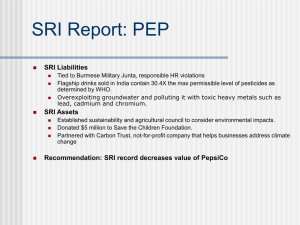

ESPs – Environmental Service Providers

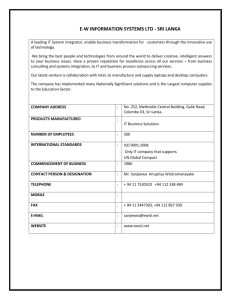

advertisement