Full Syllabus - Muncy School District

advertisement

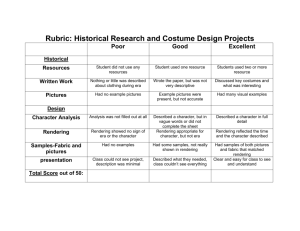

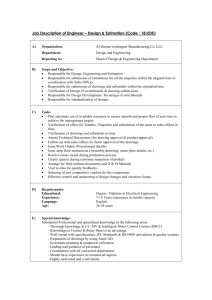

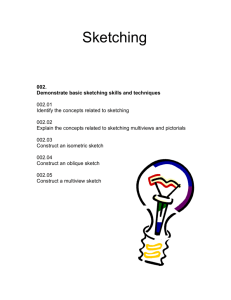

Muncy School District Muncy Jr. /Sr. High School Course Syllabus General Information: Date: January 2014 Prepared by: Mark Kreisher Grade: 10-12 Meetings/cycle: 6 Course Title: CAD 3 Solid Modeling Course Number: 769 Credit: .5 Length = Semester Course Description CAD 3-Solid Modeling is an advanced course where students will learn advanced elements of technical drawing, rendering and rapid prototyping. Instruction in the use and function of the computer aided drafting (CAD) programs and accepted drafting techniques and conventions will be demonstrated. Elements of Engineering Design will be addressed from part creation to assembly to engineering drawing creation. Students will study on-screen testing analysis and well as rendering and animation of mechanical drawings using Solidworks. Units in mechanics such as power transmission, pneumatics and hydraulics will be studied. Students will also gain insight to the world of automation through the study of LASER, CNC and rapid prototyping activities. This course is designed to be for students who are interested in the field of Mechanical Engineering and who have a desire to learn on an independent timeframe and experiment with 3D drawing software. Prerequisite(s): CAD 1 and Permission Course Outcomes Develop skills in the use of technological tools and systems Apply problem-solving techniques in search for solutions to technological problems Acquire broad-based transferable skills and knowledge which will be useful in future employment, further education and life’s experiences Synthesize learning of mathematics, science, and social studies concepts through technological activities Locate, understand, and interpret written information, communicate thoughts, ideas, information, and messages, and create documents, reports, graphs, and flow charts Course Outline 1. Introduction to Solids Modeling 2. a. Geometry review b. Basics of technical sketching c. Elements of a plan d. Part tree e. Navigator Making Parts a. Sketching parts i. Drawing 1. Lines 2. Points 3. Planes 4. Circles 5. Arcs 6. Orthographic snaps 7. Splines 8. Multi-shape 9. Polygon 10. Rectangle 11. Trim Entities 12. Convert edges 13. Offset Edges 14. Mirror 15. Pattern 16. Move ii. Dimensioning 1. Smart Dimensioning 2. Rapid Sketching 3. Construction lines iii. Modifications 1. Arrays 2. Hole Wizard 3. Cosmetic Threads b. 3D Modeling i. Extrusions ii. Extruded cuts iii. Drill holes iv. Revolutions v. Domes vi. Wraps vii. Sweeps 1. Extrusions 2. Cuts viii. Lofts 1. Extrusions 2. Cuts ix. Boundaries 1. Extrusions 2. Cuts x. Modifications 1. Shells 2. Drafts 3. Fillets 4. Chamfers c. Properties and Appearance’s i. Materials library ii. Colors Properties 3. Making Assemblies a. Importing parts i. Single Parts ii. Multiple Parts iii. Fasteners b. Constraints i. Movements ii. Axis iii. Planes c. Mates i. Concentric ii. Coincident iii. Parallel iv. Perpendicular v. Intersection vi. Plane vii. Tangent d. Advanced i. Bill of Materials ii. Motion Study iii. Assembly Features iv. Smart Fasteners v. Animations 1. Simple Animations 2. Complex Animations 4. Dimension Expert a. Auto Dimension schemes b. Location Dimensions c. Size Dimensions d. Datum e. Pattern Features f. Tolerances 5. Engineering Drawings a. Document Setup for Output i. Paper sizes ii. Title Blocks b. Inserting pages i. Adding Pages ii. Naming Pages c. Inserting drawings i. Adding drawings to pages ii. Views iii. Projected views iv. Section Details v. Adding Callouts vi. Labeling vii. Dimensioning viii. Specialty 1. Break outs 2. Breaks 3. Crops 4. Alternate Positions d. Specialties i. Datum ii. Weldments iii. Hole Callouts iv. Hatching v. Surface Finishes e. Tables i. Bill of Materials ii. Revisions iii. Hole Table iv. General Table f. Projects i. Kant Twist Clam ii. Bar Clamp iii. Water Pump iv. Fly Tying Vice v. Tool Vise 6. Testing a. Using Evaluate i. Measure ii. Mass Properties iii. Section Properties iv. Sensors v. Statistics vi. Diagnostics vii. Deviation Analysis viii. Draft Analysis ix. Undercut Analysis x. Parting line Analysis b. Structure Stress Testing-Tower c. Aerodynamic Lift and Drag test-CO2 Car d. Fluid Testing- Pipe Dynamics 7. Specialty Drawings a. Sectional b. Auxiliary c. Sheet Metal d. Fasteners 8. Advanced Working Drawings a. Mechanisms i. Gears ii. Linear Actuators iii. Pneumatics iv. Hydraulics b. Linkages i. Clutches ii. CAMs iii. Splines iv. Bearings c. Drivetrains i. Belts ii. Chains iii. Pulleys iv. Sprockets d. Welding i. Types of Welding ii. Types of Welds iii. Welding Tests 9. Rendering a. Photoview 360 i. Photo Rendering of an Object ii. Rendering into an Environment b. Animations 10. Advanced Outputs a. 3D Printing b. 3D Scanning c. LASER d. CNC e. Plotting 11. Research Project a. Making a Proposal b. Sketches c. Working Model d. Animation e. Set of Plans f. Evaluation g. Research Presentation Course Requirements Each students works at his or her own pace Course Expectations Arrive to class on time. Participate in all activities. Be respectful to all. Abide by all school rules. Consequences Warning Student - teacher conference Parent - teacher conference Office referral & parent conference Course Assessment Procedures The marking period grade will be based on the following rubric: Each drawing is worth 100 points Each exercise is worth 50 points Each quiz is worth 20 points Each test is worth 100 points Final Grade= Total Number of Points Earned Total Number of Points Possible