HERE - Home page for Frances Brodigan ( Franny )

advertisement

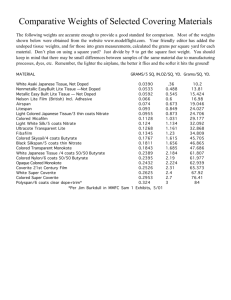

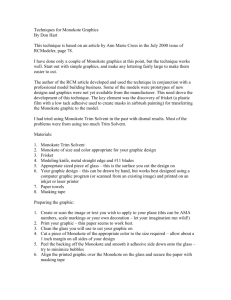

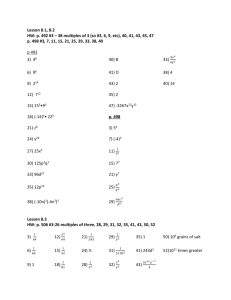

AAM Covering talk Feb 3rd, 2009 – Franny Brodigan www.frannybrodigan.com - fbrodigan@hotmail.com Covering materials (see next page for an exhaustive list): Heavy: Oracover/Ultracote Coverite 21st Century Fabric Light: CoverLite PolySpan – You will need “BalsaLoc” or equivalent Tools: Sealing Iron With thin sock Small Trim Iron Heat Gun Sanding bar Foam Sanding Blocks 18” and 36” metal straight edge #11 hobby knife and 100 new sharp blades Melamine board surface (flat, smooth, and slippery Sharpie Pen CA Debonder from Tower Hobbies – Rubber cement thinner Optional: Top Flight corner cutter BalsaLoc – For not heat adhesive coverings (PolySpan) Notes: Don’t use new MonoKote! This goes for EconoKote too. Sad to say, but the new (within the last 5 years or so) MonoKote is extremely hard to work with. It will start to go on like it did back in the day, but it will not shrink evenly and will leave you chasing ripple after wrinkle. There are so many other coverings to choose from so unless you must have a specific color that only they offer, go for Ultracote. Also, MonoKote will loosen up and wrinkle on flat balsa and those wrinkles can affect flight performance and are extremely hard to remove. When adding trim or large over lay, be careful not to apply too much heat. That will cause it to bubble. You can use the hobby knife tip prick trick, but it will show. Make sure the bottom layer is as tight as you need it to be before you put the top layer on. A trick I learned from Jim Gilpatrick. You can seam two pieces before you apply it by laying it out on a sheet of glass/mirror and using you sealing iron, seal the edge together well. The bonded sheets will then lift off the glass easily. This will allow you to have a seam that doesn’t coincide with a structural part of your airplane. Another method is to use a little soapy water to position the trim just where you want it. I have found that it can bubble with heat. This is best for pre-stick decals I think. Attach with a lower heat setting, then shrink with a higher setting – Don’t try to attach and shrink in one step. Pull, pull, pull around compound turns. Make sure you have enough extra material at wing tips and rounded fuselage section so you can maintain a good grip. Seal all edges BEFORE shrinking. Heat shrink covering does not like to be unconstrained. Use a heat gun to shrink, but keep it moving! The trim iron can be use for quick touches in those really hard places. Don’t use the “High” setting on the little trim iron. It will melt almost every covering! Work inside out – Always do inside edges first. In general cover from bottom to top. Preparation is key! You won’t get good results without a smooth structure. Sand smooth and finish with 300-ish grit. Always use a tack cloth just before you lay on the covering! Just as important as between paint coats. For fancy smaller graphics, try printing your own water-slide decals! It is great fun. If you use an ink-jet printer, you will need to seal the decals with clear lacquer before you wet them. A laser printer will help you bypass this step. Remember to apply a spray of lacquer over the applied decal once it has set. You can cut your own trim tape from scrap covering material. Easier and cheaper… and thinner Use Photoshop or other graphic program to construct and scale graphic templates like stars, insignia, etc. You can almost always find patterns on the web Read what others have posted on the building blogs such as RCUniverse, WattFlyer, RCGroups, AerodromeRC, etc. They are a fabulous resource and a great place to find tricks and tips. Spend time planning your color scheme. Maybe draw out with markers and paper first. Take your time. Use a Sharpie pen to mark the covering for cutting. Cut with a metal straight edge on Melamine board. Don’t remove the back until you are ready to place your piece to keep it clean. A tip from Ron Evans: the plastic backing makes a great plan protector for your next project! Use the CA-Debonder on a Q-Tip to remove the sharpie marks and any smeared covering adhesive. It works great! Always Use heat to remove covering. Pull gently. Use the de-bonder to cleanup any leftover adhesive. Weights of coverings in Grams per square Foot (From Ron Evans Via WattFlyer): Aerofilm 5.574-5.669 Airspan 2.119 (Mfg listed weights 2.229-2.601) Black Silkspan, 5.216 (5 Coats Thin Nitrate Dope) Colored Micafilm 3.247-3.716 Colored Nylon, 6.898 (6 Coats 50/50 Butyrate Dope) Colored Skysail, 5.087 (4 coats 50/50 Butyrate Dope) Coverite 21st Century Fabric 9.638 (Mfg Listed Weight) Coverite 21st Century Film 7.276-10.4 Coverite Black Baron Opaque 7.087 (Mfg. Listed Weight) Coverite Colored Super 8.504 Coverite MicroLite (Transparent) 1.889 Coverlite 2.803 Econokote 5.670 Esaki Light Silk (Clear) 0.97 Fibafilm 3.874-3.901 GlossTex 10.683-11.612 (Mfg Listed weight) 10.683-12.077 Japanese Tissue 0.650 Light Colored Japanese Tissue, 2.749 (3 Thin coats Nitrate Dope) Light White Silk, 3.572 (5 Coats Thin Nitrate Dope) LiteSpan 2.674-2.787 Micafilm (Red & Yellow) 4.0 MicaFilm (Transparent) 2.332 MokoKote (Florescent Orange) 9.4 Mokokote (White) 7.3 MonoKote (Black) 6.0 MonoKote (Colored Transparent) 5.307-5.5 Monokote (Metallic Platinum) 6.0 MonoKote (Red) 5.8 MonoKote (Yellow) 7.5 Nelson LiteFilm 1.950 Polycover (Opaque) 6.53 Polycover (Transparent) 4.355 Produce Bags (Thin Plastic, From Target) 0.53 Ripstop Polyester 1.575 Risteen Microlite (Corsair Blue) 0.81 Risteen Microlite (Light Yellow) 1.1 Risteen Microlite 0.90-0.95 Saran Wrap (11" x 12") 1.29 SIG AeroKote 7.9 SIG AeroKote Lite 5.8-6.0 Sig Coverall (White) 4.3 Sig Supercote (Silver) 4.8 Solarfilm 5.109-5.574 (Mfg Listed weights 4.645-6.038) Solarfilm Matt Polyester 6.503-7.432 SolarKote 6.967 Solarspan 5.574-6.503 SolarTex 8.361 (Mfg Listed weight) 7.896-8.825 SoLite 1.950 Superfabric 8.552-11.024 TowerKote 5.670 Ultracote (Cub Yellow) 6.6 Ultracote (Pearl Yellow) 8.2 Ultracote (Transparent Lite) 3.4 Ultracote (Transparent) 5.0 Ultracote 6.503 White Japanese Tissue, 6.879 (4 Coats 50/50 Butyrate Dope) White Super Coverite 7.559 WorldTex (White) 13.3 A Sampling of covering temperatures from Coverite: Recommended Iron Temperature Black Baron Film Attaching to Foam 150°-175°F Attaching to Wood 250°-275°F Partial Shrink 220°-250°F Maximum Shrink 270°-300°F (65°-80°C) (120°-135°C) (105°-120°C) (135°-150°C) Micafilm MonoKote® 21st Century Film 21st Century Fabric EconoKote® No No 175°-200°F 175°-200°F 225°F (80°-90°C) (80°-95°C) (105°C) 220°240°F 215°-240°F 190°-215°F 220°-250°F 225°F (100°-115°C) (90°-100°C) (105°-120°C) (105°C) 230°-270°F 200°-220°F 240°-280°F 225°F (110°-130°C) (95°-105°C) (115°-140°C) (105°C) 270°-350°F 220°-230°F 300°-350°F 225°F (130°-175°C) (105°-110°C) (150°-175°C) (105°C) (105°115°C) 240°260°F (115°130°C) 270°300°F (130°150°C)