Multistep Synthesis of Benzilic Acid from

Benzaldehyde

Jackson Wyers

March 17, 2013

Texas A&M at Galveston, Galveston, Texas

INTRODUCTION

Benzilic acid is known as an alpha-hydroxy acid or (AHA).

Typically, benzilic acid is an expensive material; however, a three part

synthesis reaction can be conducted in order to convert the rather

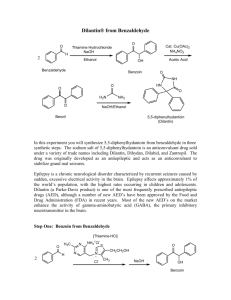

inexpensive benzaldehyde. In the overall synthesis, three different

reactions will occur. The first reaction is recognized as the benzoin

condensation reaction and is demonstrated in Equation 1. The

condensation occurs by adding heat to a mixture of benzaldehyde,

thiamine hydrochloride, and sodium hydroxide in an ethanol solution.

Equation 1: Benzoin condensation

this experiment deals with many compounds that have either (O-H)

bonds, (C=O) bonds, or both.

EXPERIMENTAL

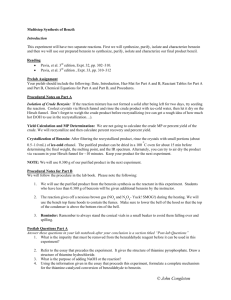

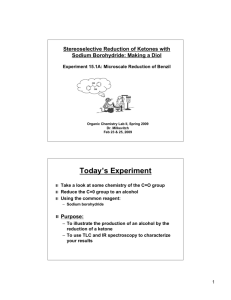

A flowchart – Figure 1 – is attached to summarize and outline the

procedures and reagents.

Benzaldehyde to Benzoin. 0.5 grams of thiamine hydrochloride

was dissolved in 0.8mL of water. 5.0mL of 95% ethanol was added

and the solution was then cooled in an ice bath. 1.0mL of 3M sodium

hydroxide was added dropwise while stirring. The pH was tested to

assure it was strongly alkaline. 15.0 mmol of benzaldehyde was then

added to this solution. Parafilm was then used to seal the flask

containing the mixture and was heated on a hot plate for

approximately two hours. Once finished heating, the flask was placed

in a dark drawer and was left undisturbed for one week.

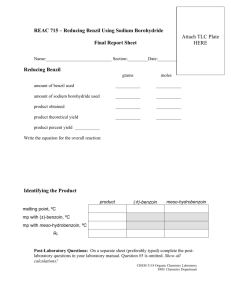

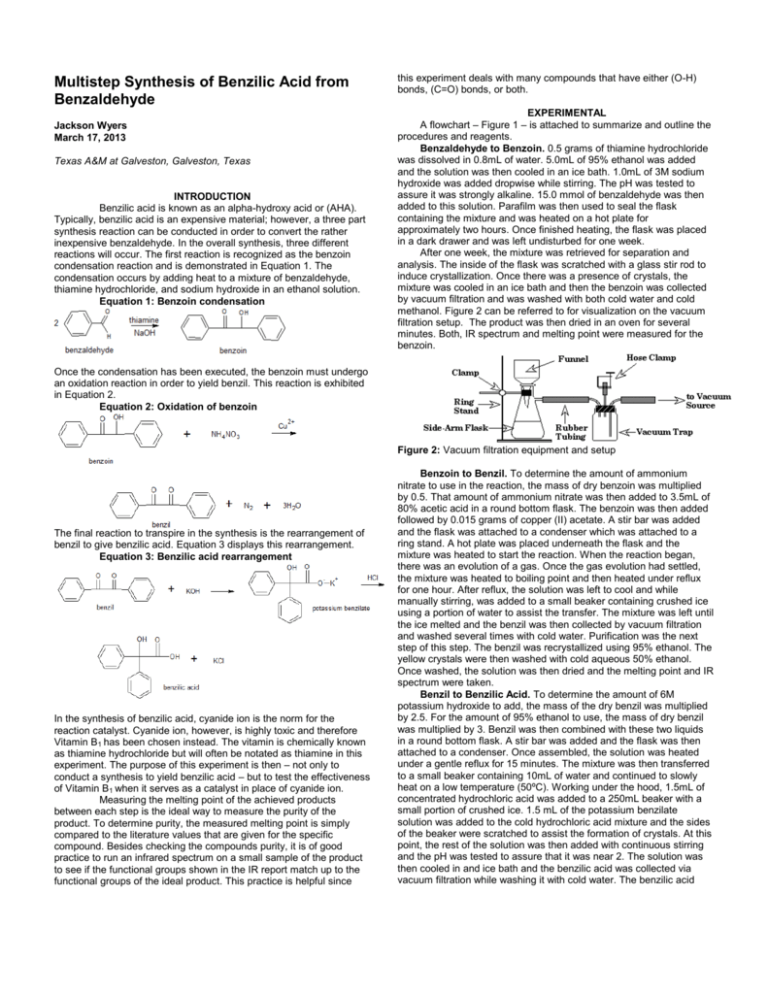

After one week, the mixture was retrieved for separation and

analysis. The inside of the flask was scratched with a glass stir rod to

induce crystallization. Once there was a presence of crystals, the

mixture was cooled in an ice bath and then the benzoin was collected

by vacuum filtration and was washed with both cold water and cold

methanol. Figure 2 can be referred to for visualization on the vacuum

filtration setup. The product was then dried in an oven for several

minutes. Both, IR spectrum and melting point were measured for the

benzoin.

Once the condensation has been executed, the benzoin must undergo

an oxidation reaction in order to yield benzil. This reaction is exhibited

in Equation 2.

Equation 2: Oxidation of benzoin

Figure 2: Vacuum filtration equipment and setup

The final reaction to transpire in the synthesis is the rearrangement of

benzil to give benzilic acid. Equation 3 displays this rearrangement.

Equation 3: Benzilic acid rearrangement

In the synthesis of benzilic acid, cyanide ion is the norm for the

reaction catalyst. Cyanide ion, however, is highly toxic and therefore

Vitamin B1 has been chosen instead. The vitamin is chemically known

as thiamine hydrochloride but will often be notated as thiamine in this

experiment. The purpose of this experiment is then – not only to

conduct a synthesis to yield benzilic acid – but to test the effectiveness

of Vitamin B1 when it serves as a catalyst in place of cyanide ion.

Measuring the melting point of the achieved products

between each step is the ideal way to measure the purity of the

product. To determine purity, the measured melting point is simply

compared to the literature values that are given for the specific

compound. Besides checking the compounds purity, it is of good

practice to run an infrared spectrum on a small sample of the product

to see if the functional groups shown in the IR report match up to the

functional groups of the ideal product. This practice is helpful since

Benzoin to Benzil. To determine the amount of ammonium

nitrate to use in the reaction, the mass of dry benzoin was multiplied

by 0.5. That amount of ammonium nitrate was then added to 3.5mL of

80% acetic acid in a round bottom flask. The benzoin was then added

followed by 0.015 grams of copper (II) acetate. A stir bar was added

and the flask was attached to a condenser which was attached to a

ring stand. A hot plate was placed underneath the flask and the

mixture was heated to start the reaction. When the reaction began,

there was an evolution of a gas. Once the gas evolution had settled,

the mixture was heated to boiling point and then heated under reflux

for one hour. After reflux, the solution was left to cool and while

manually stirring, was added to a small beaker containing crushed ice

using a portion of water to assist the transfer. The mixture was left until

the ice melted and the benzil was then collected by vacuum filtration

and washed several times with cold water. Purification was the next

step of this step. The benzil was recrystallized using 95% ethanol. The

yellow crystals were then washed with cold aqueous 50% ethanol.

Once washed, the solution was then dried and the melting point and IR

spectrum were taken.

Benzil to Benzilic Acid. To determine the amount of 6M

potassium hydroxide to add, the mass of the dry benzil was multiplied

by 2.5. For the amount of 95% ethanol to use, the mass of dry benzil

was multiplied by 3. Benzil was then combined with these two liquids

in a round bottom flask. A stir bar was added and the flask was then

attached to a condenser. Once assembled, the solution was heated

under a gentle reflux for 15 minutes. The mixture was then transferred

to a small beaker containing 10mL of water and continued to slowly

heat on a low temperature (50ºC). Working under the hood, 1.5mL of

concentrated hydrochloric acid was added to a 250mL beaker with a

small portion of crushed ice. 1.5 mL of the potassium benzilate

solution was added to the cold hydrochloric acid mixture and the sides

of the beaker were scratched to assist the formation of crystals. At this

point, the rest of the solution was then added with continuous stirring

and the pH was tested to assure that it was near 2. The solution was

then cooled in and ice bath and the benzilic acid was collected via

vacuum filtration while washing it with cold water. The benzilic acid

was then recrystallized from boiling water. The product was then dried

and weighed. An IR spectrum and the products melting point were

measured. Percent yield calculations were then done for each step of

the synthesis and then for the overall reaction.

Benzoin to Benzil

IR spectrum 3 shows the IR reading for benzil.

RESULTS

The results of the synthesis are split into the three different steps

of the overall reaction.

Benzaldehyde to Benzoin

IR spectrum 1 shows the IR reading for benzaldehyde.

Initial mass of benzoin – 0.51 grams

Mass of benzil recovered – 0.173 grams

Mass of NH4NO3 used – (0.51 grams x 0.5) = 0.255 grams

Melting

Point

93.14ºC

Table 2: The table shows data retrieved for benzil.

Lit. Value

Theoretical

Actual

Percent

Yield

Yield

Yield

95-96ºC

0.505 g

0.173 g

34.26%

0.51g L.R. (benzoin) x (1mol/212.2g benzoin) x (210.2g benzil/1mol) =

.505g = theoretical yield

Percent Yield of Benzil = (0.173g / 0.505g) x 100 = 34.26%

IR spectrum 2 shows the IR reading for benzoin.

Benzil to Benzilic Acid

IR spectrum 4 shows the IR reading for benzilic acid.

An error occurred in this step of the synthesis. Instead of having solid

benzoin form after letting the previously heated benzaldehyde, the

flask simply had a dark orange liquid with no solid. Therefore, 0.51

grams of benzoin was partitioned from the instructor to continue the

synthesis.

Melting

Point

132.27ºC

Table 1: The table shows data retrieved for benzoin

Lit. Value

Theoretical

Actual

Percent

Yield

Yield

Yield

137ºC

1.6 g

0.51 g

31.9%

Percent Yield = (Actual Yield / Theoretical Yield) x 100

Percent Yield of Benzoin = (1.6g / 0.51g) x 100 = 31.9%

Table 3: The table shows data retrieved for benzilic acid

Melting

Lit. Value

Theoretical

Actual

Percent

Point

Yield

Yield

Yield

129.17ºC

150ºC

0.1878 g

0.116 g

61.78%

0.173g of L.R. benzil x (1mol/210.2g benzil) x (228.2g benzilic acid /

1mol) = 0.1878g = theoretical yield

Percent yield of benzilic acid = (0.116g / 0.1878g) x 100 = 61.78%

DISCUSSION

The two major purposes of the experiment were to get benzilic

acid from benzaldehyde and to determine the effectiveness of Vitamin

B1 serving as a catalyst for the reaction. Benzilic acid was successfully

retrieved from the multistep synthesis however, the yields were much

lower than expected. These low yields could imply that the thiamine

hydrochloride is a poor catalyst for the synthesis; yet, thiamine has

been shown by professionals to serve as an effective and efficient

catalyst. Therefore, the low yields are likely due to procedural error.

Had this been a test on a previously untested catalyst, it would be a

good idea to further test and question the effectiveness of the catalyst

since it could be the reason for the low yields. Aside from the low

yields, the overall success of the experiment was above par and the

ideal product was reached.

Judging by the results, the percent yields were an obvious

problem. Out of the three yields, two were in the thirtieth percentile.

However, the final yield of benzilic acid was a good yield at 61.78%.

The percent yield of benzoin was 31.9% which was lower than

intended. The similar problem occurred with the percent yield of benzil

which had a yield of 34.26%. Both of these values fall into the thirtieth

percentile range, which is considerably low when an ideal yield should

have been up into the seventieth percentile or above. It is noteworthy

that the actual yield of 0.116 grams of benzilic acid did not come from

the conducted experiment. In the experiment conducted, there was an

error when the benzilic acid was to be filtered, there was not any solid

recovered. One cause of this error could have been due to the filter

paper that was used. However, this would have only affected a small

portion of the solid so there obviously were other problems. Therefore,

data on amount of benzilic acid had to come from other peer data.

This is the likely explanation as to why the yield is higher and does not

correlate with the yields of benzoin and benzil. It was previously stated

that due to an error in the first step of the experiment, a set amount of

pure benzoin was given to begin the second step. The portions that

were given out varied, and therefore the percent yield of benzoin was

directly determined by how much benzoin the instructor happened to

measure out. The numerous problems were solved as sufficiently as

possible and should not have affected the data any more than the

previously discussed possibilities.

When assessing the IR spectrums, they all appear to correlate

with the structures of the compounds. Benzaldehyde exhibits its (C=O)

stretching at 1702.39 which is in the literature range of 1740-1685.

Benzoin has aromatic peak at 3003.73 which is in the literature range

of 3100-3000. It also shows it (C=O) stretch at 1751.11, again in

range. However, the only problem with the benzoin IR is the depth of

the (O-H) stretch. You should expect to see a large bulge at the 36003200. It does show a stretch at 3413.31, yet it is very shallow. The

likely cause is that not enough of the benzoin sample was placed on

the salt disc when the IR spectrum was run. This would explain why

the (O-H) bulge is shallow and the peaks shallow as well. The

spectrum for benzil looks as it should. There is (C=O) stretching at

1713.04 which falls well within literature values. It also shows its

aromatic peak at 3003.90, which is again ideal. Benzilic acid appears

to have the same problem as seen in benzoin. The peaks are at

accurate frequencies, but the intensities are weak. It shows the (O-H)

stretch at 3379.15 which is ideal, and there is (C=O) stretching at

1678.41 which is in the literature range of 1725-1665. Therefore, all

four IR spectrum readings confirm the presence of the ideal product.

1.

2.

REFERENCES

Lehman, J. W. (2004). Microscale operational organic

chemistry.

(3rd

ed.).

New

Jersey:

Pearson/Prentice Hall.

Figure2.

http://www.chem.wisc.edu/deptfiles/genchem/lab/l

abdocs/modules/vacfilt/pic/trap.gif

Figure 1: Flowchart summary of the overall procedural process.

0.015mol Benzaldehyde

NaOH

Thiamine Hydrochloride (Vit. B1)

Reflux; cool; dark (1 week)

Vacuum filter

Rinse with chilled D.I. H2O

Rinse twice with 1mL chilled methanol

(Solid)

Benzoin – dry in oven 5 mins.

Benzaldehyde

In 10mL RBF,

NaOH

+1/2 mass NH4NO3

Vit. B1

+3.5mL 80% CH3COOH

H2O

+Benzoin

down sink)

+0.015g Cu(CH3COO)2

Heat until gas evolves

Boil, reflux (1Hour)

Air cool. Pour on 8Ml ice.

Vacuum filter

Rinse with chilled H2O

(Filtrate)

(Solid)

Benzil

Recrystallize w/ ethanol

Air cool. Chill on ice.

Cu(CH3COO)2

Vacuum filter

down sink)

Rinse twice w/ 50% ethanol

Save solid. Waste down sink.

(Filtrate)

Benzoin

NH4NO3

(Waste,

(Waste,

Benzil

Weigh. IR. Mp.

In 10mL RBF,

Benzil

+2.5x 6M KOH

+3x Ethanol

Reflux 15 min. after boil

Air cool, add to beaker

Add 10mL DI H2O, heat to dissolve

Pour over 10mL ice/1.5mL HCl(aq) mixture – chill 5 min

Vacuum filter, rinse w/ chilled H2O

(Solid) Benzilic Acid

Oven dry 5 min. weigh. Mp.

Calculate Theoretical Yields

Potassium Benzilate

H2O, Ethanol, KOH

Dispose of waste