Excercises with solutions on RC-I

advertisement

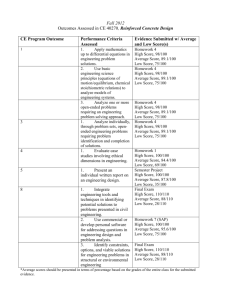

Assignment on Reinforced Concrete I 1 CIVIL SERVICE COLLAGE DEPARTMENT OF URBAN ENGINEEREING 1. Determine the ultimate moment capacities of singly reinforced rectangular beams with dimensions and quantity of reinforcement bars. a) Using the parabolic-rectangular stress block for the concrete and elastic – perfect strain curve for reinforcement. b) Using the expressions of αc and βc developed using the parabolic – rectangular stress c) Using the simplified-rectangular stress block for the concrete and elastic – perfect strain curve for reinforcement. Data: Beam size: b = 250mm h = 600mm Concrete grade: C20 d Steel grade: S460 Clear cover: C = 25mm Reinforcement: i) 2 ф 16 bars ii) 6 ф 25 bars the following plastic stressblock. plastic stress- 250mm Comment on the type of failure in each case. Solution: a. Using the parabolic-rectangular stress block for the concrete and elastic – perfect plastic stress-strain curve for reinforcement. i) 2 ф 16 bars 1. Design Strength : f cd 0.68 f c y s 0.68 * 20 9.07 N m 2 1.5 fyk 460 400 s 1.15 EffectiveDepth fyd d h c 600 25 8 567 mm 2 Let the strain distribution lie in zone - 3 c 0.0035 zone 3 yd s 0.01 X’ Endeshaw Tafesse ID-UEAR-0018/02 Assignment on Reinforced Concrete I 2 Computation of forces i. For Rectangular part Ccr bx x' fcd But, from similarity of triangle 0.002 x 0.571x 0.0035 Ccr 250 x 0.571x 9.07 927.7575 x x' ii. For parabolic dF fc y dA x' 0.571 0 0 Ccp fc( y )dA fc( y)bdy But fc(y)=1000єc(y)(1-250 єc(y)) fcd But from similarity of triangle y c y * 0.0035 x y y fcy 1000 * 0.0035 (1 250 * 0.0035 ) * 9.07 x x 2 y y fcy 31.745 27.78 2 x x x' 0.571 y y2 Ccp fc( y )dA (31.745 27.78 2 ) * 250dy x x 0 0 0.571x y2 y3 Ccp 31.745 27.78 2 2x 3x 0 Ccp 862.75 x Total Cc = CcR + Ccp = 927.75x + 862.75x = 1790.50x Horizontal force equation as per assumption fs= fyd 16 2 Ts Asfyd 2( * ) * 400 4 Ts 160849.544 But Cc = Ts 1790.50x = 160849.54 x = 89.83 mm Endeshaw Tafesse ID-UEAR-0018/02 Assignment on Reinforced Concrete I 3 Check the assumption From similarity of triangle 0.0035 s 0.0035 567 89.83 s 0.01855 0.01 The assumption is failed! Let say the assumption of strain is lie in zone-2 0 c 0.0035 zon 2 s 0.01 Computation of forces i. For Rectangular part Ccr bx x' fcd But,from similarity of triangle 0.002(567 x) x 0.2(567 x) 0.01 Ccr 250 x 0.2(567 x) 9.07 2721x 257134.5 x' iii. For parabolic dF fc y dA x' 0.571 0 0 Ccp fc( y )dA fc( y)bdy But fc(y)=1000єc(y)(1-250 єc(y)) fcd But from similarity of triangle 0.01 y c y 567 x 0.01 y 0.01 y fcy 1000 * ) * 9.07 (1 250 * 567 x 567 x 90.7 y 226.75 y 2 fcy 567 x 567 x 2 x' Ccp fc( y )dA 0 0.2 ( 667 x ) 0 ( 90.7 y 226.67 y 2 ) * 250dy 567 x 567 x 2 0.2 ( 667 x ) 90.7 y 226.67 y 2 Ccp 250 2 567 x 567 x 0 Ccp 171375.75 302.25 x Total Cc = CcR + Ccp = 2418.75x – 85758.75 Endeshaw Tafesse ID-UEAR-0018/02 Assignment on Reinforced Concrete I 4 Horizontal force equation as per assumption fs= fyd 16 2 Ts Asfyd 2( * ) * 400 4 Ts 160849.544 But Cc = Ts 2418.75x – 85758.75 = 160849.54 x = 102 mm Check the assumption From similarity of triangle 0.01 c c 567 102 c 0.0022 0 0.0022 0.0035,........ The assumption is ok ! Moment resistance, Mrd = M1 + M2 + M3 M 1 f cd b( x x' )( x' x x' ) 2 102 58 ) 2 M 1 281170 Nmm 0.28KN .m dM 2 dF M 1 9.07 * 250(102 58)(58 For the rectangular: x' 0.2 ( 567 x 0.2 ( 567 x 0 0 0 M 2 dFy 0.2 ( 567 x For parabolic: M2 0 fcydAy fcybydy 90.7 y 226.67 y 2 y * 250dy 2 567 x 567 x 0.2 ( 567 x ) 90.7 y 3 226.67 y 4 M 2 250 2 3567 x 4567 x 0 M 2 8178710.625 Nmm 8.18 KNm M 3 Ts(d x) For tension: M 3 160849.54(465 102) M 3 74795037.91Nmm 74.79 KNm Moment resistance, Mrd = M1 + M2 + M3 = 0.28 + 8.18 + 74.79 = 83.25KNm Endeshaw Tafesse ID-UEAR-0018/02 Assignment on Reinforced Concrete I b. Using 5 the expressions of αc and βc developed using the parabolic – rectangular stress block. Solution: Effective depth, d = 567mm Design strength: fcd = 9.07N/mm2 fyd = 400N/mm2 Assume the strain profile in the ULS to lie in zone 2 (guessing the write profile) It corresponds to case (ii) i.e. cm ≥o and N.A with in the section αc = 3 cm 2 kx 3 cm βc = [ cm (3 cm 4) 2 kx ] 2 cm (3 cm 2) From the above strain diagram: cm x 10 dx x 10 2 x c d x x d 3 10 dx 3 3x(10) 2(d x) x 3x(10) d 303 2 x 2d 30d 32 x 2(567) 30(567) Endeshaw Tafesse ID-UEAR-0018/02 Assignment on Reinforced Concrete I 6 32 x 1134 17010 Equilibrium equations: From ∑Fx = 0: Cc = Ts αc fcd b d = As1 fyd (32 x 2(567)) *9.07*250*567 = 246559.5 (as calculated before) 30(567) x = 102mm βc = 13.2273 x 33.30616 d = 0.07144 βcd = 40.5086mm Z = d - βcd = 526.49mm Therefore; MRd = Ts*Z = 246559.5 *526.49 = 84685095.05Nmm MRd = 84.68KNm c. Using the simplified-rectangular stress block for the concrete and elastic – perfect plastic stress-strain curve for reinforcement. Assume the strain profile in the ULS to lie in zone 2 (guessing the write profile) As calculated and checked in the above solution. Endeshaw Tafesse ID-UEAR-0018/02 Assignment on Reinforced Concrete I 7 Cc Ts 0.8 xfcd b As f yd 0.8 x(9.07 * 250) 400 * 402.12 x 88.67mm Mrd Ts (d 0.4 x) 400 * 402.12 * (567 (0.4 * 88.67)) 85495507.6 N / mm 2 Mrd 85.49 KN / m 2 ii) 6 ф 25 bars a. Using the parabolic-rectangular stress block for the concrete and elastic – perfect plastic stressstrain curve for reinforcement. Let say the assumption of strain is lie in zone-2 c 0.0035 zon 4 0 s yd Computation of forces i. For Rectangular part Ccr bx x' fcd But,from similarity of triangle 0.002( x) x 0.571x 0.0035 Ccr 250 x 0.571x 9.07 927.7575 x x' ii. For parabolic iii. For parabolic dF fc y dA x' 0.571 0 0 Ccp fc( y )dA fc( y)bdy But fc(y)=1000єc(y)(1-250 єc(y)) fcd But from similarity of triangle y c y * 0.0035 x y y fcy 1000 * 0.0035 (1 250 * 0.0035 ) * 9.07 x x 2 y y fcy 31.745 27.78 2 x x Endeshaw Tafesse ID-UEAR-0018/02 Assignment on Reinforced Concrete I x' Ccp fc( y )dA 0 8 0.571 2 (31.745 0 y y 27.78 2 ) * 250dy x x 0.571x y2 y3 Ccp 31.745 27.78 2 2x 3x 0 Ccp 862.75 x Total Cc = CcR + Ccp = 927.75x + 862.75x = 1790.50x Horizontal force equation as per assumption fs is not yielded fs Es from..similarity ..of ..triangle s c dx x c(d x) 0.0035(562.5 x) 1.969 0.0035 x s x x x 1.969 0.0035 x 393750 700 x fs Es 200000 * x x 393750 700 x 1159689431 2061670.1x Ts Asfs 2945.243 * x x But Cc = Ts 1159689431 2061670.1x 1790.51x x x 413.79 fs 251.57 Ts 740933.71 Check the assumption From similarity of triangle 0.0035(562.5 413.79 s 413.79 s 0.001257 0.0035 The assumption is ok ! Moment resistance, Mrd = M1 + M2 + M3 x x' ) 2 M 1 9.07 * 250(0.429 * 413.79)(0.714 * 413.79) M 1 f cd b( x x' )( x' For the rectangular: M 1 118922158 Nmm 118.92 KN .m For parabolic: Endeshaw Tafesse ID-UEAR-0018/02 Assignment on Reinforced Concrete I 9 dM 2 dF x' 0.571x 0.571x 0 0 0 M 2 dFy 0.571x M2 0 fcydAy fcybydy 31.745 y 27.78 y 2 y * 250dy x x2 0.571x 31.745 y 3 27.78 y 4 M 2 250 4x 2 0 3x M 2 52724762.66 Nmm 52.72 KNm M 3 Ts(d x) For tension: M 3 740933.71(562.5 413.79) M 3 110184252.2 Nmm 110.18KNm Moment resistance, Mrd = M1 + M2 + M3 Mrd = 281.83KNm b. Using the expressions of αc and βc developed using the parabolic – rectangular stress block Solution Effective depth, d = 567mm Design strength: fcd = 9.07N/mm2 fyd = 400N/mm2 Assume the strain profile in the ULS to lie in zone 4 (guessing the write profile) It corresponds to case (ii) i.e. cm ≥o and N.A with in the section αc = 3 cm 2 kx 3 cm βc = [ cm (3 cm 4) 2 kx ] 2 cm (3 cm 2) For zone 3; εcm = εcu = 0.0035 Endeshaw Tafesse ID-UEAR-0018/02 Assignment on Reinforced Concrete I 10 Substituting this value in to the above expressions: αc = 0.8095kx βc = 0.416kx Equilibrium equations: From ∑Fx = 0: Cc = Ts αc fcd b d = As1 fyd 0.8095kx*9.07*250*562.5 = 2945.243(fs) (as calculated before) But 393750 700 x fs x x x 10324991.953k x x 1159689431 2061670.1x,......but.kx d 562.5 x 411.64mm kx 0.732 kz 1 c From ∑M = 0: MRd = αc fcd b d2 kz = αc fcd b d2 (1-βc ) = 0.8095kx*9.07*250*562.52(1-0.416*0.732) = 295671813.1Nmm = 295.67KNm Endeshaw Tafesse ID-UEAR-0018/02 Assignment on Reinforced Concrete I d) 11 Using the simplified-rectangular stress block for the concrete and elastic – perfect plastic stressstrain curve for reinforcement. Assume the strain profile in the ULS to lie in zone 2 (guessing the write profile) As calculated and checked in the above solution Cc Ts 0.8 xfcd b As f s As 2945.243 fs 393750 700 x x 0.8 x(9.07 * 250) 2945.243 393750 700 x x x 412.63mm Ts 748493.663 Mrd Ts (d 0.4 x) 748493.663 * (562.5 (0.4 * 412.63)) 297487309.2 N / mm 2 Mrd 297.49 KN / m 2 2. Find the ultimate moment capacity for the RC slab shown in fig. below. a. Using the parabolic-rectangular stress block for the concrete and elastic – perfect plastic stressstrain curve for reinforcement. b. Using the expressions of αc and βc developed using the parabolic – rectangular stress block. c. Using the simplifiedrectangular stress block for 12 c/c 180mm the concrete and elastic – perfect plastic stress-strain h = 150mm curve for reinforcement. Data: Thickness of slab = 150mm Concrete grade: C25 Steel grade: S300 Reinforcement: ф12 c/c 180mm Clear cover: C = 20mm Take 1m width for analysis purpose. 1m wide Solution: a. Using the parabolic-rectangular stress block 1. Design Strength : Endeshaw Tafesse ID-UEAR-0018/02 Assignment on Reinforced Concrete I f cd 0.68 f c y s 12 0.68 * 25 11.33 N m 2 1.5 fyk 300 260.87 N / m 2 s 1.15 EffectivDepth fyd d 124mm Let say the assumption of strain is lie in zone-2 0 c 0.0035 zon 2 s 0.01 Computation of forces i. For Rectangular part Ccr bx x' fcd But,from similarity of triangle 0.002(124 x) x 0.2(124 x) 0.01 Ccr 250 x 0.2(124 x) 11.33 13569 x 280984 x' ii. For parabolic dF fc y dA x' 0.2 (136 x ) 0 0 Ccp fc( y )dA fc( y)bdy But fc(y)=1000єc(y)(1-250 єc(y)) fcd But from similarity of triangle 0.01 y c y 124 x 0.01 y 0.01 y fcy 1000 * ) * 11.33 (1 250 * 124 x 124 x 113.3 y 283.25 y 2 fcy 124 x 124 x 2 x' 0.2 (124 x ) 0 0 Ccp fc( y )dA 113.3 y 283.25 y 2 ( ) *1000dy 124 x 124 x 2 0.2 (124 x ) 113.3 y 283.25 y 2 Ccp 1000 2 124 x 124 x 0 Ccp 187364 1511x Total Cc = CcR + Ccp = 12058x – 93620 Endeshaw Tafesse ID-UEAR-0018/02 Assignment on Reinforced Concrete I 13 Horizontal force equation as per assumption fs= fyd 12 2 Ts Asfyd 2( * ) * 260.87 4 Ts 163908.83 But Cc = Ts 12058x – 93620= 163908.83 x = 21.36 mm Check the assumption From similarity of triangle 0.01 c c 124 21.36 c 0.0021 0 0.0021 0.0035,........ The assumption is ok ! Moment resistance, Mrd = M1 + M2 + M3……….about neutral axis x x' M 1 f cd b( x x' )( x' ) 2 21.36 12.63 For the rectangular: M 1 11.33 *1000(21.36 12.63)(12.63 ) 2 M 1 1741950.814 Nmm 1.742 KN .m dM 2 dF x' 0.2 (124 x ) 0.2 (124 x ) 0 0 0 M 2 dFy 0.2 (124 x ) For parabolic: M2 0 fcydAy fcybydy 113.3 y 283.25 y 2 y * 1000dy 2 124 x 124 x 0.2 (124 x ) 113.3 y 3 283.25 y 4 M 2 1000 2 3124 x 4124 x 0 M 2 1987948.764 Nmm 1.99 KNm M 3 Ts(d x) For tension: M 3 160849.54(124 21.36) M 3 16.82 Nmm Moment resistance, Mrd = M1 + M2 + M3 = 20.552KNm Assume the strain profile in the ULS to lie in zone 2 (guessing the write profile) It corresponds to case (ii) i.e. Endeshaw Tafesse ID-UEAR-0018/02 Assignment on Reinforced Concrete I 14 cm ≥o and N.A with in the section αc = 3 cm 2 kx 3 cm βc = [ cm (3 cm 4) 2 kx ] 2 cm (3 cm 2) From the above strain diagram: cm x 10 dx x 10 2 x c d x x d 3 10 dx 3 3x(10) 2(d x) x 3x(10) d 303 2 x 2d 30d 32 x 2(124) 30(124) c 32 x 248 3720 Z = d - βcd = 115.54 13.2273 x 0.06825 33.30616 d Equilibrium equations: From ∑Fx = 0: Cc = Ts αc fcd b d = As1 fyd 32 x 2(124) *11.33*1000*124 = 163908.837 (as calculated before) 30(124) x = 21.31 Endeshaw Tafesse ID-UEAR-0018/02 Assignment on Reinforced Concrete I 15 Therefore; MRd = Ts*Z = 163908.827*115.54 = 18937515.78Nmm = 18.93KNm d. Using the simplified-rectangular stress block for the concrete and elastic – perfect plastic stress-strain curve for reinforcement. Assume the strain profile in the ULS to lie in zone 2 (guessing the write profile) As calculated and checked in the above solution. Cc Ts 0.8 xfcd b As f yd 0.8 x(11.33 * 250) 163908.83 x 18.08mm Mrd Ts (d 0.4 x) 163908.83(124 (0.4 * 18.08)) 19139076.91N / mm 2 Mrd 19.14 KN / m 2 2. Determine the moment capacity of a simply supported beam of trapezoidal cross-section for the following data. a. Using the parabolic-rectangular stress block for the concrete and elastic – perfect plastic stress-strain curve for reinforcement. b. Using the simplified-rectangular stress block for the concrete and elastic – perfect plastic stress-strain curve for b2 reinforcement. Data: Concrete: C30 Steel: S400 h b1/b2/h = 300/500/600 As1 = 5ф25 bars in one layer 525 bars Cover, c = 25mm Solution: b1 From similarity of triangle from the fig. a) Using the parabolic-rectangular stress block for the concrete and elastic – perfect plastic stress-strain curve for reinforcement. Endeshaw Tafesse ID-UEAR-0018/02 Assignment on Reinforced Concrete I 16 b2 b1 b b h 2 m 2 1 h x y m hx y 2h b h b2 b1 b b h x y bx b1 m b1 2 1 h x y * 2 1 h 2h Computation of forces dF = fcddA dF2 f cd dA......., dA bx dy x x b1 h b2 b1 h x y dy h x' x C R f cd dA f cd bx dy f cd x' CR x' f cd h x b h b 1 2 b1 h x y dy 0.571x C R 2917.2 x 0.406 x 2 y y2 41.65 2 x x .0.571x 2 y y b h b2 b1 h x y dy f cy dA 47.6 41.65 2 1 x h x 0 dF2 f cy dA......., dA bx dy,.... fcy 47.6 x' Cp 0 .0.571x Cp 0 y y2 47.6 41.65 2 x x 300 * 600 500 300 600 x y dy 600 0.571 1 4228 * 10 4 y 2 12495 * 10 3 y 3 8330 * y 4 17850 * y 3 9520 * y 2 Cp 600 2x 3x 2 3x 2 4x 2 0 C p 2587.562 x 1.11x 2 C c C p C R 5504.762 x 1.516 x 2 Ts Asfyd 5( * 25 2 ) * 347.83 4 Ts 853693.6559 Cc=Ts, 5504.762x – 1.516x2 = 854120.503 x = 162.34mm Moment resistance, Mrd = M1 + M2 + M3……….about neutral axis Endeshaw Tafesse ID-UEAR-0018/02 Assignment on Reinforced Concrete I 17 600 530.32 m 88.387 bm 2m b1 476.77 mm 100 m 100 * 437.576 n 72.929 bn 2n b1 445.859mm 600 From similarity of triangl b bm br 2 488.387 mm 2 b bn bn 2 461.316mm 2 For the rectangular: M 1 f cd br (0.429 x)(0.7855 x) M 1 2238.238 x 2 M 1 59048192.4 Nmm 59.05 KN .m dM 2 dF x' 0.571x 0 0 M 2 dFy 0.571x For parabolic: M2 0 0.571x fcydAy fcybydy 0 47.6 y 41.65 y y * 461.316dy x2 x 2 0.571x 47.6 y 3 41.65 y 4 M 2 461.316 4x 2 0 3x M 2 22479916.13 Nmm 22.48 KNm M 3 Ts(d x) For tension: M 3 853693.6559(562.5 162.424) M 3 341542343.1Nmm 341.54 KNm Moment resistance, Mrd = M1 + M2 + M3 = 423.07 KNm b) Using the simplified-rectangular stress block for the concrete and elastic – perfect plastic stress-strain curve for reinforcement. From similarity of triangle. 600 600 0.8 x m 100 0.133x 100 m bm 2(100 0.133x) 300 500 0.267 x br 500 0.267 x 500 500 0.133x 2 Endeshaw Tafesse ID-UEAR-0018/02 Assignment on Reinforced Concrete I 18 Cc Ts 0.8 xfcd br As f yd 0.8 x *13.6 * (500 0.133x) 853693.6559 x 164.113mm Mrd Ts (d 0.4 x) 853693.6559(562.5 (0.4 *164.113)) 424161871.1N / mm 2 Mrd 424.16 KN / m 2 3. Compare the moment capacities for singly reinforced rectangular beams having the following properties. Beam no. 1 2 3 4 5 a. b (mm) 300 300 300 300 300 d (mm) 550 550 550 550 830 Reinforcement bars 3 ф 22 4 ф 24 3 ф 22 3 ф 22 3 ф 22 Grade of concrete C20 C20 C20 C30 C20 Grade of steel S460 S460 S300 S460 S460 Taking beam 1 as the reference point, discuss the effects of changing the area of reinforcement, grade of concrete, grade of steel and effective depth on the ultimate moment capacities. Note: Each beam has the same properties as beam 1 except for italicized quantity. b. Beam no. What is the most effective way of increasing the ultimate moment capacities? What is the least effective way? b (mm) 300 300 300 300 300 1 2 3 4 5 d (mm) 550 550 550 550 830 Beam no. b (mm) d (mm) 1 2 3 4 5 300 300 300 300 300 550 550 550 550 830 Reinforcement bars 3 ф 22 4 ф 24 3 ф 22 3 ф 22 3 ф 22 Reinforcement bars 3 4 3 3 3 ф ф ф ф ф 22 24 22 22 22 fctd 9.07 9.07 9.07 13.6 9.07 Grade of concrete C20 C20 C20 C30 C20 fyd 400 400 260.87 400 400 x Grade of steel S460 S460 S300 S460 S460 fctd fyd 9.07 9.07 9.07 13.6 9.07 400 400 260.87 400 400 Asf yd x 0.636d 0.8 f cd b ( x 0.74d ) 209.78 332.88 136.82 139.86 209.78 349.94 349.93 400 349.94 528.08 M Asf yd d 0.4 x 212.61 301.72 147.34 225.37 340.33 Endeshaw Tafesse ID-UEAR-0018/02 Assignment on Reinforced Concrete I 19 5. A two span continuous rectangular beam has been supported by three girders spaced 6m on centers as shown in fig below. Check whether the beam is safe or not for the following data. Data: Loading: Live load, LL = 15KN/m Dead load, DL = 25KN/m (excluding the self weight of the beam) Dimensions: b/h/d = 300/600/550 Material: Concrete grade: C25 Steel grade: S460 A A B B 6m 6m 420bars 420bars 550mm 550mm 300mm Solution: section A-A 300mm Section B-B 1. Design Strength : f cd 0.68 f c y s 0.68 * 25 11.33 N m 2 1.5 fyk 460 400 N / m 2 s 1.15 EffectivDepth fyd d 550mm 2. Analysis: Pd 1.3DL 1.6 LL Pd 1.3 25 25 KN / m 3 * 0.3 * 0.6 1.6 * 15 KN / m Pd 62.35 KN / m By using Cross method Relative stiffness: K I 1 L Endeshaw Tafesse ID-UEAR-0018/02 Assignment on Reinforced Concrete I - 20 Distribution Factor: DFBA, BC - K 1 0.5 K 2 DF AB, BC 1 Fixed End Moment WL2 62.35 * 6 2 187.05KNm 12 12 WL2 62.35 * 6 2 187.05KNm 12 12 M F AB M F BC M F BA M F CB Jont member DF FEM CO Final Moment M A A AB 1 187.05 -187.5 0 B BA 0.5 -187.05 -93.525 -280.575 C CB 1 187.05 187.05 0 BC 0.5 187.05 93.525 280.575 0 R2 * 6 280.575 62.35 * 6 2 R2 233.81KN F H 0 : R1 R2 62.35 * 6 R1 140.29 KN To find maximum Moment and Shear force Vx R1 62.35 x 140.29 62.35 x Mx R1 x 62.35 x2 x2 140.29 x 62.35 2 2 To obtained, maximum moment shear forc is zero, Vx=0 140.29 62.35 x 0 x 140.29 2.25m 62.35 M max 140.29 * 2.25 62.35 2.25 2 2 M max 157.83KNm BMD Endeshaw Tafesse ID-UEAR-0018/02 Assignment on Reinforced Concrete I 21 For Section A-A Let the strain distribution lie in zone - 3 c 0.0035 zone 3 yd s 0.01 Force equation: Cc Ts 0.8 xfcd b As f yd 0.8 x(11.33 * 300) 4( * 20 2 )400 4 x 184.85mm Check assumption: From similarity of triangle 0.0035 s 0.0035 s 0.0069 550 184.85 fyd 400 yd 0.002 Es 200 * 10 3 yd s 0.01 The assumption is ok! Moment equation Mrd 0.8xfcdb(d 0.4 x) 0.8 *184.85 *11.33 * 300(550 0.4 *185) Mrd 239.45KNm 157.83KNm The beam is safe for coming moment For section B-B Let the strain distribution lie in zone - 3 c 0.0035 zone 3 yd s 0.01 Cc Ts 0.8 xfcd b As f yd 0.8 x(11.33 * 300) 4( * 20 2 )400 4 x 184.85mm Check assumption: From similarity of triangle Endeshaw Tafesse ID-UEAR-0018/02 Assignment on Reinforced Concrete I 22 0.0035 s 0.0035 s 0.0069 550 184.85 fyd 400 yd 0.002 Es 200 * 10 3 yd s 0.01 The assumption is ok! Moment equation Mrd 0.8xfcdb(d 0.4 x) 0.8 *184.85 *11.33 * 300(550 0.4 *185) Mrd 239.45KNm 157.83KNm The beam is not safe for coming moment. 6. Determine the ultimate moment capacity of a doubly reinforced rectangular section with the following data. Given: b/h = 250/450mm cover, c = 25mm Concrete: C30 Steel: S460 As1 = 8ф24 bars in two layers As2 = 4ф18 bars d-x 1, Design Strength: From similarity of triangle Endeshaw Tafesse ID-UEAR-0018/02 Assignment on Reinforced Concrete I f cd 0.68 f c y s 0.68 * 30 13.6 N m 2 1.5 fyk 460 400 N / m 2 s 1.15 EffectivDepth 23 s1 fyd y 4( y1 As1 ) 4( y 2 As1 ) 47 mm 4( As1 As1 ) dx cc x x d 1 s1 cc fyd 400 0,002 E 200 * 10 3 xl im 0.636d 256.31mm s1 d 450 (47) 403mm d 2 25 18 34mm 2 Force equation: Cc Cs Ts 0.8 xfcd b Asfyd As f yd 18 2 24 2 )400 8( * )400 4 4 382.54mm xlim 256.31mm..........ok! 0.8 x(13.6 * 250) 4( * x req Compression reinforcement is required. M 1 0.8 xfcdb(d 0.4 x) M 1 0.8 * 262.67 *13.6 * 250(403 0.4 * 262.67) M 1 212861211.8KNm 212.86 KNm from...similarity ...of ...triangle s 2 xlim d 2 228.67 cc 0.0035 0.003 yd 0.002 xlim 262.67 ItisYielde d M 2 As12 fyd (d d 2 ) 1832.95 * 400(403 34) M 2 270544010.4 Nmm 270.54 KNm Cc Ts1 0.8 xfcd b As11 fyd 0.8 * 262.67 *13.6 * 250 1786.156mm2 400 24 2 As12 As1 As11 8( * ) 1786.15 1832.95mm2 4 As11 Mrd M1 M 2 212.86 270.54 483.40KNm Endeshaw Tafesse ID-UEAR-0018/02 Assignment on Reinforced Concrete I 24 7. Determine the flexural reinforcement for the rectangular concrete beam with the following data. Given: Dimensions: b/h = 600/400mm Cover, c = 25mm Loading: Msd = 500KNm Material Strengths: Concrete: C30 Steel: S-460 Solution: d-x f cd 0.68 f c y s 0.68 * 30 13.6 N m 2 1.5 fyk 460 400 N / m 2 s 1.15 Effectivdepth fyd Let..us..use.. 20.bars 20 d 400 (25 ) 365mm 2 20 d 2 25 35mm 2 Ductility ..requirment : x 0.8( 0.44) 0.448 d 163.52mm xlim Kxmax x max M sd 0.8 xfcd b(d 0.4 x) 500 * 10 6 0.8 x *13.6 * 600 * (365 0.4 x) xreq x lim ...comression. x 912.5 x 191482.84 .re inf orcement..is..required 2 x 327.1mm x req Part I F 0,....Cc Ts,. 0.8 xlim f cd b As11 fyd As11 0.8 * 163.52 *13.6 * 600 2668.65mm 2 400 H Endeshaw Tafesse ID-UEAR-0018/02 Assignment on Reinforced Concrete I 25 M : M 1 Cc * z1 0.8 xlim f cd b(d 0.4 x) M 1 0.8 *163.52 *13.6 * 600 * (365 0.4 *163.52) M 1 319.8KNm M 2 M sd M 1 500 319.8 180.2 KNm Part II M 2 Ts 2(d d 2 ) As12 * fyd (d d 2 ) 180.2 * 102 As12 * 400 * 330 As12 1365.15mm 2 As1 As11 As12 4033.80mm 2 N o.. 20bar 4033.8 12.84...... provide..13 20..bar.. for..tension..re inf orcement. 20 2 * 4 Let assume that compression reinforcement is yielded, fs2 = fyd F H 0,....As2 f yd As12 fyd As2 As12 1365.15mm2 Check the assumption From similarity of triangle s 2 xlim d 2 163.52 35 cc 0.0035 0.00275 yd 0.002 xlim 163.52 ItisYielde d ..........the...asumption...is...ok! As 2 1365.15mm 2 N o.. 20 1365.15 4.34......... provide....5 20...bars 20 2 * 4 8. Determine the quantity of reinforcement for the isolated T-beam shown in fig. below Given: bf Msd = 550KN/m Concrete: C25 hf Steel: S460 d Effective depth, d = 400mm Width of web, bw = 250mm Effective flange width, bf = 1000mm Thickness of flange, hf = 100mm bw Use ф20 bars Endeshaw Tafesse ID-UEAR-0018/02 Assignment on Reinforced Concrete I 26 Solution: Assume that the Neutral axis lie in Flange c beff h f cd Cc = 0.8xf cdbeff x 0.8x hf N.A d z = (d - 0.4x) s As fs T s =Asf y d bw strains x-section stresses resultant internal forces Using rectangular method: Moment Equation M sd 0.8 xfcd b(d 0.4 x) 550 * 10 6 0.8 x * 11.33 * 1000 * (400 0.4 x) 3616 x 2 3616000 x 550 *10 6 x 187.113mm x req h f 100mm The assumption is failed! The neutral axis lies in the web beff c fcd hf hf Cc1= h f(beff - bw)fcd fcd Cc2 = 0.8xfcdbw x 0.8x N.A h d As1 z1 = (d - 0.5h f) + s z2 = (d - 0.4x) T s1 =Asffy d T s2 =(As1 - Asf)fy d bw x-section strains Part I of the solution Overhanging portion Part II of the solution web portion For part I M 1 h f (beff bw) f cd (d 0.5h f ) M 1 100(1000 250)11.33(400 0.5 * 100) 297412500 Nmm M 1 297.41KNm M 1 Asf f yd (d 0.5h f ) Asf M1 297412500 2124.375mm 2 f yd (d 0.5h f ) 400(400 0.5 * 100) 2124.375 6.76......... provide....7 20...bars 20 2 * 4 M 1 550 297.41 252.59 KNm N o.. 20 M 2 M sd Endeshaw Tafesse ID-UEAR-0018/02 Assignment on Reinforced Concrete I 27 Ductility ..requirment : x 0.8( 0.44) 0.448 . d 179.2mm xlim x req 187.113mm Kxmax x max Compression reinforcement is required for Part II Part II d-x For Part II – I M 21 0.8 xfcd b(d 0.4 x) M 21 0.8 * 179.2 *11.33 * 250 * (400 0.4179.2) 133.32 KNm As11 0.8 xfcd b 0.8 *179.2 * 11.33 * 250 1012.48mm 2 f yd 400 M 2 2 M 2 M 21 252.59 133.32 119.27 KNm M 2 2 As12 f yd (d d 2 ) As12 M 22 119.27 * 10 6 816.92mm 2 f yd (d d 2 ) 400(400 35) As1 As11 As12 1829.40mm 2 N o.. 20 1829.40mm 2 5.8......... provide....6 20...bars 20 2 * 4 Assume that compression reinforcement yielded, fs=fyd F H 0,....Cc Ts As2 fyd As12 f yd As2 As12 As2 816.92mm 2 Endeshaw Tafesse ID-UEAR-0018/02 Assignment on Reinforced Concrete I 28 Check assumption s 2 x lim d 2 179.2 35 cc 0.0035 0.00282 yd 0.002 x lim 179.2 ItisYielde d ..........the...asumption...is...ok! As 2 816.92mm 2 N o.. 20 9. 816.92 2.6......... provide....3 20...bars 20 2 * 4 Compute the negative and positive moment capacities of the T-beam shown in fig. below. Given: Concrete: C25 Steel: S460 225 bars 625 bars Overall depth, h = 550mm Width of web, bw = 300mm Thickness of flange, hf = 150mm 25 bars Cover, c = 25mm Note: Neglect the effect of bottom 6m bars as compression reinforcement longitudinal view at the supports Consider the effect of the top bars as compression reinforcement at mid span At the supports the bars are in 3m 3m one layer section view At mid span, the bottom bars are in two layers Take the spacing b/n the bars equal to the diameter of the bar Solution: a) Design strength Endeshaw Tafesse ID-UEAR-0018/02 Assignment on Reinforced Concrete I f cd 0.68 f c y s 29 0.68 * 25 11.33 N m 2 1. 5 fyk 460 400 N / m 2 s 1.15 EffectivDepth fyd y1 25 12.5 37.5mm y 2 25 25 12.5 62.5mm y y1 A1 y 2 A2 50mm A1 A2 d 550 (50) 500mm 25 37.5mm 2 lo 0.85l 0.85 * 3000 2250mm 1 1 bw l o 2 300 * 2250 810mm beffec 5 5 b actul 3000mm d 2 25 beffec 810mm hf = 150mm Cc Cs Ts 0.8 xfcd b Asfyd As f yd 25 2 25 2 )400 6( * )400 4 4 107.26mm hf 150mm..........ok! 0.8 x(11.33 * 810) 2( * x req M 1 0.8 xfcdb(d 0.4 x) M 1 0.8 *107.26 *11.33 * 810(500 0.4 *107.26) M 1 359956590 KNm 359.96 KNm 359956590 1968.71 400500 0.4 *107.26 As12 As1 As11 6490.874 1968.71 976.533 As11 Positive moment M t M1 M 2 M t 360.414 KNm Endeshaw Tafesse ID-UEAR-0018/02 Assignment on Reinforced Concrete I 30 For negative moment Cc Cs Ts 0.8 xfcd b As f yd 25 2 0.8 x(11.33 * 810) 6( * )400 4 x req 433.25mm.. d 550 37.5 512.5mm M As12 fyd (d 0.4 x) M 6 * 490.874 * 400(512.5 4 * 433.25) M 399609978 Nmm 399.61KNm 10. A concrete floor system consists of one way slabs framed by beams as shown in fig below. The slab is poured monolithically with the beam. i) Design the slab for flexure ii) Design the beam on axis-1 and axis-2 for flexure. Data: Dimensions: Slab thickness = 150mm 6m Beam web width, bw = 300mm Over all depth, h = 450mm Loading: LL = 3.5KN/m2 DL from partition and finishing = 2kN/m2 6m Material Strengths: Concrete: C20 Steel: S300 Weight of concrete = 25KN/m3 6m Use ф 10 for the slab and ф20 for the beams Note: Consider the different loading cases and 3m 3m 3m the moment envelop 1 2 3 4 Solution: Endeshaw Tafesse ID-UEAR-0018/02 Assignment on Reinforced Concrete I 1) f cd fyd 31 Design Strength: 0.68 f c y s 0.68 * 20 9.07 N mm 2 1 .5 fyk 300 260.87 N / mm 2 s 1.15 2 2 0.21 fck 3 0.21( 20) 3 fctd 1.345 N / mm 2 s 1.15 2) Analysis: Design Load: Pd 1.3DL 1.6 LL Pd 1.3 (2 KN / m 2 *1m) 25KN / m 3 * 0.15 *1 1.6(1m * 3.5KN / m) Pd 13.075KN / m - By using Cross method Fixed End Moment WL2 13.075 * 6 2 9.81KNm 12 12 WL2 13.075 * 6 2 9.81KNm 12 12 M F AB M F BC M F CD M F BA M F CB M F DC Endeshaw Tafesse ID-UEAR-0018/02 Assignment on Reinforced Concrete I Joint member Relative stiffness, (End pine support, B BA BC C CB CD 3 I ( ) 4 3 I 3 I 3 3 I ( ) 4 3 Jont A member DF FEM CO Initial Moment Balance CO Balance CO Balance CO Balance Final Moment at support AB 1 9.81 -9.81 0 0 32 Total relative stiffness I ) K 3 I ( )) 4 K ( I 4 I ( ) K Disribiution factor I ) K I K 3 7 4 7 4 7 3 7 ( 7I 4 7I 4 I 4 B BA 3/7 -9.81 -4.905 -14.715 2.102 0.6006 0.1716 0.049 -11.7918 C BC 4/7 9.81 0 9.81 2.803 -1.4015 0.8009 -0.4004 0.2288 -0.1144 0.0654 11.7918 CB 4/7 -9.81 0 -9.81 -2.803 1.4015 -0.8009 0.4004 -0.2288 0.1144 -0.0654 -11.7918 D CD 3/7 9.81 4.905 14.715 -2.102 -0.6006 -0.1716 -0.049 11.7918 DC 1 -9.81 9.81 0 0 Reaction forces Rxn due to load Rxn due to Moment Final Rxn A 19.6125 -3.93 RA= 15.68 B 19.6125 19.6125 3.93 0 RB= 43.155 C 19.6125 19.6125 0 3.93 RC= 43.155 D 19.6125 -3.93 RD= 15.68 Endeshaw Tafesse ID-UEAR-0018/02 Assignment on Reinforced Concrete I 33 To fined maximum Moment and Shear force For span AB & CD Vx R1 13.075 x 15.68 13.075 x Mx R1 x 13.075 x2 x2 15.68 x 13.075 2 2 To obtain, maximum moment shear force is zero, Vx=0 15.68 13.075 x 0 x M max 15.68 *1.2 13.075 15.68 1.2m 13.075 1.2 2 2 M max 9.402 KNm For span BC Vx R1 13.075 x 58.835 13.075 x x2 x2 Mx R1 x 43.155( x 3) 13.075 58.835 x 129.465 13.075 2 2 To obtained, maximum moment shear force is zero, Vx=0. 58.835 13.075 x 0 x a) 58.835 4.5m 13.075 M max 58.835 * 4.5 13.075 4.5 2 129.465 2 M max 2.908KNm Design Slab for flexure Reinforcement Effective Depth determination d 150 (20 10 ) 125mm 2 Maximum, spacing S max S max i. ab f yk 78.5 * 260.87 327.82mm 0.5 *125 0.5d 2h 2 * 150 300mm 350mm 300mm For span AB & CD, Msd = 10.424KNm By using general design chart Method. sd M sd 10.424 *10 6 0.0735 0.295........ok! bd 2 f cd 1000 *125 2 * 9.07 Endeshaw Tafesse ID-UEAR-0018/02 Assignment on Reinforced Concrete I 34 Kz 0.95 M sd 10.424 * 10 6 As 336.50mm 2 k z df yd 0.95 * 125 * 260.87 From GDC for μsd = 0.066, S ( specing ) as b As * 10 2 * 1000 4 233.41mm 300mm............ok! 336.5 Pr ovide....10c / c 230mm ii. For span BC Msd = 5.463KNm By using General Design Chart Method. M sd 5.463 *10 6 sd 2 0.0385 0.295........ok! bd f cd 1000 *125 2 * 9.07 From GDC for μsd = 0.0205, Kz 0.97 As M sd 5.463 * 10 6 172.71mm 2 k z df yd 0.97 * 125 * 260.87 S ( specing ) as b As * 10 2 *1000 4 454.75mm 300mm............is..not..ok! 172.71 Pr ovide....10c / c300mm iii. For support B and C, Msd = 12.256KNm By using General Design Chart Method. sd M sd 12.256 *10 6 0.0865 0.295........ok! bd 2 f cd 1000 *125 2 * 9.07 Kz 0.94 12.256 * 10 6 399.84mm 2 0.94 *125 * 260.87 From GDC for μsd = 0.0205, As M sd k z df yd S ( specing ) as b As * 10 2 * 1000 4 196.43mm 300mm..............ok! 399.84 Pr ovide....10c / c195mm Endeshaw Tafesse ID-UEAR-0018/02 Assignment on Reinforced Concrete I 35 Design for Shear - For span AB and CD, section 1-1 and 6-6 By similarity of triangle: Vsd1 Vsd 6 - section 2-2 and 5-5 By similarity of triangle Vsd 2 Vsd 5 - 16.51 *1.612 14.876 1.263 23.695 * 1.612 22.0 1.737 section 3-3 and 4-4 By similarity of triangle 19.615 *1.375 17.98 1.5 Vrd 0.25 f ctd bd 0.25 * 9.07 *1000 *125 283437.5 Vsd 3 Vsd 4 Vrd 283.44KN Vsd (allo) Capacity of concrete for shear: vc 0.25 f ctd k1k 2 bd 10 k 2 1.6 d 1.475 1 ok! k1 1 50 As 399.84 At support 399.84 1000 *125 k1 1.16 2.....ok! As 399.84 bd 1000 *125 2 For slab section 2,3,4,5 vc 0.25 f ctd k1 k 2 bd vc 0.25 * 0.8889 *1.16 *1.475 *1000 *125 47528.372 N vc 47.528KN Vsd .....ok! For section 1&2 vc 0.25 f ctd k1k 2 bd 10 At support As 336.49 As 336.49 bd 1000 *125 k 2 1.6 d 1.475 1 ok! k1 1 50 336.49 1000 *125 k1 1.135 2.....ok! 2 For slab section 2,3,4,5 Endeshaw Tafesse ID-UEAR-0018/02 Assignment on Reinforced Concrete I 36 vc 0.25 f ctd k1 k 2 bd vc 0.25 * 0.8889 *1.135 *1.475 *1000 *125 46487.6644 N vc 46.488KN Vsd ..........ok! Design of beam on axis 1-1 3) Analysis: Design Load: Pd 1.3DL 1.6 LL Pd 1.3 (2 KN / m 2 *1.65m) 25KN / m 3 * 0.15 *1.65 (0.3 * 0.3 * 25) 1.6(1.65m * 3.5KN / m) Pd 24.50 KN / m - By using Cross method Fixed End Moment WL2 24.50 * 6 2 73.50 KNm 12 12 WL2 24.50 * 6 2 73.50 KNm 12 12 M F AB M F BC M F CD M F BA M F CB M F DC joint member Relative stiffness, (End pine support, B BA BC C CB CD 3 I I ( ) 4 6 12 I 6 I 6 3 I I ( ) 4 6 12 I ) K 3 I ( )) 4 K ( Total relative stiffness I ( ) K 7I 24 7I 24 Disribiution factor I ) K I K 3 7 4 7 4 7 3 7 ( Endeshaw Tafesse ID-UEAR-0018/02 Assignment on Reinforced Concrete I Joint A member DF FEM CO Initial Moment Balance CO Balance CO Balance CO Balance CO Balance CO Balance Final Moment at support AB 1 73.50 -73.50 0 0 37 B BA 3/7 -73.50 -36.75 -110.25 15.75 4.50 1.286 0.367 0.105 0.03 -88.212 C BC 4/7 73.50 0 73.50 21.00 -10.50 6.00 -3.00 1.714 -857 0.49 -0.2450 0.14 -0.07 0.04 88.212 CB 4/7 -73.50 0 -73.50 -21.00 10.50 -6.00 3.00 -1.714 0.857 -0.49 0.2450 -0.14 0.07 -0.04 -88.212 D CD 3/7 73.50 36.75 110.25 -15.75 -4.50 -1.286 -0.367 -0.105 -0.03 88.212 DC 1 -73.50 73.50 0 0 Reaction forces: Rxn due to load Rxn due to Moment Final Rxn A 67.62 -14.702 RA= 54.094 B 67.62 67.62 14.702 0 RB= 148.766 C 67.62 67.62 0 14.702 RC= 148.766 D 67.62 -14.702 RD= 54.094 To fined maximum Moment and Shear force For span AB & CD Vx R1 24.50 x 15.68 24.50 x Mx R1 x 24.50 x2 x2 54.09 x 24.50 2 2 To obtain, maximum moment shear force is zero, Vx=0 54.09 24.50 x 0 x M max 54.09 * 2.21 24.50 54.09 2.21m 24.50 2.212 2 M max 59.71KNm For span BC Vx R1 24.50 x 202.856 24.50 x Mx R1 x 148.766( x 6) 24.50 x2 x2 54.09 x 892.596 24.50 2 2 Endeshaw Tafesse ID-UEAR-0018/02 Assignment on Reinforced Concrete I 38 To obtain, maximum moment shear forc is zero, Vx=0 202.856 24.50 x 0 x M max 54.09 * 9 892.596 24.50 202.856 9.0m 24.50 92 2 M max 12.53KNm For span CD Vx R1 24.50x 351.622 24.50x a) Design Slab for flexure Reinforcement Effective Depth, use F6 for shear d 450 (25 20 6) 409mm 2 Effective Width for L – Beam For End span lo = 0.85l = 5100mm, beffec beffec For middle span lo= 0.7l = 4200mm 1 1 1 1 bw lo 300 5100 810mm 10 10 bw l o 300 4200 720mm beffec 10 10 bw bi 300 (150 1500 300) 4650mm bw bi 300 (150 1500 300) 4650mm 810mm beffec 720mm i. for span AB and CD, Assume that the Neutral axis lie in Flange c beff f cd Cc = 0.8xf cdbeff x 0.8x hf h Msd = 59.71KNm N.A d z = (d - 0.4x) As s fs T s =Asf y d bw x-section strains stresses resultant internal forces By using GDC methode M sd 59.71 *10 6 sd 2 0.0513 0.295........ok! bd f cd 810 * 409 2 * 9.07 Kz 0.95 From GDC for μsd = 0.066, Kx 0.11 Check the assumption x K x * d 0.11* 409 44.99mm hf 150mm The assumption is ok ! As M sd 9.402 *10 6 624.45mm 2 k z df yd 0.96 * 409 * 260.87 N o.. 20 624..45 1.988......... provide....2 20...bars 20 2 * 4 Endeshaw Tafesse ID-UEAR-0018/02 Assignment on Reinforced Concrete I ii. 39 For span BC Msd = 12.53KNm By using General Design Chart Methode M sd 12.53 *10 6 0.011 0.295........ok! bd 2 f cd 720 * 409 2 * 9.07 Kz 0.98 GDC for μsd = 0.0205, Kx 0.05 sd From Check the assumption x K x * d 0.05 * 409 20.75mm h f 150mm The assumption is ok ! M sd 12.53 * 10 6 As 118.10mm 2 k z df yd 0.98 * 409 * 260.87 N o.. 20 iii. 118.10 0.38......... for..stirrup.. provide....2 20...bars 20 2 * 4 For support B and C, Msd = 88.212 By using GDC method M sd 88.212 *10 6 0.188 0.295........ok! bd 2 f cd 300 * 409 2 * 9.07 Kz 0.89 GDC for μsd = 0.066, Kx 0.26 sd From Check the assumption x K x * d 0.26 * 409 106.34mm hf 150mm M sd 88.212 * 10 6 As 915.51mm 2 k z df yd 0.89 * 409 * 260.87 N o.. 20 915.51 2.91......... provide....3 20...bars 20 2 * 4 C) For axis 2 – 2, T- beam 4) Analysis: Design Load: Pd 1.3DL 1.6 LL Pd 1.3 (2 KN / m 2 * 3m) 25KN / m 3 * 0.15 * 3 (0.3 * 0.3 * 25) 1.6(3m * 3.5KN / m) Pd 42.15KN / m Endeshaw Tafesse ID-UEAR-0018/02 Assignment on Reinforced Concrete I - 40 By using Cross method Fixed End Moment WL2 42.15 * 6 2 126.45KNm 12 12 WL2 42.15 * 6 2 126.45KNm 12 12 M F AB M F BC M F CD M F BA M F CB M F DC joint member ( (End pine support, B BA BC C CB CD 3 I ( ) 4 6 I 6 I 6 3 I ( ) 4 6 Total relative stiffness I ) K 3 I ( )) 4 K Relative stiffness, I 8 ( I ) K I ) K I K 3 7 4 7 4 7 3 7 ( 7I 24 7I 24 I 8 Jont A member DF FEM AB 1 126.45 BA 3/7 -126.45 BC 4/7 126.45 CB 4/7 -126.45 CD 3/7 126.45 CO 126.45 0 - -63.225 0 0 63.225 DC 1 126.45 126.45 -189.675 27.096 - -126.45 -36.129 18.0643 189.675 -27.096 - 0 - 0 7.743 2.213 0.632 0.180 0.052 -151.759 126.45 36.129 18.0643 10.3213 -5.161 2.948 -1.474 0.842 -0.421 0.241 -0.1205 0.0685 151.759 -10.3213 5.161 -2.948 1.474 -0.842 0.421 -0.241 0.1205 -0.0685 -151.759 -7.743 -2.213 -0.632 -0.180 -0.052 151.759 0 Initial Moment Balance CO Balance CO Balance CO Balance CO Balance CO Balance Final Moment at support(KNm) B Disribiution factor C D Endeshaw Tafesse ID-UEAR-0018/02 Assignment on Reinforced Concrete I 41 Reaction forces: A 126.45 -25.293 RA= 101.16 Rxn due to load Rxn due to Moment Final Rxn(KN) B C 126.45 126.45 25.293 0 RB= 278.19 126.45 126.45 0 25.293 RC= 278.19 D 126.45 -25.293 RD= 101.16 To fined maximum Moment and Shear force For span AB & CD Vx R1 42.15 x 101.16 42.15 x Mx R1 x 42.15 x2 x2 101.16 x 42.15 2 2 To obtain, maximum moment shear forc is zero, Vx=0 101.16 42.15 x 0 M max 42.15 x 2.4m 101.16 M max 2.4 2 101.16 * 2.4 42.15 2 121.39 KNm For span BC Vx R1 42.15 x 379.35 42.15 x Mx R1 x R2 ( x 6) 42.15 x2 x2 379.35 x 1669.16 42.15 2 2 To obtain, maximum moment shear forc is zero, Vx=0 379.35 42.15 x 0 x M max 379.35 * 9 892.596 24.50 379.35 9.0m 42.15 92 2 M max 12.53KNm For span CD Vx R1 R2 R3 42.15x 657.55 42.15x a) Design Slab for flexure Reinforcement Effective Depth, use F6 for shear d 450 (25 20 8) 407 mm 2 Effective Width for L – Beam For End span lo = 0.85l = 5100mm, beffec beffec For middle span lo= 0.7l = 4200mm 1 1 1 1 bw lo 300 5100 810mm 10 10 bw l o 300 4200 720mm beffec 10 10 bw bi 300 (150 1500 300) 4650mm bw bi 300 (150 1500 300) 4650mm 810mm beffec 720mm iv. For span AB and CD, Assume that the Neutral axis lie in Flange Msd = 121.39KNm Endeshaw Tafesse ID-UEAR-0018/02 Assignment on Reinforced Concrete I 42 c beff h f cd Cc = 0.8xf cdbeff x 0.8x hf N.A d z = (d - 0.4x) s As fs T s =Asf y d bw strains x-section stresses resultant internal forces By using GDC method M sd 121.391 *10 6 0.0612 0.295........ok! bd 2 f cd 1320 * 407 2 * 9.07 Kz 0.96 GDC for μsd = 0.066, Kx 0.12 sd From Check the assumption x K x * d 0.12 * 407 48.84mm hf 150mm The assumption is………..ok! As M sd 121.39 *10 6 1190.94mm 2 k z df yd 0.96 * 407 * 260.87 N o.. 20 For 1190.94 3.79......... provide...4 20...bars 20 2 * 4 span BC Msd = 37.92KNm By using General Design Chart Method M sd 37.92 *10 6 0.022 0.295........ok! bd 2 f cd 1140 * 407 2 * 9.07 Kz 0.98 GDC for μsd = 0.0205, Kx 0.07 sd From Check the assumption x K x * d 0.07 * 407 28.49mm h f 150mm The assumption is ok ! As M sd 37.92 *10 6 364.43mm 2 k z df yd 0.98 * 407 * 260.87 N o.. 20 c.) 364.43 1.16........... provide....2 20...bars 20 2 * 4 For support B and C, Msd = 151.76KNm By using GDC methode Endeshaw Tafesse ID-UEAR-0018/02 Assignment on Reinforced Concrete I sd M sd 151.76 *10 0.3367 0.295.......is..not.ok! 2 bd f cd 300 * 407 2 * 9.07 From GDC for μsd = 0.3367, M - * u 43 6 Kz 0.89 Kx 0.26 s 2 2.9% d 2 d 1 0.106 f c d bd 2 0.295 * 9.07 * 300 * 407 2 =132.97KNm * us is allowable capacity of concrete without reinforcement Compression reinforcement s 2 2.9% yd 2% fs2 fyd yielded M Mu * 151.76 132.9710 6 As 2 sd 198.54mm2 d d 2 fyd 407 43260.87 Since N o.. 20 198.54 0.632......... 20 2 * 4 provide....2 20...bars For teing stirrup - tension reinforcement As1 M sd M Mu * sd 1605.61 198.54 1804.15mm 2 k z df yd d d 2 fyd N o.. 20 1804.15 5.74......... provide...6 20bar 20 2 * 4 Design for shear For span AB and CD, section 1-1 and 6-6 By similarity of triangle Vsd1 Vsd 6 - section 2-2 and 5-5 By similarity of triangle Vsd 2 Vsd 5 - 101.16 *1.993 80.005 2.4 151.75 * 3.193 134.594 3.6 section 3-3 and 4-4 By similarity of triangle 126.45 * 2.593 109.295 3 Vrd 0.25 f ctd bd 0.25 * 9.07 * 300 * 407 276862 N 276.862 KN Vsd 3 Vsd 4 Vrd 276.862KN Vsd (allo) Endeshaw Tafesse ID-UEAR-0018/02 Assignment on Reinforced Concrete I 44 Capacity of concrete for shear at support B& D, k 2 1.6 d 1.193 1 vc 0.25 f ctd k1k 2 bd ok! 20 1804.15 2 300 * 407 k1 1.7388 2.....ok! k1 1 50 As 1804.15mm 2 At support As 1804.15 bd 300 * 407 For slab section 2,3,4,5 vc 0.25 f ctd k1 k 2 bd vc 0.25 * 0.8889 *1.7388 *1.193 * 300 * 407 56285.77 N vc 56.286 KN For slab section 1,6 k 2 1.6 d 1.193 1 vc 0.25 f ctd k1k 2 bd ok! 20 At support As 2 * 314.16 628.32mm 628.32 2 300 * 407 k1 1.2573 2.....ok! k1 1 50 2 As 628.32 bd 300 * 407 vc 0.25 f ctd k1 k 2 bd vc 0.25 * 0.8889 *1.2573 *1.193 * 300 * 407 40699.39 N vc 40.699 KN S max = <, af yk 100 * 300 200mm 0.5b 0.5 * 300 0.5d 203.5mm Design shear for span AB & CD S max = 200mm Vsd,max = 134.594 Vc,max = 56.286 Vs Vsd Vc 134.594 56.286 78.308KN adf yd 100 * 407 * 260.87 S 135mm S max 200mm Vs 78.308 *10 3 Use 8c / c...135mm Design shear for span BC Vsd,max = 109.295 Vc,max = 56.286 Vs Vsd Vc 109.295 56.286 53.009KN adf yd 100 * 407 * 260.87 S 200mm S max 200mm Vs 53.009 *10 3 Endeshaw Tafesse ID-UEAR-0018/02 Assignment on Reinforced Concrete I Use 45 8c / c...200mm ANCHERAGE LENGTH a) Basic anchorage length, lb b b) f yd 4f bd 20 * 260.87 733.60mm , 4 *1.7778 fbd 2 fctd 2 * 0.8889 1.7778 Minimum anchorage length ,lb,min for tension 0.3b 0.3 * 733.6 220.08mm b, min 10 10 * 20 200mm 200mm b, min 220mm Minimum anchorage length ,lb,min for comprasion 0.6b 0.6 * 733.6 440mm b, min 10 10 * 20 200mm 200mm c). Required anchorage length, b, net b, min 440mm b, net abAs, cal , where a= 1.0 for straight bar anchorage As, req At support B & C As, cal 1804.15mm 2 As, provided 6 * 314.16 1884.95mm 2 abAs, cal 1 * 733.6 *1804.15 b, net 702.15mm b, min 220mm..... ...ok! As, req 1884.96 At span AB & CD As, cal 1190.94mm 2 As, provided 4 * 314.16 1256.64mm 2 abAs, cal 1 * 733.6 *1190.94 b, net 695.24mm b, min 220mm..... ...ok! As, req 1256.64 At span BC As, cal 364.43mm2 As, provided 2 * 314.16 628.32mm2 abAs, cal 1 * 733.6 * 364.43 b, net 420.82mm b, min 220mm..... ...ok! As, req 628.32 As, cal 198.54mm 2 At support B & C for compression As, provided 2 * 314.16 628.32mm2 Endeshaw Tafesse ID-UEAR-0018/02 Assignment on Reinforced Concrete I 46 abAs, cal 1 * 733.6 *198.54 b, net 231.8mm b, min 220mm..... ...ok! As, req 628.32 BAR CURTAILMENT A) For span BC no bar curtailment needed B) At support B & C 6 20 , let curtail 50% of the bar, 3 20 , Kz = 0.78 , d = 407mm Mrd As f yd K z d 3 * 314.16 * 0.78 * 407 * 260.87 78.03KNm No of bar = Mx 101.16 x 42.15 For X1, x2 2 78.03 101.16 x 42.15 x2 1669.16 2 x2 X2, 78.03 379.35 x 42.15 1669.16 2 x 2 6.654m l 2 x 2 L b, net al Mx 379.35 x 42.15 x2 2 ,for x1 5.495m l1 L x1 b, net al l1 6 - 5.495 0.70215 0.30525 l1 6.654 - 6 0.70215 0.30525 l1 1.51m l1 1.66m Total curtailment lt l1 l 2 3.17m C) At span AB & CD No of bar = 4 20 , let curtail 50% of the bar, 2 20 , Kz = 0.96 , d = 407mm Mrd As f yd K z d 2 * 314.16 * 0.96 * 407 * 260.87 64.04 KNm x2 Mx 101.16 x 42.15 2 For X1, and X2, 64.04 101.16 x 42.15 x2 2 , x1 0.75m x 2 4.05m lt x 2 x1 b, net al 2 lt 4.05 - 0.75 0.70215 0.305252 lt 5.84m SURVICIBILITY CHECK At span AB and CD DL = 19.5 KN, LL = 10.5 KN b/h = 300/450 , a. Un factored load Ps = DL + LL = 30 KN b. Design constant Endeshaw Tafesse ID-UEAR-0018/02 Assignment on Reinforced Concrete I 47 Ecm 29Gpa 2 2 fctk 0.21 fck 3 0.21 *16 3 1.333KN / m 2 Es 210Gpa n c. Es 210 7.2 8 Ecm 29 Design load / moment Psl 2 30 * 6 2 Mk 135KNm 8 8 d. Section property Section 1 – 1 A1 n 1As 8 13 * 314.16 6598.24mm 2 A2 n 1As 8 17 * 314.16 8796.48mm 2 A3 bh 300 * 450 135000mm 2 y1 25 8 10 43mm y 2 450 25 8 10 407mm y3 y e. 450 225mm 2 Aiyi 6598.24 * 43 8796.48 * 407 135000 * 225 227.66mm 6598.24 8796.48 135000 Ai Moment of inertia d 1 y y1 184.66mm d 2 y y 2 179.34mm d 3 y y 3 2.66mm 300 450 2 6598.24 *184.66 8796.48 *179.34 135000 * 2.66 Iut Ii Aidi 2 12 Iut 5.0889 *10 8 f. Section modulus Iut 5.0889 *10 8 2.235 *10 6 227 . 66 yt Mcr 1.7 f ctk Z 1.7 *1.333 * 2.235 5.065KNm Z Endeshaw Tafesse ID-UEAR-0018/02 Assignment on Reinforced Concrete I 48 g. Computation of Deflection i) Short term deflection s i ii max 5 48 Where δi- is the deflection due to the theoretical cracking moment Mcr acting on the un-cracked transformed section. 5 * 5100 2 * 5.065 * 10 6 i 48 0.89mm E cm Iut 29000 * 5.0889 *10 8 le 2 Mcr δii - is the deflection due to the balance of the applied moment over and above the cracking value and acting on a section with an equivalent stiffness of 75% of the cracked value. x n n n 82.41mm As As2 3 4 314.16 1 0.00257 bd 300 * 407 x Z d 379.53mm 3 le 2 Mk Mcr ii 0,75 EsAsZ d x 5 * 5100 2 * 135 5.065 * 10 6 48 ii 0.75 * 210000 * 4 * 314.16 * 379.53407 82.41 ii 13.06mm 2 δmax - is the deflection of fully cracked section Endeshaw Tafesse ID-UEAR-0018/02 Assignment on Reinforced Concrete I 49 5 * 5100 2 *135 *10 6 48 max 10.8 EsAsd x 210000 * 4 * 314.16 * 379.53(407 82.41) i ii 13.95mm shrt shrt 10.8mm max 10.8mm le 2 Mk Long term deflection l 2 1.2 As2 As1 3314.16 s 2 1.2 10.8 11.88mm 4314.16 Total deflection total s l 22.68mm Checking with the limit deflection all le 5100 25.5mm total 22.68mm...............ok! 200 200 Section 2 – 2 A1 n 1As 8 13 * 314.16 6598.24mm 2 A2 n 1As 8 12 * 314.16 4398.24mm 2 A3 bh 300 * 450 135000mm 2 y1 25 8 10 43mm y 2 450 25 8 10 407mm 450 225mm 2 Aiyi 6598.24 * 43 4398.24 * 407 135000 * 225 222.26mm y 6598.24 4398.24 135000 Ai y3 Moment of inertia. Endeshaw Tafesse ID-UEAR-0018/02 Assignment on Reinforced Concrete I 50 d 1 y y1 179.26mm d 2 y y 2 184.74mm d 3 y y 3 2.74mm 300 450 2 Iut Ii Aidi 2 12 Iut 3.632 *10 8 6598.24 *179.26 2 4398.24 *184.74 2 135000 * 2.66 2 Section modulus. Iut 3.632 *10 8 1.634 *10 6 222.26 yt Mcr 1.7 f ctk Z 1.7 *1.333 *1.634 3.70 KNm Z Computation of Deflection i) Short term deflection s i ii max 5 48 Where δi - is the deflection due to the theoretical cracking moment Mcr acting on the un-cracked transformed section. 5 * 4200 2 * 3.70 *10 6 le Mcr 48 i 0.62mm E cm Iut 29000 * 3.632 *10 8 2 δii - is the deflection due to the balance of the applied moment over and above the cracking value and acting on a section with an equivalent stiffness of 75% of the cracked value. x n n n 181.69mm As As2 3 2314.16 1 0.0018 bd 300 * 407 x Z d 346.44mm 3 2 Endeshaw Tafesse ID-UEAR-0018/02 Assignment on Reinforced Concrete I ii 51 le Mk Mcr 2 0,75 EsAsZ d x 5 * 4200 2 * 108 3.70 *10 6 48 ii 0.75 * 210000 * 2 * 314.16 * 346.44407 181.69 ii 23.82mm δmax - is the deflection of fully cracked section 5 * 4200 2 *108 *10 6 le Mk 48 max 18.50mm EsAsd x 210000 * 2 * 314.16 * 346.44(407 181.69) i ii 24.44mm shrt shrt 18.5mm max 18.50mm 2 ii) Long term deflection As 3314.16 18.5 3.70mm l 2 1.2 2 s 2 1.2 As1 2314.16 iii) total deflection total s l 22.20mm Checking with the limit deflection all le 4200 21mm total 22.20mm...............ok! 200 200 11. A petroleum station consists of RC slab which cantilevers 3m on each side of central RC beam and is monolithic with it. The RC beam is simply supported on columns over a clear span of 6m. Design the slab for flexure. Data: Dimensions: Material Strength Slab thickness = 100/300m Concrete: C25 Beam web width, bw = 400mm Steel: S460 Over all depth of beam is limited to 500mm Loading: Unit weight of concrete = 25KN/m3 Use ф 10 bars for the slab and ф20 bars for the beam LL = 2KN/m2 Endeshaw Tafesse ID-UEAR-0018/02 Assignment on Reinforced Concrete I 52 DL from finishing = 1KN/m2 Solution: Slab design A) Design load and Moment f cd fyd 0.68 f c y s 0.68 * 25 11.33 N m 2 1 .5 fyk 460 400 s 1.15 To make a uniform load take 1m strip 0 .5 0 .1 * 1 * 25 ) + 1.6(2*1) 2 Pd * l 2 14.25 * 3.2 2 M 72.96 KNm 2 2 h f 100mm Pd= 1.3 (1*1 + = 14 95KN/m 300 100 200mm 2 d h 25 5) 170mm h By using General Design Chart Methode M sd 72.96 *10 6 sd 2 0.223 0.295........ok! bd f cd 1000 *11.33 *170 2 Kz 0.87 From GDC for μsd = 0.0205, Kx 0.31 Check the assumption x K x * d 0.31 *170 52.7mm h f 100mm The assumption is ok ! M sd 72.96 *10 6 As 1233.27mm 2 k z df yd 0.87 *170 * 400 S ( specing ) asb As 10 2 * 1000 4 63.68mm 300mm..............ok! 1233.27 * Pr ovide....10c / c60mm Beam design consider as a T - beam lo 2l 2 * 3.2 6.4 6400mm 1 1 bw l o 2 400 * 6400 2960mm beffec 5 5 b actul 6400 * 2 12800mm beffec 2960mm hf = 100mm Endeshaw Tafesse ID-UEAR-0018/02 Assignment on Reinforced Concrete I 53 Design load and moment Pd 1.36.40.1 * 25 0.5 * 0.2 * 25 0.2 * 0.4 * 25 1 * 6.4 1.62 * 6.4 73KN / m 73 * 6 2 M 328.5KNm 8 d 500 25 10 465mm By using General Design Chart Methode M sd 328.5 *10 6 0.0453 0.295........ok! bd 2 f cd 2960 *11.33 * 465 2 Kz 0.975 GDC for μsd = 0.0205, Kx 0.105 sd From Check the assumption x K x * d 0.105 * 465 46.5mm h f 100mm The assumption is ok ! M sd 328.5 * 10 6 As 1811.414mm 2 k z df yd 0.975 * 465 * 400 N o.. 20 1811.414 5.76......... provide....6 20...bars 20 2 * 4 24.50 KN/m A 6m RA B x RB 6m C RC D 6m RD x x Endeshaw Tafesse ID-UEAR-0018/02