LECTURE 08: COST ANALYSIS AND ESTIMATION. EMPIRICAL

LECTURE 08: COST ANALYSIS AND ESTIMATION.

EMPIRICAL ESTIMATION OF COST FUNCTIONS

The study of cost curves has its origin with Joel Dean, who wrote the first textbook on managerial economics, and conducted many of the studies dating back to the 1930s. As in the case of production functions, we are interested in estimating cost functions both in the short run and in the long run. The short-run function helps define short-run marginal costs and thus assist the manager in determining output and prices. In the long run, the decision that a firm faces involves building the most efficient size of plant. That determination will depend on the existence of scale economies and diseconomies.

In investigating short -run cost functions, using regression analysis, the researchers have most frequently employed the time series technique with data for a specific plant or firm over time.

The size of the plant or firm, as well as technology, should not change significantly during the time interval used in short-run cost function.

Long -run cost function---the planning functions ---allow for changes in all factors including plant size. Most studies of long-run cost functions have employed cross-sectional analysis.

Empirical estimates of cost functions are essential for many managerial decision purposes.

Knowledge of short-run cost functions is necessary for the firm in determining the optimal level of output and the price to charge. Knowledge of long- run cost functions is essential in planning for the optimal scale of plant for the firm to build in the long run. We will examine the most important techniques for estimating the firm's short-run and long-run cost curves, and consider some of the data and measurement problems encountered in estimation, and summarize the results of some empirical studies of short-run and long-run cost functions.

THE ESTIMATION OF SHORT-RUN COST

FUNCTIONS Data and Measurement Problem

The most common method of estimation the firm’s short-run cost functions is regression analysis, whereby total variable costs are regressed against output and a few other variables, such as input prices and operating conditions, during the time period when the size of the plant is fixed. The total variable cost rather than total cost function is estimated because of the difficulty of allocating fixed cost to the various products produced by the firms. The firm’s total cost function can then be obtained by simply adding the best estimate possible of the fixed costs to the total variable costs. The firm’s average variable and marginal cost functions can be easily obtained from total variable cost function.

EMPIRICAL ESTIMATION DATA COLLECTION ISSUES

Opportunity Costs Must Be Extracted from Accounting Cost Data

Costs Must Be Divided Among Products

Costs Must Be Matched to Output Over Time

Costs Must Be Corrected for Inflation

The firm's cost functions are based on the assumption of constant input prices. If input prices increase, they will cause an upward shift of the entire cost function. Therefore, input prices will have to be included as additional explanatory variables in the regression analysis in order to identify their independent effect on costs. Other independent variables that may have, to be included in the regression analysis are fuel and material costs, the quality of inputs, the technology used by the firm, weather conditions, and changes in the product mix and product

1 © St. Paul’s University.

quality.

The actual independent or explanatory variables included in the regression (besides output) depend on the particular situation under examination. Thus, we can postulate that

(1) C = f(Q, X

1

, X

2

,... ,X n

)

Where C refers to total variable costs, Q is output, and the X’s refer to the other determinants of the firm‘s costs. Using multiple regression analysis allows us to isolate the effect on costs of changes in each of the independent or explanatory variables. By concentrating on the relationship between costs and output, we can then identify the firm’s total variable cost curve.

Economic versus Accounting Costs : Most empirical studies of cost functions have used

Accounting data that record the actual costs and expenses on a historical basis. However decision-making data---economic data should also include opportunity costs. The problem that arise in the estimation of short-run cost functions because of differences between accounting and economic costs are the most difficult to solve.

One fundamental problem that arises in the empirical estimation of cost functions is that opportunity costs must be extracted from the available accounting cost data. That is, each input used in production must be valued at its opportunity cost based on what the input could earn in its best alternative use rather than the actual expenditures for the input. For example, if the firm owns the building in which it operates, the cost of using the building is not zero but is equal to the rent that the firm would obtain by renting the building to the highest bidder. Similarly inventories used in current production must be valued at current market prices rather than at historical cost. Finally, the part of the depreciation of fixed assets, such as machinery, that is based on the, actual usage of the assets (as contrasted to the depreciation of the assets based on the passage of time alone) should be estimated and included in current production costs for each product. These data are often difficult to obtain from the available accounting data.

Not only must costs be correctly apportioned to the various products produced by the firm but care must also be exercised to match costs to output over time (i.e., allocate costs to the period in which the output is produced rather than to the period when the costs were incurred)

Specifically, the leads and lags in costs from the corresponding output must be adjusted so as to achieve a correct correspondence between costs and output. For example, while a firm may postpone all but emergency maintenance until a period of slack production, these maintenance costs must be allocated to the earlier production periods.

The manager must also determine the length of time over which to, estimate cost functions while daily, weekly, monthly, quarterly, or yearly data can be used monthly data over a period of two or three years are usually used. The period of time must be long-enough to allow for sufficient variation in output and costs but not long enough for the firm to change plant size (since the firm would then no longer be operating in the short run). Since output is usually measured in physical units (e.g., number of automobiles of a particular type produced per time period) while costs are measured in monetary units, the various costs must be deflated by the, appropriate price index to correct for inflation. That is, with input prices usually rising at different rates, the price index for each category of inputs will have to be used to obtain their deflated values to use in the regression analysis.

2 © St. Paul’s University.

THE FUNCTIONAL FORM OF SHORT-RUN COST FUNCTIONS

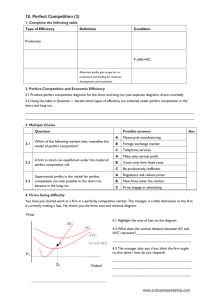

Economic theory postulates an S-shaped (cubic) TVC curve as indicated in the left panel of

Figure 1, with corresponding U-shaped AVC and MC curves. The general equations for these functions are, respectively,

Cubic TVC Function

(2) TVC = a (Q) + bQ

2

+ cQ

3

(3) AVC = TVC = a+ Q+cQ

2

(4)

Q

MC = a + 2bQ+ 3cQ

2

Where conditions for U-shape cost functions are: a > 0, b < 0 and c > 0

The right panel of Figure 1 shows a linear approximation to the cubic TVC curve, which often gives a good empirical fit of the data points over the observed range of outputs. The estimated equations of the linear approximation to the S-shaped or cubic TVC curve and of its corresponding AVC and MC curves are

Linear TVC Function

(5) TVC = a + bQ

(6) AVC = a/Q + b

(7) MC= b

Quadratic TC Function

TC = a + bQ +cQ

2

AC = a/Q + b + cQ

MC = b + 2cQ

(8)

(9)

(10)

Where a > 0, c > 0 and b < 0

SHORT-RUN COST FUNCTION

Alternative specifications of the Total Cost function (relating total cost and output)

• Cubic relationship

As output increases, total cost first increases at a decreasing rate, then increases at an increasing rate

•

Quadratic relationship

As output increases, total cost increases at an increasing rate

• Linear relationship

As output increases, total cost increases at a constant rate

3 © St. Paul’s University.

Having estimated the parameters of the TVC curves (i.e; the value of a and b in Equation 5), we can use these estimated parameters to derive the corresponding AVC and MC functions of the firm, as indicated in Equations (6) and (7). We might note that estimated parameter a ( the constant in estimated Regression 5) cannot be interpreted as the fixed cost of the firm since we are estimating the TVC function. Since Q = 0 is usually far removed from the actual observed data points on the TVC curve (from

Q’ to Q”

in the right panel of Figure1, no economic significance can be attached to the estimated parameter a . We might also note that the AVC curve in the right panel becomes quite flat, approaching the value of ( the horizontal

MC curve). This i b s often observed in the actual empirical estimation. Another nonlinear theoretical from of the TVC curve that is often closely approximated by a linear TVC is the quadratic form. The quadratic TVC curve rises at an increasing rate (i.e., faces diminishing returns) throughout (and so do the corresponding AVC and MC curves). One possible explanation for this is that while the amount of capital (say the number of machines) that the firm has is fixed in the short run, the may keep some machines idle when output is low and bring them into operation by hiring more labour when it wants to increase output. Since the ratio of machines to output as well as machines to labour tends to remain constant in the face of changes in output, the firm’s AVC and MC to remain approximately constant.

THE SHAPES OF SHORT-RUN COST FUNCTION

Three different specifications of cost functions are: cubic, quadratic and Linear. Each represents a possible shape of the cost curves. The economist, after collecting and adjusting the data, will use one of these specifications to measure the relationship between cost and output. Other statistical functions could be employed (e.g; the Cobb-Douglas power function), but the three shapes are the ones most frequently encountered in statistical studies, that is, cubic, quadratic or Linear.

4 © St. Paul’s University.

EMPIRICAL ESTIMATION LONG-RUN COST CURVES

Cross-Sectional Regression Analysis

Engineering Method

Survival Technique

ESTIMATING LONG-RUN COST FUNCTIONS WITH CROSS-SECTIONAL DATA

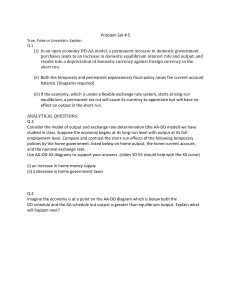

The empirical estimation of long-run cost curves is even more difficult than the estimation of short-run cost curves. The objective of estimating the long-run cost curves is to determine the best scale of plant for the firm to build in order to minimize the cost of producing the anticipated level of output in the long run. Theoretically, long-run cost curves can be estimated with regression analysis utilizing most of the time Cross-Sectional Data.

Regression analysis using Cross-Sectional Data to estimate the long-run cost curves also presents some difficulties, however. For one thing, firms in different geographical regions are likely to pay different prices for their inputs, and so input prices must be included together with the levels of output as independent explanatory variables in the regression.

It may also be very difficult to determine if each firm is operating the optimal scale of plant at the optimal level of output (i.e; at the point on its SAC curve which forms part of its LAC curve). Specifically, in order to be able to estimate LAC curve

A’’ C’’ G’’ R’’

in Figure 2, the firms represented by SAC

1

, SAC

2

, SAC

3 and SAC

4

must operate at points

A’’, C’’, G’’, and R’’,

respectively. If in fact the four firms are producing at points A *, C*, G*, and R*, respectively, we would be estimating the dashed

LAC’

curve, which overestimates the degree of both the economies and diseconomies of scale. The estimated long-run average cost curves seem to indicate sharply increasing returns to scale (falling LAC curve) at low levels of output followed by near-constant returns to scale at higher levels of output (i.e; the LAC curve seems to be L-shaped or nearly so).

ESTIMATING LONG-RUN COST FUNCTIONS WITH ENGINEERING AND

SURVIVAL TECHNIQUES

When sufficient data are not available for cross-sectional regression estimation of the longrun cost curves, the engineering or the survival techniques are used. The engineering technique uses knowledge of the physical relationship between inputs and output expressed by the production function to determine the optimal input combination needed to produce,

5 © St. Paul’s University.

various levels of output by multiplying the optimal quantity of each input by the price of the input, we obtain the long-run cost function of the firm. Knowledgeable professionals calculate the quantity of inputs required to produce any quantity of outputs. The engineering technique is particularly useful in estimating the cost functions of new products or improved products resulting from the application of new technologies, where historical data are not available.

The advantage of the engineering technique over cross -sectional regression analysis is that it is based on the present technology, thus avoiding mixing the old and current technology used by different firms in cross -sectional analysis. Neither does the problem of different input prices in different geographical regions arise. Many of the difficult cost-allocation and inputvaluation accounting problems that plague regression estimation are also avoided.

The engineering technique is not without problems, however. These arise because it deals only with the technical aspects of production without considering administrative, financing, and marketing costs; it deals with production under ideal rather than actual real-world conditions; and it is based on current technology, which may soon become obsolete. The engineering technique has been successfully applied to examine the cost-to-output relationship in many industrial sectors, such as petroleum refining and chemical production.

The results obtained seem to confirm those obtained with cross-sectional regression analysis.

That is, the

LAC’

Curve seem to be L-shaped. Generally, engineering cost estimates shows declining unit costs up to a point and substantially flat unit costs at higher production quantities.

6 © St. Paul’s University.