General Audits

advertisement

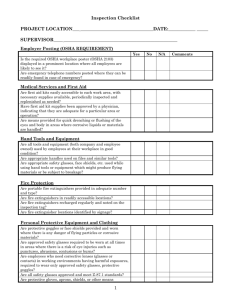

BLOOD BORNE PATHOGENS Place a check mark by all defective conditions you find from the list below. __ 1. Company does not have Blood borne Pathogen Exposure Policy with the following elements. __ 2. Companies Blood Borne Pathogen Exposure Policy does not contain the following: __ a. List of immediate actions to be taken by exposed employees. __ b. When and how quickly an employee must report an exposure. __ c. Where and to whom the exposed employee must report. __ d. Which forms the employee must complete. __ e. Directions for investigating the incident. __ f. Medical follow-up including post-exposure vaccinations. __ 3. Company 1st Aid Training does not include training in preventing disease transmission. __ 4. First aid kits do not contain proper self-protective equipment. Check missing items below.) __ a. Gloves (add Mask, Goggles & Gown for severe arterial bleeding.) __ b. Anti-bacterial wipes when hand-washing is impractical. __ c. Resuscitation mouthpieces. __ 5. Employees are not trained in locations of emergency wash stations (eye wash, etc.) COMPRESSED GASES Place a check mark by all defective conditions you find from the list below. __ 1. Tanks and cylinders of oxygen, acetylene, propane or other compressed gases not in an upright position for storage. (Acetylene cylinders that have been tipped must be stored upright overnight before using.) __ 2. Tanks of oxygen, acetylene, propane or other compressed gases not transported with the gauges removed and safety caps mounted. __ 3. Compressed gases including compressed air being blown towards any person or used to blow off dust. __ 4. Oxygen & fuel gasses not stored 20 ft apart or with no approved firewall between them. __ 5. Compressed gasses for welding not transported with approved cart. CONFINED SPACE ENTRY Place a check mark by all defective conditions you find from the list below. __ 1. Confined spaces not labeled and permit-required confined spaces not identified as such. __ 2. Entry Permits not completed and filed before entering permit-required confined spaces. __ 3. Corrective action not taken before permit-required confined spaces entered. __ 4. Confined space entered that has not had the energy controls locked out. __ 5. Confined space entered without an attendant stationed outside trained in how to rescue entrant. __ 6. Entering a permit-required confined space when the potential for engulfment, oxygen deficiency, or toxic or flammable gas buildup exists. __ 7. Continuous monitoring by trained and approved personnel not being done while performing operations such as welding, burning, grinding, cleaning, etc. (operations which may change the atmosphere) in a confined space. CONVEYORS Place a check mark by all defective conditions you find from list below. __ 1. Workers on conveyors who are not authorized and who have not received task training operating conveyors. __ 2. When the operator does not have a full view of the conveyor, the conveyor is not equipped with an audible warning siren that can be sounded 30 seconds prior to starting the conveyor. (If the conveyor isn't started at the 30-second time, another warning must be sounded and another 30-second interval allowed before starting.) __ 3. A conveyor being loaded or put into motion before a check is made to verify that all employees are clear. __ 4. Conveyors not locked out and tagged out with a "Do Not Operate" tag during repairs and when operation is hazardous to employees performing maintenance work. __ 5. Workers riding or walking on a moving conveyor belt. __ 6. Adjusting skirts and scrapers while conveyor belts are running. __ 7. Workers adjusting belts on conveyors who are not authorized and who have not received task training in the specific pre-approved procedures CRANES AND HOISTS Place a check mark by all defective conditions you find from the list below. __ 1. Overhead hoists or cranes being operated by workers without task training. __ 2. Mobile cranes not being operated by certified crane operators. __ 3. Pre-use inspections not being done or done properly on equipment. a. Check controls to verify proper function. b. Check pendant cables for cuts, kinking, or signs of wear. c. Check swaged sockets for damage and pins for excessive wear. d. Visually check hoist cables for fraying, kinking, crushing and twisting of the cables between the cable and the drum. e. Visually inspect the hook for cracks, bending or distortion. __ 4. Malfunctioning hoist not tagged with tag describing malfunction. __ 5. Not using a spotter when working near overhead power lines. (Neither the hoist nor any portion of the cable can come within 10 feet of any overhead power line.) __ 6. Exceeding the safe load limit of hoisting equipment. (Only trained and approved persons who are completely familiar with the weight capacity at various locations and boom angles are permitted to operate hoists.) __ 7. Equipment with the weight capacity not prominently displayed). __ 8. Load chains that have been lengthened or repaired. __ 9. The hoist not positioned directly over the load. __ 10. Swinging the hook or load when moving the hoist. __ 11. Not pulling in a straight line (Hoist body or load chain/rope angled around something. __ 12. After placing the hook in the lifting ring, NOT applying slight pressure to the hoist to ensure that the lifting ring is seated in the bottom of the hook and that the hook is properly aligned. __ 13. Between lifts, not checking to see that the rope is properly reeved on drum. __ 14. Not attaching sufficient guide ropes to control the load. __ 15. Not checking the intended movement path to see that it is clear of people and obstructions and that the intended destination is ready to receive the load. __ 16. Tampering with any part of the hoist when worker is not authorized to do so. __ 17. Not checking brakes for excessive drift. __ 18. Workers not positioning themselves on the pendant side of the hoist to get maximum clearance from the load and to prevent entanglement of cables. __ 19. Starting, stopping, or reversing a load suddenly. __ 20. Failure to raise the load only high enough to avoid obstructions. __ 21. Hoisting loads over workers -- not waiting until the area is clear. __ 22. Leaving a load suspended in the air without attendants. __ 23. Untrained or unqualified personnel operating hoists. __ 24. Carrying workers on the hook or load. __ 25. Operating a hoist to the extreme limits of the chain or rope. __ 26. Using the hoist rope or chain as a sling. __ 27. Not keeping loaded sling ropes or chains as near to vertical as possible (horizontal sling ropes, chains or cables may break or be severely damaged). __ 28. Use the hoist chain or rope as a ground for welding or touching a live welding electrode to the chain or rope. __ 29. Chains and slings not inspected regularly for damage. (Where damage is found, chains and slings must be replaced.) __ 30. Inspection records not kept on chains, hooks, etc. in accordance with OSHA. __ 31. Replacing a clevis pin with a bolt. CRUSHING AND SCREENING PLANTS: Place a check mark by all defective conditions you find from the list below. __ 1. Tools or other material left on stairs, platforms, walkways, belts or machinery. __ 2. Hand rails on stairs not maintained in good condition. __ 3. Repairing, oiling or wiping of machinery being done while machinery is in motion (Does not include machinery that is properly adapted to do these services without removing guards or contacting the equipment with moving parts.) __ 4. Belts being installed while machinery is running. __ 5. Conveyor head pulleys, tail pulleys and idlers being cleaned while conveyor is in motion. __ 6. Machinery being started after repair work before inspecting to make sure all tools are removed and all personnel are in the clear. __ 7. Approved company lock-out/tag-out procedures not being used on repair jobs or any time personnel are working on equipment. FIRE FIGHTING & FIRE EXTINGUISHERS Place a check mark by all defective conditions you find from the list below. __ 1. Employees with no training or inadequate training in the use of fire extinguishers. __ 2. Employees unable to show location of fire extinguishers in their area or explain how to use them. __ 3. Mobile equipment without an approved fire extinguisher designated as type ABC mounted on the vehicle in a location that is easily accessible to the operator. __ 4. Work areas, buildings, offices, etc., without an approved fire extinguisher readily available. __ 5. Fire extinguishers not placed in an accessible well-marked location. __ 6. Articles placed on, or in front of, any fire-fighting equipment or in a position that will obstruct its accessibility or hinder its use. __ 7. Fire Department phone numbers not conspicuously posted at all telephones. __ 8. Employee not trained to direct emergency personnel to his/her work location. __ 9. Used fire extinguisher not replaced immediately. LADDERS SAFETY CHECKLIST Place a check mark by all defective conditions you find from the list below. __ 1. Defective ladders not tagged for immediate repair or disposal. __ 2. Ladders placed in passageways or any other location where they may be knocked down unless protected by barricades or guards. __ 3. Portable ladders not of industrial quality or meeting ANSI standards. __ 4. Workers on straight ladders standing on any of the top three rungs (top two for stepladders). __ 5. No mechanical devices (such as block and tackle, ropes or hoists) available for raising bulky or heavy materials which could make ladder climbing difficult. __ 6. Straight ladders not equipped with safety feet or something to lash the top with. __ 7. Ladders in use carrying more than one worker. __ 8. Stepladders in use not fully open or on all four (4) feet (secure base). __ 9. Workers using unapproved scaffolding, rope, and rails. __ 10. Workers not using company-provided ladders. __ 11. Straight ladders not placed with the feet one-fourth the length of the ladder out from the wall (or out from a point directly below the top of the ladder) and tied off on the bottom and top. __ 12. Wood ladders that have been painted over. __ 13. Metal ladders. (Not allowed for electrical hazards.) __ 14. Portable ladders improperly stored - never store upright unless tied off at bottom and top. OFFICE SAFETY CHECKLIST Place a check mark by all defective conditions you find from the list below. __ 1. Items stored out of reach. __ 2. Heavy items stored on upper shelves. __ 3. Superfluous materials (including files, papers, books etc.) not disposed of. __ 4. Sharp or jagged corners on doors, desks, chairs, shelving, file cabinets, etc. __ 5. Lack of ladder or step stool where needed. __ 6. Waste receptacles being used as ashtrays. __ 7. Cabinet doors or drawers open. __ 8. Poor general housekeeping __ 9. Unstable shelving or overloaded shelves. __ 10. Doors left open, unnecessarily. (Follow fire marshal's rules about doors.) __ 11. Heaviest loads not in lower drawers in multi - drawer file cabinets. __ 12. Power cords running across walking or work area floor. __ 13. Office workers not trained in proper lifting techniques, or not using proper lifting techniques. __ 14. Heating electrical appliances (coffeepots) not on fireproof surface or left on when not in use. __ 15. Unstable office chairs or other furniture. __ 16. Insufficient ventilation for personnel using office. PERSONAL PROTECTION AND PPE CHECKLIST The first line of defense against accident or injury will be the development of a suitable engineering control - one, which eliminates the hazard. The second line of defense will be a change in administrative procedures, which minimize exposure of employees to the hazard, and the third line of defense will be PPE. An in-depth evaluation of the workplace to determine what PPE is needed will be made annually or whenever major process modifications occur to determine what, if any, changes in the requirements for PPE are recommended. Place a check mark by all defective conditions you find from the list below. __ 1. Company-approved safety glasses and hard-toed shoes not being worn in all locations. __ 2. Hard hats not worn in all areas except in company offices. __ 3. Workers not wearing extra PPE required in special work areas. Specific work areas may require the use of goggles, gloves, aprons, or respirators. __ 4. Areas requiring special PPE not posted or employees not instructed on the PPE they are required to use. __ 5. The proper face shield, goggles or protective hood must be worn over safety glasses when grinding, welding, cutting, working with molten metal or other similarly hazardous materials. __ 6. Company-approved hearing protection not being worn in designated areas or as required by conditions. __ 7. Gloves being worn where they are creating a greater hazard by becoming entangled in the moving parts of machinery. __ 8. Machines where gloves are forbidden are not posted as such. __ 9. Seat belts not fastened before mobile equipment is moved on plant premises. __ 10. A Coast-Guard-approved flotation device not used while working where there is a danger of falling into water. __ 11. A life ring with rope attached not in the immediate area where workers are exposed to water danger. __ 12. Respirators not used when spray painting or performing other operations that may contaminate the air with dust or fumes and foreign particles. __ 13. Respirators not being used in areas where MSHA has found employee overexposures to dust. __ 14. A worker wearing a respirator that has not been fit tested, trained, or had a medical evaluation. __ 15. Personal Fall Arrest Systems not used when there is a danger of falling. __ 16. A safety belt being worn as a fall arrest system. __ 17. Any employee on a walking/working surface with an unprotected side or edge which is 6 feet or more above a lower level that is not protected from falling by the use of a guardrail system, a belt and lanyard which prevents the person from walking over the edge, or a full-body harness and shock-absorbing lanyard. __ 18. Employees not trained before using personal fall protection. __ 19. A second person not tending the lifeline when bins, tanks, silos or other dangerous areas are entered. __ 20. Floor openings not guarded by standard guardrails and toeboards or covers that are secured against accidental displacement. __ 21. Floor hole covers not stenciled "Hole Cover - Do not remove". ALCOHOL AND DRUG SAFETY. Place a checkmark for deficient policy, training, or condition. __ 1. Company has no policy on "On Property Alcohol/Drug Use". __ 2. Company policy does not contain the following elements (Check all that apply): __ a. Disciplinary actions for Alcohol/Drug use on property. __ b. Employee actions required when taking a prescription drug. __ c. Drug and alcohol testing policy. __ d. Training supervisors to recognize employee drug use. __ 3. Supervisors trained to use "Employee -Fit for duty" checklist (See below). "Red Flag" behaviors indicating possible alcohol/drug use. __ Poor coordination and balance. __ Inappropriate verbal response to questions. __ Unusual tardiness or long absences from assigned tasks. __ Smell of alcohol/drugs about the person. __ Inappropriate emotional responses (Usually exaggerated.) __ Observation of actual use.