UH Department of Chemical and Biomolecular Engineering

advertisement

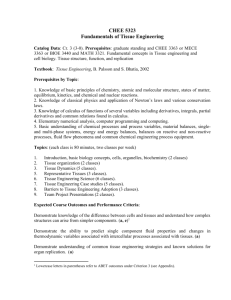

CHEE 3367 Process Modeling and Control CATALOG DATA CHEE 3367: Process Modeling and Control Cr. 3. (3-0). Prerequisites: CHEE 3334, MATH 3321, CHEE 3363 or ENGI 3363 and PHYS 1322. Modeling techniques of chemical engineering problems with emphasis on process control. REQUIRED TEXTBOOK Stephanopoulos, G., Chemical Process Control - An Introduction to Theory and Practice, Prentice-Hall, 1984. RECOMMENDED 1. D. E. Seborg, T. F. Edgar, and D. A. Mellichamp, Process Dynamics and Control, TEXTBOOKS Wiley and Sons, 1989. 2. Ogunnaike, B. A., And W. H. Ray, Process Dynamics, Modeling, and Control, Oxford, 1994. 3. Marlin, T. E., Process Control - Designing Processes and Control Systems for Dynamic Performance, McGraw-Hill, 1995. 4. Bequette, B. W., Process Control: Modeling, Design and Simulation, Prentice-Hall, 2003. SUPPLEMENTARY Notes from the instructor and bibliographical references will be posted on Blackboard MATERIAL (http://blackboard1.egr.uh.edu) PREREQUISITES BY 1. TOPIC Engineering problem solving in interactive computing environments (e.g., Spreadsheets, Matlab, Mathematica). 2. Programming using procedural languages (e.g., Fortran, Matlab, Mathematica). 3. Matrix algebra. 4. Elementary complex algebra. 5. Differential and integral calculus, and differential equations. 6. Basic transport phenomena. 7. Basic thermodynamics. EXPECTED COURSE 1. OUTCOMES AND PERFORMANCE CRITERIA 2. 3. 4. 5. 6. 7. 1 Demonstrate understanding of the scientific and engineering fundamentals (goals, capabilities, limitations) as well as practical issues (technologies, heuristics, equipment, cost) related to process control techniques widely used in process industries. (a, e)1 Demonstrate ability to identify a variety of process control problems in traditional and emerging chemical engineering fields, and how to combine technological, mathematical, experimental, and computational tools for effective and efficient solution through control system (and partially process) design. (e, c, j, k) Demonstrate ability to use existing software packages (e.g. Matlab and Toolboxes, Mathematica) or customized code in modeling, simulation, and controller design problems. (e, k) Demonstrate ability to present the input and output of a computer-assisted project in a comprehensive, comprehensible, editable, and interpretable way. (g) Demonstrate knowledge of bibliographical and Internet resources related to process control and automation. (h, i, j) Demonstrate understanding of the interdisciplinary nature, history, technological and economic impact, as well as societal effects of process control and, more generally, automation, and ability to follow and assess future developments in this field. (h, i, j) Demonstrate ability to identify the hardware and software of a feedback control loop; collect experimental data to develop a mathematical process model; design a controller based on the model; and test the efficacy of the controller both via computer simulations and experimentally. (b) Lowercase letters in parentheses refer to ABET outcomes under Criterion 3 (see Appendix). ABET Outcome, Criterion 3 Appendix Program-Specific Outcomes (a) an ability to apply knowledge of mathematics, science and engineering. (b) an ability to design and conduct experiments as well as to analyze and interpret data. (c) an ability to design a system, component, or process to meet desired needs within realistic constraints such as economic, environmental, social, political, ethical, health & safety, manufacturability, and sustainability. (d) an ability to function on multidisciplinary teams. (e) an ability to identify, formulate and solve engineering problems. Use chemistry and physics concepts to set up and solve chemical engineering problems Use mathematical tools to solve chemical engineering problems Select appropriate experimental equipment and techniques necessary to solve a given problem Evaluate and interpret experimental results using statistical tools and chemical engineering concepts Apply material and energy balance concepts to design a unit operation Define objectives and perform the design of an integrated chemical process under realistic constraints Define roles and responsibilities to align with capabilities of team members and fulfill project requirements Develop and carry out a project plan through team work Translate an engineering problem into a mathematical model or other suitable abstraction Use mathematical model or other suitable abstraction to solve an engineering problem and interpret results Demonstrate knowledge of professional code of ethics. Identify ethical issues and make decisions for a chemical engineering problem. (f) an understanding of professional and ethical responsibility. (g) an ability to communicate effectively. (h) the broad education necessary to understand the impact of engineering solutions in a global, economic, environmental, and societal context. (i) a recognition of the need for and an ability to engage in lifelong learning. Understand the impact of chemical engineering solutions in a global, economic, environmental, and societal context. (j) a knowledge of contemporary issues. (k) an ability to use the techniques, skills, and modern engineering tools necessary for engineering practice. Recognize the importance of advanced education and development opportunities Identify, retrieve, and organize information necessary to solve open-ended problems Know the interplay between current technical and societal issues Know the recent history, current status, and future trends of chemical engineering Use modern software to solve chemical engineering problems Understand how to operate equipment relevant to chemical engineering systems Make presentations that are factual and tailored to the audience Can communicate in writing to non-technical and technical audiences