UTS: Engineering Dean's Presentation Night Spring 2012

advertisement

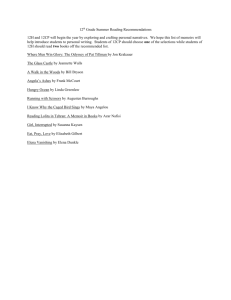

UTS: Engineering Dean’s Presentation Night Autumn 2013 Faculty of Engineering and Information Technology Dean’s Presentation Night Tuesday 16 July 2013 5:00pm Assemble and light refreshments 5:30pm Welcome 5:35pm Student presentations of their Capstone Projects (15 min each plus 5 min question time) Matthew Cremona Civil Engineering Investigating the Hydraulic Roughness of Loop Profile - (12cp) Michelle Youssef Mechatronic Engineering Human Gesture Capture based Robotic Imitation and Recall - (12cp) Srdjan Djukic Civil Engineering Development of Engineered Bamboo for Structural Application (12cp) Mark Dunstan Electrical Engineering Firmware and Hardware Design of an Inertial Measurement Unit (12cp) 6:55pm Break (10 min) David Chadwick Mechanical Engineering Submersible Pylon Inspection Robot – Designing a Supervised Autonomous Solution for Inspection and Servicing of Underwater Infrastructure - (12cp) Abraham Khoury Civil Engineering An Assessment of Concrete Properties Using Recycled Glass Sand in Standard and RMS Paving Applications - (6cp) Dean McNiven ICT Engineering Laser Scanner Interface - Model LS-PA-IF1 - (12cp) 8:05pm Judging 8:30pm Announcement of the Dean’s Prize winner 1 UTS: Engineering Dean’s Presentation Night Autumn 2013 Investigating the Hydraulic Roughness of Loop Profile - (12cp) Matthew Cremona - S12-031 Supervisor: Ali Keshavarzi Assessor: Hadi Khabbaz Major: Civil Engineering Major BE and BEDipEngPrac Since the introduction of trenchless technology into the sewer rehabilitation industry, innovative technologies have been developed to address the need for cost effective and low disruptive sewer rehabilitation. Loop Profile, a novel spirally wound trenchless technology, was developed by Interflow to rehabilitate sewer pipelines incorporating bends. It features a unique ‘loop’, which, when the profile is spirally wound into the deteriorated host pipe, enables the Loop Profile pipe to contract and extend at the loop to form the shape of the bend. However, concern had been raised about the ‘loop’ potentially acting as a contraction to flow through the pipe. Therefore, the aim of the Capstone project was to conduct an experimental investigation to measure the hydraulic roughness of Loop Profile. From this investigation, the measured roughness of Loop Profile would be compared against roughness values of PVC, Expanda Profile and concrete to determine the applicability of Loop Profile as a trenchless rehabilitation technology. In development of a methodology, it was found that the standard for spirally wound pipes, I.S EN13566-7:2007 failed to propose a methodology for determination of hydraulic roughness. Therefore, the secondary aim of the project was to address this limitation through development of a certified experimental methodology for investigating hydraulic roughness. The roughness of Loop Profile was calculated through measurement of head losses occurring throughout a Loop Profile pipe. Pressure measurements were taken from five points along the pipe and substituted into roughness equations to determine the friction coefficients. These coefficients were then compared against appropriate roughness coefficients for PVC, Expanda Profile and concrete. The project successfully established a methodology for calculating hydraulic roughness and accurately determined the hydraulic roughness of Loop Profile. The comparison illustrated that the roughness of Loop Profile was within an acceptable range and certified the profile as an acceptable rehabilitation technology. 2 UTS: Engineering Dean’s Presentation Night Autumn 2013 Human Gesture Capture based Robotic Imitation and Recall - (12cp) Michelle Youssef - S12-169 Supervisor: Mary-Anne Williams & Xun Wang Assessor: Benjamin Johnston Major: Mechanical and Mechatronic Engineering Major BE and BEDipEngPrac The presence of robots operating in society is continuously increasing. To compensate for this many methods have been designed to enable easier programming of robots, both industrial and domestic. Often the methods that are used are complex, involve expensive technologies and result in the robot generating non-human-like motions. This can cause reluctance for humans to interact with the robotic systems. Instead of devising new systems for each robot that needs to be taught a task, it would be easier if a human could demonstrate the task as if they were showing another person. This promotes human-robot interactions and makes working with robots much simpler. This project involved exploring different possibilities to teach a robot action from a human example using various tools. Willow Garage technologies were mainly used for implementations with the accessibility of their robot operating system (ROS) and their PR2 platform. The XBOX Kinect was also used in conjunction with OpenNI which contains modules to interact with the Kinect. Other methods were also explored with the intention of comparison to the Kinect-ROS-PR2 system. The project is based on real-time data transference between the movement mapping device, the interpretation program, and a robot’s actuators. The project consisted of developing a PC program to change the input from the movement capture in to an output for the robot’s joints. The real-time nature of the project implementation showcases the ability of a demonstrator to perform corrections and adjustments to movement as you go. Advanced robotics is one of the fields identified as a “disruptive technology” or a technology that will cause drastic changes to the future of living. Advances in learning technology for robots could have immense implications on future robotics frameworks. This project aims to promote further development in the fields of social robotics and human-robot interaction. Further developments could include using neural networks for motion planning and comparison of programming interfaces. 3 UTS: Engineering Dean’s Presentation Night Autumn 2013 Development of Engineered Bamboo for Structural Application - (12cp) Srdjan Djukic - S12-038 Supervisor: Rijun Shrestha Assessor: Emre Erkmen Major: Civil Engineering Major BE and BEDipEngPrac In today’s world of construction, the greatest topics are the environmental benefits and cost. Construction consumes large quantities of resources such as materials and energy, which generate environmental impacts throughout construction, operation, as well as demolition. Timber is known to be a natural construction material that is environmentally beneficial in building construction. Timber’s embodied energy is the lowest compared to majority of common construction materials as well as minimising energy through production, construction, and its environmental advantages of renewability and carbon storage. Major let down is that its supply is found to be depleting. The environmental aspects of building construction have influenced current industry leaders and organisations to invest in alternative materials and methods of manufacture, to provide solutions to environmental benefits and cost reduction. Similar to timber, bamboo is known to be commonly used as a traditional construction material but in minor construction. Bamboo’s tensile strength is comparable to mild steel; however, there is large variation in properties of bamboo among different species and within even same species. Bamboo’s harvest duration is eight times faster than timber, making it one of the most cost effective construction materials whilst it sequesters an equal or greater amount of carbon. (Hoogendoorn 2010) This capstone investigates the development of engineered bamboo for structural application through a low cost method of producing bamboo beams with manufacturing, testing and analysis with its similar materials (timber) for the processing of bamboo to make it more durable and usable in terms of building materials. Engineered beams formed out of bamboo will overcome the unfavorable properties such as presence of inter-nodes, hollow core and durability issues of bamboo. This was proved to be achievable with comparable results but with major weaknesses found not within the bamboo structure itself, yet the chemical bonding between bamboo that need to be further researched and tested for improvement. 4 UTS: Engineering Dean’s Presentation Night Autumn 2013 Firmware and Hardware Design of an Inertial Measurement Unit - (12cp) Mark Dunstan - S12-041 Supervisor: Steven Su Assessor: Li Li Major: Electrical Engineering Major BE and BEDipEngPrac An Inertial Measurement Unit (IMU) is a device which can be used to determine the orientation, velocity and gravitational forces acted upon it by the use of accelerometers, gyroscopes and magnetometers. IMUs are used in a variety of applications including navigation, entertainment, motion research and human health and safety. Specifically, UTS has the idea to develop a home based telecare system, which may include various portable noninvasive sensors to monitor physiological variables as well as body movements. Another potential application of an IMU by UTS includes research on gait recognition, as a person’s self-selected gait can lead to a person’s likeliness to fall. While there are already some IMU solutions on the market, they are either too expensive or do not have the desired flexibility for uses in many applications. Therefore it is highly advantageous for UTS to have their own designed IMU. My capstone project involves the firmware and hardware design of an IMU and to ensure that the IMU designed can be flexible enough to be used for many future applications. The IMU that has been designed is self-powered via a re-chargeable Li-Ion battery and includes communications to a PC via USB and Bluetooth, data storage for sensor samples and 9 degrees of freedom sensing. The firmware includes a communication protocol that allows external changes to the configuration of the IMU for different data output formats and frequencies to ensure high flexibility and optimum performance for different applications. As my capstone is a continuation of an ongoing project, I commenced the project with a completely untested prototype of the IMU hardware and no firmware. Since commencement, I have written all firmware and created a new version of the hardware, in which 20 of the new version of IMUs have been built and tested successfully. 5 UTS: Engineering Dean’s Presentation Night Autumn 2013 Submersible Pylon Inspection Robot – Designing a Supervised Autonomous Solution for Inspection and Servicing of Underwater Infrastructure - (12cp) David Chadwick - S12-021 Supervisor: Dikai Liu Assessor: Gamini Dissanayake Major: Mechanical Engineering Major BE and BEDipEngPrac The regular inspection and maintenance of bridges is necessary to meet their intended lifetime and ensure safety. The greater majority of bridges that span bodies of water have part of the structure submerged. Traditionally human divers are employed to maintain and inspect the submerged structure. However this work is laborious and dangerous, presenting a problem in limited operating times and the possibility of serious injury. A supervised autonomous robotic system provides a promising and feasible solution. Autonomous Underwater Vehicle (AUV) and Remotely Operated Vehicle (ROV) designs vary greatly to provide flexibility in operational tasking. However, no AUV has been designed to perform the complex task of underwater pylon servicing. Given the capability gap in existing technology and the task requirements, the question posed is; can a supervised AUV be developed to perform these tasks effectively? The aim of this project is to produce a supervised autonomous robotic solution for underwater maintenance and inspection of structures. In order to achieve this, the complex problem must be analysed and system requirements must be derived. The overall concept design must be developed. Auxiliary systems, control systems, machine sensing, and a method of adhesion must be developed, prototyped, and tested. The entire system must be capable of operating in a hostile and challenging underwater environment. This capstone provides findings from research into current devices and procedures used to perform underwater pylon servicing. A detailed constraints analysis of the problem and recommendations for system requirements is presented. Current literature has been reviewed to determine the novelty of the research and the results discussed. An overall concept design is presented with a discussion on its evolution of development and options for several subsystem solutions explored. A kinematic analysis of one manipulator arm is presented and a way forward for continued development of the entire design suggested.An Assessment of 6 UTS: Engineering Dean’s Presentation Night Autumn 2013 Concrete Properties Using Recycled Glass Sand in Standard and RMS Paving Applications - (6cp) Abraham Khoury - A13-020 Supervisor: Hadi Khabbaz Assessor: Behzad Fatahi Major: Civil Engineering Major BE and BEDipEngPrac The rising difficulties associated with escalating carbon dioxide emissions and the increasing demand for more sustainable building solutions, are concurrently placing pressures on the concrete industry to amend traditional concrete mix design practices. Concrete manufacture is not only heavily reliant on the use of earth’s scarce resources, but also an intensive energy process leading to the generation of undesirable greenhouse gases. Such characteristics define the unsustainable nature associated with traditional concrete manufacture. Boral Australia has recognised the importance in catering for the development of environmentally sustainable concrete. The organisation has introduced a recycled glass sand product into its standard 32 MPa concrete mixes. Glass constitutes an approximate fine aggregate replacement value of 25%. This study aims to investigate the influence of incorporating such glass content by comparing performance of fresh and hardened concrete properties in relation to a control mix design not containing glass sand. In further facilitating the development of environmentally sustainable concrete, this study aims to investigate the influence of incorporating recycled glass sand at various replacement contents of the fine aggregate component in RMS R83 concrete designed mixes. Such study of assessment pertained to assessing fresh and hardened concrete properties in relation to performance tolerances depicted in the R83 specification. Incorporation of recycled glass at replacement contents of 10%, 20% and 40 % of the fine aggregate component in a paving base concrete mix, enabled the determination of how recycled glass interacts within the concrete matrix at various intensity volumes and assessment of the suggested 30% replacement rate as specified in the proposed new revision of the RMS R83 specification. Hence, trends in concrete performance with relation to replacement levels of incorporated recycled glass are studied to verify the optimal glass replacement content in paving base mixes. The findings of this project indicate that using recycled glass sand in paving applications can yield sustainable concrete at 40% replacement rates whilst inducing improvements in drying shrinkage behavior and concrete workability. The neutral effects of glass sand on air entrainment and marginal reductions in hardened concrete properties yielded from such study further supports the use of glass sand in a paving application. 7 UTS: Engineering Dean’s Presentation Night Autumn 2013 Laser Scanner Interface - Model LS-PA-IF1 - (12cp) Dean McNiven - S12-091 Supervisor: Rob Jarman Assessor: Peter McLean Major: ICT Engineering Major BE and BEDipEngPrac The laser scanner interface (model LS-PA-IF1) was developed at TOMRA Sorting Solutions Pty Ltd between July 2012 and May 2013. The laser scanner interface project addresses several problems with the current laser scanner used on an ore sorting machine for the mining industry. The existing control electronics consist of several individual PCBs, increasing the total cost of the system. The number of inter-board connections used between these PCBs coupled with their physical separation within the sorter greatly increases the chances that noise will affect the signal quality. The other significant problem with the existing control electronics is the increasing financial costs of maintaining the hardware as the significant components are now classed as legacy devices by their respective manufacturers. As such, these components are becoming increasingly difficult, and therefore increasingly more expensive to obtain. To address these issues with the existing control electronics I have developed the laser scanner interface. The laser scanner interface replaces the existing combination of PCBs with a single integrated solution that is installed within the laser scanner assembly. The benefits of the laser scanner interface project include a reduction in the cost of the laser scanner, a modular design allowing the laser scanner to be used with any commercial machine vision system and integrated signal processing providing better quality data. 8 UTS: Engineering Dean’s Presentation Night Autumn 2013 Finalists for the best poster for Capstone Project Ian Gilmore (absent) Civil Engineering Comparison of Regional Flood Methods for New South Wales Bradley Ham Electrical Engineering Compliance of Voltage Unbalance Standards throughout Low Voltage Power Distribution Networks Hang He Civil Engineering An Investigation into the Construction and Design Aspects of Tailings Dams and Stability Analysis Using Slope/W Arman Jizan ICT Engineering An Interactive Virtual Stock Exchange Simulator for Investment and Analysis Quang Viet Cuong Lam Mechanical and Mechatronics Engineering Derivation, Implementation and Testing of Fuzzy and LQR Controllers for Active Hydraulically Interconnected Suspension Michael Leversha Mechanical Engineering Development of a Condition Monitoring Framework A Case Study in the Implementation of ISO 17359:2011 Frank Lukacevic Mechanical Engineering Investigation into Conversion of Existing Gasoline Internal Combustion Engines to 85% Ethanol Blended Fuels (E85) Tuan Hiep Pham Mechanical and Mechatronics Engineering Modeling, Control and Experimental Testing of the Active Hydraulically Interconnected Suspension) Wenzhe Shan Civil Engineering Influence of Polyurethane Soil Stabiliser on the Strength of Cement Treated Kaolinite Soil Willis Susanto Civil Engineering Biotechnical Stabilisation of Kaolinite Soil Using Micro organism Simon Varley Mechanical Engineering Cooling System Design for Formula SAE Yue Zhao Civil Engineering Influence of Soil Stabiliser Polymer Polyurethane on Stiffness of Cement Treated Mixture 9