scaffolding

advertisement

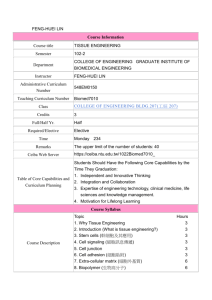

HEALTH, SAFETY AND ENVIRONMENT SPECIFICATION Scaffolding, Working at Heights or Over Water, Lifting Operations and Earthworks DOCUMENT ID - SP 1257 REVISION - 1.0 DATE - 15/07/02 HSE – SPECIFICATION Setting Clear Requirements Authorised for Issue by the HSE IC 15/07/02 Document Authorisation Document Authority ‘dapo Oguntoyinbo Ref. Ind: CSM Date: 15/07/02 Document Custodian Hamad Khalfeen Ref. Ind: CSM/11 Date: 15/07/02 Document Author Hamad Khalfeen Ref. Ind: CSM/11 Date: 15/07/02 The following is a brief summary of the four most recent revisions to this document. Details of all revisions prior to these are held on file by the Document Custodian. Version No. Version 1.0 Date July 2002 Author Hamad Khalfeen CSM/11 Scope / Remarks Original issue. Supersedes HSE Standards Manual Chapter 9 ‘Safety Standards for Scaffolding, Working at Heights or Over Water, Lifting Operations and Earthworks’. User Notes: The requirements of this document are mandatory. Non-compliance shall only be authorised by CSM through STEP-OUT approval. A controlled copy of the current version of this document is on PDO's EDMS. Before making reference to this document, it is the user's responsibility to ensure that any hard copy, or electronic copy, is current. For assistance, contact the Document Custodian. This document is the property of Petroleum Development Oman, LLC. Neither the whole nor any part of this document may be disclosed to others or reproduced, stored in a retrieval system, or transmitted in any form by any means (electronic, mechanical, reprographic recording or otherwise) without prior written consent of the owner. Users are encouraged to participate in the ongoing improvement of this document by providing constructive feedback. SP 1257 REVISION 1.0 Page ii HSE – SPECIFICATION Setting Clear Requirements Contents 1. INTRODUCTION ................................................................................................. 1 1.1 1.2 1.3 1.4 PURPOSE............................................................................................................... 1 CHANGES TO THE SPECIFICATION ................................................................................ 1 SCOPE .................................................................................................................. 1 DELIVERABLES ........................................................................................................ 1 1.5 1.6 1.7 RESPONSIBILITIES ................................................................................................... 2 PERFORMANCE MONITORING ...................................................................................... 3 REVIEW AND IMPROVEMENT ....................................................................................... 3 1.4.1 1.4.2 2.0 Records ........................................................................................................ 1 Reports ........................................................................................................ 2 PERFORMANCE REQUIREMENTS .................................................................... 4 2.1 2.2 LEGAL REQUIREMENTS .............................................................................................. 4 WORK ON HIGH STRUCTURES ..................................................................................... 5 2.3 SCAFFOLDING ......................................................................................................... 7 2.2.1 2.2.2 2.2.3 2.2.4 2.2.5 Personnel ..................................................................................................... 5 Means of Access ........................................................................................... 5 The High Structure ........................................................................................ 5 Pre-Work Checks .......................................................................................... 5 Work Practices .............................................................................................. 6 2.3.1 2.3.2 General ........................................................................................................ 7 Personnel ..................................................................................................... 7 2.3.3 2.3.4 Means of Access ........................................................................................... 8 Activity Controls ............................................................................................ 9 2.3.5 2.3.6 2.3.7 Pre Work Checks ......................................................................................... 10 General Access Scaffolds ............................................................................. 11 Scaffold Material Standards ......................................................................... 13 2.3.8 2.3.9 2.3.10 2.3.11 2.3.12 Tower Scaffolds .......................................................................................... 14 System Scaffolds ......................................................................................... 15 Power Operated Mobile Work Platforms ........................................................ 16 Ladders ...................................................................................................... 17 Dismantling ................................................................................................ 17 TABLE 1: TRAINING AND EXPERIENCE REQUIREMENTS ................................................................ 8 TABLE 2: LOADS AND DIMENSIONS FOR SCAFFOLD TUBE AND FITTINGS .......................................... 9 TABLE 3: SCAFFOLD MATERIAL STANDARDS ........................................................................... 14 SP 1257 2.4 WORK OVER WATER .............................................................................................. 18 2.5 LIFTING OPERATIONS ............................................................................................. 19 2.6 EARTHWORKS ....................................................................................................... 20 2.4.1 2.4.2 General Requirements ................................................................................. 18 Working Outside Handrails .......................................................................... 18 2.5.1 2.5.2 General ...................................................................................................... 19 Gin Blocks .................................................................................................. 20 2.6.1 2.6.2 2.6.3 2.6.4 2.6.5 2.6.6 2.6.7 2.6.8 General ...................................................................................................... 20 Excavation Permit ....................................................................................... 20 Excavation and Trenching ............................................................................ 21 Specifications and Backfilling ....................................................................... 22 Restoration ................................................................................................. 22 Identification of Services ............................................................................. 23 Roadworks ................................................................................................. 23 Rock Breaking ............................................................................................. 23 REVISION 1.0 Page iii HSE – SPECIFICATION Setting Clear Requirements 1. Introduction 1.1 Purpose This Specification describes PDO's requirements for: 1.2 Working on high structures Scaffolding Working over water Lifting operations Earthworks, roadworks and excavations. Changes to the Specification This Specification replaces Chapter 9 of the HSE Standards Manual – ‘Safety Standards for Scaffolding, Working at Heights or Over Water, Lifting Operations and Earthworks’. 1.3 Scope This Specification applies to all activities involving scaffolding (onshore and offshore), working at heights or over water, lifting operations and earthworks, undertaken by PDO, and Contractor/Sub-Contractor personnel authorised to work on behalf of PDO. Although this Specification is focused on "Construction Contracts", it applies equally to all similar activities, whether for maintenance, production operations or any other purpose. 1.4 Deliverables 1.4.1 Records Records shall be maintained to document the implementation of this Specification (refer to CP 122 HSE Management System Manual, Part 2 Chapter 6). Scaffolding Records Scaffold Inspectors shall record and maintain records of scaffolding and related equipment in a site scaffolding/staging inspection log book. Inspectors shall either accept the scaffold or reject it and detail deficiencies to be corrected in the log book. Personnel Records for Scaffolders Personnel records of scaffolders shall be maintained and kept up to date. They shall show: full name of employee date of birth job category employment application or personal data sheet (resumes) company service agreement copy of employee papers. (with visa page, labour permits, NOC’s) authorisation for the release of personal data and record information records of disciplinary actions and unsatisfactory performance records of exceptional performance and achievements SP 1257 REVISION 1.0 Page 1 HSE – SPECIFICATION Setting Clear Requirements medical assessment reports resignation notices copy of PDO passes and driving licence. Excavation Register An excavation register shall be maintained on site. All inspections, including gas testing, shall be recorded immediately following the inspection/gas test. 1.4.2 Reports Data shall be submitted to the CSM Department monthly (refer to CP 122 HSE Management System Manual, Part 2 Chapter 6). For PDO staff, any non-compliance with this Specification shall be notified, investigated and reported per the ‘Non Compliance Report Form’ in CP 122 HSE Management System Manual, Part 2 Chapter 6. For Contractors, any non-compliances with this Specification shall be reported to the Contract Holder. 1.5 Responsibilities Asset Managers Asset Managers are responsible for ensuring that the activities they control are managed in accordance with the requirements of this Specification. In the event that circumstances prevent compliance with this Specification, Asset Managers shall seek the advice and if necessary, a ‘step-out approval’ from the Document Authority. This approval requires recording subject areas, which do not conform as a non-compliance (refer to the ‘Non Compliance Report Form CP 122 HSE Management System Manual, Part 2 Chapter 6). Corporate Functional Discipline Heads Corporate Functional Discipline Heads are responsible for ensuring that the requirements of this Specification are reflected in the documents for which they are responsible. Contract Holders Contract Holders are responsible for communicating this Specification to Contractors, and for ensuring that the requirements of this Specification are adhered to within the scope of their contracts. In the event that circumstances prevent compliance with this Specification, Contract Holders shall seek the advice and if necessary, a ‘step-out approval’ from the Document Authority. This approval requires recording subject areas, which do not conform as a non-compliance (refer to the ‘Non Compliance Report Form CP 122 HSE Management System Manual, Part 2 Chapter 6). Contractors Contractors are responsible for ensuring that activities undertaken within the scope of their contracts are managed in accordance with the requirements of this Specification and reported, where applicable to the Contract Holder. SP 1257 REVISION 1.0 Page 2 HSE – SPECIFICATION Setting Clear Requirements 1.6 Performance Monitoring Compliance with this Specification shall be monitored through workplace supervision, and periodic site inspection. 1.7 Review and Improvement Any user of this document who encounters a mistake or confusing entry is requested to immediately notify CSM using the ‘User Feedback Form’ provided in CP 122 HSE Management System Manual, Part 2 Chapter 3. This Specification shall be reviewed every 4 years. However changes to the current version may be made in less than four years as the need arises depending upon the issue of new and relevant environmental legislation and/or major organisational changes in PDO. SP 1257 REVISION 1.0 Page 3 HSE – SPECIFICATION Setting Clear Requirements 2.0 Performance Requirements 2.1 Legal Requirements Legal requirements for industrial safety in Oman are established in Chapter 7 of Sultan’s Decree No. 34 1973 “Oman Labour Law”. Legal requirements stipulate: Every employer must advise workers about workplace hazards, and the preventive measures to be employed. Every employer must take the necessary precautions to protect workers from injury to their health and safety by making sure that: Adequate safety and hygienic conditions prevail in all places of work Machinery, pieces of equipment and tackle are installed and maintained in the safest possible way Places of work are clean and comply with conditions of health and comfort A worker must: Not carry out an action which is forbidden by workplace instructions and is bad practice or causes damage. Not shortcut the means provided for protection of the worker’s health and safety, or the health and safety of fellow workers. Use protective methods and undertake to regard them with care, and carry out instructions laid down for the worker’s protection and the prevention of injury. Inspectors appointed by the Ministry have the power to examine the worker-related records of an establishment and to enter places of work. Inspectors also have the authority to question whoever they wish and to publish reports on the results of their investigations. On the basis of the reports produced by the inspectors, the Ministry will issue a written warning to an employer who infringes the regulations, stating the nature of the offence and the time limit set for it to be discontinued. If there is danger to the health or safety of workers, and the employer refrains from carrying out the instructions of the Ministry, the Ministry may order the premises to be closed down partially or completely, or to stop one or more pieces of equipment working. Any employer contravening the health and safety regulations stipulated above is liable to a fine not exceeding OR 5 for every worker employed. The punishment will be doubled if the offence is repeated. Any employer who refuses entry to inspectors, or provides false statements to inspectors is liable to a fine not exceeding OR 100 or one month imprisonment. The penalty will double if the offence is repeated. SP 1257 REVISION 1.0 Page 4 HSE – SPECIFICATION Setting Clear Requirements 2.2 Work on High Structures 2.2.1 Personnel Personnel shall be adequately trained and experienced in their work, specifically as applied to operating above ground level. Supervisors, adequate in number, training and experience shall be provided for the control of work. Personal Protective Equipment All persons working above ground level shall be provided with and shall use personal protective equipment, in accordance with the requirements of SP 1234 Personal Protective Equipment. 2.2.2 Means of Access The means of access to high structures such as scaffolding, hydraulically lifted baskets or suspended baskets, shall be of sound construction, suitable for the purpose and shall be approved by PDO prior to use. Where the means of access is of a mobile or portable type, it shall not be moved either mechanically or manually, whilst personnel are upon it, unless it is specifically designed and approved for the carriage of persons. Where the means of access is of a mobile or portable type, any loose articles e.g. tools, equipment, scaffold boards, etc. shall be removed or securely lashed down, prior to the means of access being moved. Where personnel must transfer from the means of access the high structure, or vice versa, the arrangements at the point of transfer shall be such that personnel are not at risk. The means of access shall adequately provide for safe means of egress, for all personnel, from the high structure. 2.2.3 The High Structure The integrity of the high structure shall be such that the required operations can be performed safely. This includes: 2.2.4 the loading of the structure e.g. men, equipment and materials the environmental conditions the forces imposed upon it by any means of access which is connected to it the forces imposed upon it by any lifting or winching operations in which the high structure serves as an anchor point, counterweight or tie point. Pre-Work Checks Before work commences, the supervisor in charge of the work shall ensure: SP 1257 that all necessary permits have been obtained. that any necessary electrical, mechanical and process isolations have been positively carried out. that all static, moving, lifting and anchoring equipment integral to the means of access and high structure, including those associated with the work task, are correctly fitted in a sound condition and fit for the intended purpose. REVISION 1.0 Page 5 HSE – SPECIFICATION Setting Clear Requirements 2.2.5 that all personnel have been provided with the required personal protection. that all personnel have been briefed in, and understand, the safety aspects of the job. Communications drills between members of the work team have been adequately rehearsed and all communications equipment is functioning. that suitable emergency transport is permanently available for use on site. Work Practices In order to minimise exposure to risk, the minimum practical number of personnel shall be assigned to the job. All operations above ground level (including scaffold erection and dismantling) shall be carried out in such a way that non-involved personnel in the vicinity of the work are not at risk. Personnel shall not be permitted to climb whilst carrying tools or heavy loads, the only exception being tools carried in a waist belt designed specifically for the purpose. Where necessary, tools shall be hauled up and lowered in a suitable container. Electrical, pneumatic and hydraulic tools shall not be hauled up or lowered by their power lines. Where practical, personnel shall not be assigned to work directly below the overhead work positions or other persons. Where this is unavoidable, suitable precautions shall be taken. Safety nets shall be installed. All personnel shall be attached to the structure using a suitable harness when not moving about the structure (ref SP 1234 Personal Protective Equipment). Tools, equipment etc. shall be kept in such a location that they do not represent a tripping hazard and cannot fall or be knocked from the structure. Where no catchment means are located below the workplace, safety lines shall be attached to tools and similar equipment. During the possibility of a thunderstorm, no work shall be executed at a height where a person can be exposed to lightning. All overhead work shall cease when wind speed reaches 40 km/h. The only exception being such work which is intended to render the high structure or its means of access safe. Any overhead work which must be carried out during the hours of darkness, shall be subject to written authorisation from the Company Site Representative. Such authorisation shall include the required standard of illumination. Erection and / or dismantling of scaffolding during the hours of darkness is only permitted in cases of extreme urgency and when no other practicable alternative can be identified. When overhead work is required on wet structures or their means of access, those facilities shall be inspected by the job supervisor and Company Site Representative prior to starting the work. SP 1257 REVISION 1.0 Page 6 HSE – SPECIFICATION Setting Clear Requirements Where such facilities become wet during the operation, work may continue only in order to make the structures safe. Work shall then cease until inspection by the job supervisor and Company Site Representative confirms that it is safe to continue. Upon completion of the day's work, all ropes and tackles shall be securely tied back to a permanent structure. The means of access shall be blocked off and any crane jibs shall be tied down to their resting brackets. Where there is a risk to third parties, high visibility warning tape, notice boards and warning lights shall be sited. 2.3 Scaffolding 2.3.1 General Adequate scaffolding and ladders shall be erected to provide safe access to all parts of any works situated 1.5 metres or more above ground level. Personnel, other than the Scaffold Inspectors, Scaffolders and Labourers involved, shall only be permitted upon scaffolding and staging that has been inspected and clearly labelled "ready for use" (refer section 2.3.4 of this Specification). No part of any operational line or pressurised piping shall be used as a support, or tie point for scaffolds or staging. All scaffolding and staging equipment shall be of a proprietary manufacture and shall meet the requirements of this Specification. The mixing of scaffold or staging types in any one structure (e.g., steel/aluminium couplers, wooden boards/metal grid boards) shall not be permitted. Access or general purpose scaffolding, or any part thereof, shall not be used as a support for any part of process plant. 2.3.2 Personnel In addition to the general requirements for working at heights, the following requirements apply to scaffolding work. Training and Experience All personnel employed for the purpose of erecting, modifying or dismantling scaffolding will meet the requirements of Table 1. The erection of proprietary system scaffold by unqualified personnel shall be an exception to the above requirement. All personnel who supervise activities that include the use of scaffolding and access platforms, including all HSE Advisers, shall complete LXE 044 “Scaffolding Appreciation” training course. Personnel who meet the requirements of a Scaffold Inspector in Table 1 (below) do not need to complete this course. Successful completion of this course does not, however, qualify personnel as Scaffold Inspectors for erection or dismantling. SP 1257 REVISION 1.0 Page 7 HSE – SPECIFICATION Setting Clear Requirements Table 1: Training and Experience Requirements Job Category Qualifications Scaffold Inspector Advanced Scaffolder Basic Scaffolder Trainee Scaffolder Experience CITB Advanced Scaffolder, or After qualification, 3 years working as an Advanced NVQ level 3 "Accessing" Scaffolder, the third year of which must be spent working with an inspector. Must hold certificate of demonstrated competence in scaffold inspection, as specified by current employer. CITB Advance Scaffolder, or Minimum 12 months on-site experience as a Basic Scaffolder NVQ Level 3 "Accessing" CITB Basic Scaffolder Part 2, or NVQ level 2 "Accessing" Minimum 12 months planned onsite experience as a Trainee Scaffolder. CITB Basic Scaffolder Part 1, Minimum 6 months continuous experience on site working or alongside Basic Scaffolder. NVQ level 1 "Accessing”, continuing towards CITB Basic Scaffolder part 2, or NVQ Level 2 “Accessing” Undertaken with an approved accredited training institute. Notes: All scaffolding personnel in Table 1 shall complete a PDO HSE Induction Course. Scaffolding personnel not holding (CITB) Construction Industry Training Board or (NVQ) National Vocational Qualification Levels 1, 2, or 3, may provide evidence of work experience, accompanied by theory based qualifications such as diplomas, degrees, trade certificates, etc. and seek PDO’s approval for compliance with Table 1. Personal Protective Equipment All persons involved in the erection and dismantling of scaffolding and staging shall be provided with and shall use personal protective equipment, in accordance with the requirements of SP 1234 Personal Protective Equipment. 2.3.3 Means of Access The means of access to, and means of egress from, all scaffolding and staging shall be via ladder/s or staircases. Ascending and descending any tower by using the horizontal members shall not be permitted. SP 1257 REVISION 1.0 Page 8 HSE – SPECIFICATION Setting Clear Requirements 2.3.4 Activity Controls Design and Approval The access and working scaffolds listed in Table 2 (below), with their construction criteria, shall be designed accordance with BS 1139 “Metal Scaffolding”. In all cases wind force, soil preparation and slope conditions are design criteria and subject to specific design types. Table 2: Loads and Dimensions for Scaffold Tube and Fittings Type of Scaffold Use of Scaffold loading per m2 Maximum number of working platforms Maximum spacing between Standards Typical load examples per bay Very light duty independent Light duty independent Inspection access and painting Power cleaning, painting, light engineering 75 kg 1 working platform 2.7 m 150 kg 2 working platforms 2.4 m 1 man and tools. No materials 2 men and tools. No materials General purpose independent Light engineering, e.g. welding or electrical 200 kg 2 working platforms and 1 at very light duty 2.1 m 2 men and 175 kg of materials Heavy duty independent Heavy engineering, e.g. large pipework or structural 250 kg 2 working platforms and 1 at very light duty 2.0 m 2 men and 250 kg of materials Scaffold Special purpose To be stated on design drawings All scaffolds outside the format of Table 2, shall be designed to BS 5973 “Code of Practice for Access and Working Scaffolds and Special Scaffold Structures in Steel” by a competent engineer. The engineer shall prove the design by applying engineering principles. In addition to the design sketch and calculations, the engineer shall provide a written erection/dismantling procedure. In all cases, the following scaffold types are subject to specific design: SP 1257 access scaffolds above 50m in height hanging or slung scaffolds external free standing scaffolds scaffolds required to withstand anticipated wind force to safeguard personnel and equipment false work and support scaffolds dependant on soil / slope conditions extra heavy duty scaffolds in excess of the heavy duty specification in Table 2 loading platform for loads exceeding 2.5 kN/m2 lifting access scaffolds public access scaffolds temporary roofs offshore overside scaffolds. REVISION 1.0 Page 9 HSE – SPECIFICATION Setting Clear Requirements Note: Hanging or slung scaffolds for onshore application do not normally provide the facility of conducting a lightning strike to earth and during the design of such scaffolds, consideration shall be given to suitable earthing arrangements (reference BS 6651). Various scaffolding systems are commercially available. However only PDO approved systems, equipment and material is to be utilised. No combination of different systems can be made unless approved in writing by PDO. Erection Prior to erection, any necessary work permits shall be obtained (ref PR 1172 Permit To Work System Procedure Manual). The operational and geographical parameters specified in the permit shall be fully complied with. 2.3.5 Pre Work Checks Prior to installation Prior to installation commencing a Scaffold Inspector shall inspect: the ground area upon which the scaffold is to be positioned. all equipment which shall form any part of the scaffold staging, means of access, work platform and lifting facilities. If the inspection proves satisfactory, approval shall be given for scaffolding installation. Such approval shall be recorded in the site scaffold/staging inspection log book (refer to Section 1.4 of this Specification). Prior to work each day For scaffolds outside the format of Table 2, after erection, and before work commences upon the scaffold, the engineer shall inspect and approve the scaffold and shall record this inspection in the site scaffold/staging inspection log book (refer to Section 1.4 of this Specification). Prior to work each day, a Scaffold Inspector shall inspect all scaffolding, staging and peripheral equipment. Where any scaffold or staging is altered or adjusted in any way, it shall be inspected by the Scaffold Inspector prior to work upon it re-commencing. Subsequent to rain or heavy wind, a Scaffolding Inspector shall inspect all scaffolding and staging prior to work re-commencing. Labelling A weather-proof plasticised or equivalent label (e.g., SCAFFTAG) shall be placed at each access point and at the boundary of each scaffold section to clearly indicate if the scaffold is “ready for use” or “not to be used”. The label shall state: SP 1257 Date erected, with name and initials of Scaffolder Date inspected, with name and initials of Scaffold Inspector Date modified, with name and initials of Scaffolder Date re-inspected, with name and initials of Scaffold Inspector (maximum 7 day intervals) REVISION 1.0 Page 10 HSE – SPECIFICATION Setting Clear Requirements Expiry date of label Dismantling date Other Signage Other signs to be placed at all access points to the scaffold indicate: “Incomplete Scaffold – Do Not Use” with a ‘cross’ marked in the centre. The letters shall be white on a red background and the sign shall be 400mm long by 300mm wide. Where access in by ladder, the lower section of the ladder shall be either removed or barricaded in such a way that the ladder cannot be ascended. “Scaffold OK to Use” with a ‘tick’ marked in the centre. The letters shall be white on a green background and the sign shall be 400mm long by 300mm wide Modifications Where any scaffold or staging is altered or adjusted in any way it shall be inspected and approved by the Scaffold Inspector prior to work upon it re-commencing. If unauthorised modifications are observed, they shall be reported to the supervisor and a “NOT TO BE USED” warning shall be displayed. 2.3.6 General Access Scaffolds Base Bases shall be adequate for the load imposed at each standard and for the weight of the whole scaffold. On hard surfaces, such as steel or good concrete, standards may be placed directly on the surface. On other surfaces (including soft surfaces and gratings) the load shall be spread by placing the standards on sole plates and base plates. The earth beneath shall be firm and level. Sole plates should preferably support at least two standards. Standards Standards shall be vertical or slightly inclined towards the host structure and shall be spaced to provide adequate support. Type of Scaffold Heavy duty scaffold General purpose Light duty/access Spacing 1.8 m 2.1 m 2.4 m Maximum Load 3.0 kN/m2 2.0 kN/m2 1.5 kN/m2 The joints of standards shall be staggered, so that all vertical joints do not occur in the same bay. Ledgers Ledgers shall be fixed horizontally inside of the standards. They shall be fixed with load bearing right-angled couplers. The joints of ledgers shall be staggered so that they do not occur in the same bay. SP 1257 REVISION 1.0 Page 11 HSE – SPECIFICATION Setting Clear Requirements Transoms Transoms shall be fixed to ledgers or standards with right-angled couplers or putlog clips. The maximum spacing for transoms shall be related to board thickness as follows: Board Thickness 32 mm 40 mm 51 mm 63 mm Transom Spacing 0.9m 1.5m 2.5m 3.2m Ledger Bracing Ledger bracing shall be provided between alternate pairs of standards. These shall start at base level and continue through the full height of the scaffold. They shall be coupled to the ledgers, close to the node point, using 90 degree couplers. Facade Bracing Facade bracing shall be provided to preserve longitudinal stability, unless such stability is provided by another means. Facade bracing shall start at base plate level and continue to the top lift, it may zig-zag from bottom to top, or can be a continuous sloping tube. It shall be tied at every lift to extend transoms, with rightangled couplers or to the standards with swivel couplers. Guard rails Guard rails shall be provided where the working platform is above 1.5m. They shall also be provided, at any height, where the scaffold is over water or where the person may fall onto dangerous surfaces, a fragile roof, machinery, etc. Guard rails shall be: between 1.0 and 1.2 m above the platform level rigid other than on tank/vessel staging, where they may be steel rope. Persons not moving around the staging shall be attached to the structure using a suitable harness (ref SP 1234 Personal Protective Equipment). Work Platforms Platforms shall be at least 600mm wide and may be made from various materials such as platform boards, scaffold boards or staging. Full details for various types of use are listed in the table below. Function Minimum Width Working platform only (no deposit of material) Passage of materials Deposit of materials (a passageway of 430 mm must be maintained) 600mm 600mm 800mm Note: Notwithstanding the above, the platforms shall be fully boarded between hand railings. SP 1257 REVISION 1.0 Page 12 HSE – SPECIFICATION Setting Clear Requirements Toe Boards Toe boards shall be provided around all open sides of work platforms, gangways or runs. They shall normally be placed inside the standards, securely fixed and shall extend at least 150 mm above the platform. The gap between the toe board and the guard rail shall not exceed 750 mm. On certain small tank/vessel stagings, toe boards may be impractical. In this case, written authorisation for exclusion may be requested from the PDO Company Representative. Ties Every scaffold, with the exception of tower scaffolds below 10 metres, shall be provided with ties fixing the scaffolding to fixed structures. These shall be fitted at a minimum ratio of one tie for every 40 m sq. of scaffold area and shall be evenly distributed throughout the scaffold. Ties shall comply with the requirements of BS 5973 “Code of Practice for Access and Working Scaffolds and Special Scaffold Structures in Steel” and types may be mixed where this enhances the integrity of the scaffold. Fans, Catchment Platforms Where it may be necessary to protect passing personnel or plant/equipment located below a scaffold, fans or catchment platforms, of adequate strength and dimension, shall be provided at optimum positions. Tube End Caps Tube end caps are mandatory for all tubes on erected scaffolds where personnel may come into contact with tube ends and risk injury. Boards Boards shall be securely fastened and supported to meet the requirements listed in the table listed below. Loose laid plywood sheets are not permitted for use as scaffold boards, staging, or platform boards. 2.3.7 Nominal Thickness of Board (mm) Maximum Span Between Supports (m) Minimum Overhang Maximum Overhang 38 50 63 1.5 2.6 3.25 50 50 50 150 200 250 Scaffold Material Standards In all cases access equipment, whether tube and fittings, proprietary systems or special equipment shall be suitable in all respects for its intended application. For the majority of applications this will entail the use of steel tube, fittings and boards in accordance with Table 3 (over). However, the use of proprietary systems manufactured from steel or aluminium or the use of special equipment shall be acceptable where the access is required for a short period only, or is required to be easily moveable and there is a firm footing. SP 1257 REVISION 1.0 Page 13 HSE – SPECIFICATION Setting Clear Requirements Aluminium alloy shall not be used in the construction of any type of scaffold in Zone 0 or Zone 1 hazardous areas. Table 3: Scaffold Material Standards 2.3.8 Material Standard Additional Requirements Steel tube BS 1139 Parts 1 and 2 Fittings BS 1139 Parts 1 and 2 Boards BS 2482 Only galvanised tube to be used. Tubes to be regularly inspected and cleaned. All tubes to be checked before use for corrosion and general condition. Defective tubes to be discarded. Butt welded tubes may be used on condition that the welding has been carried out to an approved procedure All fittings to be examined before use for damage and wear. Damaged or worn fittings to be discarded. No heat to be applied to fittings. Moving parts to be lubricated. Where any hot work is to be carried out, boards shall be protected with a noncombustible covering which shall be laid and tied in such a way that it shall not constitute a tripping hazard. Tower Scaffolds Where tower scaffolds are used, in addition to all preceding requirements, the following shall be provided: The work platform shall be within the base dimension. The minimum base to height ratio shall be: - 1:4 (internal) - 1:3.5 (external) Where ballast is required, it shall be properly positioned and securely lashed. Simple tower scaffolds of the prefabricated or system type may be erected, and altered by persons not qualified as Scaffolders. However, any tower structure more extensive than a simple 4-legged layout, or a tower constructed from tube and fittings shall only be erected by qualified Scaffolders and shall be subject to the requirements below. Prefabricated and system towers shall be assembled to manufacturer’s specifications and the manufacturer's maximum permitted loads shall be taken into account when selecting the type to be used. For towers constructed from tube and fittings, the maximum loading shall be 75kg/m2. The tower foundation shall be capable of sustaining the total load at all times so that a stable condition is maintained. Towers shall not be erected directly on recently made up ground or on lightweight manhole covers and timber spanning excavations. The legs of static towers shall always rest on metal base plates or SP 1257 REVISION 1.0 Page 14 HSE – SPECIFICATION Setting Clear Requirements castors and the load spread by timber soleplates at least 225mm wide by 40mm deep and long enough to ensure no undue ground settlement. All towers, regardless of the type of component used, shall be adequately braced. Mobile Tower Scaffolds Mobile scaffolds shall only be used on solid, level surfaces. All necessary precautions shall be taken when moving the scaffold. No person shall ride on any part of the scaffold. Castors/wheels shall be of 125 to 175 mm diameter and shall have effective locking devices. Wheels shall be locked facing outwards when the scaffold is not being moved. Foot ties shall be as near to the castor/wheels as is practical. The access ladder shall be clear of the ground and shall be an integral part of the scaffold or shall be of proprietary manufacture, and hooked to the scaffold in such away that it can not move during usage. The minimum base to height ratio shall be: 1:3.5 (internal) 1:3 (external) 2.3.9 System Scaffolds System scaffolds are proprietary systems fabricated from steel or aluminium alloy and comprise a complete set of unique components capable of assembly into a scaffold structure without the use of any other equipment. Using such systems, structures under 2.0 m in height and not exceeding 18m 3 in volume may be erected by unqualified personnel, under the guidance of qualified Scaffolders. In the case of wireline operations access, structures may be erected and inspected by Advanced Scaffolders with at least one year experience in that category. Personnel erecting system scaffold shall be able to read and fully understand the manufacturer’s instructions and shall follow these instructions at all times. If instructions are not available, work shall not proceed unless under the supervision of a qualified person. When using system scaffold, instructions shall be obtained from the system manufacturer when: deviations outside the normal system parameters are required sheeting or fans are added other changes are made which will affect the structural loading on the system. When manufacturer’s instructions are not available, deviations shall be the subject of specific designs. SP 1257 REVISION 1.0 Page 15 HSE – SPECIFICATION Setting Clear Requirements 2.3.10 Power Operated Mobile Work Platforms Personnel Training of WP operators shall be carried out at an approved Training Institute and followed by a R.O.P Heavy Equipment test. Design All power operated mobile work platforms (WPs) shall be approved by PDO. The following information shall be conspicuously displayed on the platform of a WP: the safe working load and the maximum number of persons allowed on the platform. the maximum gradient on which the WP may operate. Inclinometers, spirit levels or other suitable devices with scales, bands or other markings shall be provided so that the operator can easily see the tilt of the machine and whether it is within specified limits. The floor of the platform shall be slip-resistant and designed to prevent the accumulation of water. Safety devices shall be fitted to prevent the unwarranted movement of any part of the WP. A safe means of access and egress to the platform when at ground level shall be provided. Use Special precautions shall be taken when WPs are used in the vicinity of live electrical conductors (refer to SP 1242 Activities in the Vicinity of Overhead Power Lines). Maintenance, Inspection and Testing Before being put into service for the first time or following any major repair or alteration, a WP shall be tested over its range of duties with a proof load at least 1.5 times the safe working load by a specialist servicing company under the auspices of PDO. A certificate of test and thorough examination giving details of the results of the safe working load and range of duties of the WP shall be issued. Only qualified and authorised persons shall carry out adjustments and repairs to WPs. At the beginning of each work period, the operator shall check: SP 1257 pneumatic tyres are inflated to the correct pressure and tyres are free from cuts and damage the operation of the brakes the operation of any lights, which include safety warning lights/audibles lubricant, coolant and fuel levels the integrity of the supporting structure for leaks in hydraulic/pneumatic systems correct functioning of powered mechanisms, e.g. raising, slewing, etc. correct functioning of communications systems between platform and ground. REVISION 1.0 Page 16 HSE – SPECIFICATION Setting Clear Requirements At weekly intervals (or every 50 operational hours/manufacturer’s recommended intervals) an authorised maintenance person shall carry out: all checks made at the beginning of each work period and a full operational check of the appliance a check of the condition of the chassis, support structure, platform and powered mechanisms. At six monthly intervals (or 1000 operational hours/manufacturer’s recommended interval) a thorough examination shall be carried out by an authorised person. This type of examination shall also be carried out after an accident, major repair or modification. A certificate shall be issued by the authorised person stating that the WP is in safe condition. 2.3.11 Ladders Ladders shall be of proprietary manufacture and shall be constructed from timber or aluminium. Timber ladders shall not be painted. Ladders shall be positioned at 15 degrees off vertical and shall be adequately secured, with a minimum vertical protrusion of 1 metre at the upper step-off point. Where a height greater than 9 metres has to be climbed, a series of ladders with intermediate platforms properly protected with guard rails and toe boards, shall be provided. Aluminium ladders shall not be used in Zone 0 or Zone 1 hazardous areas. 2.3.12 Dismantling No persons other than trained, experienced scaffolders (refer to Table 1 of this Specification) shall be involved in dismantling scaffolding and staging. No items shall be thrown to the ground. It is preferable to lower all items by line, but lowering by hand is permissible if sufficient scaffolders are available. Relative to the reducing height of the scaffold/staging, boards shall be transferred down lift by lift to form adequate work platforms for the scaffolders involved in dismantling. SP 1257 REVISION 1.0 Page 17 HSE – SPECIFICATION Setting Clear Requirements 2.4 Work Over Water 2.4.1 General Requirements Structures and walkways over water shall be of suitable construction for their intended use and, where applicable, shall follow the requirements of this Specification. Vehicle access shall be controlled and the weight limit clearly displayed at the entrance to all such structures. Handrails shall be fitted and life buoys, with a minimum 27m of buoyant rope, shall be provided at intervals not exceeding 5m wherever people are regularly required to work over water. Effective means of communication (radio or telephone) shall be readily available. 2.4.2 Working Outside Handrails For construction and maintenance operations which have to be done outside handrails, or if handrails have to be removed, additional precautions shall be taken including the most practical of the following: a 'buddy' system shall be operated and each person required to wear a life jacket safety nets fitted, such that persons cannot fall more than 2 m Safety belts and line worn and attached such that personnel cannot fall into the water. a rescue boat, with a minimum crew of 2 men, stationed in the immediate work area and carrying rescue hooks or hoops. The action to be taken if a person falls in the water shall be agreed before the work starts and all personnel are to be made familiar with it. At least one person in the working group shall be trained in resuscitation. SP 1257 REVISION 1.0 Page 18 HSE – SPECIFICATION Setting Clear Requirements 2.5 Lifting Operations 2.5.1 General Lifting operations shall comply with the requirements of: PR 1508 Procedure for Lifting Operations SP 1239 Specification for Lifting Equipment and Lifting Operations SP 1251 Training Requirements for Lifting Operations Personnel. The Contractor's HSE Plan shall contain a method statement for critical lifting operations with drawings showing reach load and crane capacity. The following shall be considered in determining whether a lifting operation is critical: Weight of load (Load exceeding 50% of capacity of crane at the required reach shall be considered critical). Size of load Load bearing capacity of ground Facilities within the reach of the crane boom Lifting equipment such as cranes, winches, chain blocks, hoists and forklifts shall comply with SP 1239 Specification for Lifting Equipment and Lifting Operations and PDO’s SP 2000 Road Transport Manual. The lifting operator shall be responsible for following approved lifting plans, and shall discontinue the operation if any parameter deviates from the lifting plan conditions. All operators of lifting plant shall: complete a PDO “Vehicle Mounted Crane Operators” course (ref SP 1157 Specification for HSE Training), or hold a Level 2 NVQ in Lifting Plant Operations (Construction) awarded by the Association of Industrial Truck Trainers (AITT) or the Construction Industry Training Board (CITB), or have equivalent training and experience approved by PDO. Operators of other types of lifting equipment shall be trained to the satisfaction of PDO. All cranes shall be correctly supported and all outriggers and other lifting aids shall be deployed before lifting commences. Cranes and other side booms shall be positioned so that they lift vertically and are not used to pull loads sideways. Mobile lifting equipment shall not be operated when the top of the jib or fly-jib can reach within 3m of live overhead power cables. Other special precautions shall be taken when mobile lifting equipment is used in the vicinity of live electrical conductors (refer to SP 1242 Activities in the Vicinity of Overhead Power Lines). All lifting operations shall be controlled by a trained banks man. SP 1257 REVISION 1.0 Page 19 HSE – SPECIFICATION Setting Clear Requirements During lifting operations, no person shall be positioned beneath the load, hoist or jib. Similarly, loads shall not be slewed over the heads of personnel. 2.5.2 Gin Blocks Gin blocks shall be used to lift materials only when the load to be lifted does not exceed 50kg. Gin blocks shall never be used for personnel transfer. A gin block shall be mounted on a cantilever tube projecting outwards from the scaffold at a distance not exceeding 750mm. This supporting tube shall be attached to two standards. 2.6 Earthworks 2.6.1 General Earthworks shall comply with the requirements of: SP 1143 Specifications for Earthmoving and Construction Equipment ERD-17 01 "Civil and Building Construction Specifications" Section (C) "Excavation and Earthworks" BS 6031 " Code of Practice for Earthworks' In addition, the following requirements shall apply when performing earthworks: Position warning signs informing that earthworks are in progress. Such signs shall be: - in Arabic/English - pictorial - positioned to the satisfaction of the Company Representative. Ensure that all operators of plant are aware of hazards such as pits and slopes which may cause the plant to overturn and that these hazards are adequately marked with drums, stakes and/or bunting. Ensure that all plant is operated in a safe manner by suitably qualified and experienced supervisors. The suitability of operators and supervisors shall be demonstrated to the to the satisfaction of PDO. Under no circumstances shall any person drive any plant or equipment unless they have in their immediate possession a current Royal Oman Police licence for driving plant. Environmental requirements associated with earthworks are defined in SP 1012 Land Management. 2.6.2 Excavation Permit An excavation permit shall be obtained prior to the commencement of any excavation on, or in close proximity to, any camp, industrial area, residential area, designated road, or access road, temporary or otherwise, serving any facility previously mentioned. Specific requirements regarding excavation permits are described in the following documents: SP 1257 PR 1002 "Operations Excavation Procedure” for excavation where existing lines or services may be encountered. PR 1172 Permit to Work System Procedure Manual for excavation in the proximity of any oil, gas or other facilities SP 1104 Electrical Safety Rules for excavation at, or in the proximity of, any electrical facility (including gathering, transformer, feeder or testing facilities), REVISION 1.0 Page 20 HSE – SPECIFICATION Setting Clear Requirements sub-surface or overhead electrical transmission systems (including overhead line rights of way). Before any excavation or ground levelling is commenced, the Company Representative shall be consulted as to whether an excavation permit is required. 2.6.3 Excavation and Trenching Prior to Excavation Commencing Prior to any excavation commencing, the supervisor in charge of the work shall ensure that all required equipment is on site before authorising the work to begin. The excavation shall be carried out in strict accordance with the conditions stated on the permit. If any marker, pipe, cable or foundation not identified on the excavation permit is uncovered, work shall stop immediately and a report shall be made to the person issuing the permit. Inspections All excavations shall be inspected daily, before work starts, by a person suitably qualified and approved by PDO. Such inspections shall include all parts of the excavation, including of shoring, supports and access. Where the permit requires the excavation to be gas tested before work starts, the above mentioned inspection shall not be carried out until the excavation is proven to be gas free. All excavations shall be inspected subsequent to any rain, and subsequent to the ingress of water from other sources. Where the water entering the excavation appears to be ground water, work shall cease immediately until the excavation has again been cleared as being gas free. Work Practices When hand digging is specified, personnel shall be informed that picks and shovels can damage cables and GRE and steel pipelines. Work requiring the digging of trenches shall be programmed so that trenches are left open for no longer than is essential. All trenches, slopes or pits, in excess of 1.2m in depth, into which personnel may be required to enter, shall be suitably shored to prevent cave-ins or sliding materials. The use of a trench cage or trench box may also be permitted. In all cases the protection shall be designed by an engineer qualified for such work and endorsed by the responsible supervisor for the work. As an alternative, all sides of the excavation, trench or pit in excess of 1.2m in depth may be sloped back to a safe angle of repose to prevent earth slides. This can vary in dry conditions from vertical in rock, to 1:1 for sand. In such cases, the angle of repose shall be determined by an engineer qualified for such work and endorsed by the supervisor for the work In the event that an Excavation Permit is required, the design of the cave-in protection shall be attached to the permit. SP 1257 REVISION 1.0 Page 21 HSE – SPECIFICATION Setting Clear Requirements Excavated earth shall not be stored close to the trench edges. Where practical, a one metre wide strip on both sides of the trench shall be levelled and cleared of loose items/materials. This strip may be used to store materials required in the excavation for a short period, provided such materials are stored in a safe manner. If there is a possibility that materials may fall into the excavation or may initiate an earth slide, then they shall not be placed on this strip. Personnel shall not work or move close to the edges of excavations. Temporary crossings for personnel shall be provided over any trench. Such crossings shall be at least 600 mm wide, of adequate strength and shall have a handrail on at least one side. All pits, trenches and excavations (excepting main oil/gas pipelines during construction stage) shall be roped off and suitable warning notices shall be provided. Where any excavation is to remain open during the hours of darkness, warning lights, in sufficient numbers, shall be strategically positioned. All pits, trenches, and excavations associated with the construction of main underground pipelines shall conform to the requirements of PCS01"Pipeline Construction Specification ". Where any plant (i.e. power shovel, digger, rock breaker, etc.) is working around, or in an excavation, no person shall be permitted to work in the excavations within 5m of the machine, or within 3m of the maximum reach of the machine. Where personnel are required to hand trim excavations within 5m of the machine, it shall be stopped from operating until the hand trimming is complete. All equipment exhaust gases shall be directed away from the excavation to avoid accumulation of toxic gases in the excavation. For excavations or pits where natural oxygen supply might be hampered, tests shall be made to check oxygen levels and air supply blowers may have to be installed. 2.6.4 Specifications and Backfilling The following backfilling specifications shall be precisely followed: Particulate size and depth of bed, overburden and compaction density. The backfilling of an excavation can affect the integrity of the service lines/cable within the excavation or trench. Cable tiles and markers Separation in common service trenches, whether physical separating or separation by distance Where tipper trucks are used to dump fill in or close to trenches, a banks man shall be available to stop reversing vehicles from getting too close to the excavation. 2.6.5 Restoration Excess spoil, not backfilled into the excavation, shall be removed from site, unless a windrow is specified. The supervisor in charge of the work shall ensure that the backfilled and compacted excavation matches the level of the surrounding earth, and shall sign to this effect in the Excavation Register (refer to Section 1.4.1 of this Specification). SP 1257 REVISION 1.0 Page 22 HSE – SPECIFICATION Setting Clear Requirements 2.6.6 Identification of Services Mark existing drawings to show where new services have been laid in an area, or where redundant services have been removed from an area. 2.6.7 Roadworks Work carried out on, across, or within 2.5 m of a road shall comply with the requirements ERD-17-08 “Guide to Safe Road Works”. In addition, the following shall apply: Inform the Company Representative and the Royal Oman Police Force of the location and estimated duration of the work, at least 72 hours before the work starts. If practicable ,construct a by-pass road away from the works as agreed with the Company Representative. Provide warning signs as detailed in the Ministry of Communications Highway Design Standards, or where necessary, other signs as requested by the Company Representative. Provide flag-men to warn and control traffic. Flag-men shall be competent persons aware of their responsibilities. Provide fluorescent type vests for all personnel involved in the work and ensure that they are worn at all times. During hours of darkness, provide operational flashing lamps, amber in colour, situated in such a manner as to clearly indicate the hazard to road users. Ensure the cleanliness of the road immediately adjacent to the area of work and that no hazard to road users exists. Where graders are in use, drivers shall maintain a gap of at least 50m between machines. The leading machine on the team shall drive on the right hand side of the road. Where Contractor’s operations cause damage to the roads on, or leading to, a worksite which is in excess of the regular wear and tear covered by PDO’s normal road maintenance programme, the Contractor shall repair the damage. On completion of the work, road(s) shall be left in a safe and satisfactory condition. Measures shall be taken to prevent debris from falling onto the roads and to continuously remove any such debris that does fall onto the road during the work. Environmental requirements associated with roadworks are defined in SP 1012 Land Management. 2.6.8 Rock Breaking Hydraulically operated hammers are recommended for all rock-breaking activities. The alternative of blasting using explosives shall only be applied in those cases where a clear financial advantage is present (e.g., long buried pipelines) and subject to prior approval from PDO. In such a case the following shall apply : Royal Oman Police "General Rules for Blasting" All personnel involved in the blasting site activities shall be approved by PDO The Contractor shall submit a safety plan including but not limited to the following topics: - receipt of explosives and detonators, SP 1257 REVISION 1.0 Page 23 HSE – SPECIFICATION Setting Clear Requirements - transport and storage site preparation demarcation of safe areas protective equipment warning signs detonation misfiring procedures emergency contingency procedures. The Contractor shall have the Safety Plan for blasting verified and signed by an independent consultant specialised in blasting operations. SP 1257 REVISION 1.0 Page 24