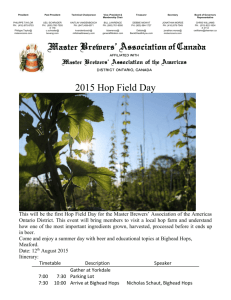

2.13.1 Factors Affecting Both Local And Modern

advertisement