community. We operate a Health, Safety and Environmental (HSE) Management System to help us meet our vision of ‘no harm to anyone at any time’ and our commitment to sustainability. Our HSE Management System supports Hydro Tasmania’s: Occupational Health and Safety Commitment; Environmental Policy; and Sustainability Code. These documents set the business expectation for HSE performance and are publically available on the Hydro Tasmania website (www.hydro.com.au). 2.1.1 Hydro Tasmania values Hydro Tasmania’s corporate values underpin the way we do business, including our approach to HSE management. Our values are: We put people’s health and safety first; We build value for our partners and customers through innovation and outstanding service; We behave with honesty and integrity; We work together, respect each other and value our diversity; We are accountable for our actions; and We are committed to creating a sustainable future Page 6 of 38 HSE 2.1.2 Health, Safety & Environment (HSE) Induction Guide (Level 2) Revision 1 CAUTION: printed document is uncontrolled Print Date: 06/03/2016 Health and safety committment Page 7 of 38 HSE 2.1.3 Health, Safety & Environment (HSE) Induction Guide (Level 2) Revision 1 CAUTION: printed document is uncontrolled Print Date: 06/03/2016 Environmental policy Page 8 of 38 HSE 2.1.4 Health, Safety & Environment (HSE) Induction Guide (Level 2) Revision 1 CAUTION: printed document is uncontrolled Print Date: 06/03/2016 Sustainability code Page 9 of 38 HSE 2.2 Health, Safety & Environment (HSE) Induction Guide (Level 2) Revision 1 CAUTION: printed document is uncontrolled Print Date: 06/03/2016 HSE management system Hydro Tasmania has an integrated Health, Safety and Environment (HSE) Management System that meets, and is certified to the international standards OHSAS 18001 and ISO 14001. This HSE management system enables the organisation to manage its HSE risks and improve its HSE performance. It is a practical system where people, compliance and effective risk management practices aim to deliver our visions of ‘no harm to anyone at any time’ and ‘a sustainable future through responsible management’. The WH&S Commitment and Environmental Policy reflect the rules governing the way the business addresses health, safety and environmental management. They are overview documents detailing Hydro Tasmania’s commitment, objectives and responsibilities to the health and safety of people and the sustainable management of the environment. The WH&S and environmental policies are supported by the Hydro Tasmania Health Safety and Environment (HSE) Management System, which sets out the business’s objectives for HSE management through a number of HSE Elements, as outlined in the HSE Manual. The 16 Elements set the criteria or standards for how the business is expected to manage HSE. Deviation from prescribed elements constitutes a breach of applicable policy, except in emergency situations in order to protect life, serious asset damage or environmental disaster. Hydro Tasmania’s HSE procedures are designed to meet the requirements of the Elements. They explain how specific work tasks can be undertaken to effectively manage the HSE risks, in alignment with the HSE Elements and policies. HSE forms, checklists, registers and reference documents, associated with each procedure, aid the implementation of the HSE management system. The relationship between Hydro Tasmania’s purpose and vision, codes, principles and values, HSE policies, HSE Elements, procedures and supporting documents can be depicted as follows: Page 10 of 38 HSE Health, Safety & Environment – HSE Induction Guide (Level 2) Revision 1 CAUTION: Printed Document is Uncontrolled Print Date: 06/03/2016 Page 11 of 38 HSE 2.3 Health, Safety & Environment – HSE Induction Guide (Level 2) Revision 1 CAUTION: Printed Document is Uncontrolled Print Date: 06/03/2016 Cardinal rules The cardinal rules apply to all employees as well as external contractors working for Hydro Tasmania on Hydro Tasmania controlled work sites. The cardinal rules are: No person shall attempt to operate an energy isolation, dissipation or restraint device which has been locked or tagged. No person shall wilfully sabotage any property or infrastructure belonging to, or under the control of, the corporation. No person shall wilfully bypass any safety interlock unless authorised to do so. No person shall carry on any fighting or horseplay which could, or does, give rise to serious injury to people or extensive damage to property. A failure to comply with these rules will result in disciplinary action and, where appropriate, dismissal or cancellation of contract. 2.4 Breaches and disciplinary action Hydro Tasmania expects all employees and contractors working on Hydro Tasmania-controlled sites to comply with our HSE Management System. Breaches in HSE processes may result in: 1. Counselling 2. Written warning 3. Final warning 4. Termination of employment or contract. Significant breaches can result in summary dismissal or termination of employment or contract without notice. Page 12 of 38 HSE 3. Health, Safety & Environment (HSE) Induction Guide (Level 2) Revision 1 CAUTION: printed document is uncontrolled Print Date: 06/03/2016 HSE awareness, training and competency Hydro Tasmania requires that all workers are trained and deemed competent to perform their work, including managing the HSE risks. Training and induction requirements and checks are in place to manage competency. 3.1 HSE training A range of HSE training is available Hydro Tasmania employees and contractors. The specific types of training required depend on the business division, role and HSE risks associated with each worker. The HSE training requirements register provides information on training requirements by role, as well as descriptions of the HSE training units and information on how to arrange training. HSE training topics include, but are not limited to: HSE inductions HSE assessment and planning HSE incident management Specific hazard training, e.g. – o Chemical handling o Oil spill response o Cultural heritage o Work in the Tasmanian Wilderness World Heritage Area o Weeds, pests and pathogens (field hygiene) Workplace health and safety competencies, e.g. – o Hydro Tasmania permit to work o Confined space entry o Heights safety Occupational health and hazards, e.g. – o Manual handling o Fatigue management o Defensive and off-road driving Further information about HSE training is available through the HSE intranet page. 3.1.1 First aid training A current first aid certificate is mandatory for Hydro Tasmania employees and contractors to work in the following areas: Field-based areas, including power stations, remote areas, outdoor work, work in or around waterways, construction sites and maintenance activities: o Employees - level 2 / senior first aid. o Contractors - level 1 / apply first aid, however there must be at least one level 2 first aid qualified colleague on site. Office environments, including Entura and Momentum offices and the Hobart office: o As defined by role and business unit. Page 13 of 38 HSE 3.2 Health, Safety & Environment (HSE) Induction Guide (Level 2) Revision 1 CAUTION: printed document is uncontrolled Print Date: 06/03/2016 Hydro Tasmania induction levels Hydro Tasmania has three levels of induction. These inductions are designed to ensure all workers understand the requirements and obligations when working for Hydro Tasmania. The Level 2 and Level 3 inductions are designed to ensure all workers understand the HSE hazards and risk management requirements for Hydro Tasmania in general (Level 2 induction) and the specific work site (Level 3 induction). The induction levels are: Corporate (Level 1) Introduces all Hydro Tasmania employees to the organisation, including relevant information on Hydro Tasmania values, policies and expected conduct. Completed by all employees and by those contractors requiring unsupervised access to Hydro Tasmania property and information systems. Valid for duration of employment. Health, safety & environment (Level 2) Introduces all Hydro Tasmania employees and contractors to Hydro Tasmania’s health, safety, and environmental hazards and management requirements and the HSE management system. It outlines the obligations and responsibilities of all workers to apply the HSE management system. Valid for two years from date of issue. Site specific (Level 3) Specific to each Hydro Tasmania, work site, this induction introduces all workers (employees and un-accompanied contractors) to the site, including the specific hazards, controls, emergency procedures and project/task specific safety requirements. Required for each site where work will be done, it is conducted before starting any work. Any person on a site who is not Level 3 inducted will be appropriately supervised. Valid for two years from date of issue. 3.3 Site access To access Hydro Tasmania sites, workers are required to have completed the relevant levels of induction and be granted access through issuing of ID cards and / or registering their attendance (contractors). In addition workers may also require: 3.3.1 A photo ID tag for use on tag boards; An understanding of the scope of works and physical limits of the work area; First aid training: o Level 1 (apply first aid) minimum for contractors. o Level 2 (senior first aid) for employees. A valid construction industry white card; Hydro Tasmania Permit to Work training: o Hydro Tasmania instructed person (IP). o Hydro Tasmania person in charge (PIC). Personal protective equipment (PPE) All persons on Hydro Tasmania sites must comply with PPE requirements. Mandatory PPE requirements for Hydro Tasmania work sites and sign posted areas (excluding office environments and sites not classified as construction areas) are: Hard hat; Page 14 of 38 HSE Health, Safety & Environment (HSE) Induction Guide (Level 2) Revision 1 CAUTION: printed document is uncontrolled Print Date: 06/03/2016 Safety glasses; High visibility clothing (long sleeves and long pants); Safety boots; and Hearing protection and gloves carried and used where required. Note that the minimum equipment listed may not always be adequate for the job and additional PPE should be used based upon job specific risk and as posted in the workplace. PPE provides essential protection against injury and illness and as such it shall be kept in a clean and reliable condition, free of defects or damage, and be capable of providing the necessary protection. Any PPE that is degraded, damaged, worn out or otherwise in disrepair shall be discarded and replaced. Additionally, the following safety clothing requirements apply: 3.3.2 Loose jewellery is an entanglement hazard and shall be contained or removed; Long hair including beards shall be safely contained; Long sleeved shirts and pants shall be worn on work sites; and Clothing shall be properly fitted and fastened at all times to prevent entanglement. Hazardous and restricted areas There are additional specific training and awareness requirements for access to Hydro Tasmania hazardous and restricted areas. Restricted areas are sites that are kept secure at all times for safety and business risk, including but not limited to: Power station buildings; Switchyards; Intake structures (e.g. intake gate buildings, hill-top valve houses, dam galleries); Work sites with a Permit To Work in place; and Offices and amenities. You can only access a restricted area if you have been authorised. Access to these areas is controlled using locks and keys or electronic swipe card systems, and entry conditions are strictly followed. This Page 15 of 38 HSE Health, Safety & Environment (HSE) Induction Guide (Level 2) Revision 1 CAUTION: printed document is uncontrolled Print Date: 06/03/2016 may include a site specific induction, signing on to a Permit to Work or being accompanied at all times. 3.3.3 Visitors Visitors may access permitted areas on Hydro Tasmania sites, provided they are continuously accompanied by a suitably accountable person. Visitors are required to register their attendance and may also be required to wear a visitors tag in Hydro Tasmania offices. 3.4 High risk licences All employees and contractors performing work activities requiring a high risk licence shall hold a valid licence for that work activity and be considered competent to perform the task. The licenced person shall carry their licence with them and present it on request. The main types of high risk licences required for work with Hydro Tasmania include: 3.5 Cranes and hoists Dogging and rigging Scaffolding work Forklift operation Pressure equipment HSE communication and consultation Hydro Tasmania shares HSE knowledge and experience through a range of methods, including communications sessions, training and awareness programs, electronic communications and fieldbased safety and environmental advisors. Workplace health and safety information is commonly shared through ‘local safety teams’, who coordinate health and safety communications and initiatives at Hydro Tasmania site. Opportunities are provided for employees and contractors to raise HSE issues and concerns and to provide feedback on Hydro Tasmania’s HSE performance. The business currently follows a structure which provides resources to proactively engage employees and managers in HSE management. All groups across Hydro Tasmania, including contractors, have the ability to address HSE issues at their level and to escalate any issue through proactive communication lines using line management. This can be done through a number of avenues including: HSE hazard and incident reporting; Site or project toolbox meetings; Environmental or safety representatives; Line managers and job managers; Safety or environmental advisors; Team meetings; Group meetings; Page 16 of 38 HSE Health, Safety & Environment (HSE) Induction Guide (Level 2) Revision 1 CAUTION: printed document is uncontrolled Print Date: 06/03/2016 Defined HSE meetings; and Executive safety meetings, chaired by CEO. Page 17 of 38 HSE 4. Health, Safety & Environment (HSE) Induction Guide (Level 2) Revision 1 CAUTION: printed document is uncontrolled Print Date: 06/03/2016 Legal and other requirements Hydro Tasmania meets or exceeds legislated work health and safety and environmental management requirements through our staff and contractors implementing approved HSE processesAll employees and contractors shall be aware of the HSE requirements that are relevant to their work activities. 4.1 Health and Safety The Work Health and Safety Act 2012 sets out the legal duties that employers and workers have with regard to managing health and safety in the workplace. Section 19 of the act outlines the employer’s duties and states that an employer must ensure, where practicable, that: Employees (including contractors) at work are safe from injury and risks to health; A safe working environment is provided and maintained; Safe systems of work are in place; and Plant and substances are maintained in a safe condition. Hydro Tasmania must also provide reasonable information, instruction, training and supervision to ensure the employees safety. Employees, including contractors, are also legally required to take reasonable care for their own health and safety and for the health and safety of others, including complying with any direction given by an employer or their representative with respect to health and safety matters. 4.1.1 Legally defined workplace roles For the purpose of Hydro Tasmania’s HSE Management System, the following definitions shall be considered to represent and be in line with the definitions of a Person Conducting a Business or Undertaking (PCBU), as described under Work Health and Safety legislation Officer: a person responsible for ensuring due diligence and that the PCBU complies with legislative requirements. Worker: a person who undertakes work activities who is responsible for taking reasonable care, obeying HSE instructions, co-operating and taking care to work in a safe and environmentallysensitive manner. A worker is any person carrying out work in any capacity for Hydro Tasmania Group, including employees, contractors and sub-contractors, employees of a labour hire company, outworkers, apprentices or trainees, work integrated learning or work experience students and volunteers. Competent person: A person who has, through a combination of training, education, assessment and experience, acquired knowledge and skills to correctly perform a specified task. A competent person is responsible for assessing the HSE risks and reviewing the effectiveness of controls for a work activity they are performing or are accountable for, within their area of competency. Page 18 of 38 HSE 4.2 Health, Safety & Environment (HSE) Induction Guide (Level 2) Revision 1 CAUTION: printed document is uncontrolled Print Date: 06/03/2016 Environment Environmental legal responsibilities and requirements exist under a range of State and National legislation, including the Environmental Protection and Biodiversity Conservation Act 1999 and state legislation around protecting threatened species, preventing pollution and managing waterways. Due to the complex nature of environmental legislation, Hydro Tasmania has established a team of environmental specialists who can provide information and advice on environmental compliance requirements that apply to specific work projects or activities. The types of activities and impacts that must meet environmental legislative requirements include, but are not limited to: Prevention of pollution: preventing emissions on to air, water and soil, including: o Minimising smoke, dust and any other air-born pollutants; o Minimising the risks of waterway contamination through chemical spills, including oil; o Managing soils, excavations, stockpiles and quarries to minimising the risk of erosion; o Minimising waste production and ensuring that wastes, in particular controlled wastes, are disposed of appropriately and in accordance with legal requirement; and o Minimising noise pollution. Plants and animals: managing threats to flora and fauna such as: o Protecting threatened plants and animals; o Preventing the spread of soil pathogens and weeds; o Obtaining permits to clear vegetation; o Obtaining permits to survey or sample plants and animals; and o Notifying the relevant authorities of planned impacts on plants or animals, such as draining waterways. Cultural heritage: managing historic and aboriginal heritage values, including: o Arranging aboriginal heritage surveys for planned work with ground disturbance; o Obtaining and complying with Permit to Disturb requirements; and o Protecting identified cultural heritage values and complying with heritage management plans. Protecting World Heritage values: complying with all requirements for working in the Tasmanian Wilderness World Heritage Area, such as: o Giving the required notifications and obtaining relevant permits; and o Implementing the agreed environmental control measures. In order to ensure compliance with environmental legislation, all employees and contractors must comply with the Hydro Tasmania Environmental Policy and the requirements of our HSE management system, obtain any relevant environmental permits prior to work starting, and seek advice from relevant experts as required. 4.2.1 Environmental impact assessments and management plans Depending on the nature and scale of work an environmental impact assessment (EIA) may be required. Control measures to manage the risks identified in the EIA are documented in an environmental management plan (EMP). All Hydro Tasmania employees and contractors shall comply with the control measures listed in the EMP. Completing an EIA will also assist with determining the requirement for regulatory approvals, licences, permits, etc. Page 19 of 38 HSE 5. Health, Safety & Environment (HSE) Induction Guide (Level 2) Revision 1 CAUTION: printed document is uncontrolled Print Date: 06/03/2016 Hazard identification and risk management The sorts of HSE hazards present on Hydro Tasmania work sites varies between business divisions, work locations and project types. Many of our work sites are in remote locations and subject to extreme weather changes. The electricity generating business presents high energy hazards at many worksites that must be well managed and comply with legislation and the requirements of being part of the National Electricity Supply Industry. Hydro Tasmania has developed and implemented specific work practices and procedures to control these risks and facilitate safe access to our generating plant and equipment. As the largest water manager in Australia and a significant land owner in Tasmania, Hydro Tasmania must manage environmental risks associated with our activities. These risks include working in the Tasmanian Wilderness World Heritage Area, managing waterways, protecting threatened plants and animals, managing vegetation, preventing pollution and preventing the spread of weeds, pests and diseases. For Entura, HSE risks can vary greatly depending on the customer’s site and the project requirements, as well as the legislative requirements of the jurisdiction where the work is carried out (including international projects). Workers must also be aware of and manage office-based hazards, such as poor housekeeping and inefficient resource use. 5.1 Basic risk management approach Hydro Tasmania’s HSE risk management requirements are determined by the level of risk involved. Risk is a product of nature of hazards and environmental aspects, the location, complexity and duration of the work, any simultaneous operations in progress, and the size and make-up of the labour force, as well as the competencies of the workers involved. As a minimum, all workers are expected to adhere to Hydro Tasmania’s HSE systems and processes. In addition to compliance with legislative requirements, including duty of care, all work activities conducted under Hydro Tasmania direction shall have risks managed to a level as low as reasonably practicable. HSE risk management at Hydro Tasmania follows the hierarchy of controls. The hierarchy lists the methods of risk control in order of effectiveness. Hydro Tasmania requires that efforts are made to address the risk effectively as high up the hierarchy as reasonably practicable. Eliminate: where possible the hazard should be eliminated (or reduced to a level as low as reasonably practicable) by altering the job design, methods, location or other possible change. When it is impractical to eliminate the hazard, work down the hierarchy to identify ways to reduce the risks associated with that hazard. Substitute: replace the hazardous component, practice or substance with a less-hazardous alternative. Isolate: prevent access or exposure to the hazard through the use of personal isolation locks or other access or operation restriction methods. Engineering: alter the product design or work environment to reduce the risk associated with a hazard (e.g. putting guards in place). Page 20 of 38 HSE Health, Safety & Environment (HSE) Induction Guide (Level 2) Revision 1 CAUTION: printed document is uncontrolled Print Date: 06/03/2016 Administrative: develop safe working methods, implement procedures, deliver training or other measures to improve people’s management of the risk. Personal Protective Equipment (PPE): wear the appropriate protective equipment to reduce the likelihood or severity of injury. PPE should be considered and used as the last line of defence against injury. Reduced effectiveness ELIMINATE SUBSTITUTE ISOLATE ENGINEERING ADMINISTRATIVE PPE Poor housekeeping is a safety risk. Cleaning as you go will mean that all work areas can be kept safe. Off-cuts and waste materials shall be disposed of in an approved manner and no waste should be allowed to become airborne or unsafe. 5.2 Hazard identification and risk management tools Hydro Tasmania has a range of tools available to help workers to accurately identify the HSE hazards associated with work activities and to effectively manage the associated risks. Detailed information on how to use these tools is provided in the HSE Management System. A selection of these tools is discussed below. Strategic Health, Safety and Environmental Risk management: The objective of the strategic risk assessment process is to highlight significant business risks and to enable prioritisation for strategic planning. The strategic risk profile drives HSE programs such as training, auditing and compliance as well as prioritising programs and projects for improvement of HSE outcomes. Safety Improvement Plans and Environmental Plans are examples of strategic HSE plans. Workplace hazard register: Hydro Tasmania has developed a workplace hazard register for the majority of our work sites. The hazard register assist in identifying HSE hazards, risk levels, control measures and remedial actions for specific Hydro Tasmania sites and assets. This register is to be used by workers to identify known hazards and should be considered in any risk assessment process, such as Take 5, Job Hazard Analysis, Environmental Impact Assessment or Safe Work Method Statement. For most work activities, one or more of the following risk management tools will need to be used in conjunction with the Take 5 process to manage the HSE risks. Take 5: The Take 5 process shall be used to identify and assess basic HSE hazards throughout a job. Take 5 checklist pads are available to assist and prompt you through the basic risk assessment steps. Job hazard analysis (JHA): A JHA is a documented, task-specific risk assessment, used to systematically analyse the steps of a job to ensure reasonable and practicable measures are taken to control the associated HSE hazards. A JHA is the main risk management tool used at Hydro Tasmania as is required for most field-based work activities. You must carry out a job hazard analysis if: A Take 5 identifies the uncontrolled risk level to be greater than low. Page 21 of 38 HSE Health, Safety & Environment (HSE) Induction Guide (Level 2) Revision 1 CAUTION: printed document is uncontrolled Print Date: 06/03/2016 A permit to work (PTW) is required. An approved JHA, Environmental Management Plan or Safe Work Method Statement for the task does not already exist. Environmental Impact Assessment (EIA): An (EIA) is used to document the environmental, social and cultural heritage risks associated with a project or work activity. An EIA is required for any work activity that involves a defined environmental impact activity (see HSEP0301 – Hazard Identification and Risk Management). Environmental Impact Assessments (EIAs) must be conducted or reviewed by persons who are competent in the relevant subject matter, for example, a person with expertise in environmental management, flora and fauna assessments or heritage management. Environmental Management Plans may be incorporated into HSE Management Plans provided sufficient detail is retained to effectively manage the risks. Safe Work Method Statement (SWMS): A SWMS is a detailed description of how a specific task is performed. It is required for any tasks that involve high risk work activities, as per the Workplace Health and Safety Act 2012. Toolbox meetings: Toolbox meeting are mandatory pre-start meetings held before work commences for each day or shift, at the beginning of a major job task or if there is a change to plant, process or materials. Contractors are required to attend all Hydro Tasmania toolbox meetings for the projects or sites they are working on. Safe act observations (SAO): A SAO is intended to reinforce positive safety behaviour, identify any inappropriate safety behaviours, agree on modified behaviours and prevent injuries and property damage. The SAO process involves: Observing a person performing a work activity; Engaging the observed person to discuss the activity; and Discussing any relevant health and safety issues or concerns with the person. HSE management plans: It is a requirement of Hydro Tasmania to use HSE management plans for all major shutdowns, projects and specific jobs. Either a combined HSE management plan, or separate safety and environmental (including cultural heritage) management plans may be developed. The management plans explain what the HSE risks are and how they shall be managed. They are living documents that are reviewed throughout the project and updated as new hazards are identified, as risks change or as better controls are identified. All management plans shall be reviewed by relevant HSE experts and approved by Hydro Tasmania line management prior to starting work on the project or job. Page 22 of 38 HSE 6. Health, Safety & Environment (HSE) Induction Guide (Level 2) Revision 1 CAUTION: printed document is uncontrolled Print Date: 06/03/2016 Fitness for work It is your responsibility to ensure that you are fit for work. You are required to tell your supervisor or Hydro Tasmania representative if you are unfit for work. This could include being ill, injured, using medication that may impair your ability to work safely, being under the influence of illicit drugs or alcohol, being tired, and fatigued or having personal issues. 6.1 Alcohol and other drugs Hydro Tasmania is committed to providing a drug and alcohol free workplace to improve the safety and wellbeing of all. As such, all workers (employees and contractors) are required to: Have zero blood alcohol content (BAC) in the workplace, including offices, workshops, power stations, construction sites and Hydro Tasmania vehicles; Not be affected by the consumption of illicit drugs; and Notify their line manager and colleagues of any prescription or general medication that could affect the ability to drive, operate machinery or complete tasks safely. Hydro Tasmania conducts drug and alcohol testing where such testing helps to manage HSE risks. Workers are required to take part in testing as requested by Hydro Tasmania management. Contractor personnel are required to consent to Hydro Tasmania’s testing policies as the commencement of their engagement. Hydro Tasmania is committed to providing education on alcohol and drugs for all employees and provides assistance to any employees impacted by alcohol or drug problems through the employee assistance program (EAP). Alcohol and drug testing may be conducted in the following circumstances: 6.2 A program of random testing may be implemented in any Hydro Tasmania workplace at any time, on any employee, contractor or visitor; Following a serious incident or near miss; Voluntarily self-testing your blood alcohol content prior to working; and ‘Causal testing’ as requested by a colleague or manager if there is reasonable suspicion that the requirements have been contravened. Transmissible infections and diseases All workers have a responsibility to help prevent the spread of infectious diseases in the workplace. Normal hygiene measures should be used at all times: Cover your cough; Wash your hands; Keep your distance; Know the signs of the flu; and Stay at home if sick. Page 23 of 38 HSE 6.3 Health, Safety & Environment (HSE) Induction Guide (Level 2) Revision 1 CAUTION: printed document is uncontrolled Print Date: 06/03/2016 Work hours and fatigue management Fatigue is a physical condition that occurs when an individual’s physical or mental limits are reached and can be associated with physical exertion, mental exertion or inadequate or disturbed sleep. As well as contributing to reduced performance and increasing the likelihood of workplace and vehicle accidents, fatigue can also lead to long term health problems. Managing fatigue is an important component of Hydro Tasmania’s overall approach to ensuring fitness for work. Hydro Tasmania’s fatigue management procedure shall be followed, with fatigue to be considered in the planning stages of all work activities, especially where the specific tasks may accelerate fatigue (e.g. working in a hot or cramped position, driving, or working using high risk plant and equipment). Hydro Tasmania has established a reasonable working hours guideline to help to manage fatigue: Working two hours past your normal work day: discuss your fitness for work/travel with your manager to change the situations you may find yourself or your workmates in – o Sometimes just the conversation is enough to find a solution or check that you are okay to continue or to put control measures in place to help you. o Sometimes your job manager or line manager will challenge whether the work needs to be completed before you get some rest. Working four hours past your normal work day: discuss your fitness for work/travel with your manager further to ensure your safety comes first, even if there is the perception or feeling that we may be letting our customer down – o Your manager shall conduct a formal fatigue assessment to measure your fatigue levels and take the results into account when deciding if work should proceed. o Your manager shall seek approval from their manager for you to work beyond 12 hours in any 24 hour period, if your fatigue assessment indicates you are fit for work. Working beyond 14 hours: working beyond 14 hours within a 24 hour period may only be permitted in emergency situations, with the approval of senior management. A fatigue management JHA and formal fatigue assessments are required. These guidelines apply to contractors working on Hydro Tasmania sites or under Hydro Tasmania’s direction, as well as to employees and, where appropriate, formal strategies shall be developed to address fatigue related risk. 6.4 Smoke free workplace Hydro Tasmania is a smoke free environment: 6.5 Smoking is not permitted in our work buildings, facilities or other enclosed workplaces. o This includes offices, motor vehicles, workshops, underground power stations and mess rooms. Smoking is only allowed in designated smoking areas. Tobacco products shall not be sold in Hydro Tasmania workplaces. Occupational health Hydro Tasmania work sites may pose specific hazards to worker health and well-being. Where such hazards are identified, Hydro Tasmania implements control measures to manage the risks and provide a safe, healthy work environment that helps our employees and contractors remain fit for work. Site specific hazards will be communicated at the site - level 3 induction. Page 24 of 38 HSE 6.5.1 Health, Safety & Environment (HSE) Induction Guide (Level 2) Revision 1 CAUTION: printed document is uncontrolled Print Date: 06/03/2016 Manual handling Lifting and moving objects incorrectly, including performing repetitive physical tasks, can lead to injuries. All workers shall take care when handling objects to do so in a safe manner. The best way to make manual handling safer is to redesign the task or workplace. There are a number of ways to do this. Where practicable: 6.5.2 Eliminate unnecessary handling; Modify the task to use mechanical handling equipment or tools such as levers, hooks or crowbars; Use multiple people or team lifting; Modify / disassemble the object being handled so it is easier to hold, or manoeuvre; Modify workplace and workstation layout to reduce stooping and reaching; Ensure work surfaces are at the correct height; Ensure that all heavy objects are at waist level where they can be handled comfortably; Reduce body movements and forces such as twisting, reaching and holding; Perform basic stretches before doing any unusual physical activity; and Ensure ongoing evaluation of physical tasks. Electromagnetic fields (EMF) There are a number of electromagnetic field sources at some Hydro Tasmania worksites. These sources are all signed and a JHA shall be used cover all the work in these areas. Signs are posted for all areas where the magnetic field strength has been assessed as above 5, 000 mG; Signs have been posted as close to the source of high EMF as possible; Each sign refers to a specific source of high EMF (e.g. equipment, busbar, cable); and Cardiac pacemaker signage has been posted at all sites warning that ‘magnetic fields existing in these power stations may adversely affect pacemaker operation and could be hazardous to health’. All workers shall comply with any signage and not interfere with telecommunications or radio equipment. 6.5.3 Managing employee health and well-being Hydro Tasmania maintains a range of programs to help employees to manage their health and wellbeing. Details of these programs can be found on Hydro Tasmania’s intranet and include: The Healthy Hydro Program, with services including: o Health assessments & fitness programs o ergonomic/postural assessment o Voluntary medical or Muscular/skeletal assessment The Employee Assistance Program, professional confidential counselling services for assistance with issues including: o Emotional stress or anxiety o Relationship problems o Alcohol or other drugs problems o Work related problems Page 25 of 38 HSE o o o 6.5.4 Health, Safety & Environment (HSE) Induction Guide (Level 2) Revision 1 CAUTION: printed document is uncontrolled Print Date: 06/03/2016 Gambling problems Grief and loss Financial or legal problems Rehabilitation Rehabilitation is the process that Hydro Tasmania puts in place to enable employees to return to full health and meaningful, productive work following an illness or injury. Our rehabilitation program covers injury and illness that is work related as well as non-work related situations where an employee is prevented from working or from performing all the duties of their position. Page 26 of 38 HSE 7. Health, Safety & Environment (HSE) Induction Guide (Level 2) Revision 1 CAUTION: printed document is uncontrolled Print Date: 06/03/2016 Operational controls 7.1 Work permits Hydro Tasmania uses a permit to work system to manage specific hazards and work activities. These permits are issued by Hydro Tasmania. The types of permits in use include: Hydro Tasmania Permit to Work Confined space permit Concealed services permit Hot work permit Diving permit Additional permits issued by external authorities may be required to perform a specific task or approve a project. These include legal and environmental permits and approvals. 7.1.1 Permit to work (PTW) system The permit to work is the over-arching permit used to manage HSE risks on Hydro Tasmania work sites. The objectives of the permit to work (PTW) system are to: Ensure safety of people. Prevent harm to the environment, equipment or other property. Preserve our capability to deliver to our customers. The PTW system is applicable to all work being carried out on Hydro Tasmania owned and/or operated plant and assets. It follows fundamental hazard identification, communication and risk management processes. Employees and contractors whose work activities may require a PTW shall undertake Hydro Tasmania Instructed Person (IP) training. Those in charge of work undertaken under a PTW shall undertake Hydro Tasmania Person in Charge (PIC) training. 7.1.2 Excavation, drilling, civil works Hydro Tasmania worksites have cabling and piping installations that are not immediately apparent or visible such as fibre optic cables and unmarked services. Commonly called concealed services, the precise locations of these installations shall be identified and clearly marked to prevent damage during work. No excavation/penetration shall be performed on site before an approved concealed services permit has been issued, confirming that all such installations have been identified and will be protected. A JHA and/or Safe Work Method Statement shall also be used in conjunction with the concealed services permit. Page 27 of 38 HSE 7.2 Health, Safety & Environment (HSE) Induction Guide (Level 2) Revision 1 CAUTION: printed document is uncontrolled Print Date: 06/03/2016 Energy isolation The isolation procedure is designed to protect people from unexpected energisation, which is the start-up or release of energy, while they are working on plant. All Hydro Tasmania employees and contractors who work on equipment that can be energised shall be instructed in the use of Hydro Tasmania’s isolation procedure and issued with personal isolation locks. The isolation procedure covers the three categories of isolations used by Hydro Tasmania: 7.2.1 Directly controlled isolations: where locking and tagging is not necessary. o Applies where isolation, dissipation or restraint of energy sources is carried out by physical removal or separation of plant components, o each worker can keep the means of isolation, dissipation and restraint under continuous observation and control, and there is no potential to interrupt production. Personal isolations: where it is practicable for an individual to personally isolate, tag and lock out the plant, and that person is competent and authorised to do so. o Each person shall lock every device used for isolating, dissipating or restraining energy on the plant, if the device is capable of being locked. o The locking shall be done with red personal isolation locks. o Each person shall tag every device or other means used for isolating, dissipating or restraining energy on the plant with a correctly-completed personal danger tag. o Each person shall then verify the isolation is effective before commencing work on the plant. Group isolations: where the Hydro Tasmania asset owner (or their delegate) selects and designates an authorised issuing officer to plan and carry out the isolation and restoration of the plant once work is completed. The authorised issuing officer: o Identifies all potentially harmful sources of energy. o Prepares a schedule of plant operations that will documents all operations, deenergisation steps required to ensure the safety of all workers. o Checks and confirms all isolations have been correctly performed and plant is safe before giving the authority for work to start. Locking rules All persons required to perform isolations shall undertake Hydro Tasmania Instructed Person training, including detailed instruction on Hydro Tasmania’s locking requirements. The key rules for isolation locking and tagging shall, however, be understood by all employees and contractors. Breach of these rules may result in disciplinary action. An isolation point shall not be operated, nor an attempt made to override or tamper with an isolation point that has been secured by a personal isolation lock/tag or an isolation lock. Note that this is a Cardinal Rule. Each person working shall lock on using their personal isolation lock prior to starting work and remove their personal lock once they have finished work or are about to leave site. Group isolation locks shall only be placed or removed by a competent and authorised issuing officer. Page 28 of 38 HSE Health, Safety & Environment (HSE) Induction Guide (Level 2) Revision 1 CAUTION: printed document is uncontrolled Print Date: 06/03/2016 The owner of any personal isolation lock shall be easily identifiable to another person. Personal isolation locks shall only be placed or removed by the owner, unless the lock/tag removal process is followed with due process and authorisation. A person shall not lend their personal isolation lock or key to another person. Loss of a personal isolation lock or a key for a personal isolation lock shall be reported. Only locks that are approved by Hydro Tasmania that meet the criteria of the isolation procedure can be used. Page 29 of 38 HSE 8. Health, Safety & Environment (HSE) Induction Guide (Level 2) Revision 1 CAUTION: printed document is uncontrolled Print Date: 06/03/2016 Specific hazards Specific hazards will be identified as part of the risk assessment and work planning processes. Where a Hydro Tasmania procedure exists for managing a specific hazard, that procedure shall be followed. 8.1 Hazardous substances A range of hazardous substances may be encountered on Hydro Tasmania work sites, including, but not limited to: Industrial chemicals Oils and other petro-chemicals Explosives Sulphur hexafluoride (SF6) gas Asbestos Care must be taken when working with hazardous substances, including following the relevant HSE Management System procedures and other risk management documents. Note that no explosives can be brought into a Hydro Tasmania worksite or used without the approval of a Hydro Tasmania representative in accordance with the seismic survey procedures. 8.1.1 Chemical handling Only approved and registered chemicals and dangerous goods can be used at Hydro Tasmania worksites. Safety data sheets (SDS) contain all the relevant information on a chemical, including: The hazards and risks associated with chemical use any personal protective equipment (PPE) requirements Storage and disposal requirements; and Spill and emergency response information. The SDS shall be kept where the chemical is stored and be consulted when conducting a risk assessment and developing a risk management plan for the work. 8.2 Hazardous environments 8.2.1 Safety signs Hydro Tasmania work sites contain a range of potential hazards. Signs are used to communicate critical safety information and shall be complied with at all times. Safety signs identify recognised hazards and give important information that you shall follow for your safety and the safety of others. Colours used in safety signs for the occupational environment (AS 1319) are: Red – prohibitive. Blue – mandatory (regulatory). Yellow – hazard (warning/caution). Green – emergency information. Page 30 of 38 HSE Health, Safety & Environment (HSE) Induction Guide (Level 2) Revision 1 CAUTION: printed document is uncontrolled Print Date: 06/03/2016 All persons on Hydro Tasmania sites shall comply with the information provided on safety signs. 8.2.2 Working alone, or in isolated or remote area Working alone is defined as an employee working or travelling for work on their own and without routine interaction with other persons. This may be due to the timing, location or nature of their work. A remote area, both in Australia and overseas, is ‘an area that is remote from others or isolated from the assistance of others because of the time, location or nature of the work’. Any situation with an emergency response time greater than 30 minutes should be considered remote. All persons working alone and / or in remote areas must comply with the relevant HSE procedures, including: Lodging a field schedule with their designated contact; Carrying a trunk mobile radio or satellite phone; Following the check-in procedure documented in the JHA; Carrying a personal first aid kit with essential items and medications for the planned work and to treat any known allergies; and Carrying an emergency position indicating radio beacon (EPIRB) or a geographic information system (GIS) tracking device, if required in the JHA. Failure to follow the agreed check-in schedule will trigger the missing person response protocol, with the level of response escalating until contact is made. If a person has not made contact by 9 pm they will be officially reported as missing to the police service and their next of kin notified. 8.2.3 Working in or near water As a minimum a JHA shall be completed before working in and around water, addressing the hazards involved in the work. A Safe Work Method Statement may also be required if undertaking construction activities in or around water. The hazards involved with working in, on or near water include, but are not limited to: Pollution of waterways; Spread of weeds, pests and pathogens; Drowning; Exposure or hypothermia; Collision with boats and infrastructure; Slip and fall; and Snagging and entanglement. Weather and water conditions shall be reviewed prior to commencing work in water, and work postponed if weather conditions are unsuitable. A certified coxswain shall be on board and in charge of any boat and is responsible for the safety of all people on board. Page 31 of 38 HSE 8.2.4 Health, Safety & Environment (HSE) Induction Guide (Level 2) Revision 1 CAUTION: printed document is uncontrolled Print Date: 06/03/2016 Working at heights Hydro Tasmania has developed a working at heights procedure to manage the risks of workplace falls. All workers, where there is a risk of falling 1.8 metres or greater, or working within two metres of a live edge or brittle surface: 8.3 Shall be trained for height safety and competent in the height safety systems unless control measures can be used to protect the worker from the exposed edge or brittle surface; and Shall complete a JHA and a working at heights checklist. Electrical safety Electrical hazards are present on many Hydro Tasmania work sites, such as power stations and switchyards. Hydro Tasmania has a range of processes in place to manage the risks associated with work around electricity. The common electrical hazards and causes of injury can be categorised as the following: 8.3.1 Electric shock causing injury or death: the electric shock may be received by direct contact, tracking through or across a medium, induction, or by arcing. Arcing, explosion or fire causing burns: the injuries are often suffered because arcing or explosion or both occur when high fault currents are present. Toxic gasses causing illness or death: burning and arcing associated with electrical equipment causes a range of gases and contaminants to be present. Compounds ranging from ozone to cyanide and corrosive acids can be present as well as risks such as low oxygen content. Electrical work competency requirements Any person working on electrical equipment must be deemed a competent electrical worker by Hydro Tasmania. A competent electrical worker means: A licensed electrical practitioner; A person holding a restricted electrical licence; or An employee authorised under Hydro Tasmania’s electrical safety management system (ESMS). Additionally, all employees undertaking electrical work shall be qualified in low voltage (LV) rescue and resuscitation (CPR) and undertake refresher training annually. Employees shall maintain a copy of evidence of competence with them when signing on to a Permit to Work (PTW) involving electrical work. 8.3.2 Live work Work on live (energised) electrical equipment shall not be undertaken without a risk assessment (e.g. Safe Work Method Statement) approved by the appropriate Officer or their direct delegate. Generally, live electrical work is deemed an unacceptable practice. The only exception is when the electrical work is necessary in the interests of safety and the risk of harm would be greater if the circuits and equipment were de-energised before the work started. In this situation, the work shall be carried out in accordance with Model Work Health and Safety Regulations part 4.7, AS 4836 and Page 32 of 38 HSE Health, Safety & Environment (HSE) Induction Guide (Level 2) Revision 1 CAUTION: printed document is uncontrolled Print Date: 06/03/2016 with appropriate safety measures, which includes a safety observer who is competent in performing the particular task, and is competent in electrical rescue and CPR. 8.3.3 Electric shock Hydro Tasmania employees or contractors experiencing an electrical shock shall receive a medical examination. This applies at all Hydro Tasmania sites, including those with contractors managed by Hydro Tasmania. If a suitably qualified person can determine beyond doubt that the shock was a static electric shock or an Extra Low Voltage (ELV) shock a medical examination is not mandatory, but can be provided if warranted. Where there is doubt as to the nature and severity of the electric shock, a medical examination is always required. 8.4 Tools and mobile equipment Tools and mobile equipment include items such as power tools, gas cylinders, lifting equipment (e.g. forklifts and mobile work platforms).There are specific hazards relating to the tools and mobile equipment used on Hydro Tasmania work sites. These hazards shall be identified through the job risk assessment process and suitable controls put in place. Where relevant Hydro Tasmania procedures exist, they shall be followed to reduce the risks associated with tools and mobile equipment. 8.4.1 Compressed air safety Compressed air can kill if it enters your body: never direct compressed air at another person or any body part. Use only approved fittings and clips in accordance with manufacturers specification and use the appropriate personal protective equipment (PPE). Also, alert others in the work area before operating compressed air equipment. When you have finished working with high pressure equipment, depressurise all fittings and hoses. All work on pressurized systems shall be controlled by a JHA. High pressure gases and fluids can be found in some work areas. Your Level 3 Site induction shall identify these hazards. 8.4.2 Power tools As a minimum, Hydro Tasmania requires all electrical equipment used on its sites to be compliant to the Australian Standard AS/NZS 3760:2010 in-service safety inspection and testing of electrical equipment. Inspections relating to construction sites can be found in AS 3012:2010 “electrical instillations-construction and demolition sites”. In addition to this: People shall perform pre-use inspections on all electrical equipment before use and again after, before returning the equipment; All electrical tools shall be connected to a residual current device (RCD) to protect against electrical surges or shorting; and All electrical equipment that is not in test date or damaged shall be tagged out of service and removed from use until it can be tested and tagged by a competent person. Page 33 of 38 HSE 8.5 Health, Safety & Environment (HSE) Induction Guide (Level 2) Revision 1 CAUTION: printed document is uncontrolled Print Date: 06/03/2016 Travel and transport Work for Hydro Tasmania may involve travel, including driving to remote worksites, travelling interstate and travelling overseas. Procedures are in place to manage the risks associated with travel and shall be complied with by Hydro Tasmania employees and contractors travelling on our behalf. 8.5.1 International travel The hazards associated with international travel vary extensively depending on the destination and the nature of the work to be done. Where international travel is required for work purposes, Hydro Tasmania employees shall follow the international travel procedure and ensure they meet the following requirements: Job hazard analysis completed, assessing o The risks associated with the journey; o The risks associated with working in the destination country; Approval given by the level 2 manager; Call-in processes and emergency response plans developed and approved prior to departure, and complied with once in-country; Any required vaccinations or other medical requirements identified and administered, prior to departure; and Where possible, seek the advice of other Hydro Tasmania employees who have visited the intended destination. Workers travelling overseas shall monitor in-country conditions closely, review and update their trip JHA as the situation changes and notify their Line Manager of any health and safety concerns. Workers shall not compromise their safety or the safety of others. Where concerns have been raised, workers shall wait for Hydro Tasmania to provide advice or permission to proceed. 8.5.2 Domestic travel Domestic travel, including travel by road and air, may be required by Hydro Tasmania workers. The HSE hazards of travel within Australia may include: Trip duration and fatigue; Road safety and driving hazards; Remote and isolated locations; and Aircraft use, including light aircraft and helicopters. All workers travelling on behalf of Hydro Tasmania shall comply with the domestic travel procedure. Additionally, those travelling to or through remote or isolated areas shall follow the remote area and working alone procedure. The risks associated with other hazards, including the mode of transport, shall be assessed as part of the work risk assessment (e.g. Job Hazard Analysis). 8.5.3 Road safety Driving is a significant safety hazard for Hydro Tasmania. To minimise the hazards associated with driving: Hydro Tasmania’s road safety guideline shall be followed by all employees and contractors. Page 34 of 38 HSE 8.6 Health, Safety & Environment (HSE) Induction Guide (Level 2) Revision 1 CAUTION: printed document is uncontrolled Print Date: 06/03/2016 Check over the vehicle prior to departure, ensuring it is fit for purpose, including the weather and road conditions and in good working order including the check of o The weather and road conditions. o The vision is unobstructed and windows are clear. o The tyres are in good condition and suitable for the expected conditions. o The fuel type is known and there is enough fuel to reach a suitable service station. o The load (if any) is properly loaded and secured. o The equipment required for the conditions you are likely to encounter. Drivers are required to: o Manage fatigue by taking regular breaks to rest and walk around. o Follow the Hydro Tasmania fatigue management and maximum work hour procedure. o Maintain a zero blood alcohol and drug level at all times. Follow the road rules and drive to suit the current conditions at all times by: o Slowing down in wet conditions. o Using defensive driving techniques; do not drive aggressively. Be aware of likely hazards you may encounter by: o Watching for animals at dawn and dusk. o Wearing sunglasses to minimise glare. o Watching for parked vehicles in tourist areas. o Being mindful that logging trucks and other heavy vehicles will hold to the middle of dirt roads. o If travelling through remote areas, especially if out of normal business hours phone check-in is required. o Report any defect noted while operating a vehicle and correct any unsafe conditions before further use of that vehicle. Do not use mobile phones or two-way radios when driving unless using a Bluetooth headset or in-car hands free kit (with phone caddy) by: o Aiming to pull over to make or answer calls, even when using a hands-free kit. o Not texting, using phone data services (e.g. emails) and otherwise handling your phone. Ergonomics Ergonomics is essentially about the process of designing or arranging the workplace so it fits the person. If you experience discomfort at your work station, desk or other location, speak with your line manager and report the symptoms early. Symptoms may include: decreased range of motion deformity or swelling decreased grip strength loss of function, e.g. cannot close hand persistent numbness burning sensation pain and tingling cramping and stiffness. Page 35 of 38 HSE 9. Health, Safety & Environment (HSE) Induction Guide (Level 2) Revision 1 CAUTION: printed document is uncontrolled Print Date: 06/03/2016 Management of contractors and suppliers Hydro Tasmania’s HSE requirements for contractors and suppliers are determined by the level of risk involved in the work. As a minimum, all contractors and suppliers shall adhere to Hydro Tasmania’s HSE systems and processes and meet the responsibilities and requirements described in the Hydro Tasmania procedure for HSE management of contractors and suppliers. Core HSE documents, including this procedure, are made available to contractors on the Hydro Tasmania website (www.hydro.com.au). All contractor and sub-contractor personnel working on Hydro Tasmania sites must also meet the requirements for site access. 9.1 Hydro Tasmania responsibilities Hydro Tasmania representative is responsible for establishing and managing the contracted / supplied work and managing the associated HSE requirements, in accordance with the procedure for HSE management of contractors and suppliers. These responsibilities include, but are not limited to: 9.2 Ensuring that the HSE hazards have been accurately identified and the risks fairly assessed; Confirming that the nominated controls are adequate to manage the HSE risks; Checking that all control measures are in place and functioning before work commences, including that any training and induction requirements have been met; and Monitoring the HSE performance of contractors and suppliers, providing feedback, advice and support. Contractor / supplier responsibilities The contractor or supplier has HSE duties and joint responsibility for the safe, environmentally-sound delivery of the contracted work. The contractor / supplier is also responsible for: Consulting with Hydro Tasmania to ensure the HSE hazards associated with the work have been accurately identified and are understood by all relevant parties; Ensuring the work is delivered as per the HSE management requirements identified in the contract documents; Complying with Hydro Tasmania’s nominated HSE controls, including inductions and competency requirements and providing copies of any requested documentation; and Providing HSE oversight for the contracted works, including supervising contractor workers, monitoring HSE risks and controls and responding to any HSE incidents, hazards or nearmisses. Page 36 of 38 HSE 10. 10.1 Health, Safety & Environment (HSE) Induction Guide (Level 2) Revision 1 CAUTION: printed document is uncontrolled Print Date: 06/03/2016 Incident management and emergency response Incident management Hydro Tasmania takes its commitment to protecting the health and safety of people and the environment very seriously and places great emphasis on reporting and learning from HSE incidents, including potential hazards and near misses. Everyone, including contractors, has a responsibility to report any safety or environmental incidents to their line manager immediately. A written incident report is to be provided within 24 hours of an incident occurring, using Hydro Tasmania’s Incident Notification Form or online hazard and near-miss reporting. These reports are entered into Hydro Tasmania’s incident database for investigation and reporting. Key points to remember about incident management: Assess the situation and, where possible, control or contain the issue – o Consider your safety and the safety of others first and prioritise avoiding risks to life; o Follow the relevant emergency response plans for the site you are working on; o Ensure the site is preserved and undisturbed as far as practicable so a proper investigation can occur. Where there is a risk to others or of further spread (e.g. oil spills to waterways), raise the alarm; Seek help to manage the situation, if required; Notify the Area Owner or Job Manager about the incident once it is safe to do so; Follow directions provided by your manager, emergency services and / or HSE advisors; Complete and submit a detailed incident report to the appropriate Line Manager o All incidents of a moderate severity or greater must be reported to the Line Manager immediately after the situation has been stabilised. o All incidents, hazards or near-misses must be reported within 24 hours. Report all safety and/or environmental incidents, near misses, hazards, environmental incidents, non-conformances, opportunities for improvement, all regulatory breaches and any other HSE issues – if you are unsure, always report it. 10.2 Emergency preparedness An emergency is any unplanned or abnormal event in a specific location that demands immediate attention, usually by team members on the spot. Most emergencies do not result in a crisis (an event that has major actual or potential long-term consequences) but do require efficient and effective responses. Emergency incidents encompass any situation where: Injuries have been, or could be, incurred to Hydro Tasmania personnel, contractors, visitors or members of the public; and/or There is potential to seriously damage the environment (e.g. oil spill to waterway); and/or Property damage has occurred or property is placed in jeopardy of damage (e.g. bushfire). It is a Hydro Tasmania requirement that that appropriate emergency response procedures are developed and can be practically implemented when an emergency situation arises. Page 37 of 38 HSE Health, Safety & Environment (HSE) Induction Guide (Level 2) Revision 1 CAUTION: printed document is uncontrolled Print Date: 06/03/2016 All Hydro Tasmania work sites develop emergency response plans that guide what to do in case of an emergency and emergency response information is provided to contractors as part of the site (Level 3) induction. An emergency information manual is provided at all Hydro Tasmania power stations containing all the relevant information on potential emergencies and response actions for that site. These manuals are located near the entry to each power station and can be accessed by all workers on site, including contractors. 10.2.1 Evacuation Each site has its own evacuation procedure detailed in the site emergency information manual or displayed on notice boards. The site (level 3) induction will cover the unique evacuation procedures for that site. 10.3 Incident and emergency response equipment Equipment for managing HSE incidents and emergencies is available at most Hydro Tasmania sites. Where equipment is not normally kept on site, relevant equipment shall be transported to the site and kept there while the risk is present (e.g. during project works). Emergency and rescue equipment shall only be used by people who are authorised and competent to use the equipment. The incident and emergency response equipment provided by Hydro Tasmania includes: First aid kits – First aid kits are kept and maintained at all major Hydro Tasmania sites and in all Hydro Tasmania vehicles. Report any items used from the kit to your Line Manager to ensure the kits remain accurately stocked. The site specific (level 3) induction includes the locations of first aid kits. Fire-fighting equipment – fire extinguishers, fire blankets and other fire-fighting equipment is kept and maintained at all major Hydro Tasmania sites and in all Hydro Tasmania vehicles. This equipment is provided for use where necessary to protect the safety of people and allow evacuation until the Fire Service arrives. Spill kits – kits for the containment and clean-up of smaller spills are provided in all power stations, laboratories and other areas where spills commonly occur. Kits are specific for the type of substance spilled (e.g. oil and petrochemicals, HAZCHEM chemicals) and it is important to ensure the correct kit is used. Spill response trailers – mobile spill containment and clean-up equipment for larger oil or chemical spills in Tasmania. There are two trailer types: an initial response trailer for containing the spill, and a clean-up trailer. Trailers can be collected when a spill occurs, or brought on site for major works or projects with a high risk of spills. Oil recovery equipment – equipment for containing and recovering large spills to waterways is held at strategic locations across Tasmania. Information on how to respond to incidents and emergency situations, including fire, flood and oil spill response plans, is found in the emergency information manual or emergency information board at each site. Page 38 of 38 HSE 11. Health, Safety & Environment (HSE) Induction Guide (Level 2) Revision 1 CAUTION: printed document is uncontrolled Print Date: 06/03/2016 Notes Page 39 of 38