procdiag

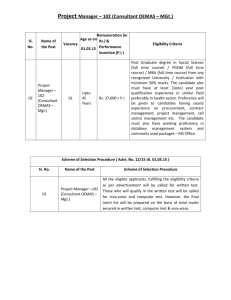

advertisement

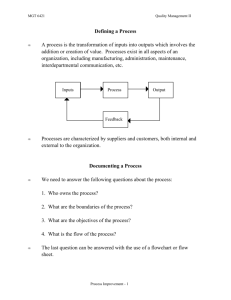

MGT 6421 Quality Management II Defining a Process A process is the transformation of inputs into outputs which involves the addition or creation of value. Processes exist in all aspects of an organization, including manufacturing, administration, maintenance, interdepartmental communication, etc. Inputs Process Output Feedback Processes are characterized by suppliers and customers, both internal and external to the organization. Documenting a Process We need to answer the following questions about the process: 1. Who owns the process? 2. What are the boundaries of the process? 3. What are the objectives of the process? 4. What is the flow of the process? The last question can be answered with the use of a flowchart or flow sheet. Process Improvement - 1 MGT 6421 Quality Management II Process Flowcharts There are two types of flow charts: 1. A systems flowchart is a pictorial summary of the sequence of operations. 2. A layout flowchart depicts the "floor plan" of an area, and usually shows the flow of material. Flowcharts should be made to show how the process is currently working, not just how it was designed to function. There are a number of ways to draw the flow chart. I will give one set of symbols which can be used. Process Improvement - 2 MGT 6421 Quality Management II Example: Process Improvement - 3 MGT 6421 Quality Management II Diagnosing a Process There are a number of very simple, but effective techniques to diagnose a process. Process diagnosis leads to the elimination of common causes of variation, and eventually to process improvement. We will discuss the following process diagnosis techniques: 1. Brainstorming 2. Cause-and-Effect diagrams 3. Check sheets 4. Pareto Analysis. Process Improvement - 4 MGT 6421 Quality Management II Brainstorming Brainstorming is used to elicit ideas from a group of people in a short period of time. It is usually done in groups of 3-12 people. The group members do not have to be experts, but should be familiar with the process. Variety in the group membership is very useful. Steps: 1. Select the topic (problem) to be discussed. 2. Participants write their ideas in about 10 minutes. 3. Each person reads one idea at a time until all ideas are exhausted. 4. The leader asks each member for any additional ideas they have after hearing the other ideas. 5. If members reach an impasse, the leader asks the participants for their "wildest" ideas. Rules: 1. Do not criticize (by word or gesture). 2. Do not discuss ideas, except for clarification. 3. Do not hesitate to give ideas. 4. Only one idea at a time from each member. 5. Do not let the group be dominated by 1 or 2 members. 6. Do not let the brainstorming turn into a gripe session. Process Improvement - 5 MGT 6421 Quality Management II Cause and Effect Diagram This is also referred to as an Ishikawa diagram or a fishbone diagram. This method is often used to organize the ideas of a brainstorming session. Construction Steps: 1. State the problem or "effect." Draw the effect on the right hand side with an arrow going into it. 2. Identify the main causes. The most commonly used main causes are "the 4 M's." These are machines, manpower, methods, and materials. The main causes become the main branches of the diagram. 3. Identify subcauses. Process Improvement - 6 MGT 6421 Quality Management II 4. Evaluate the causes and circle the most likely causes. 5. Verify the cause (through measurement). Example Process Improvement - 7 MGT 6421 Quality Management II Check Sheets Check sheets are a simple and effective way for collecting and analyzing data in a logical format. There are a number of different types of check sheets: 1. Tally 2. Location 3. Clustering by type 4. Traveling Process Improvement - 8 MGT 6421 Quality Management II Example1 1From Wadsworth, Stephens and Godfrey (1986). Modern Methods for Quality Control and Improvement, New York: John Wiley and Sons, 300. Process Improvement - 9 MGT 6421 Quality Management II Pareto Analysis Used to determine what problems to solve rather than how to solve them. The Pareto Principle: Relatively few factors account for a large percentage of the total cases. Constructing the Diagram: 1. Establish categories for the data being analyzed. 2. Construct a frequency table showing the number of observations for each category identified. 3. Draw a bar chart from the frequency table, ordering the bars in the order of the most frequently occurring category to the least. Process Improvement - 10